– 4 –

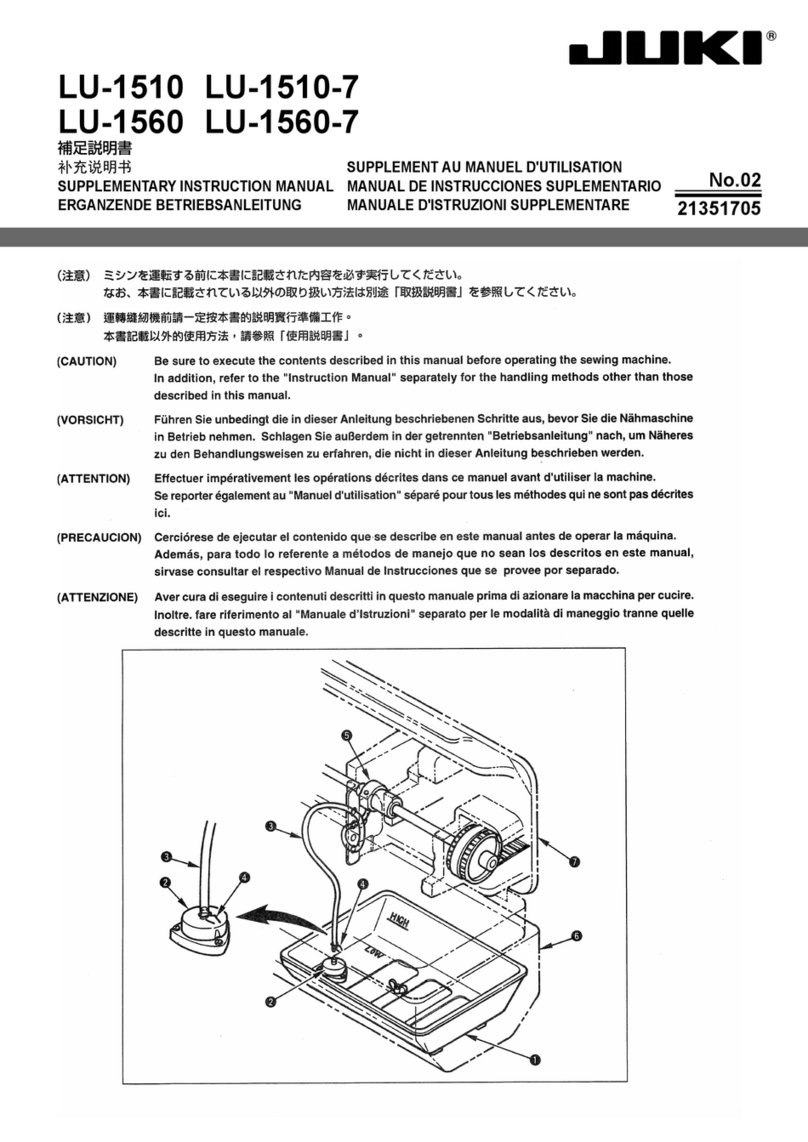

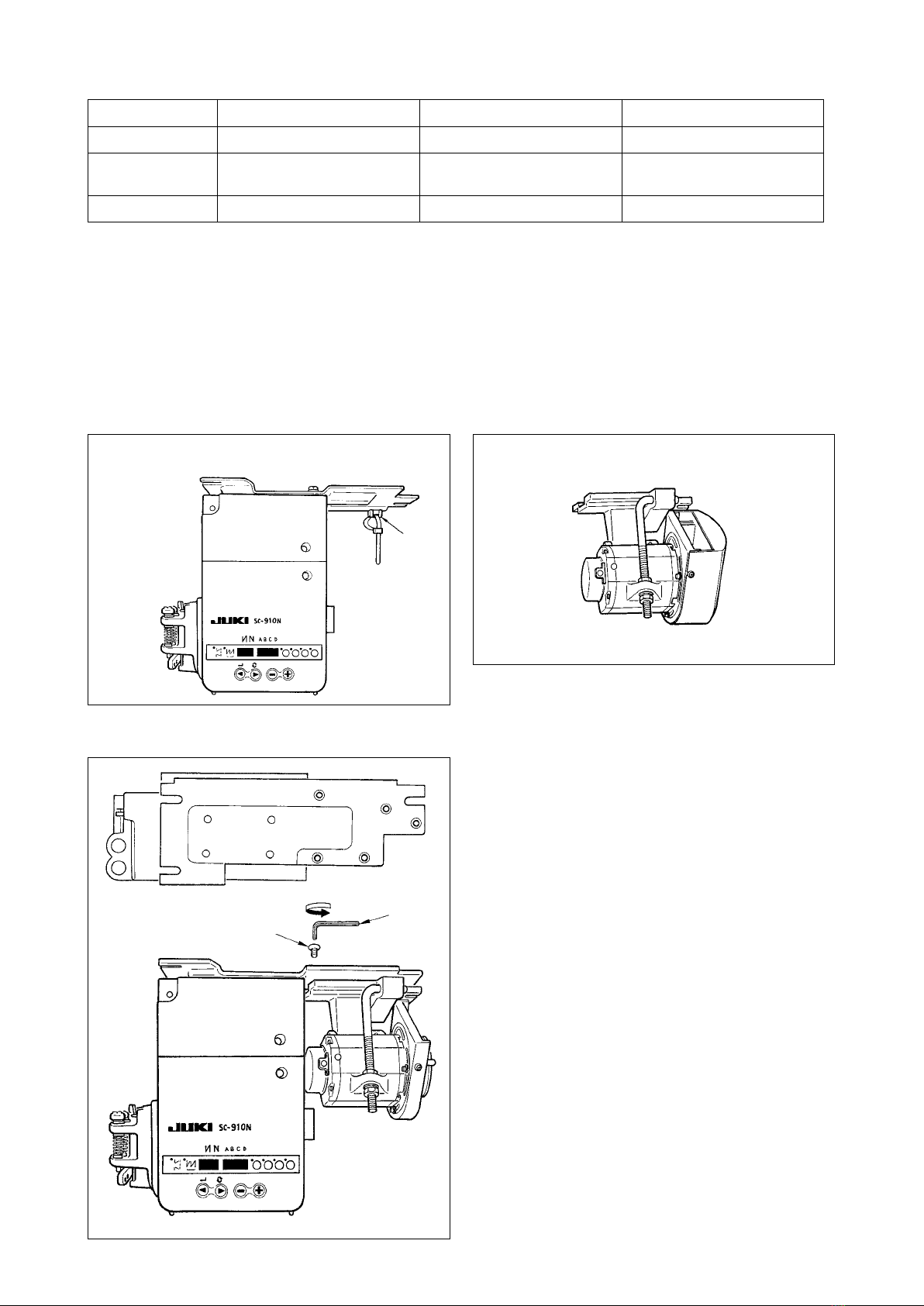

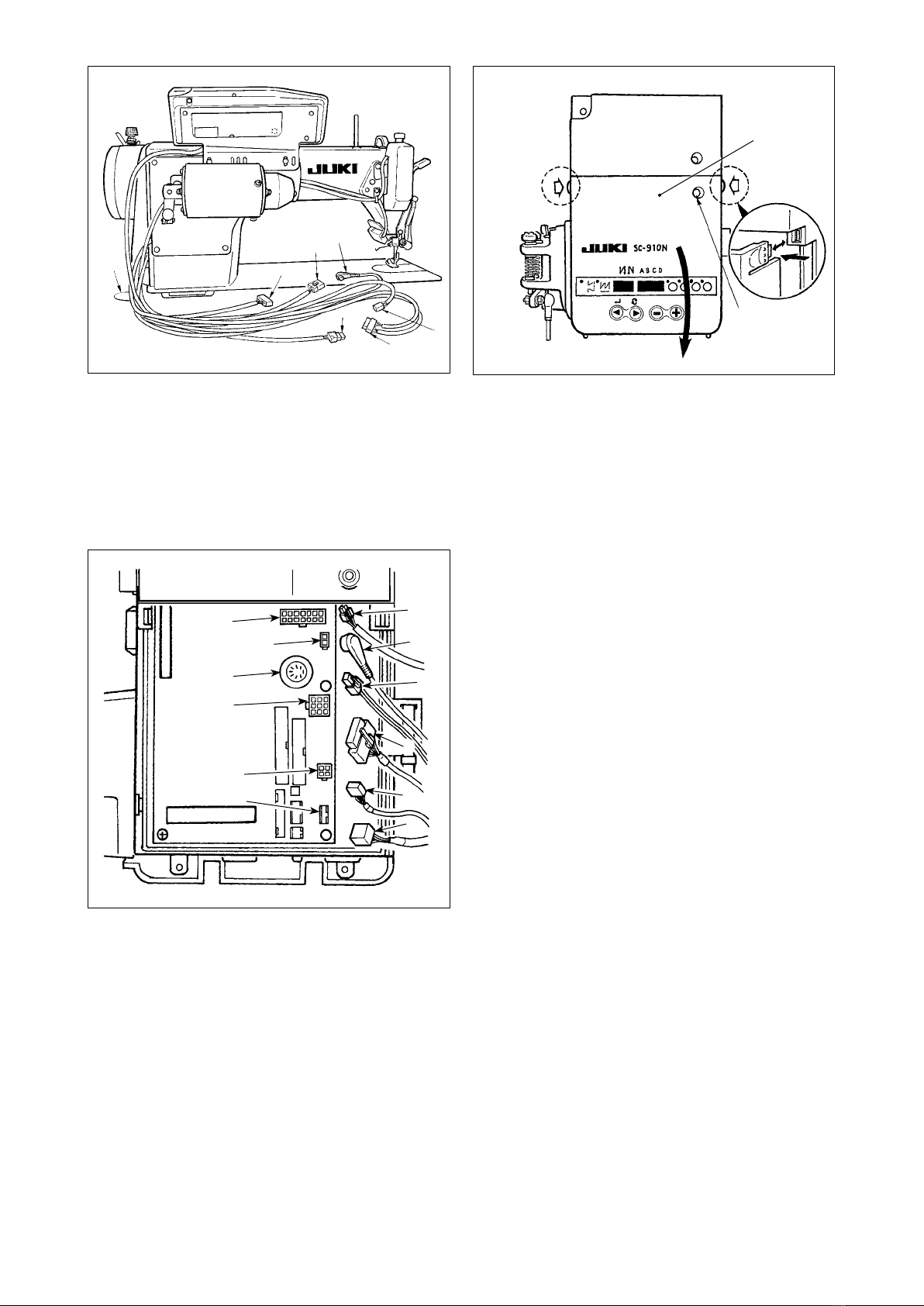

Following connectors are prepared on the front face of SC-910N. Connect the connectors coming from the

machine head to the corresponding places so as to t the devices mounted on the machine head.

1CN30 Synchronizer : it detects the needle bar

position.

2 CN35 CP-170 panel : Various kinds of

programmed sewing can be executed.

(Refer to the Instruction Manual for each

panel for the details of functions.)

3CN31 Machine head connector 4P

4CN42 External input/output connector : input/

output of up/down detection signal, rotation

prohibition signal, etc. is prepared.

5CN48 Safety switch (standard) : When tilting the

sewing machine without turning the power

OFF, the operation of the sewing machine is

prohibited so as to protect against danger.

Optional switch : by changing over the

internal functions, 6 kinds of functions can

be selected.

6CN40 Presser foot lifter solenoid. (For automatic

presser foot lifter type only)

7CN46

Machine head solenid : Thread trimming, reverse-

stitching solenoid, touch-back switch, etc.

8CN47 Optional circuit board connection connector

: Required when using JUKI standard

bobbin thread remaining amount detection

sensor, etc.

9CN39 Motor signal connector

!0 CN32 Standing machine pedal : JUKI standard

PK-70, etc. Sewing machine can be

controlled with the external signal.

!1CN34 IP-110 panel (LCD panel) : Various kinds of

programmed sewing can be executed.

!2 CN45 Material end detection sensor ED-5, etc.

!3 CN43 Fan

* By adding the optional unit A, the following optional

devices of JUKI standard can be connected.

1CN128 Left/right needle detection

2CN127 Thread holding, thread suction, thread

drawing

3CN122 Needle cooler (bottom fan)

4CN121 Bobbin thread remaining amount detection

5CN120 +24V external power source

6CN123 Needle/bobbin thread remaining amount

detection sensor

7CN125 External interface I/F D/A Input

8 CN126 Left/right lock SW, LED

9CN129 Thread holding, thread suction, thread

drawing, bobbin thread remaining amount

detection.

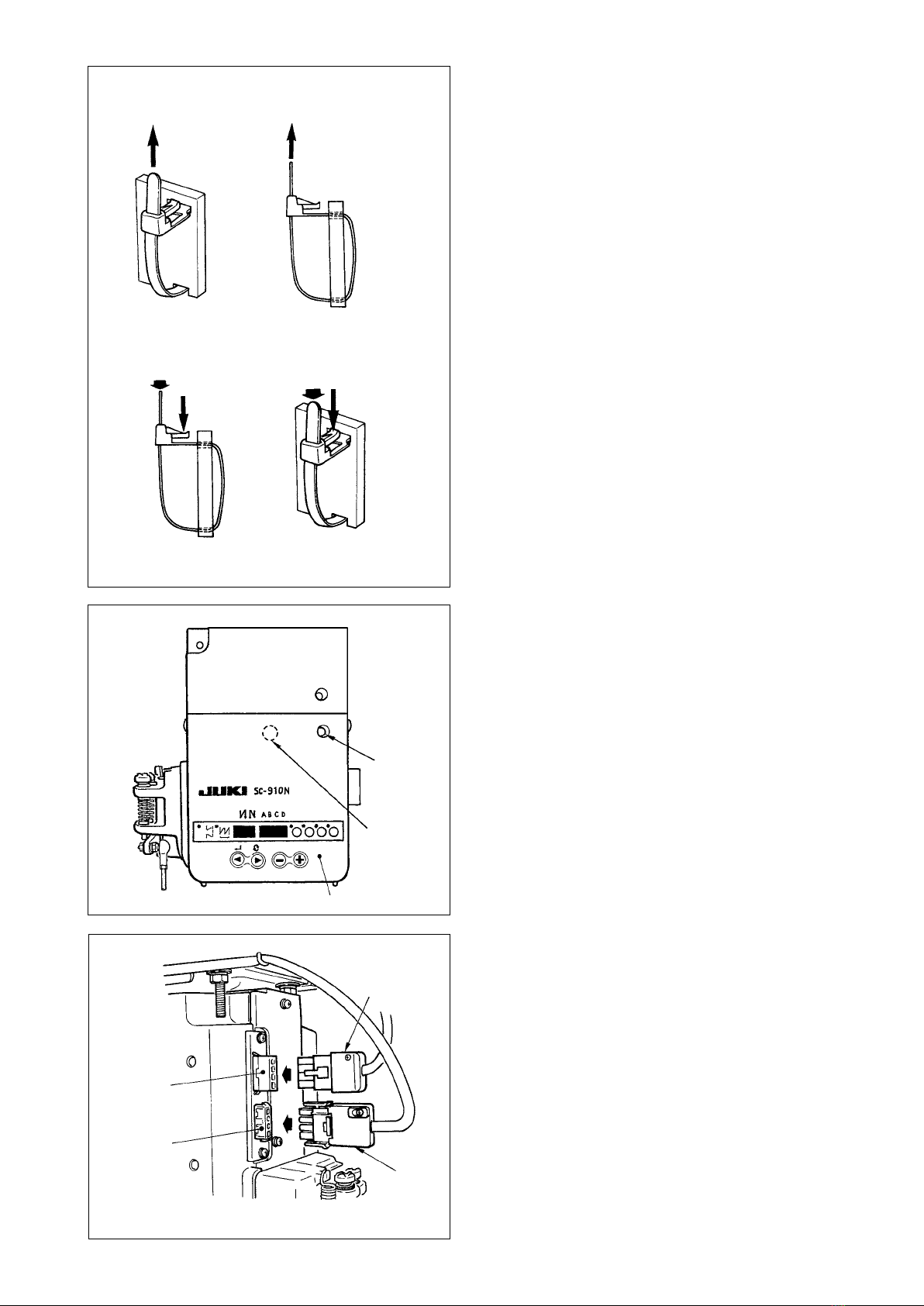

WARNING :

• To prevent personal injury caused by abrupt start of the sewing machine, carry out the work after

turning OFF the power switch and a lapse of 5 minutes or more.

• To prevent damage of device caused by maloperation and wrong specifications, be sure to

connectallthecorrespondingconnectorstothespeciedplaces.

• To prevent personal injury caused by maloperation, be sure to lock the connector with lock.

• As for the details of handling respective devices, read carefully the Instruction Manuals supplied

with the devices before handling the devices.

5. Connecting the cords

Optional unit A

1

2

3

4

5

6

7

8

9

1

7

2

6

3

4

5

9

!0

8

!2

!3

!1