– 1 –

"IMPORTANT SAFETY INSTRUCTIONS"

When using an electrical appliance, basic safety precautions should always be followed, including the

following: Read all instructions before using this sewing machine.

"DANGER ____ To reduce the risk of electric shock:"

1. An appliance should never be left unattended when plugged in.

2. Always unplug this appliance from the electric outlet immediately after using and before cleaning.

"WARNING ____ To reduce the risk of burns, re, electric shock, or injury to persons:"

1. Do not allow this appliance to be used as a toy. Close attention is necessary when this appliance

is used by or near children. This appliance can be used by children aged from 8 years and above

and persons with reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction concerning use of the appliance

in a safe way and understand the hazards involved. Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children without supervision.

2. Use this appliance only for its intended use as described in this manual. Use only attachments

recommended by the manufacturer as contained in this manual.

3. Never operate this appliance if it has a damaged cord or plug, if it is not working properly, if it has

been dropped or damaged, or dropped into water. Return the appliance to the nearest authorized

dealer or service center for examination, repair, electrical or mechanical adjustment.

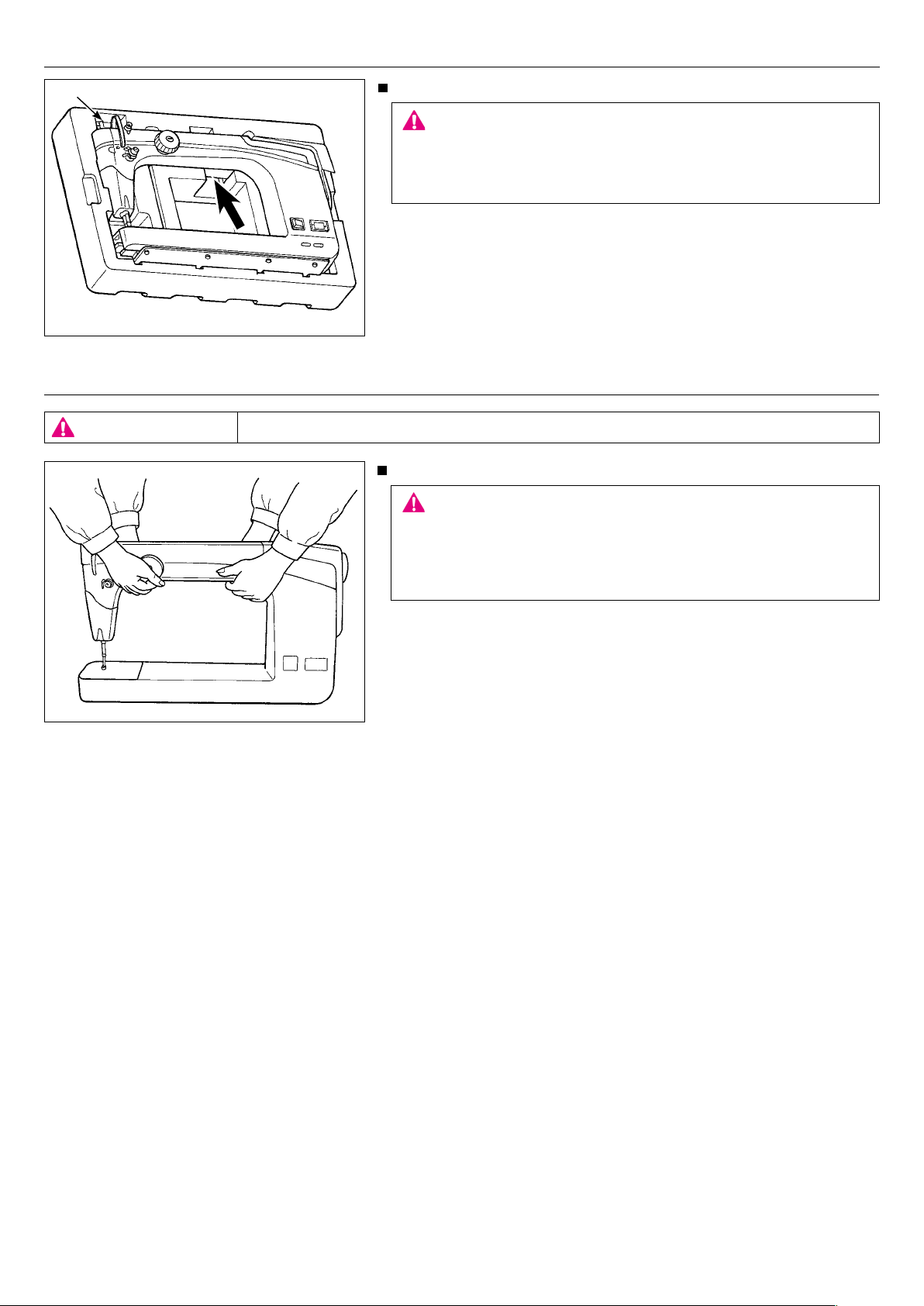

4. Never operate the appliance with any air openings blocked. Keep ventilation openings of the sew-

ing machine and foot controller free from the accumulation of lint, dust and loose cloth.

5. Keep ngers away from all moving parts. Special care is required around the sewing machine

needle.

6. Always use the proper throat plate. The wrong plate can cause the needle to break.

7. Do not use bent needles.

8. Do not pull or push fabric while stitching. It may deect the needle causing it to break.

9. Switch the sewing machine off ("O") when making any adjustments in the needle area, such as

threading needle, changing needle, threading bobbin, or changing presser foot and the like.

10. Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or

when making any other user servicing adjustments mentioned in the instruction manual.

11. Never drop or insert any object into any opening.

12. Do not use outdoors.

13. Do not operate where aerosol (spray) products are being used or where oxygen is being adminis-

tered.

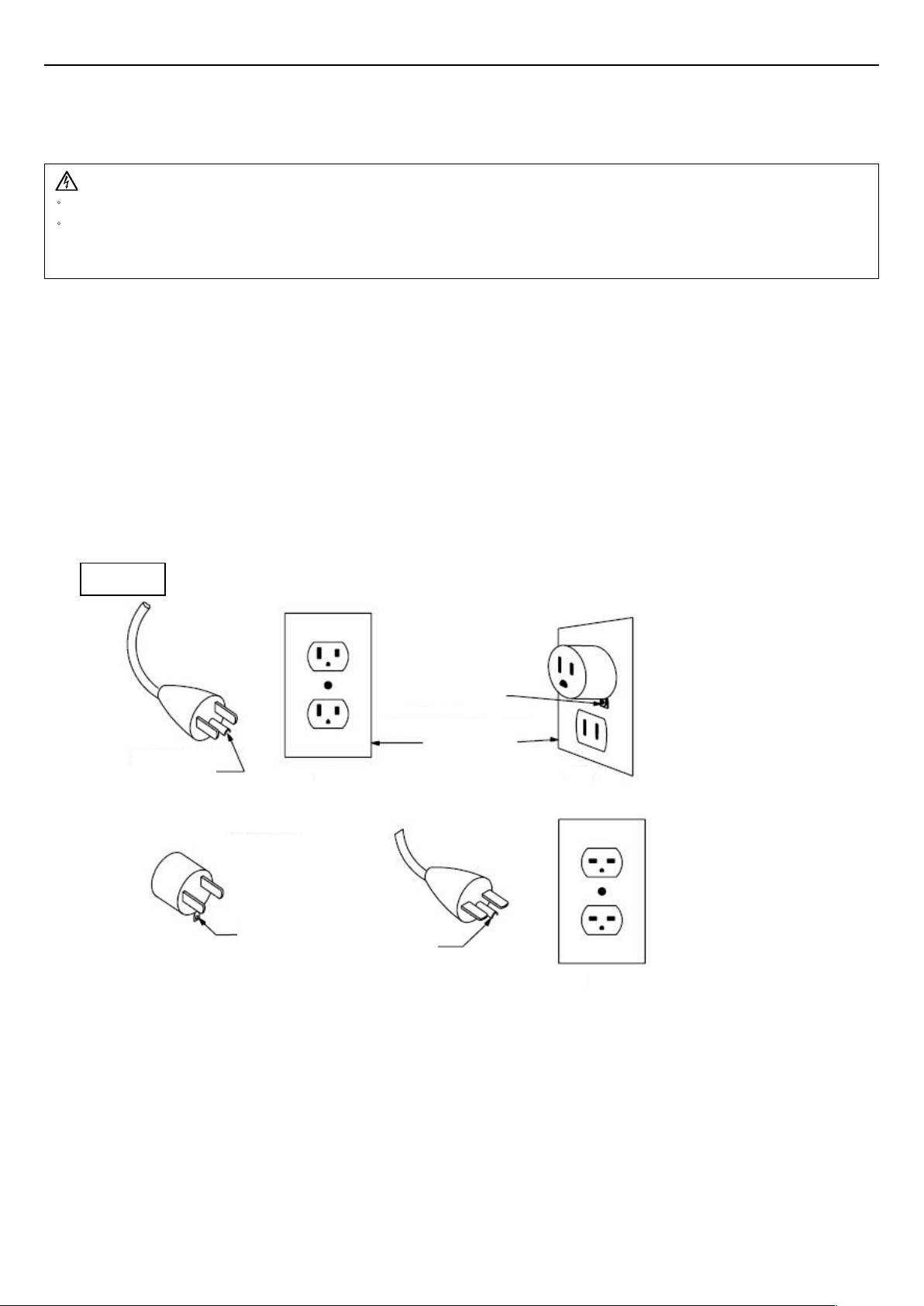

14. To disconnect, turn all controls to the off ("0") position, then remove plug from outlet.

15. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

16. Turn OFF the power switch before insertion/removal of any cords and any plugs.

17. Basically, the machine should be disconnected from the electricity supply when not in use.

18. If the power cord of this appliance is damaged, it must be replaced with a special cord byyour

nearest authorized dealer or service center.

"SAVE THESE INSTRUCTIONS"

This sewing machine is intended for household use only.

Use the stitch regulator made by the Grace Company.

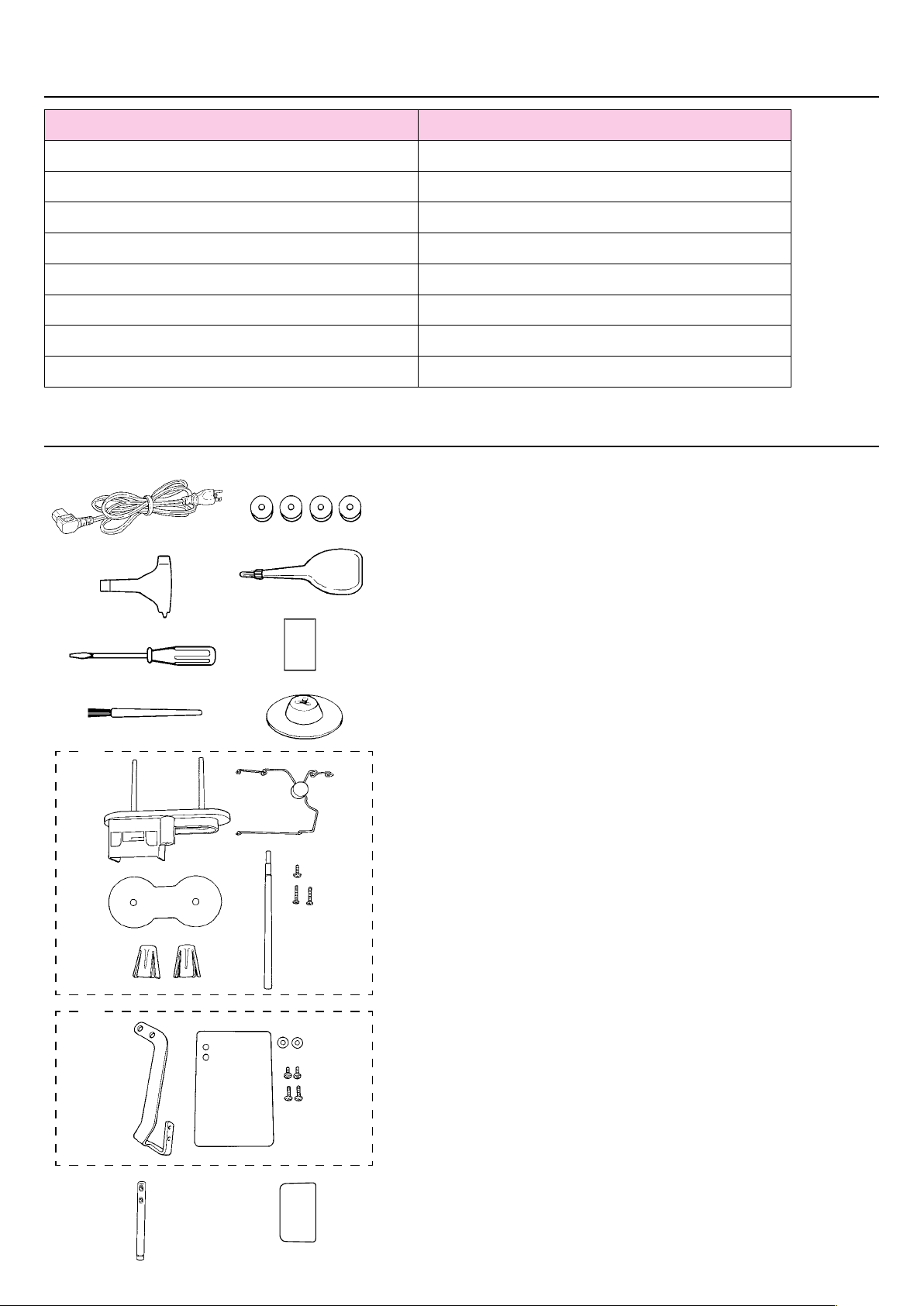

Stitch regulator can be used on the following machine model-number.

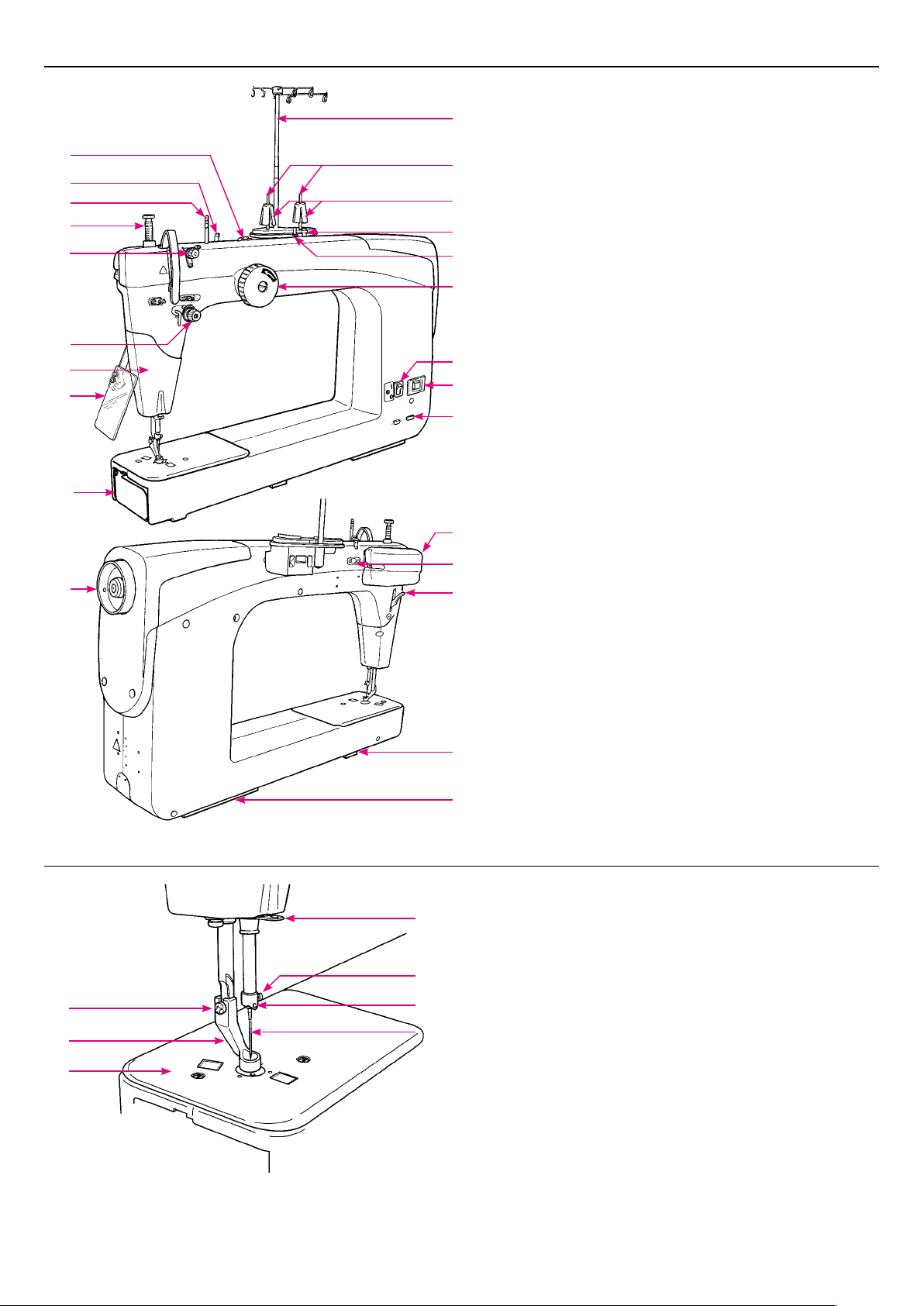

In order to use your machine safely, be sure to read the Instruction Manual for the Sure Stitch for

JUKI J-350QVP provided by Grace Company for how to install the machine on the frame, how to con-

nect the stitch regulator and how to operate the machine.

Sewing machine model number Stitch regulator model number

J-350QVP Sure Stitch for JUKI J-350