1.GENERAL......................................................................................................................... 1

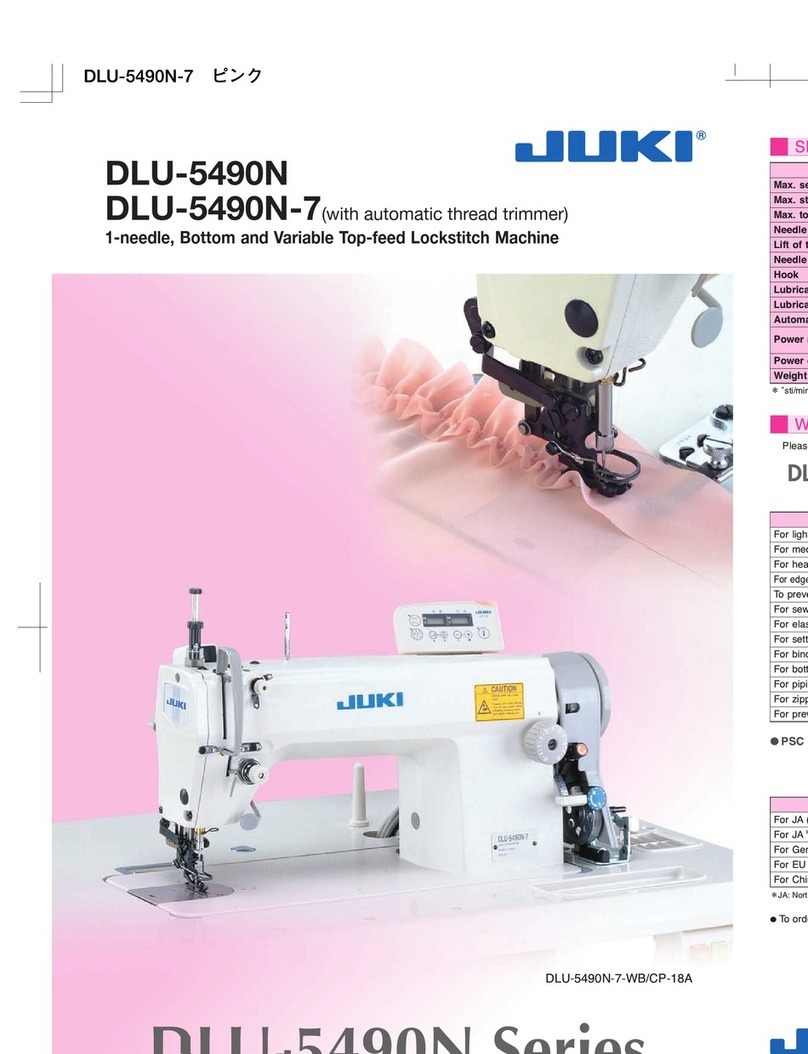

1-1. Features ................................................................................................................................................ 1

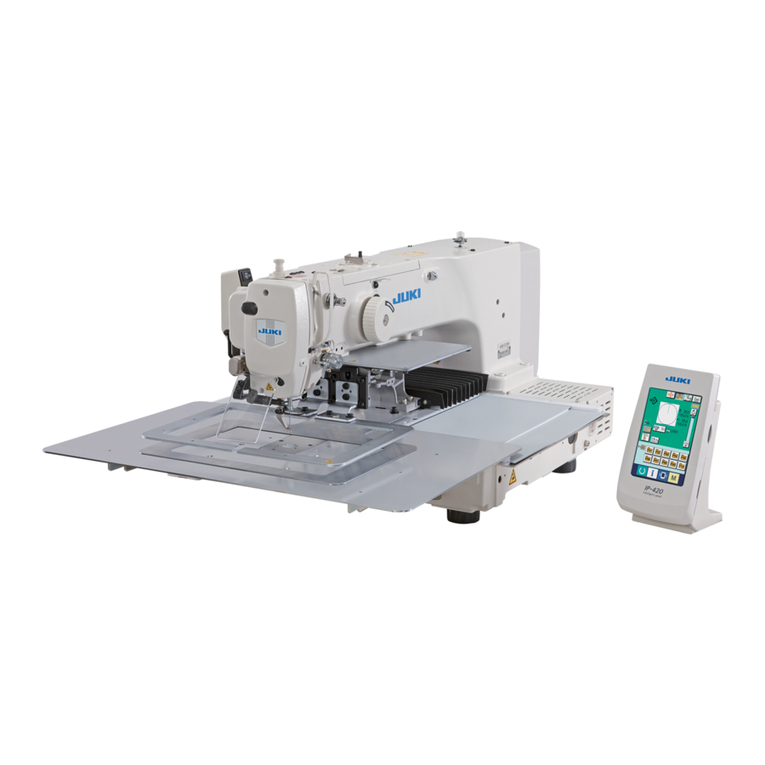

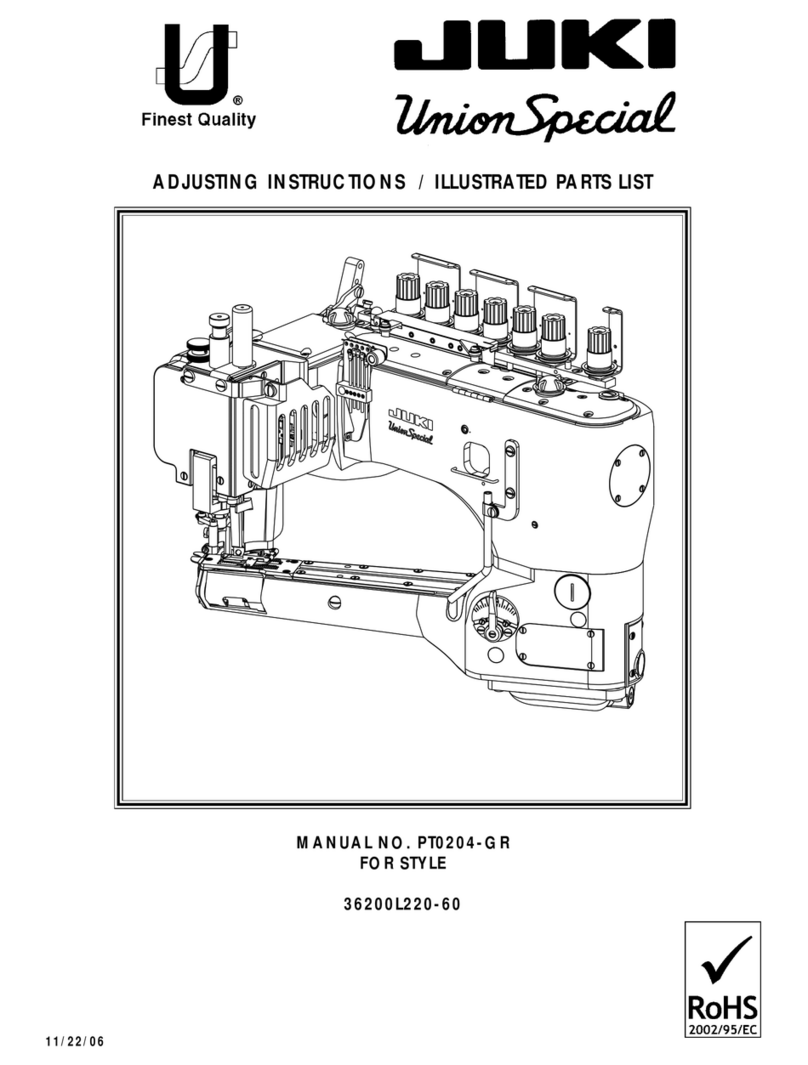

1-2. Configuration of the main parts ......................................................................................................... 2

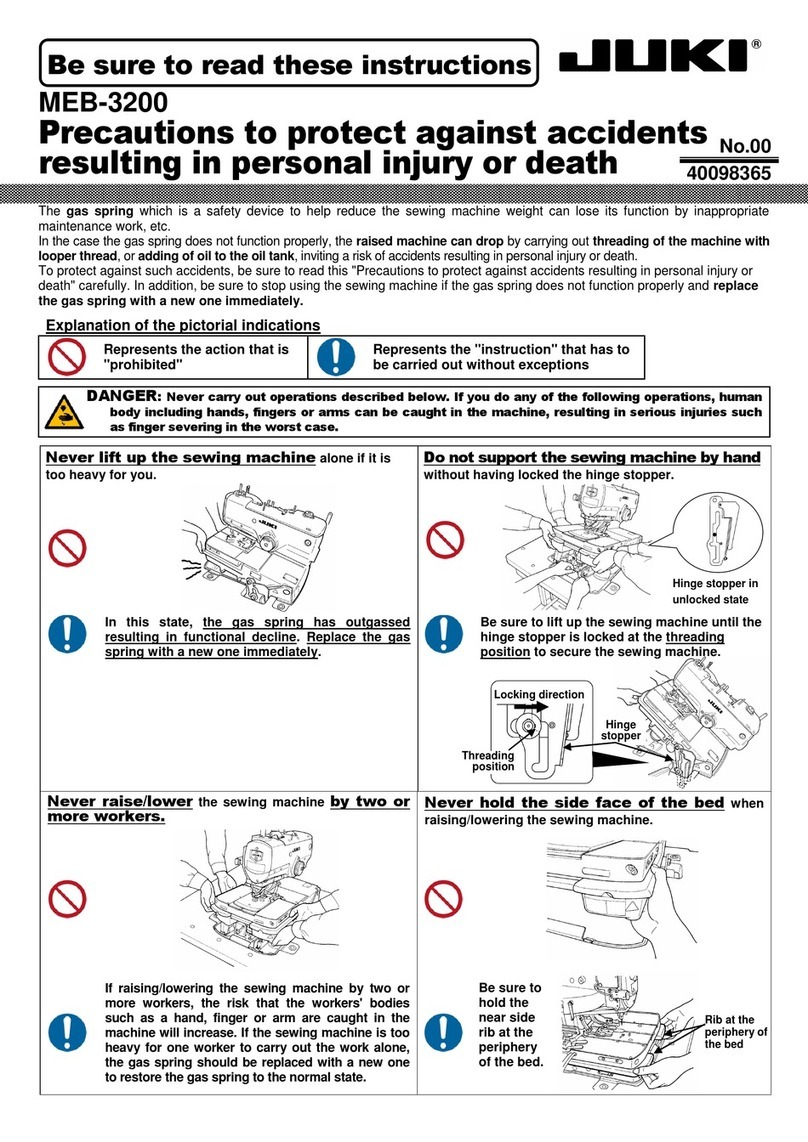

1-3. Operating precautions ......................................................................................................................... 3

2. SPECIFICATIONS ........................................................................................................... 3

3. INSTALLTION ..................................................................................................................4

3-1. Installing the device ............................................................................................................................. 4

3-2. Installing the thread stand .................................................................................................................. 4

3-3. Connecting the power supply ............................................................................................................. 4

3-4. Installing the air hose .......................................................................................................................... 5

3-5. How to operate the air gun ..................................................................................................................5

3-6. Installing the cloth plate ...................................................................................................................... 6

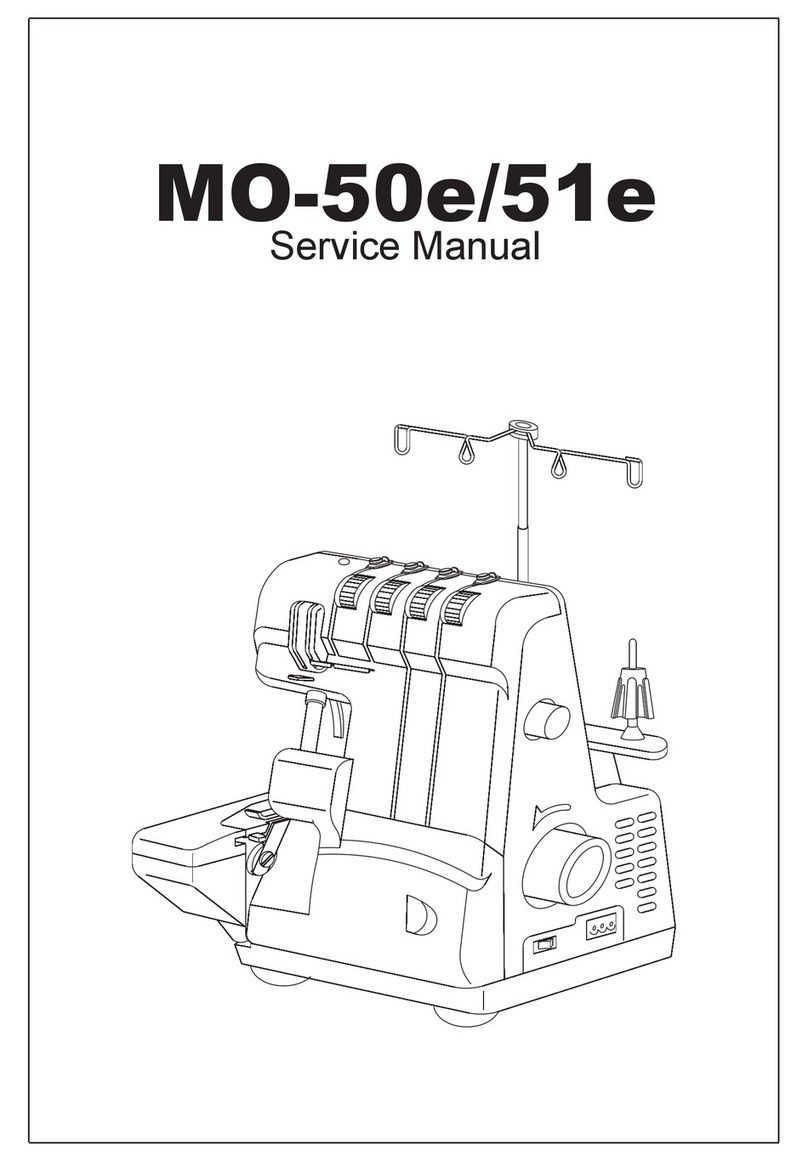

3-7. Installing the machine head ................................................................................................................ 7

(1)Lubrioation .......................................................................................................................................... 7

4. OPERATION AND ADJUSTMENT .................................................................................. 8

4-1. Operating switches and adjusting pneumatic components ............................................................ 8

(1) Power switch ...................................................................................................................................... 8

(2) Pause switch ...................................................................................................................................... 8

(3) Knee switch ........................................................................................................................................ 9

(4) Hand switch ........................................................................................................................................ 9

(5) Workpiece detector switch .............................................................................................................. 10

(6) Preset adjusting knob ..................................................................................................................... 10

(7) Adjusting the air blower .................................................................................................................. 11

(8) Vacuum adjusting metal fittings ..................................................................................................... 13

(9) Sensor to detect the number of garment bodies stacked ............................................................ 13

4-2. Operation of the sewing machine.....................................................................................................14

(1) Inserting the needle ......................................................................................................................... 15

(2) Threading the needle-thread ........................................................................................................... 15

(3) Threading the bobbin case .............................................................................................................. 16

(4) Adjusting the bobbin thread tension ............................................................................................. 16

(5) Installation of bobbin case .............................................................................................................. 17

(6) Installing the knife............................................................................................................................ 17

(7) Remove and installing the bobbin case......................................................................................... 18

4-3. Adjusting the seam allowance ..........................................................................................................19

(1) Adjusting distance A ....................................................................................................................... 19

(2) Adjusting distance B ....................................................................................................................... 19

4-4. Adjusting the carriage lamp .............................................................................................................. 20

(1) Adjusting the position of the clamps .............................................................................................20

(2) Adjusting the clamping force ..........................................................................................................20

4-5. Adjusting the stacking board of the stacker ................................................................................... 21

5. Operation ...................................................................................................................... 22

CONTENTS