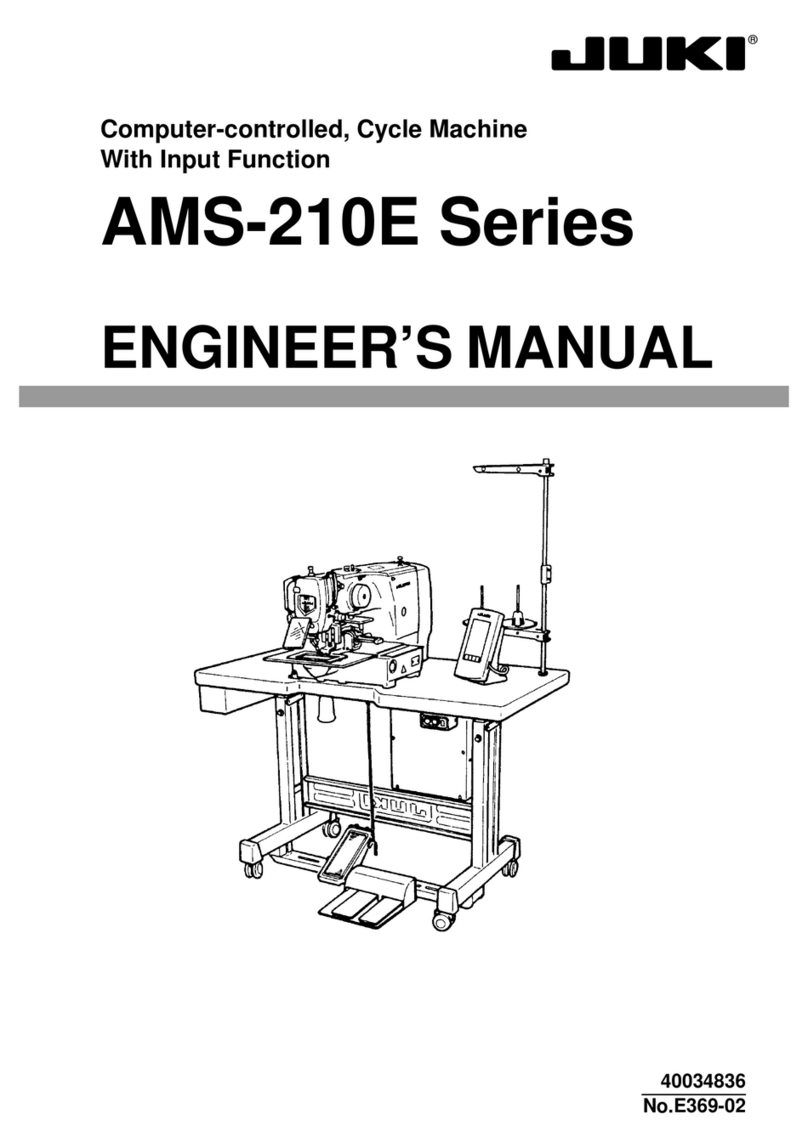

iv

1. NAME OF EACH COMPONENT ............. 1

2. SPECIFICATIONS ................................... 2

2-1. Specifications of the machine head .......... 2

2-2. Specifications of the electrical box ........... 2

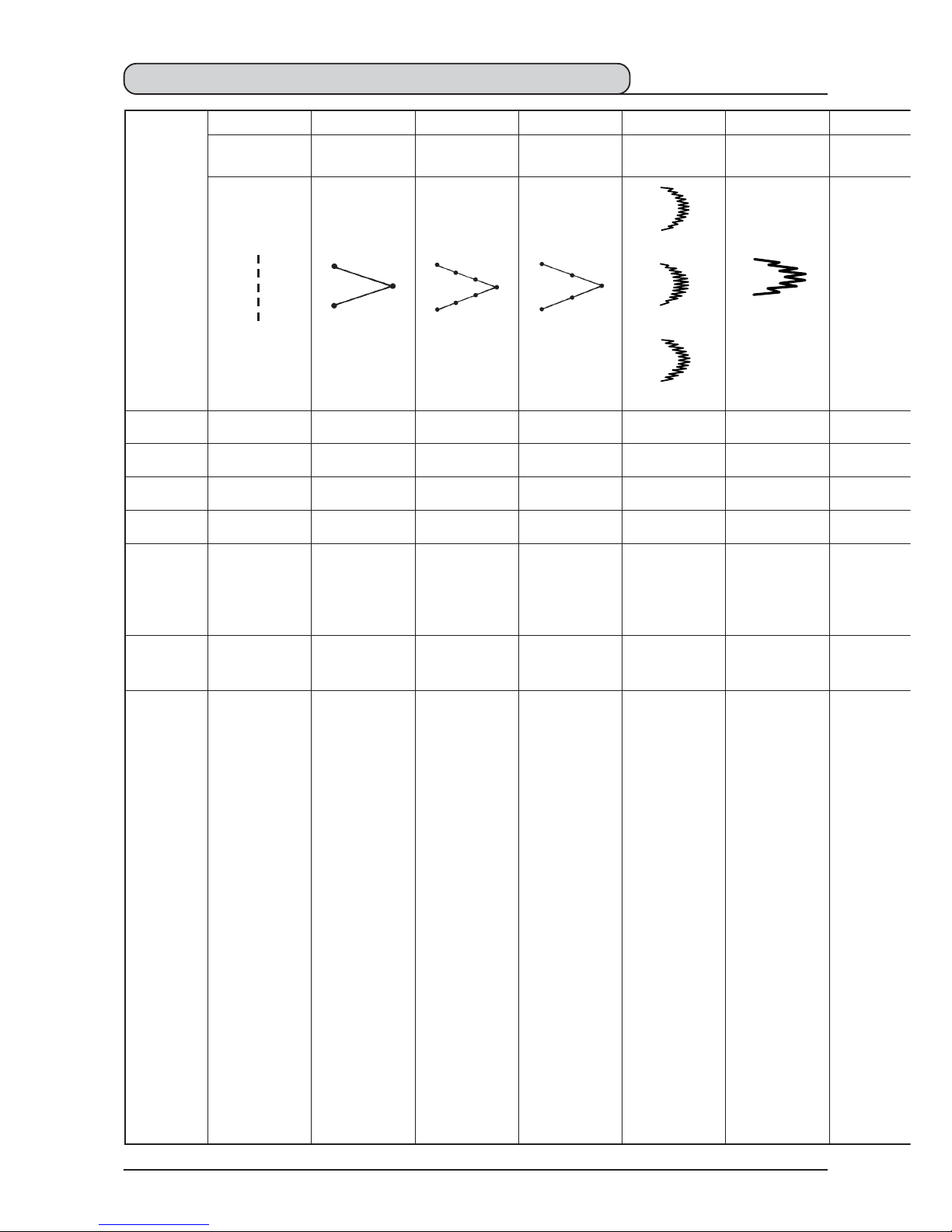

3. STITCH PATTERN TABLE ..................... 3

3-1.

Initial value of the stitch pattern and the table ....

4

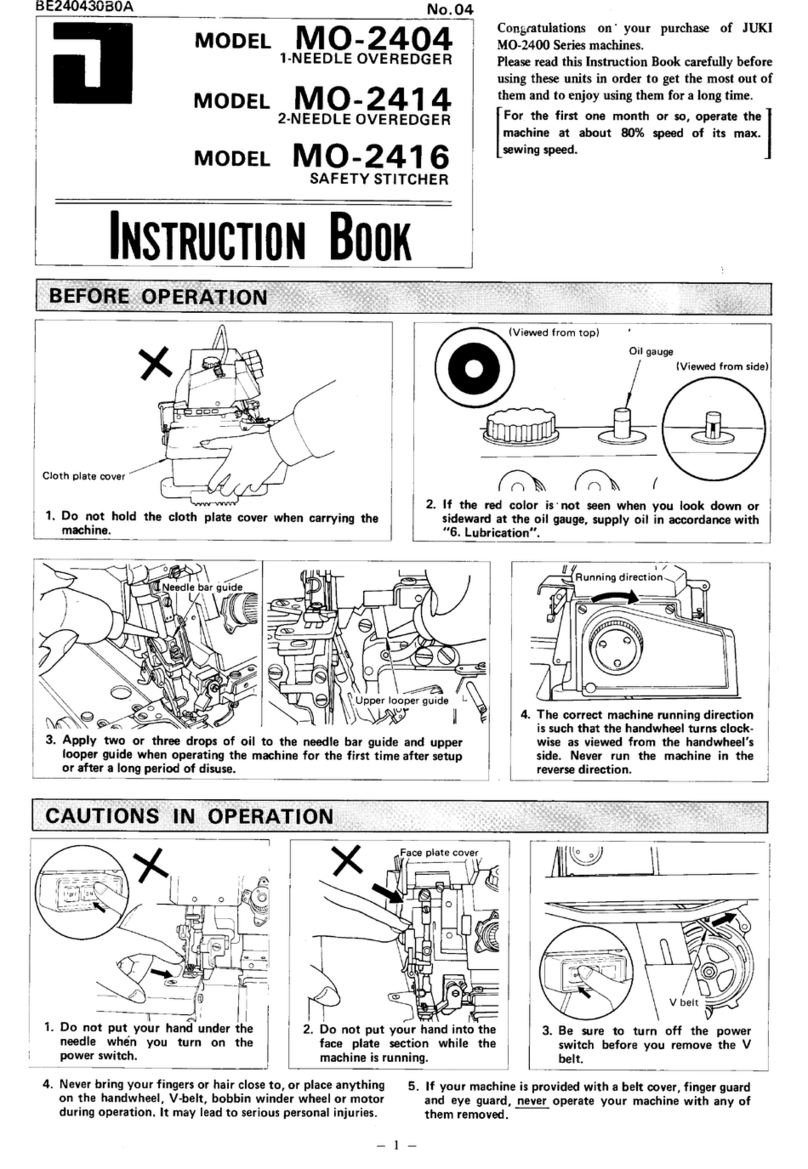

4. INSTALLATION ....................................... 6

4-1.

Installation of the sewing machine head ........

6

4-2. Removing the needle bar stopper ............. 7

4-3. Attaching the knee-lifter ............................. 7

4-4. Adjusting the height of the knee lifter ....... 7

4-5. Installing the electrical box ........................ 8

4-6. Connecting the power switch cord ............ 8

4-7.

Installing the

operation

panel (IP-100(D)) ....

8

4-8. Connecting the cords ................................. 9

(1) Preparation of wiring .................................... 9

(2) Connecting the connectors ........................ 10

4-9. Attaching the connecting rod................... 14

4-10. Adjustment of the pedal ......................... 15

4-11. Installing the thread stand ...................... 15

4-12.

Installing the bird’s nest prevention (CB)

type sewing machine ..................................

15

4-13. Lubrication

..................................................

17

4-14. Test run .................................................... 18

(1) Turn ON the power .................................... 18

(2) How to operate the pedal ........................... 18

5. PREPARATION BEFORE SEWING ..... 19

5-1. Inserting the needle .................................. 19

5-2. Removing the bobbin case ....................... 19

5-3. Winding the bobbin thread ....................... 19

5-4.

Placing the bobbin case and the bobbin ....

20

5-5. Threading the machine head .................... 21

5-6. Adjusting the stitch length ....................... 21

5-7.

Adjusting the condensation stitching ........

21

6.

HOW TO USE THE OPERATION PANEL ...

22

6-1.

Names and functions of the respective sections ....

22

6-2. Before setting the pattern ......................... 24

(1) Limitation of the max. zigzag width ............ 24

(2) Setting the reference of stitch base line ..... 26

(3) Setting the feed amount ............................. 27

6-3. Basic screen .............................................. 28

6-4.

List of the display pictographs of each screen...

29

6-5. Setting the sewing pattern ....................... 52

(1) Selecting the zigzag pattern ....................... 52

6-6. Setting of the sewing shape ..................... 54

(1) Standard zigzag, 2-step zigzag and

3-step zigzag stitch .................................... 54

(2) Scallop stitching ......................................... 56

(3) Blind stitch sewing ..................................... 59

(4) Custom pattern stitching ............................ 60

(5) T stitch, left ................................................. 61

(6) T stitch, right .............................................. 62

(7) Pattern 1 .................................................... 64

(8) Pattern 2 (fagoting) .................................... 65

(9) Pattern 3 .................................................... 67

(10) Pattern 4 .................................................. 69

6-7. Setting of the number of rotations........... 71

6-8. Reverse feed stitching .............................. 71

(1) Standard condensation .............................. 72

(2) 2-point condensation .................................. 74

(3) Condensation custom ................................ 75

(4) Comparision table of the reverse

stitch of each shape .................................. 76

6-9. Selection of the kind of stitching ............. 77

(1) Overlapped stitching .................................. 77

(2) Programmed stitching ................................ 77

6-10. Custom pattern ........................................ 79

(1) Custom pattern setting ............................... 79

(2) New creation of the custom pattern ........... 80

(3) Custom pattern edit .................................... 81

(4) Registration, copy and deletion

of the custom pattern ................................. 81

6-11. Condensation Custom ............................ 83

(1) Condensation custom setting ..................... 83

(2) Condensation custom edit ......................... 84

6-12. Pattern stitching ...................................... 85

(1) Setting the pattern stitching ....................... 85

(2) Registering the pattern stitching ................ 86

(3)

Copy and deletion of the pattern stitching ....

87

6-13. Continuous stitching .............................. 88

(1) New creation of the continuous stitching ... 89

(2) Continuous stitching edit ............................ 89

(3)

Copy and deletion of the continuous stitching ...

91

6-14. Cycle stitching ......................................... 92

(1) New creation of the cycle stitching ............. 92

(2) Cycle stitching edit ..................................... 92

(3) Copy and deletion of the cycle stitching ..... 94

(4) Teaching .................................................... 95

(5) Performing the programmed stitching

using the cycle stitching ............................ 96

6-15. Counter ..................................................... 96

(1) Thread trimming counter ............................ 96

(2) Bobbin thread counter ................................ 96

6-16. Information ............................................... 97

(1) Sewing common data ................................ 98

•

Limiting procedure of max.zigzag width limitation ..

98

• Max.zigzag width limitation value .................... 98

• Reference of stitch base line .......................... 98

• Reverse feed limitation value ......................... 98

• Normal feed limitation value ............................98

• Mirror function setting ......................................99

•

Position of the stitch base line of condensation custom ..

99

• Counter function ..............................................99

• Key lock ...........................................................99

• Selection of max. zigzag width limitation

display when the power is turned ON ............ 99

(2) Sewing management information ............ 100

(3) Communication mode .............................. 103

6-17. Setting for functions ............................. 107

(1) How to change over to the function

setting mode ............................................ 107

(2) Function setting list .................................. 110

(3)

Detailed explanation of selection of functions....

114

6-18. External interface .................................. 119

(1) Smart media slot ...................................... 119

(2) RS-232C port ........................................... 119

(3)

General input port (Production control

switch

connecting connector) ................... 119

CONTENTS