CONTENTS

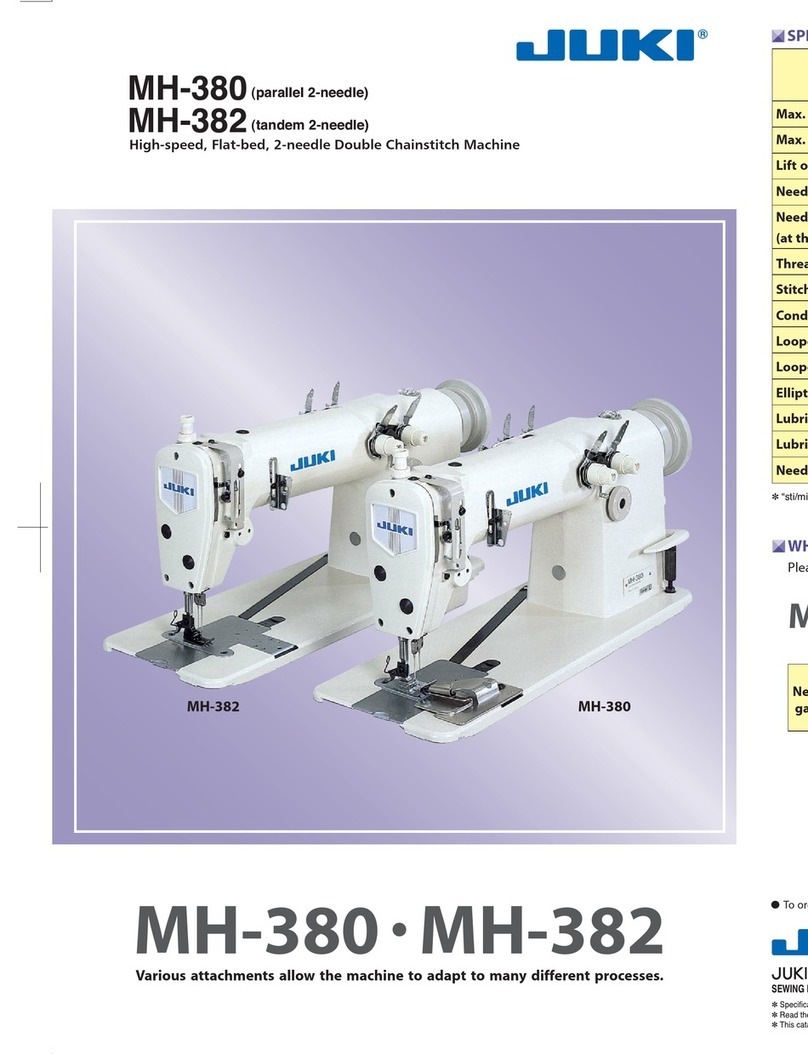

1. SPECIFICATIONS...................................................................................................................................1

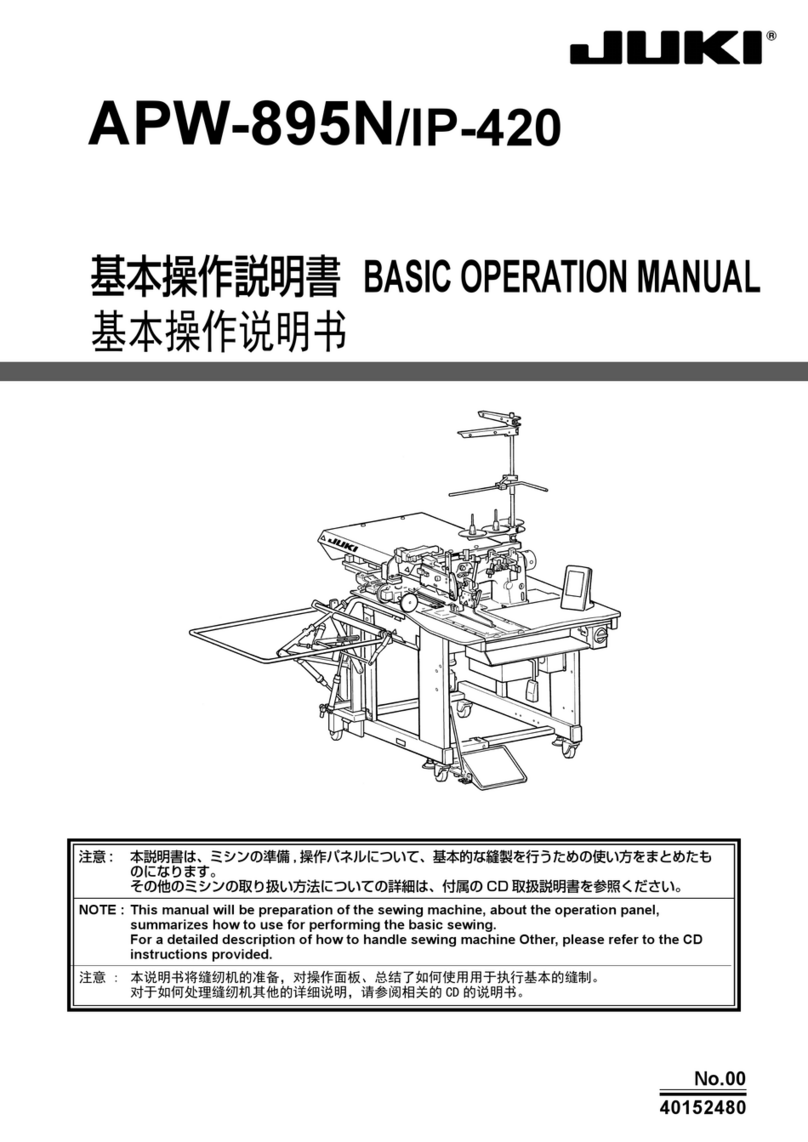

2. NAME OF EACH COMPONENT.............................................................................................................2

(1) Name of the main unit ................................................................................................................................................. 2

3. OPERATION OF THE SEWING MACHINE ............................................................................................3

(1) Names of the operation panel switches .................................................................................................................... 3

(2) Pattern table ................................................................................................................................................................. 4

(3) How to operate and use the memory switch (User level) ........................................................................................ 5

4. STANDARD ADJUSTMENT ...................................................................................................................6

(1) Height of the needle bar.............................................................................................................................................. 6

(2) Positioning the needle and the looper....................................................................................................................... 6

(3) Timing the travel of the yoke slide............................................................................................................................. 8

(4) Timing of the tension disc No. 2 ................................................................................................................................ 8

(5) Lift and pressure of the button clamp ..................................................................................................................... 10

5. ADJUSTMENT OF THE THREAD TRIMMING MECHANISM ..............................................................10

(1) The mechanism and the name of each component of the thread trimmer .......................................................... 10

(2) Adjusting the position of the moving knife............................................................................................................. 12

(3) Adjusting the height of the thread separating claw of the moving knife ............................................................. 12

6. PROCEDURES IN DISASSEMBLING AND ASSEMBLING ................................................................14

(1) Name of each component ......................................................................................................................................... 14

(2) Disassembling the circuit board .............................................................................................................................. 16

(3) Disassembling the machine arm and bed ............................................................................................................... 18

(4) Disassembling the looper shaft ............................................................................................................................... 20

(5) Disassembling the driving shaft .............................................................................................................................. 22

7. ADJUSTMENT OF THE SENSORS......................................................................................................26

(1) Adjusting the starting sensor................................................................................................................................... 26

(2) Adjusting the presser lifter sensor .......................................................................................................................... 26

(3) Adjusting the feed origin sensor ............................................................................................................................. 28

(4) Adjusting the presser lifter stopper......................................................................................................................... 28

8. HOW TO OPERATE AND USE THE MEMORY SWITCH (SERVICE LEVEL) ....................................30

(1) Memory switch function table .................................................................................................................................. 31

9. HOW TO OPERATE AND USE THE INPUT CHECK MODE FUNCTION ...........................................33

(1) INPUT CHECK CORRESPONDENCE TABLE .......................................................................................................... 34

10. HOW TO OPERATE AND USE THE ALL CLEAR FUNCTION ...........................................................35

11. PARTS TO BE GREASESD..................................................................................................................36

12. ERROR LIST .........................................................................................................................................37

13. CHANGE-OVER OF THE POWER SOURCE VOLTAGE ....................................................................38

14. CAUSE OF TROUBLES AND THE CORRECTIVE MEASURES.........................................................39

(1) Thread trimming troubles and the corrective measures ....................................................................................... 39

(2) Cause of troubles and the corrective measures for MB-1800 ............................................................................... 40

15. CIRCUIT BOARD DIAGRAM ................................................................................................................41

(1) MAIN circuit board..................................................................................................................................................... 41

(2) PWR circuit board ..................................................................................................................................................... 42

(3) PANEL circuit board.................................................................................................................................................. 42

16. BLOCK DIAGRAM 1/2 ..........................................................................................................................43

17. CONNECTION DIAGRAM AND CIRCUIT DIAGRAM ..........................................................................45

(1) Power connection diagram....................................................................................................................................... 45

(2) Sensor connection diagram ..................................................................................................................................... 46

(3) Motor circuit diagram ................................................................................................................................................ 47

(4) Encoder circuit diagram ........................................................................................................................................... 48

(5) Solenoid circuit diagram........................................................................................................................................... 48

18. DRAWING OF THE TABLE ..................................................................................................................49