i

CONTENTS

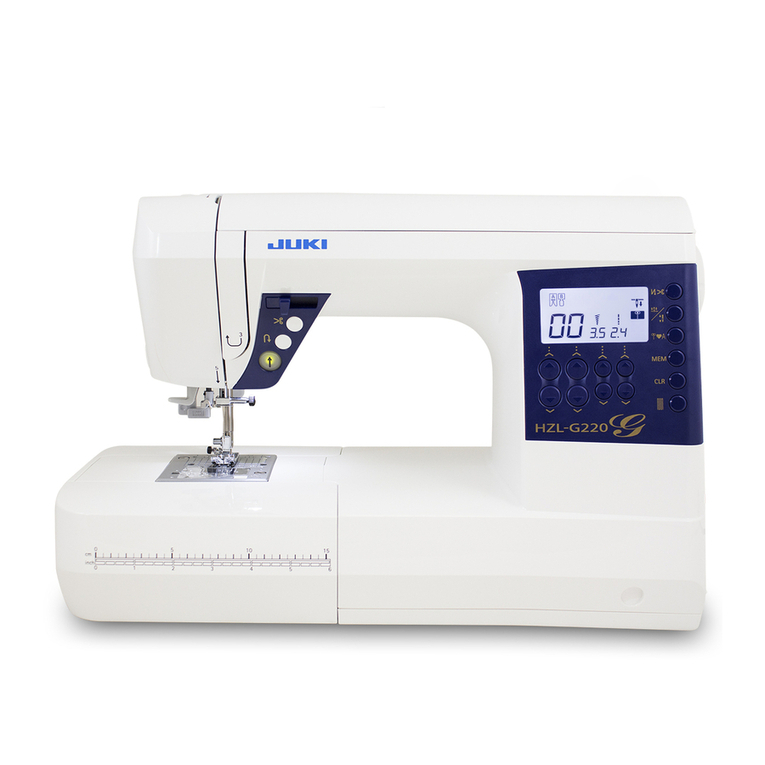

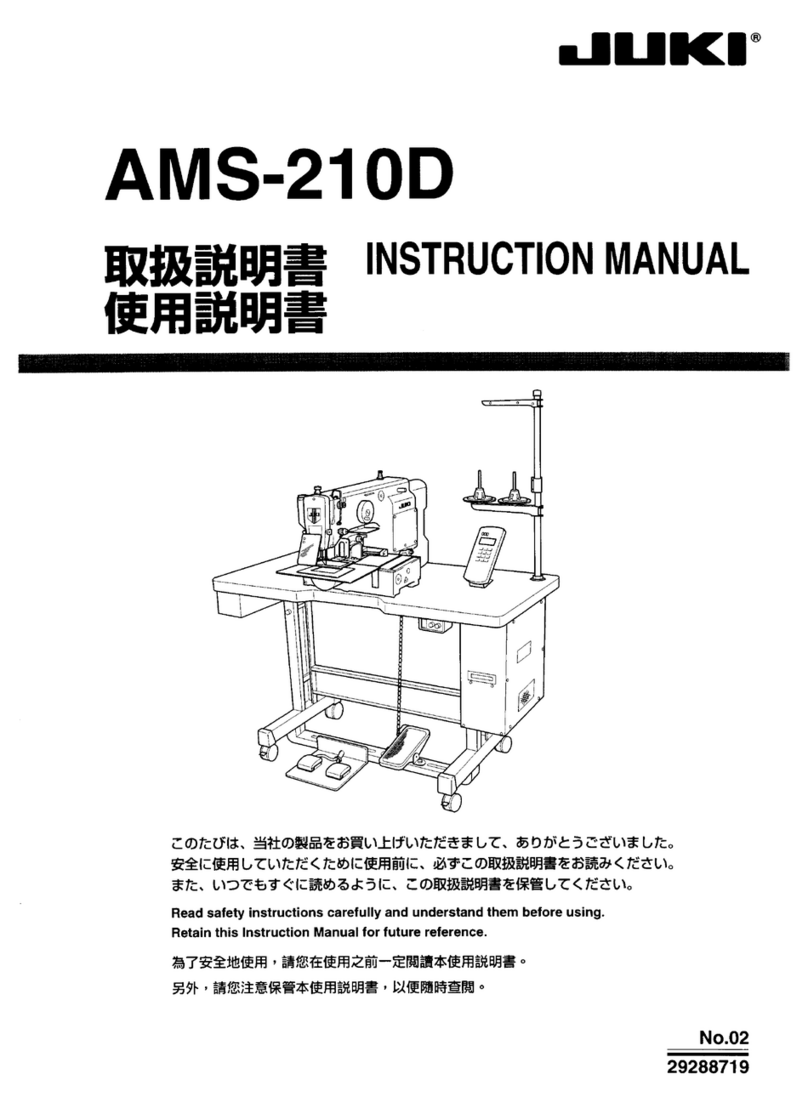

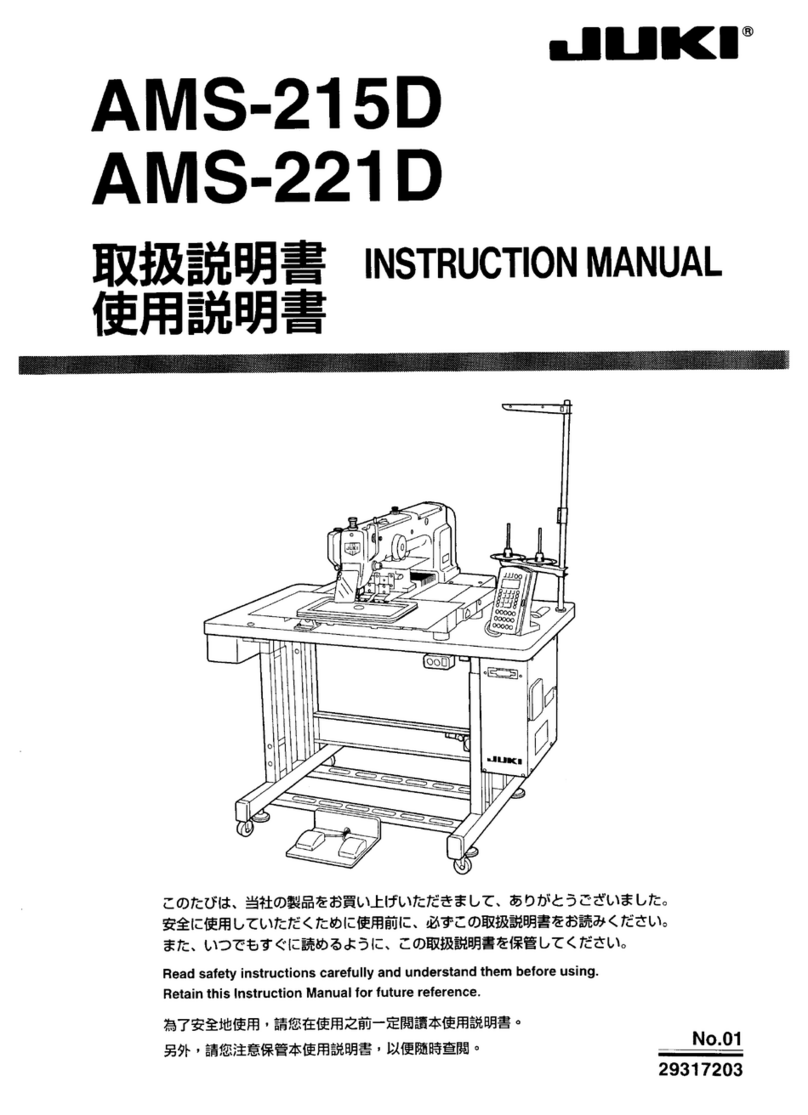

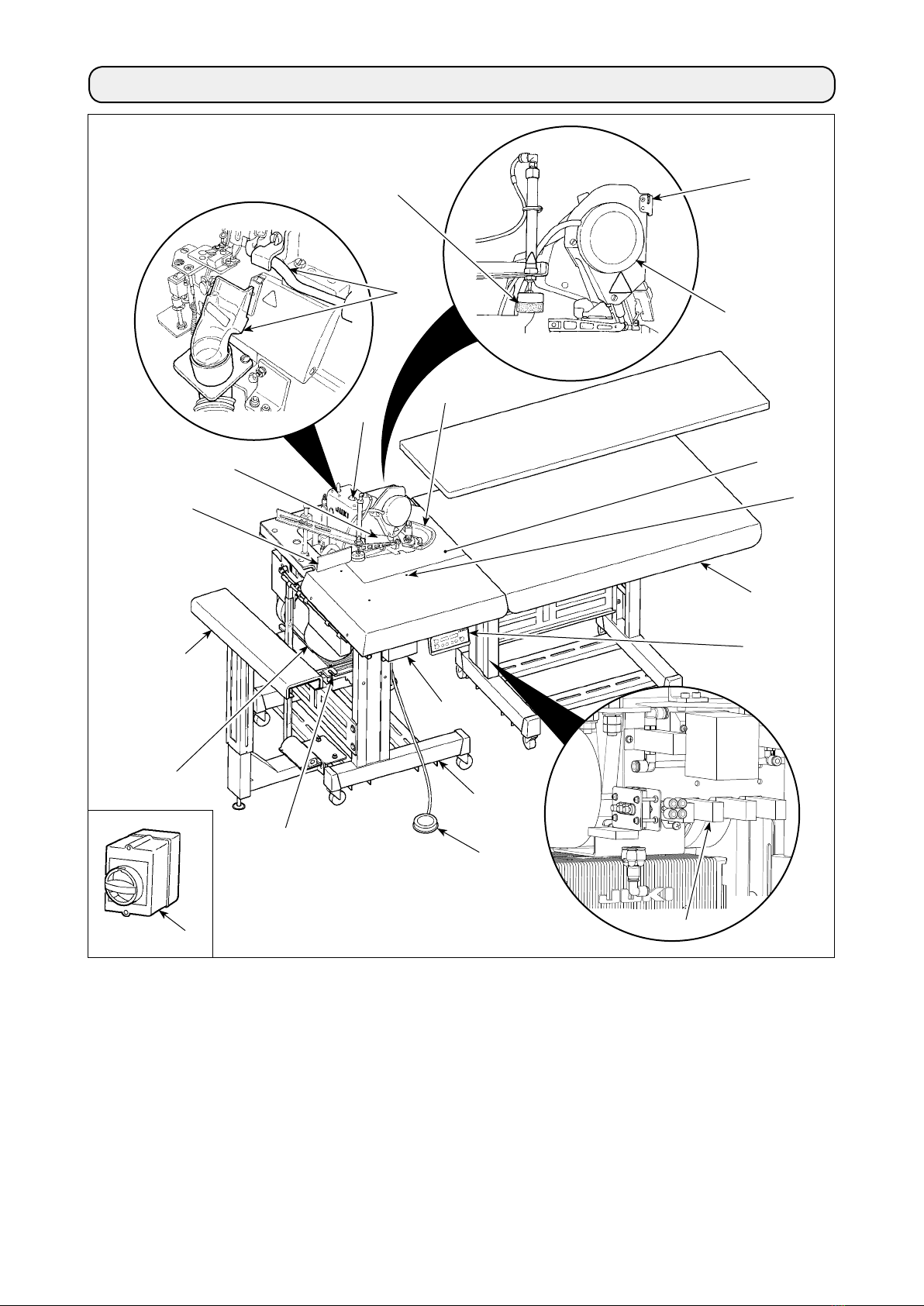

1. CONFIGURATION OF THE MACHINE ...................................................... 1

2. SPECIFICATIONS....................................................................................... 2

3. INSTALLATION........................................................................................... 3

3-1. Removing packing materials ............................................................................................................3

3-2. Securing the machine........................................................................................................................ 3

3-3. Installing the dust collector ..............................................................................................................4

3-4. Installing the stacker .........................................................................................................................5

3-5. Installing the stacker cloth guide .....................................................................................................6

3-6. Installing the cloth plate and the cloth guide unit ..........................................................................7

3-7. Installing the thread stand ................................................................................................................8

3-8. Installing the regulator ......................................................................................................................8

3-9. Connecting the air coupler................................................................................................................ 9

3-10. Connecting the starting pedal for the machine............................................................................. 9

3-11. Joining the sub-table (only for the long table type).................................................................... 10

3-12. Connecting the power plug........................................................................................................... 12

3-13. Installing the cloth receiving board (KM-5) (optional) ................................................................13

3-14. Installing the 3-pedal unit (PK-79) (optional)...............................................................................14

4. PREPARATION......................................................................................... 15

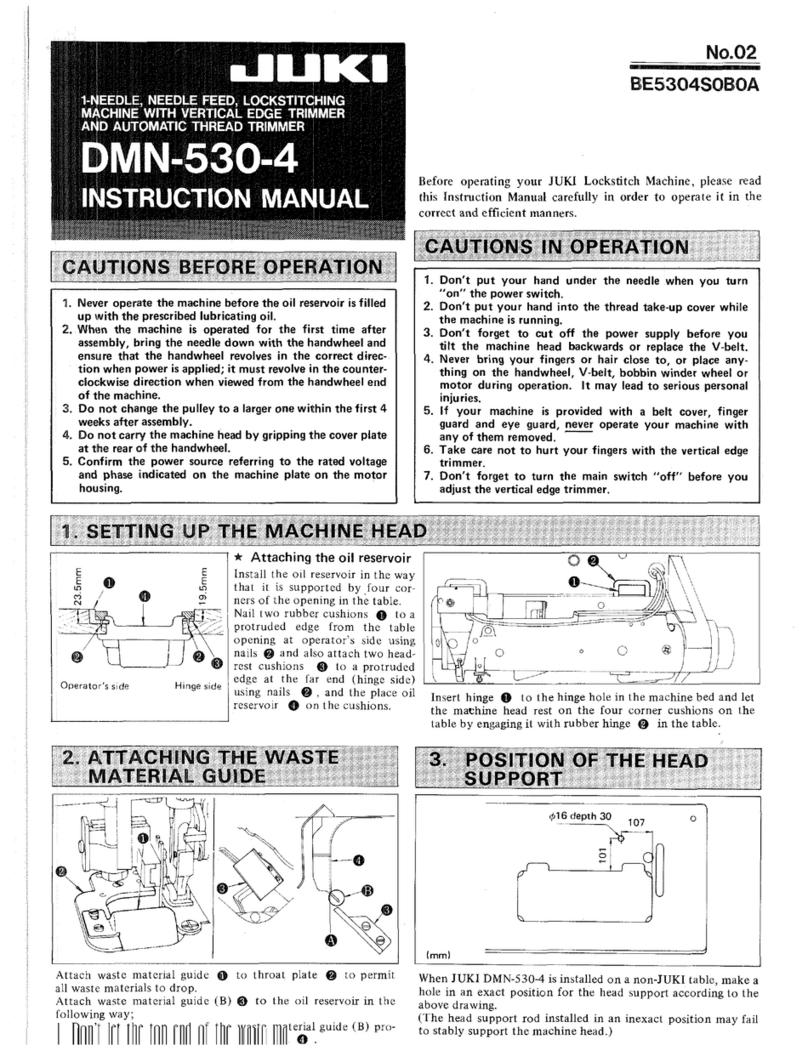

4-1. Caution before operation ................................................................................................................15

4-2. Lubrication........................................................................................................................................ 15

4-3. Threading the machine.................................................................................................................... 16

4-4. Adjusting the pressure of the presser foot and removing the presser foot............................... 17

4-5. Adjusting the stitch length..............................................................................................................17

4-6. Differential feed mechanism ...........................................................................................................18

5. OPERATION ............................................................................................. 19

5-1. Sewing procedure ............................................................................................................................19

5-2. Explanation of the operation panel ................................................................................................22

5-3. Description of the pedals and the switches on the machine head ............................................. 23

5-4. List of functions to be set ...............................................................................................................24

5-5. Details of selected functions ..........................................................................................................25

5-6. Other settings................................................................................................................................... 28

5-7. Initialization of the setting data ......................................................................................................28

6. ADJUSTMENT .......................................................................................... 29

6-1. Stacker support board adjustment................................................................................................. 29

6-2. Adjusting the position of the thread trimmer presser ..................................................................30

6-3. Adjusting the air blow......................................................................................................................30

6-4. Adjusting the edge guide ................................................................................................................31

6-5. Adjusting the cloth guide ................................................................................................................32

6-6. Regulator adjustment ......................................................................................................................32

6-7. Adjusting the cloth chip suction force...........................................................................................33

6-8. Adjusting the sensors......................................................................................................................34