CONTENTS

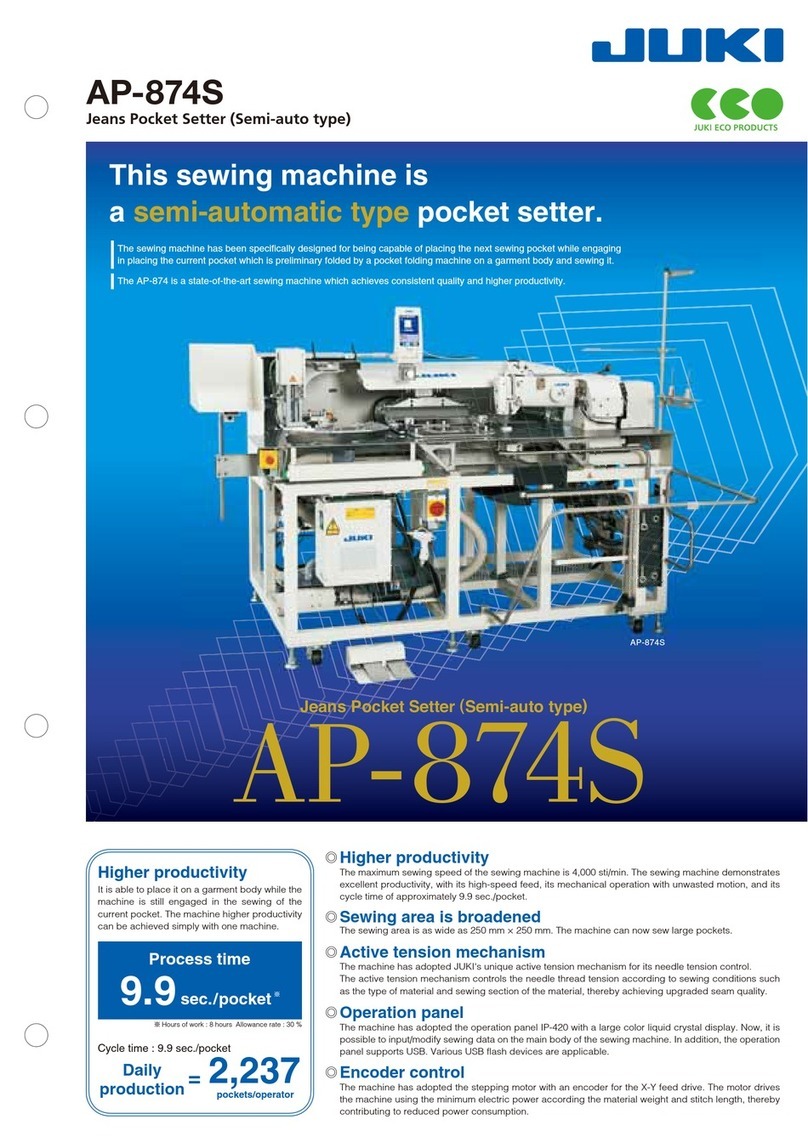

1. SPECIFICATIONS ........................................................................................................... 1

(1) Specifications ....................................................................................................................................... 1

(2) Shapes of buttons ................................................................................................................................ 2

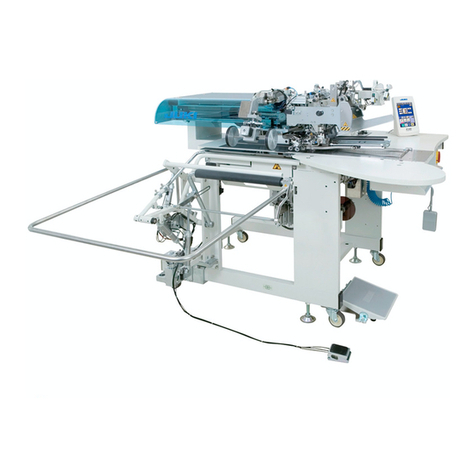

2. CONFIGURATION ........................................................................................................... 4

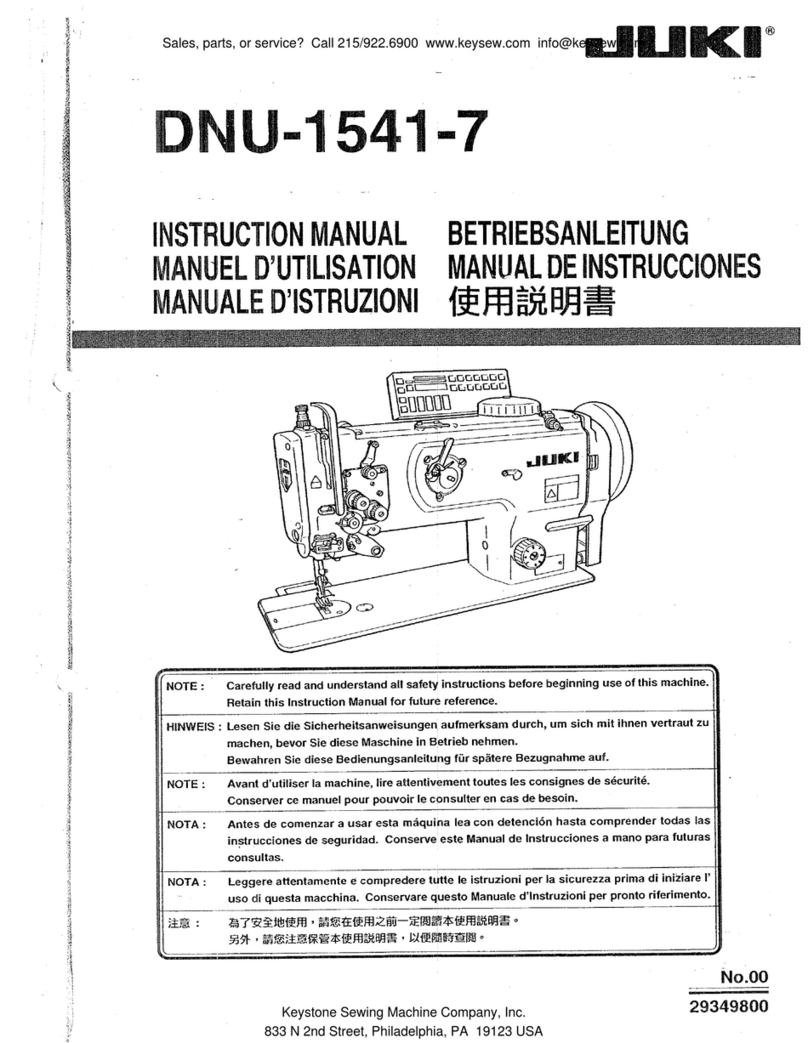

(1) Sewing machine....................................................................................................................................4

(2) Operation panel .................................................................................................................................... 5

3. STANDARD ADJUSTMENT ............................................................................................ 6

(1) Adjusting the height of the needle bar ...............................................................................................6

(2) Adjusting the clearance between the needle and the looper ...........................................................6

(3) Adjusting the needle and the needle guide .......................................................................................8

(4) Adjusting the position of the york slide .............................................................................................8

(5) Wiper adjustment ................................................................................................................................ 10

(6) Adjusting the face plate thread tension ........................................................................................... 12

(7) Adjusting the cloth presser cylinder for sewing flat button directly to cloth ............................... 14

(8) Adjusting the position of Y top feed motor ......................................................................................16

(9) Adjusting the position of Y bottom feed motor................................................................................ 18

(10) Adjusting the tongue up/down cylinder .........................................................................................20

(11) Adjusting the chuck up/down motor .............................................................................................. 22

(12) Adjusting the differential feed motor .............................................................................................. 24

(13) Adjusting the tongue stopper .........................................................................................................26

(14) Adjusting the chuck inversion cylinder .......................................................................................... 28

(15) Adjusting the chuck open/close cylinder .......................................................................................30

(16) Adjusting the respective sensors ...................................................................................................32

4. DISASSEMBLING, ASSEMBLING AND ADJUSTMENT ............................................. 36

(1) Disassembling and assembling of the main shaft .......................................................................... 36

(2) Disassembling and assembling of the face plate ............................................................................ 40

(3) Disassembling and assembling of the needle bar rocking base and the needle bar crank rod .... 42

(4) Disassembling and assembling of the needle throwing motor and the needle bar rocking arm ... 44

(5) Replacing the main motor .................................................................................................................48

(6) Replacing the looper rocking base ...................................................................................................50

(7) Disassembling and assembling the looper rocking link and the looper rocking shaft ...............52

(8) Replacing the thread trimmer cylinder .............................................................................................54

(9) Replacing and adjusting the active tension (VCM) ......................................................................... 56

(10) Replacing and adjusting the thread drawing cylinder ..................................................................58

(11) Replacing the thread drawing motor .............................................................................................. 60

(12) Replacing the loader motor .............................................................................................................62

(13) Replacing and adjusting the cloth presser cylinder for sewing

and wrapping flat button with blindstitch ......................................................................................64

(14) Replacing and adjusting the tongue release cylinder ..................................................................66

(15) Adjusting the moving knife and the fixed knife .............................................................................68

5. OPERATION PANEL ..................................................................................................... 72

(1) Sewing method and sewing shape list .............................................................................................72

(2) Data list ................................................................................................................................................ 73

(3) Sensor list ........................................................................................................................................... 75

(4) Comunication function.......................................................................................................................76

(5) Information function ........................................................................................................................... 78