LK-1900BN Series

FOR THE USE OF MACHINE

注意 :正しくミシンをセットアップし、安全にご使用いただくために、WEB 取扱説明書を必ずお読み下さい。

下記 URL、または右の QR コードから、当社サイトにアクセスし閲覧することができます。

本書は大切に保管してください。

http://www.juki.co.jp/manual/ism/00006

NOTE : In order to set up the sewing machine correctly and use it safely, be sure to read the

online Instruction Manual.

The online Instruction Manual can be found on the JUKI website which can be accessed

by entering the below-stated URL or by scanning the QR code shown on the right.

Be sure to keep these documents carefully.

http://www.juki.co.jp/manual/ism/00006

HINWEIS : Um die Nähmaschine korrekt einzurichten und sicher zu benutzen, lesen Sie unbe-

dingt die Online-Bedienungsanleitung durch.

SiendendieOnline-BedienungsanleitungaufderJUKI-Website,diedurchEingebenderuntenangegebenen

URL oder durch Scannen des rechts gezeigten QR-Codes aufgerufen werden kann.

Bewahren Sie diese Dokumente unbedingt sorgfältig auf.

http://www.juki.co.jp/manual/ism/00006

REMARQUE:And’installercorrectementlamachineàcoudreetdel’utiliserentoutesécurité,veilleràlirelemoded’emploi

en ligne.

Lemoded’emploienligneestdisponiblesurlesiteWebdeJUKIaccessibleensaisissantl’URLci-dessous

ouenscannantlecodeQRillustréàdroite.

Veilleràsoigneusementconservercesdocuments.

http://www.juki.co.jp/manual/ism/00006

NOTA: Parainstalarycongurarlamáquinadecosercorrectamenteyusarlaencondicionesdeseguridad,asegúresede

leer el Manual de Instrucciones en línea.

ElManualdeInstruccionesenlíneaseencuentradisponibleenelsitiowebdeJUKI,queesaccesibleintroducien-

doladirecciónURLindicadaacontinuaciónoescaneandoelcódigoQRquesemuestraaladerecha.

Asegúresedeguardarestosdocumentoscuidadosamente.

http://www.juki.co.jp/manual/ism/00006

NOTA: Alnediinstallarelamacchinapercucirecorrettamenteeutilizzarlainmodosicuro,assicurarsidileggereattenta-

mente il Manuale d'Istruzioni online.

IlManualed'IstruzionionlinepuòesseretrovatosulsitowebJUKIacuisipuòaccedereinserendol'URLindicato

di seguito o scannerizzando il codice QR mostrato sulla destra.

Conservarequestidocumentiinunluogosicuro.

http://www.juki.co.jp/manual/ism/00006

注意 :为了正确地设置和安全地使用本缝纫机,请一定阅读 WEB 使用说明书。

可以利用下列 URL 或者右面的 QR 二维码访问本公司网站进行阅览。

请妥善地保管本说明文件。

http://www.juki.co.jp/manual/ism/00006

NOT: DikişmakinesinidoğrubirşekildekurmakvegüvenlibirşekildekullanmakiçinçevrimiçiKullanmaKılavuzunumut-

laka okuyun.

ÇevrimiçiKullanmaKılavuzunu,aşağıdabelirtilenİnternetadresigirilerekveyasağdagösterilenkarekodutaranarak

erişilebilenJUKIwebsitesindebulabilirsiniz.

Budokümanlarımutlakadikkatlicemuhafazaedin.

http://www.juki.co.jp/manual/ism/00006

ПРИМЕЧАНИЕ :

Для правильной настройки и безопасного использования швейной машины обязательно прочитайте в Интернете «Руководство по

эксплуатации».

«Руководство по эксплуатации» в Интернете может быть найдено на веб-сайте JUKI, к которому можно получить доступ путем входа

по нижеуказанному унифицированному указателю информационного ресурса, или путем просмотра QR-кода, указанного справа.

Обязательно тщательно сохраняйте эти документы.

http://www.juki.co.jp/manual/ism/00006

No.00

40194087

For the sewing machine, automatic machine and ancillary devices (hereinafter collectively referred to as

"machine"), it is inevitable to conduct sewing work near moving parts of the machine. This means that there

is always a possibility of unintentionally coming in contact with the moving parts. Operators who actually

operate the machine and maintenance personnel who are involved in maintenance and repair of the machine

are strongly recommended to carefully read to fully understand the following SAFETY PRECAUTIONS

before using/maintaining the machine. The content of the SAFETY PRECAUTIONS includes items which

are not contained in the specications of your product.

The risk indications are classied into the following three different categories to help understand the meaning

of the labels. Be sure to fully understand the following description and strictly observe the instructions.

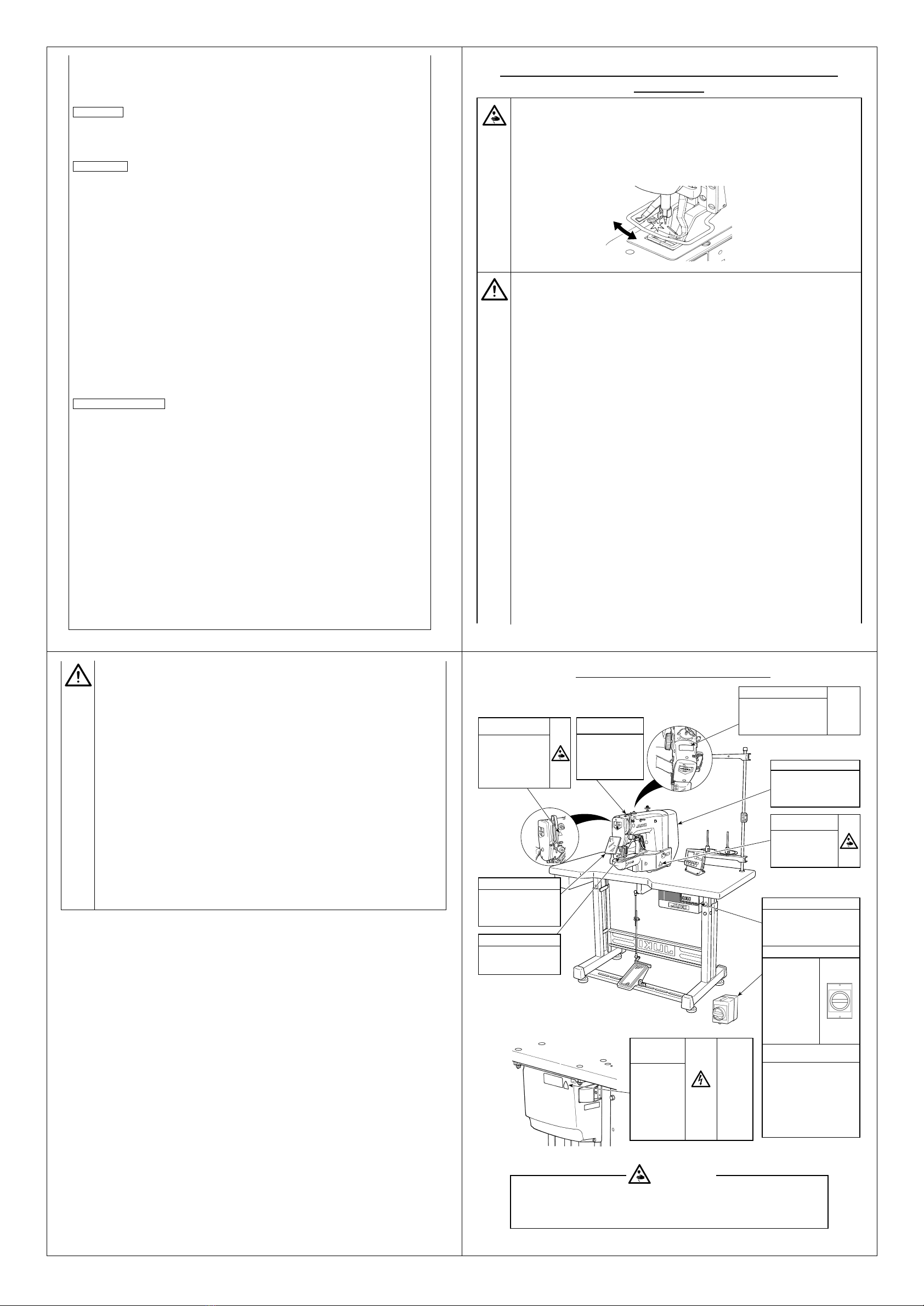

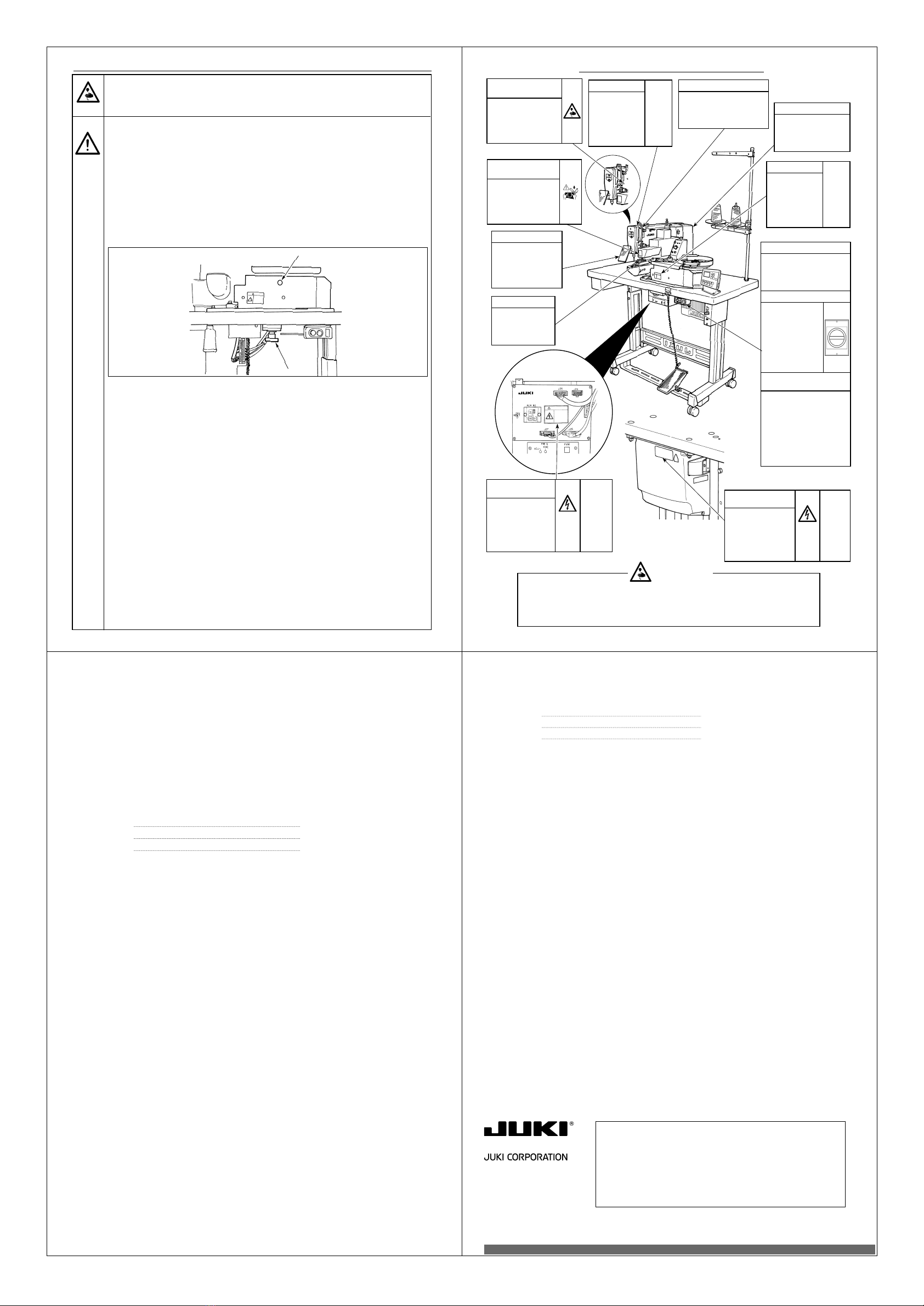

Warning label

❶

❷

❸

❶•Thereisthepossibilitythatslighttoseriousinjuryordeathmaybecaused.

•Thereisthepossibilitythatinjurymaybecausedbytouchingmovingpart.

❷•Toperformsewingworkwithsafetyguard.

•Toperformsewingworkwithsafetycover.

•Toperformsewingworkwithsafetyprotectiondevice.

❸•BesuretoturnthepowerOFFbeforecarryingout"machine-headthreading",

"needlechanging","bobbinchanging"or"oilingandcleaning".

❸

❷

❶

Electrical-shock

dangerlabel

DANGER :

Thisindicationisgivenwherethereisanimmediatedangerofdeathorserousinjuryifthepersoninchargeoranythird

partymishandlesthemachineordoesnotavoidthedangeroussituationwhenoperatingormaintainingthemachine.

WARNING :

Thisindicationisgivenwherethereisapotentialityfordeathorseriousinjuryifthepersoninchargeoranythird

partymishandlesthemachineordoesnotavoidthedangeroussituationwhenoperatingormaintainingthemachine.

CAUTION :

Thisindicationisgivenwherethereisadangerofmediumtominorinjuryifthepersoninchargeoranythirdpar-

tymishandlesthemachineordoesnotavoidthedangeroussituationwhenoperatingormaintainingthemachine.

Itemsrequiringspecialattention.

Pictorialwarningindication

Thereisariskofinjuryifcontact-

ingamovingsection.

Pictorialwarning

indication

Beawarethatholdingthesewing

machineduringoperationcan

hurtyourhands.

Thereisariskofelectricalshockif

contactingahigh-voltagesection.

Thereisariskofentanglementin

thebeltresultingininjury.

Thereisariskofaburnifcontact-

ingahigh-temperaturesection.

Thereisariskofinjuryifyou

touchthebuttoncarrier.

Beawarethateyedeciencycan

becausedbylookingdirectlyatthe

laserbeam.

Indicationlabel

Thecorrectdirectionisindicated.

Thereisariskofcontactbetween

yourheadandthesewingma-

chine.

Connectionofaearthcableis

indicated.

TO ENSURE SAFE USE OF YOUR SEWING MACHINE

(I)Explanationofrisklevels

(II)

Explanationofpictorialwarningindicationsandwarninglabels

1. Whenitisnecessarytoopenthecontrolboxcontainingelectricalparts,besuretoturnthepower

offandwaitforveminutesormorebeforeopeningthecoverinordertopreventaccidentleadingto

electricalshock.

Accidentmeans"tocause

personalinjuryordeathor

damagetoproperty."

DANGER

CAUTION

Basicprecaution

1. Besuretoreadtheinstructionmanualandotherexplanatorydocumentssuppliedwithaccessoriesof

themachinebeforeusingthemachine.Carefullykeeptheinstructionmanualandtheexplanatorydocu-

mentsathandforquickreference.

2. Thecontentofthissectionincludesitemswhicharenotcontainedinthespecicationsofyourproduct.

3. Besuretowearsafetygogglestoprotectagainstaccidentcausedbyneedlebreakage.

4. Thosewhouseaheartpacerhavetousethemachineafterconsultationwithamedicalspecialist.

Safetydevicesandwarninglabels

1. Besuretooperatethemachineafterverifyingthatsafetydevice(s)iscorrectlyinstalledinplaceand

worksnormallyinordertopreventaccidentcausedbylackofthedevice(s).

2. Ifanyofthesafetydevicesisremoved,besuretoreplaceitandverifythatitworksnormallyinorderto

preventaccidentthatcanresultinpersonalinjuryordeath.

3. Besuretokeepthewarninglabelsadheredonthemachineclearlyvisibleinordertopreventaccident

thatcanresultinpersonalinjuryordeath.Ifanyofthelabelshasstainedorcomeunstuck,besureto

changeitwithanewone.

Applicationandmodication

1. Neverusethemachineforanyapplicationotherthanitsintendedoneandinanymannerotherthanthat

prescribedintheinstructionmanualinordertopreventaccidentthatcanresultinpersonalinjuryor

death.JUKIassumesnoresponsibilityfordamagesorpersonalinjuryordeathresultingfromtheuseof

themachineforanyapplicationotherthantheintendedone.

2. Nevermodifyandalterthemachineinordertopreventaccidentthatcanresultinpersonalinjuryor

death.JUKIassumesnoresponsibilityfordamagesorpersonalinjuryordeathresultingfromthema-

chinewhichhasbeenmodiedoraltered.

Educationandtraining

1. Inordertopreventaccidentresultingfromunfamiliaritywiththemachine,themachinehastobeused

onlybytheoperatorwhohasbeentrained/educatedbytheemployerwithrespecttothemachineoper-

ationandhowtooperatethemachinewithsafetytoacquireadequateknowledgeandoperationskill.To

ensuretheabove,theemployerhastoestablishaneducation/trainingplanfortheoperatorsandedu-

cate/trainthembeforehand.

Itemsforwhichthepowertothemachinehastobeturnedoff

Turningthepoweroff: Turningthepowerswitchoff,thenremovingthepowerplugfromtheoutlet.

Thisappliestothefollowing.

1. Besuretoimmediatelyturnthepoweroffifanyabnormalityorfailureisfoundorinthecaseofpower

failureinordertoprotectagainstaccidentthatcanresultinpersonalinjuryordeath.

2. Toprotectagainstaccidentresultingfromabruptstartofthemachine,besuretocarryoutthefollow-

ingoperationsafterturningthepoweroff.Forthemachineincorporatingaclutchmotor,inparticular,

besuretocarryoutthefollowingoperationsafterturningthepoweroffandverifyingthatthemachine

stopscompletely.

2-1. Forexample,threadingthepartssuchastheneedle,looper,spreaderetc.whichhavetobethread-

ed,orchangingthebobbin.

2-2. Forexample,changingoradjustingallcomponentpartsofthemachine.

2-3. Forexample,wheninspecting,repairingorcleaningthemachineorleavingthemachine.

3. Besuretoremovethepowerplugbyholdingtheplugsectioninsteadofthecordsectioninordertopre-

ventelectrical-shock,earth-leakageorreaccident.

4. Besuretoturnthepoweroffwheneverthemachineisleftunattendedbetweenworks.

5. Besuretoturnthepoweroffinthecaseofpowerfailureinordertopreventaccidentresultingofbreak-

ageofelectricalcomponents.

PRECAUTIONSTOBETAKENINVARIOUSOPERATIONSTAGES

Transportation

1. Besuretoliftandmovethemachineinasafemannertakingthemachineweightinconsideration.Refer

tothetextoftheinstructionmanualforthemassofthemachine.

2. Besuretotakesufcientsafetymeasurestopreventfallingordroppingbeforeliftingormovingthe

machineinordertoprotectagainstaccidentthatcanresultinpersonalinjuryordeath.

3. Oncethemachinehasbeenunpacked,neverre-packitfortransportationtoprotectthemachineagainst

breakageresultingfromunexpectedaccidentordropping.

Unpacking

1. Besuretounpackthemachineintheprescribedorderinordertopreventaccidentthatcanresultin

personalinjuryordeath.Inthecasethemachineiscrated,inparticular,besuretocarefullychecknails.

Thenailshavetoberemoved.

2. Besuretocheckthemachineforthepositionofitscenterofgravityandtakeitoutfromthepackage

carefullyinordertopreventaccidentthatcanresultinpersonalinjuryordeath.

Installation

(I)Tableandtablestand

1. BesuretouseJUKIgenuinetableandtablestandinordertopreventaccidentthatcanresultinper-

sonalinjuryordeath.IfitisinevitabletouseatableandtablestandwhicharenotJUKIgenuineones,

selectthetableandtablestandwhichareabletosupportthemachineweightandreactionforceduring

operation.

2. Ifcastersarettedtothetablestand,besuretousethecasterswithalockingmechanismandlock

themtosecurethemachineduringtheoperation,maintenance,inspectionandrepairinordertoprevent

accidentthatcanresultinpersonalinjuryordeath.

(II)Cableandwiring

1. Besuretopreventanextraforcefrombeingappliedtothecableduringtheuseinordertoprevent

electrical-shock,earth-leakageorreaccident.Inaddition,ifitisnecessarytocableneartheoperating

sectionsuchastheV-belt,besuretoprovideaspaceof30mmormorebetweentheoperatingsection

andthecable.

2. Besuretoavoidstarburstconnectioninordertopreventelectrical-shock,earth-leakageorreaccident.

3. Besuretosecurelyconnecttheconnectorsinordertopreventelectrical-shock,earth-leakageorre

accident.Inaddition,besuretoremovetheconnectorwhileholdingitsconnectorsection.

(III)Grounding

1. Besuretohaveanelectricalexpertinstallanappropriatepowerpluginordertopreventaccidentcaused

byearth-leakageordielectricstrengthvoltagefault.Inaddition,besuretoconnectthepowerplugtothe

groundedoutletwithoutexceptions.

2. Besuretogroundtheearthcableinordertopreventaccidentcausedbyearthleakage.

(IV)Motor

1. Besuretousethespeciedratedmotor(JUKIgenuineproduct)inordertopreventaccidentcausedby

burnout.

2. Ifacommerciallyavailableclutchmotorisusedwiththemachine,besuretoselectonewithanentan-

glementpreventivepulleycoverinordertoprotectagainstbeingentangledbytheV-belt.

Beforeoperation

1. Besuretomakesurethattheconnectorsandcablesarefreefromdamage,dropoutandloosenessbe-

foreturningthepoweroninordertopreventaccidentresultinginpersonalinjuryordeath.

2. Neverputyourhandintothemovingsectionsofthemachineinordertopreventaccidentthatcanresult

inpersonalinjuryordeath.

Inaddition,checktobesurethatthedirectionofrotationofthepulleyagreeswiththearrowshownon

pulley.

3. Ifthetablestandwithcastersisused,besuretosecurethetablestandbylockingthecastersorwith

adjusters,ifprovided,inordertoprotectagainstaccidentcausedbyabruptstartofthemachine.

Duringoperation

1. Besurenottoputyourngers,hairorclothingclosetothemovingsectionssuchasthehandwheel,

handpulleyandmotororplacesomethingnearthosesectionswhilethemachineisinoperationinorder

topreventaccidentcausedbyentanglementthatcanresultinpersonalinjuryordeath.

2. Besurenottoplaceyourngersnearthesurroundareaoftheneedleorinsidethethreadtake-uplever

coverwhenturningthepoweronorwhilethemachineisinoperationinordertopreventaccidentthat

canresultinpersonalinjuryordeath.

3. Themachinerunsatahighspeed.Neverbringyourhandsnearthemovingsectionssuchaslooper,

spreader,needlebar,hookandclothtrimmingknifeduringoperationinordertoprotectyourhands

againstinjury.Inaddition,besuretoturnthepoweroffandchecktobesurethatthemachinecomplete-

lystopsbeforechangingthethread.

4. Becarefulnottoallowyourngersoranyotherpartsofyourbodytobecaughtbetweenthemachine

andtablewhenremovingthemachinefromorreplacingitonthetableinordertopreventaccidentthat

canresultinpersonalinjuryordeath.