COnTEnTS

[1]SpecicationsofHZL-GSeries............................................................1

[2]Searchbytrouble(relatedtomechanicalcomponents).....................3

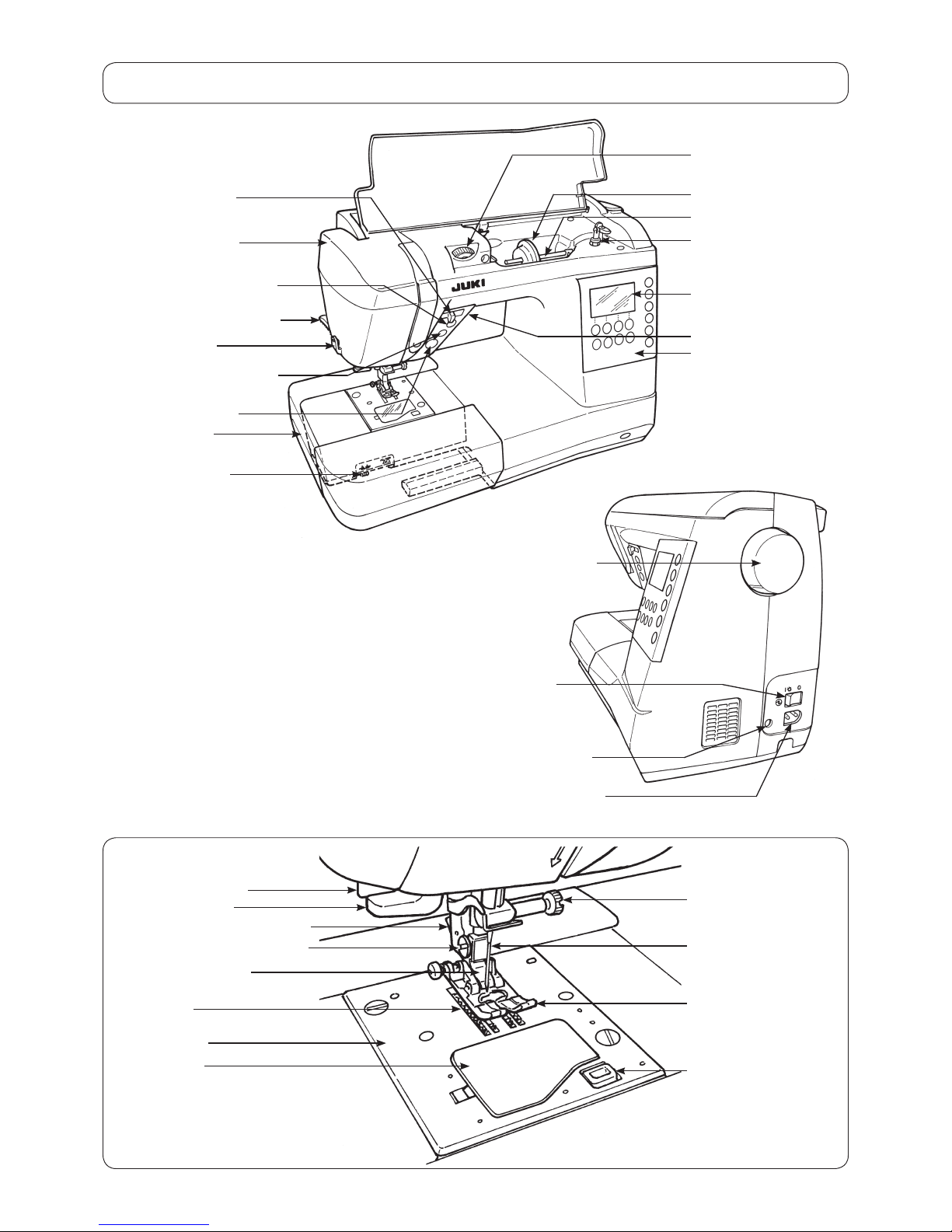

[3]Principalparts........................................................................................4

[4]Disassemblingthemachinecovers.....................................................5

[5]PCBconnectiondiagram......................................................................9

[6]Adjustment...........................................................................................13

6-1 Adjustingtheneedlebarheight......................................................................13

6-2 Adjustingtheneedleentrypoint.....................................................................14

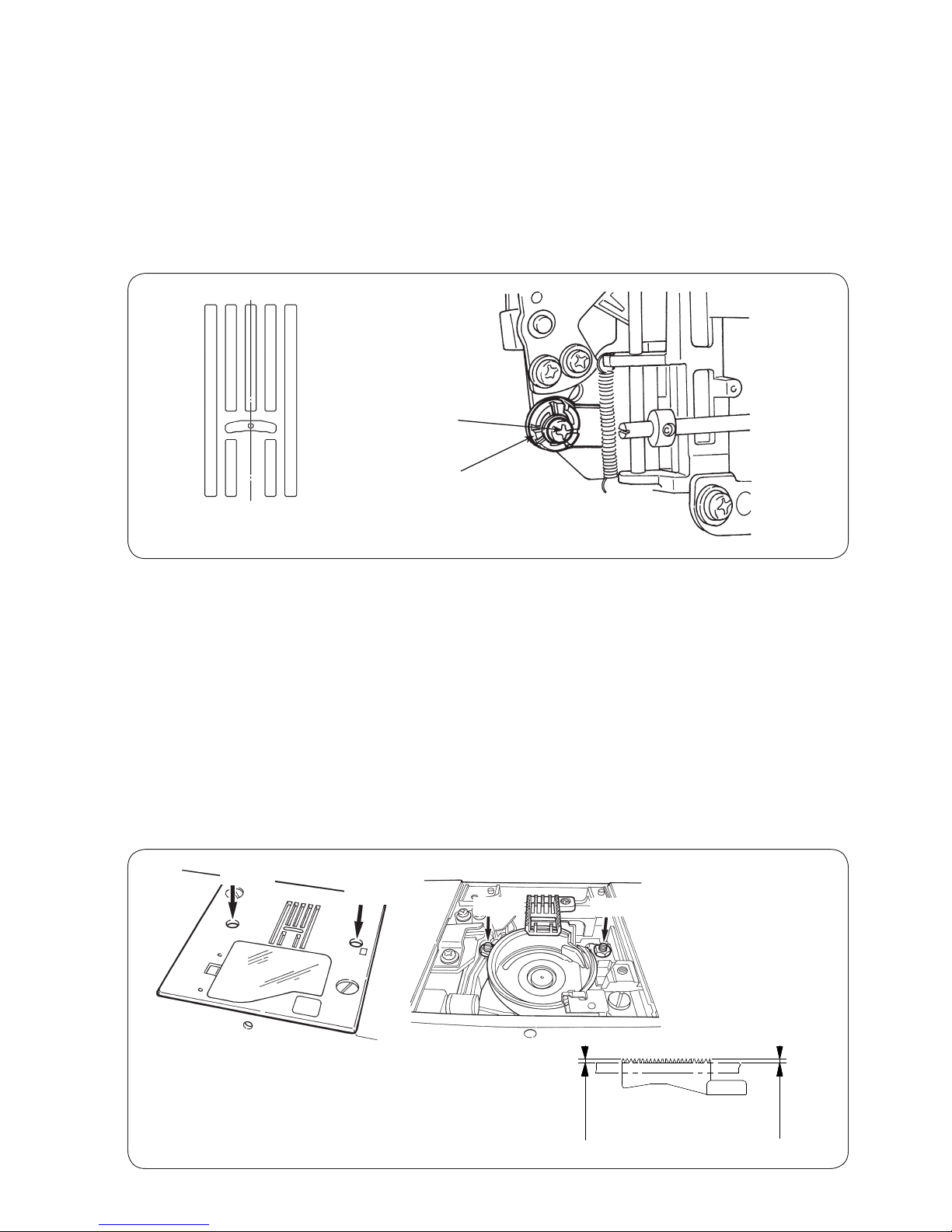

6-3Feeddogheight...............................................................................................14

6-4Timingbelt........................................................................................................15

6-5Feedtiming.......................................................................................................15

6-6 Timingbetweentheneedleandthehook.......................................................16

6-7 Clearancebetweentheneedleandthebladepointofhook.........................17

6-8 Positionofthehookrotationstopperplate....................................................18

6-9Adjustingthebobbinthreadtension..............................................................18

6-10 Adjustingthediskopeningamount..............................................................19

6-10-1Adjustingthetensionreleaseadjustingplate...................................19

6-10-2 Tensiondiskopeningamount............................................................19

6-10-3Basetensionopeningamount............................................................20

6-10-4Adjustingthediskopeningamountatthetimeofthreadtrimming

(HZL-G210)...............................................................................................21

6-11 Adjustingtheneedlethreadtension.............................................................21

6-12 Verticalpositionoftheneedlethreadinghook............................................22

6-13Adjustingthepresserfootliftingswitch......................................................23

6-14Adjustingthepresserbarheight..................................................................23

6-15Motorbelt........................................................................................................24

6-16 Automaticthreadtrimming(HZL-G210).......................................................25

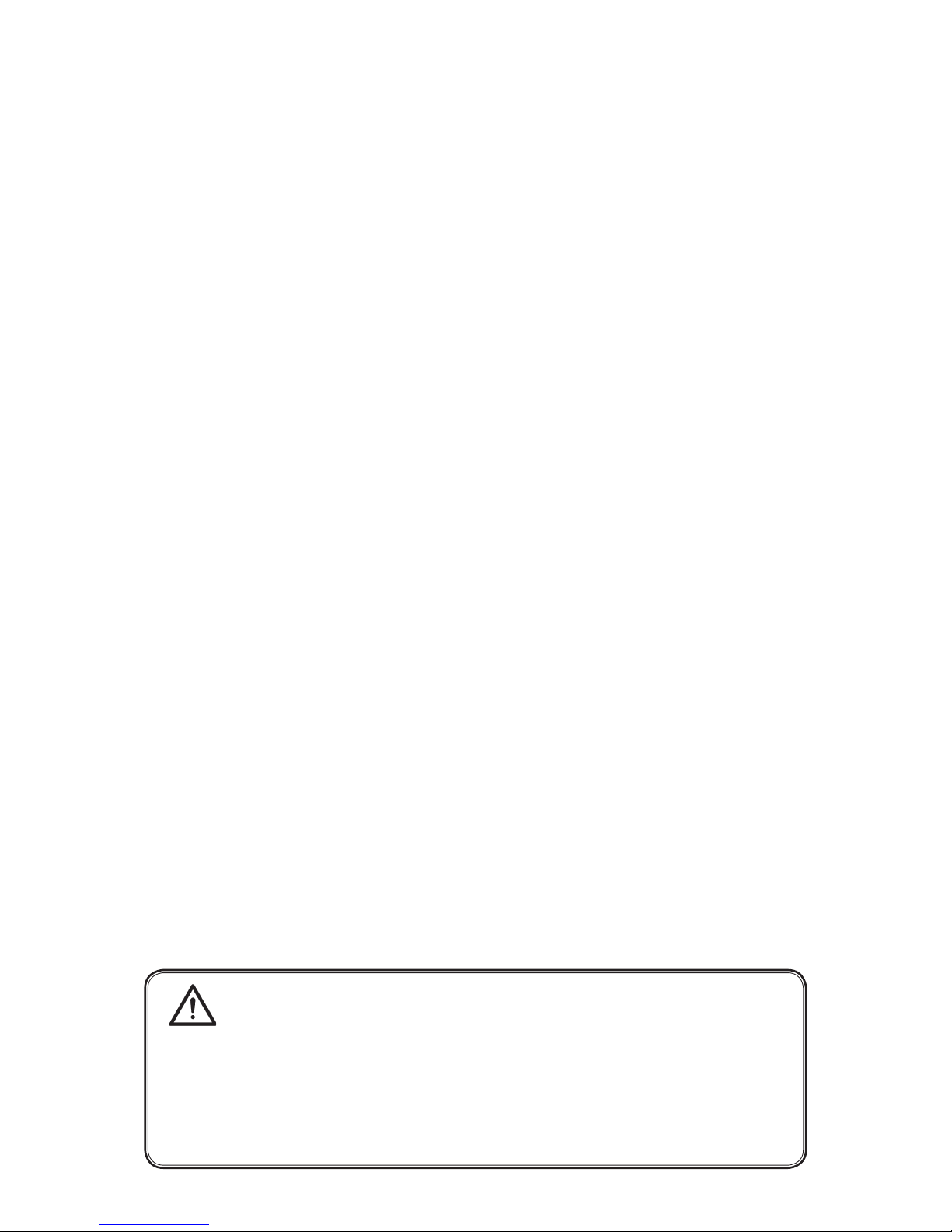

6-16-1Lateralpositionofthethreadtrimmingmechanismbase..........................25

6-16-2Phaseofthecatchingunitdrivingcam.......................................................26

6-16-3Replacingthethreadtrimmingblade..........................................................27

6-17 Longitudinalfeed...........................................................................................28

6-18Buttonhole......................................................................................................29

6-19Servicemode.................................................................................................30

6-20-1 Servicemodescreen...................................................................................30

5-20-2Service-modeitemsanddescriptions.........................................................30

Be sure to observe the following to protect against a re, electrical shock, injury or damaged

components.

* Be sure to unplug the machine before disassembly, assembly or adjustment of the machine.

* Be sure to carefully prevent electric cords from being caught, coated surfaces from being

damaged as well as wrong wiring during assembly.

* Be sure to use the proper genuine parts when changing any of the machine parts.

CauTIOn: