CONTENTS

1. SPECIFICATIONS ............................................................................................. 1

2. STANDARD ADJUSTMENT ............................................................................. 2

(1) Height of the needle bar ................................................................................................. 2

(2) Needle-to-hook timing .................................................................................................... 2

(3) Needle rocking timing..................................................................................................... 4

(4) Height of the needle bar rocking rod (adjusting the reference of needle bar

rocking components)...................................................................................................... 4

(5) Adjusting the stitch width PM arm and backlashes of the stitch base line

and stitch width gears ....................................................................................................6

(6) Detecting the origin of the stitch base line stepping motor ....................................... 6

(7) Detecting the origin of the stitch width stepping motor ............................................. 8

(8) Backlash of the feed gear............................................................................................... 8

(9) Longitudinal position of the presser and the feed shaft ........................................... 10

(10) Knife drop position...................................................................................................... 10

(11) Knife bar/position of the knife installing base/knife bar stroke .............................. 12

(12) Knife detector sensor.................................................................................................. 14

(13) Position of the starting safety arm............................................................................. 16

(14) Adjusting the starting safety hook............................................................................. 16

(15) Adjusting the starting sensor..................................................................................... 18

(16) Adjusting the needle thread trimmer control lever .................................................. 20

(17) Adjusting the stop-motion solenoid .......................................................................... 20

(18) Stroke of the stop-motion solenoid ........................................................................... 22

(19) Longitudinal amount of the needle thread trimmer.................................................. 22

(20) Lateral position of the needle thread trimmer .......................................................... 24

(21) Height of the needle thread trimmer.......................................................................... 24

(22) Position of winding the needle thread at the start of sewing.................................. 26

(23) Opening timing of the needle thread trimmer........................................................... 26

(24) Spring pressure of the needle thread trimmer.......................................................... 28

(25) Adjusting the needle thread trimmer lever................................................................ 28

(26) Position of the bobbin thread trimmer/position of bobbin thread clamp plate ..... 30

(27) Timing to open the bobbin thread trimmer and the opening amount / adjusting

the bobbin winder trip latch........................................................................................ 30

(28) Height of the presser................................................................................................... 32

(29) Adjusting the thread tension solenoid ...................................................................... 32

(30) Adjusting the safety switch ........................................................................................ 34

(31) Adjusting the bobbin winder ...................................................................................... 34

(32) Adjusting the thread breakage detecting plate......................................................... 36

(33) Adjusting the presser lifting solenoid ....................................................................... 36

(34) Adjusting the presser lifting air cylinder................................................................... 38

(35) Adjusting the presser fall detecting plate ................................................................. 38

3. DISASSEMBLING/ASSEMBLING PROCEDURE .......................................... 40

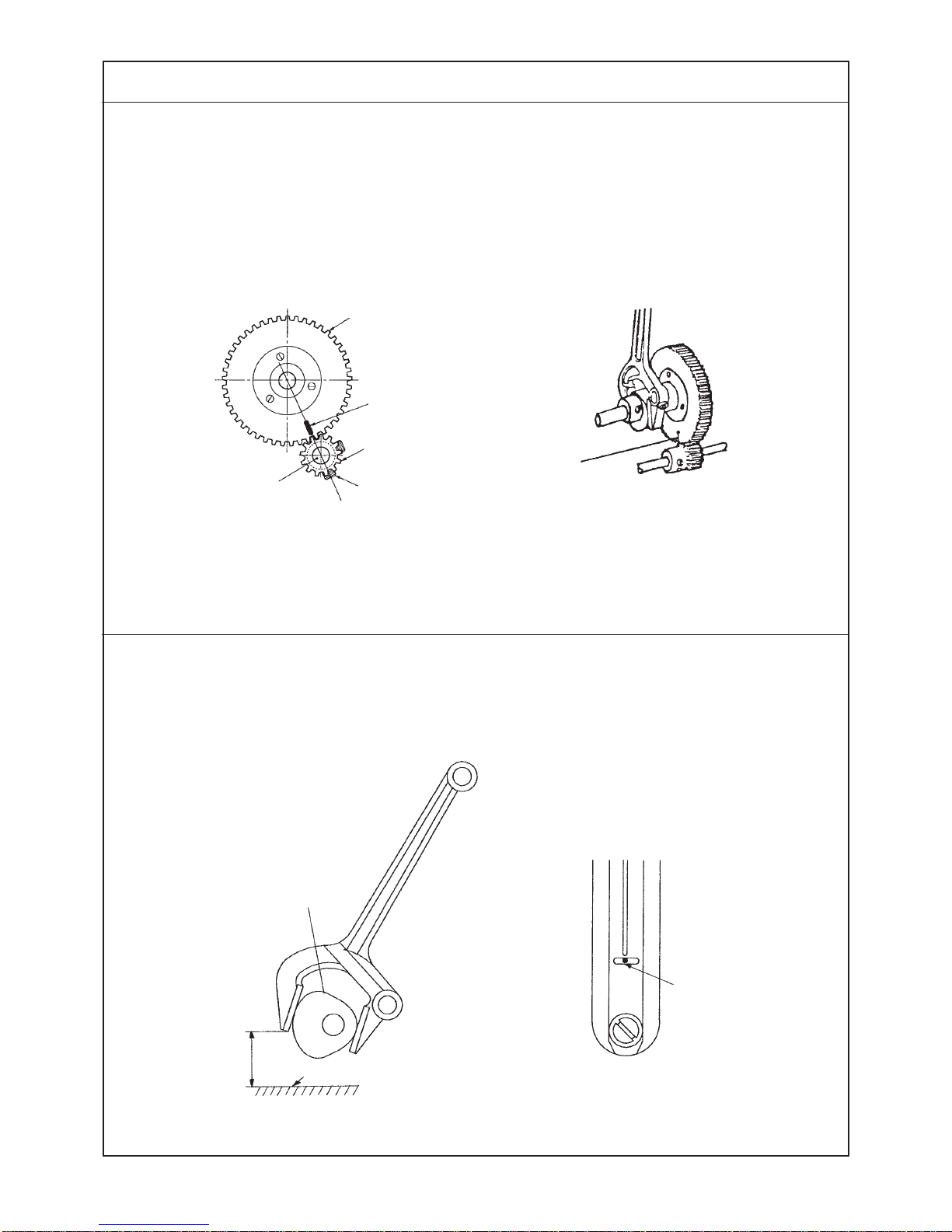

(1) Disassembling/assembling the hook driving shaft.................................................... 40

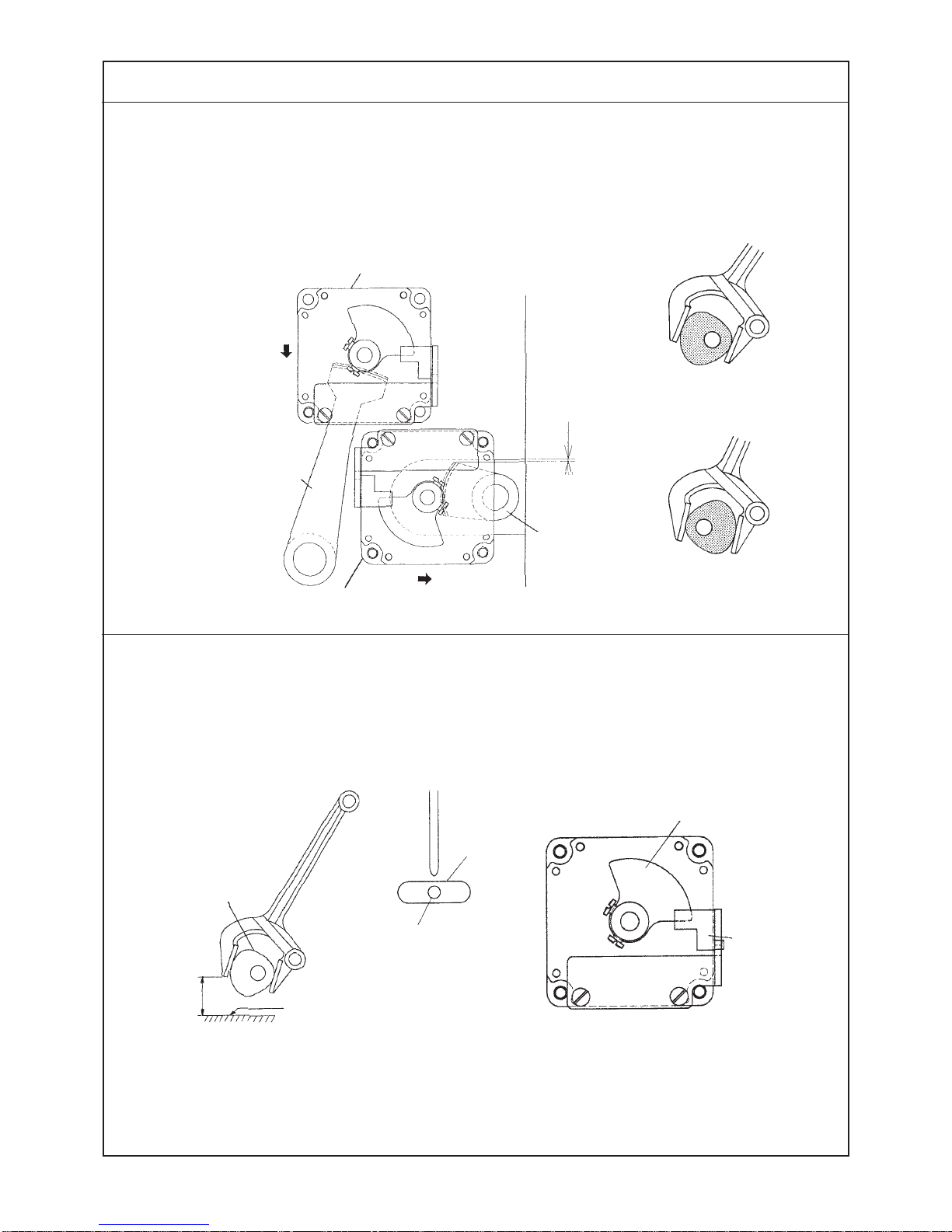

(2) Disassembling/assembling the main shaft ................................................................. 42

(3) Adjusting the timing belt tension................................................................................. 44