– 1 –

SPECIFICATIONS

S : Micro-quantity lubrication

M :

Semi-dry

D :

Dry

S : Medium-weight materials

H :

Heavy-weight materials

A :

Light weight materials

• The sewing speed will vary depending on the sewing conditions. The sewing speed preset at the time of shipping is 4,000sti/min. The thread trimming

speed can be changed within the range of ( ). The thread trimming speed preset at the time of shipping is 500sti/min.

* 1 : When stitch length exceeds 4 mm or more, set the max. sewing speed to 4,000 sti/min or less for use.

* 2 : Needle used depends on the destination.

*3 : MA type is for light-weight materials. In the case the sewing machine is used with its speed of stitch set at 4,000 sti/min or higher, the presser

regulating spring and thread tension spring should be changed with S type ones.

DDL-9000B-

-SS

-MS

-DS -SH -MA

*3

Max. sewing speed

5,000 sti/min 4,000 sti/min 4,500 sti/min 5,000 sti/min

Thread trimming speed

500 sti/min (100 to 500sti/min)

Stitch length 5mm *1 4mm

Presser foot lift

(by knee lifter)

10 mm (standard) 15 mm (max.)

Needle*2 134 #65 to #110

DP×5 #65 to #110

134 #125 to #160

DP×5 #125 to #160

134 #60 to #75

DP×5 #60 to #75

DB×1 #9 to #18

DB×1 #9 to #18

DB×1 #20 to #23

DB×1 #20 to #23

DB×1 SAN10 #8 to #11

DB×1 SF #8 to #11

Lubricating oil

JUKI NEW DEFRIX OIL No. 1 or JUKI MACHINE OIL #7 - JUKI NEW DEFRIX OIL No. 1 or JUKI MACHINE OIL #7

Noise SS,MS,MA ;

'- Equivalent continuous emission sound pressure level (LpA) at the workstation:

A-weighted value of 77 dBA ; (Includes KpA = 2.5 dBA) ; according to ISO 10821- C.6.2 -ISO 11204 GR2 at 4,000 sti/min.

SH ;

'- Equivalent continuous emission sound pressure level (LpA) at the workstation:

A-weighted value of 77 dBA ; (Includes KpA = 2.5 dBA) ; according to ISO 10821- C.6.2 -ISO 11204 GR2 at 4,000 sti/min.

DS ;

'- Equivalent continuous emission sound pressure level (LpA) at the workstation:

A-weighted value of 79 dBA ; (Includes KpA = 2.5 dBA) ; according to ISO 10821- C.6.2 -ISO 11204 GR2 at 4,000 sti/min.

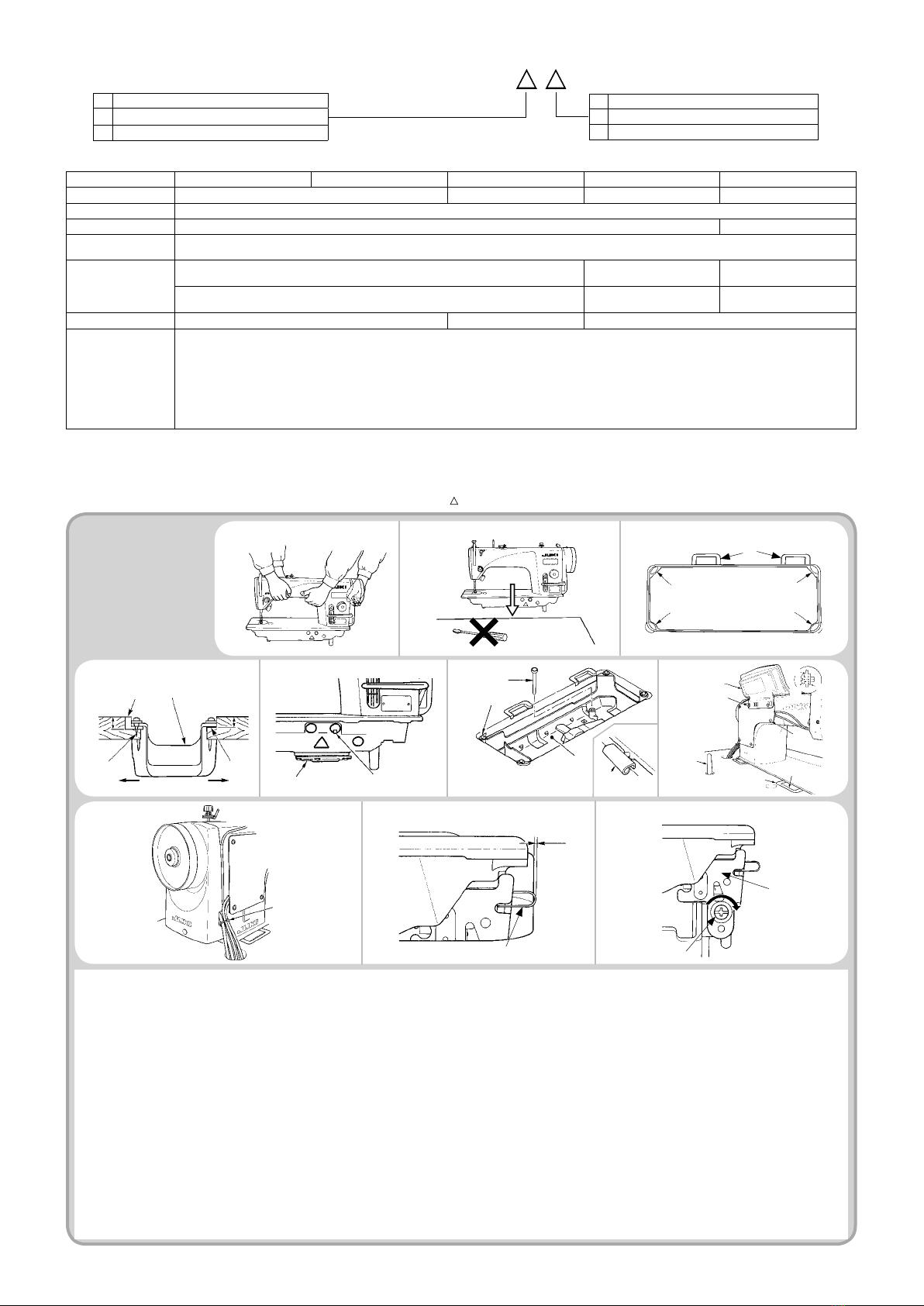

1. INSTALLATION 1) 2)

8)

23.5 mm 19.5 mm

1

2

4

3

A B

3)

4) 5)

1) Carry the sewing machine with two persons as shown in the gure above.

(Caution) Do not hold the handwheel.

2) Do not put protruding articles such as the screwdriver and the like at the location where the sewing machine is placed.

3) The under cover should rest on the four corners of the machine table groove. Mount rubber hinge seat 8 on the table and x it on the table with a nail.

4) Fix two rubber seats 1on side A(operator’s side) using nails 2as illustrated above. Fix two cushion seats 3on side B(hinged side) using a rubber-based adhesive. Then place

under cover 4 on the xed seats.

5) Remove air vent cap 5attached to the machine bed.

(Caution)

1. If the sewing machine is operated without removing air vent cap 5, oil leakage from gear box portion C may occur.

2. Be sure to attach cap 5when transporting the machine head in the state that the machine head is removed from the machine table.

6) Fit knee lifter pressing rod 6. Fit hinge 7 into the opening in the machine bed, and t the machine head to table rubber hinge 8before placing the machine head on cushions 9on

the four corners.

7) Securely attach head support rod !0 to the table until it goes no further. Regarding the control panel !1, remove two side plate xing screws !2, place the rubber packing !3, which is

one of the accessories of the control panel !1, between the head section and control panel !1, then x them together.

(Caution)

1. Do not use the screws supplied as accessories of control panel !1.

2.

Be sure to mount the machine head support bar on the machine table so that its height from the table surface becomes 55 to 60 mm. For the sewing machine provided with

the AK device, be sure to mount the support bar on the table so that its height from the table surface becomes 38 to 43 mm.

8) Bundle cable clip band !4 supplied as accessories of the machine head at the root of the cable.

9) Check to be sure that the table and the safety switch arm !5 are engaged with each other by 2.0 mm to 3.5 mm, with the sewing machine slightly tilted.

(Caution) If the engagement between the table and the safety switch arm is 2 mm or less, Error 302 may occur at the time of startup. Or, if the aforementioned engagement is

3.5 mm or more, safety switch arm !5 may break.

10) If the engagement between the table and safety switch arm !5 is outside the range of 2.0 mm and 3.5 mm, loosen safety switch mounting screw !6 and tilt safety switch !7 in the

direction of the arrow to adjust the engagement of safety switch arm !5 with the table.

9

7

6

4!0

!1

!2 !2

!1

!3

!2

7

8

6),7)

C5

!4

11

3

3

8

6)

9) 10)

!5

2.0 to 3.5 mm

!6

!7