6

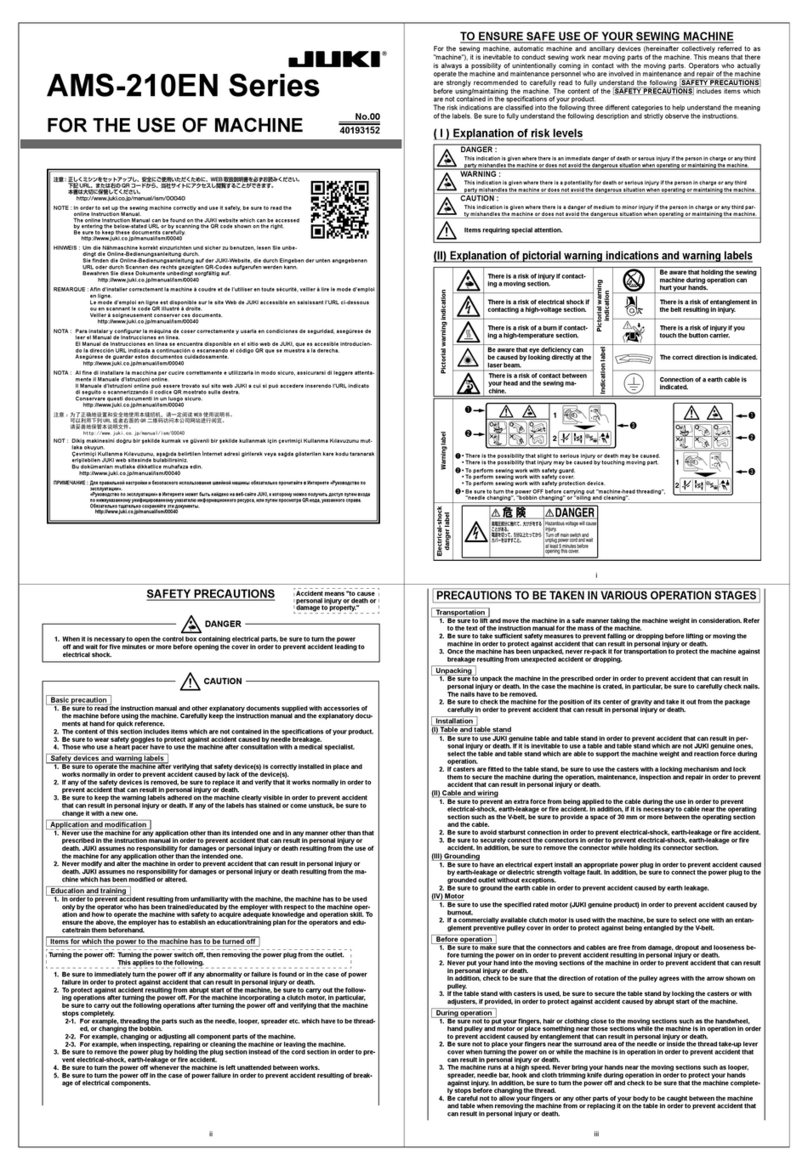

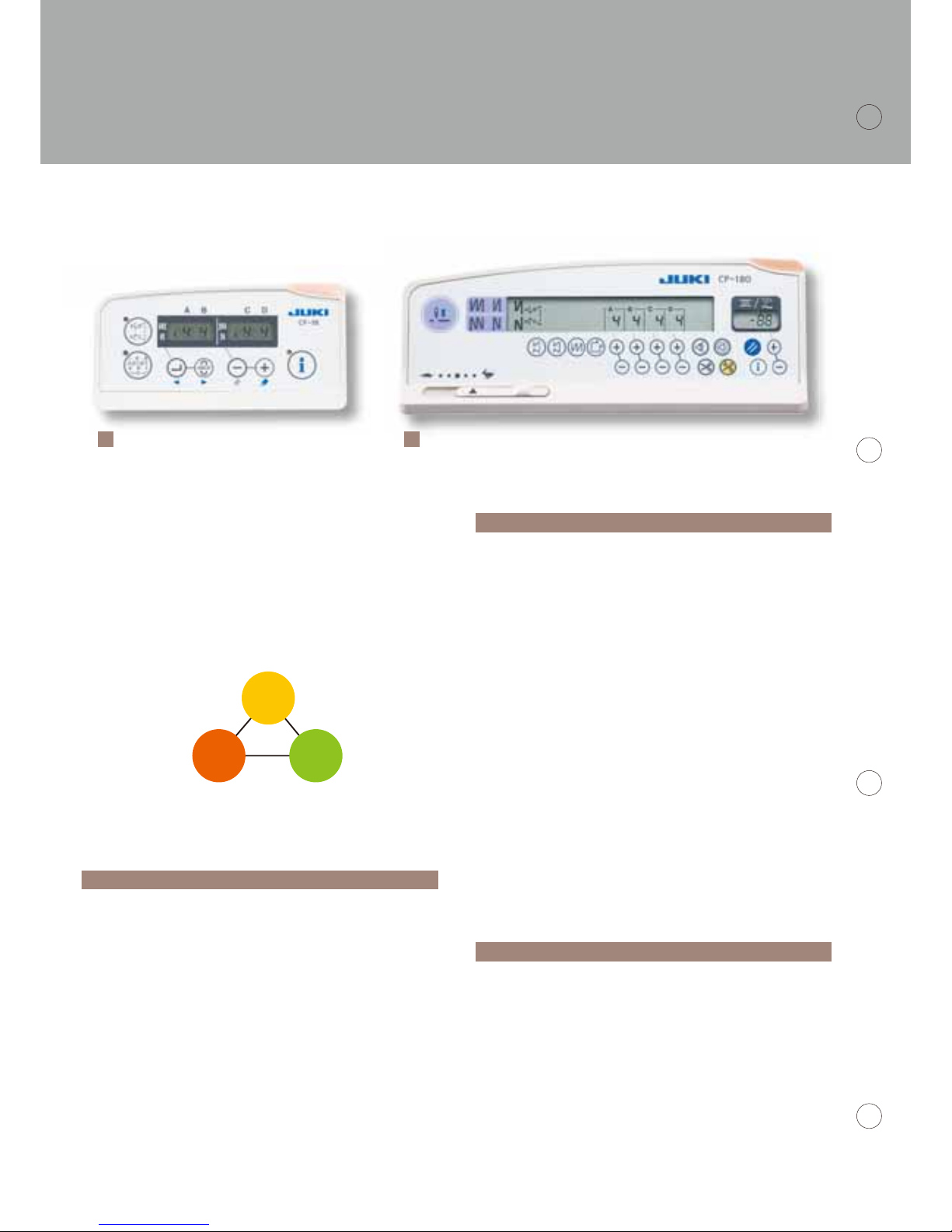

With automatic thread trimmer

Control box

Without automatic thread trimmer

Operation panel

WHEN YOU PLACE ORDERS

Feed system

Needle-feed

Bottom-feed

Code

A

B*

Machine head

Standard hooks

Organized split needle bar,

standard hooks

Code

28

68

Large hooks

Organized split needle bar,

large hooks

78

88

Seam application

Medium-weight

Jeans and heavy-weight

Code

S

G

Auto-lifter

Not provided

Provided

Code

AK135

Wiper

Provided

One-touch type reverse feed

Provided

Code

WB

Wiper and one-touch type reverse feed

Wiper

Notprovided

Notprovided

One-touch type reverse feed

Notprovided

Provided

Code

00

0B*

Attachment

Standard

For tape attaching

Code

S

T*

Seam

application

Light-weight

Foundation

Medium-weight

Jeans and

heavy-weight

Code

LH-3528A LH-3568A

A

F

S

G

–

–

S

G

LH-3578A

–

–

–

G

LH-3588A

–

–

–

G

* Feed system "B" (bottom feed) is applicable to all

models LH-3528A-A (for light-weight materials)

and LH-3528A-F (for foundation) is only applicable

to the needle gauge system "B", "D" or "F".

* Only the seam application "G" is available for the

LH-3578A-7 and LH-3588A-7.

* Refer to the Parts List for details.

* The AK device is applicable only when "0B" is

selected from the classification menu by the wiper

and one-touch type reverse feed mechanism.

* "T" represents the presser foot with guide, throat

plate of sewing tape and bed slide for sewing tape,

and only applies to the LH-3528A-F (for foundation).

* "0B" is only applicable to the LH-3528A-F (for foundation).

* When the "0B" is selected, the sewing machine comes with the direct-drive motor.

The model designations beyond the

classification by feed type only apply to the LH-3528A.

: A gauge designed for factory-installation at delivery.

: A gauge available as a part.

: A gauge designed for factory-installation at delivery.

: A gauge designed for factory-installation to the bottom feed model at delivery.

: A gauge available as a part.

Auto-lifter

Not provided

Provided

Code

AK135*

Power supply

Single-phase 100〜120V

3-phase 200〜240V

Single-phase 200〜240V (for General Export)

Single-phase 200〜240V (for CE)

Single-phase 200〜240V (for China)

Code

S

D

K

N

U

LH35 A

LH35

SC920A

CP180A

CP18A

A 7WB

Please note when placing orders, that the model name should be written as follows:

The needle gauge up to 47.0mm is applicable.

Machine head

Standard hooks

Organized split needle

bar, standard hooks

Code

28

68

Large hooks

Organized split needle

bar, large hooks

78

88

* Refer to the Parts List for details.

•

To order, please contact your nearest JUKI distributor.

A

B

C

D

E

F

G

H

K

W

L

M

N

P

Q

R

S

T

U

3/32 2.4

1/8 3.2 △ △ △ △ △ △

5/32 4.0 △ △ △ △ △ △

3/16 4.8 ○ ○ ○ ○ ○ ○

7/32 5.6 △ △ ○ △ △ △

1/4 6.4 ○ ○ ○ ○ ○ ○

9/32 7.1 △ △ △ △ △ △

5/16 7.9 △ △ △ △ △

3/8 9.5 ○ △ △ △ △ △

7/16 11.1 △ △ △

1/2 12.7 △ △ △ △ △ △

5/8 15.9 △ △ △ △ △ △

3/4 19.1 △ △ △ △ △ △

7/8 22.2 △ △ △ △ △ △

1 25.4 △ △ △ △ △ △

1-1/8 28.6 △ △ △

1-1/4 31.8 △ △ △

1-3/8 34.9

1-1/2 38.1

inch

Needle gauge

LH-3528A-7 LH-3568A-7

LH-3578A-7 LH-3588A-7

Seam application

Code

mm S G S G G G

A

B

C

D

E

F

G

H

K

W

L

M

N

P

Q

R

S

T

U

3/32 2.4 △

1/8 3.2○○△△△△ △ △

5/32 4.0 △ △ △ △ △ △ △

3/16 4.8 ○ ○ ○ ○ ○ ○ ○ ○

7/32 5.6 ○ △ △ ○ △ △ △

1/4 6.4○○○○○○ ○ ○

9/32 7.1 △ ○ △ △ △ △ △ △

5/16 7.9 △ ○ ○ △ △△ △ △

3/8 9.5 △ ○ △ ○ △ △ △

7/16 11.1 △ △ △ △ △

1/2 12.7 △ △ △ △ △ △ △

5/8 15.9 △ △ △ △ △ △

3/4 19.1 △ △ △ △ △ △ △

7/8 22.2 ○ △ △ △ △ △ △

1 25.4 ○ ○ △ △ △ △ △

1-1/8 28.6 △ △ △ △

1-1/4 31.8 △ △ △ △

1-3/8 34.9 △ △ △

1-1/2 38.1 △ △ △

inch

Needle gauge LH-3528A

LH-3568A

LH-3578A LH-3588A

Seam application

Code

mm A F S G S G G G