CONTENTS

1. SPECIFICATIONS.............................................1

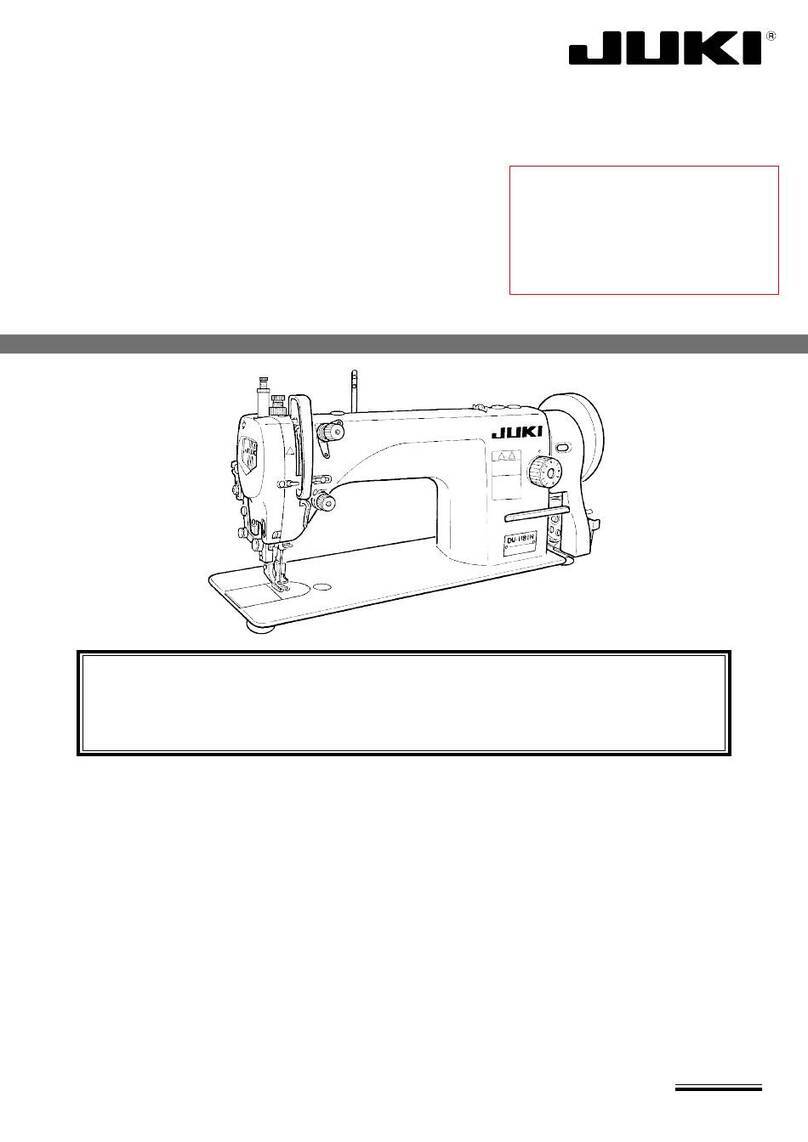

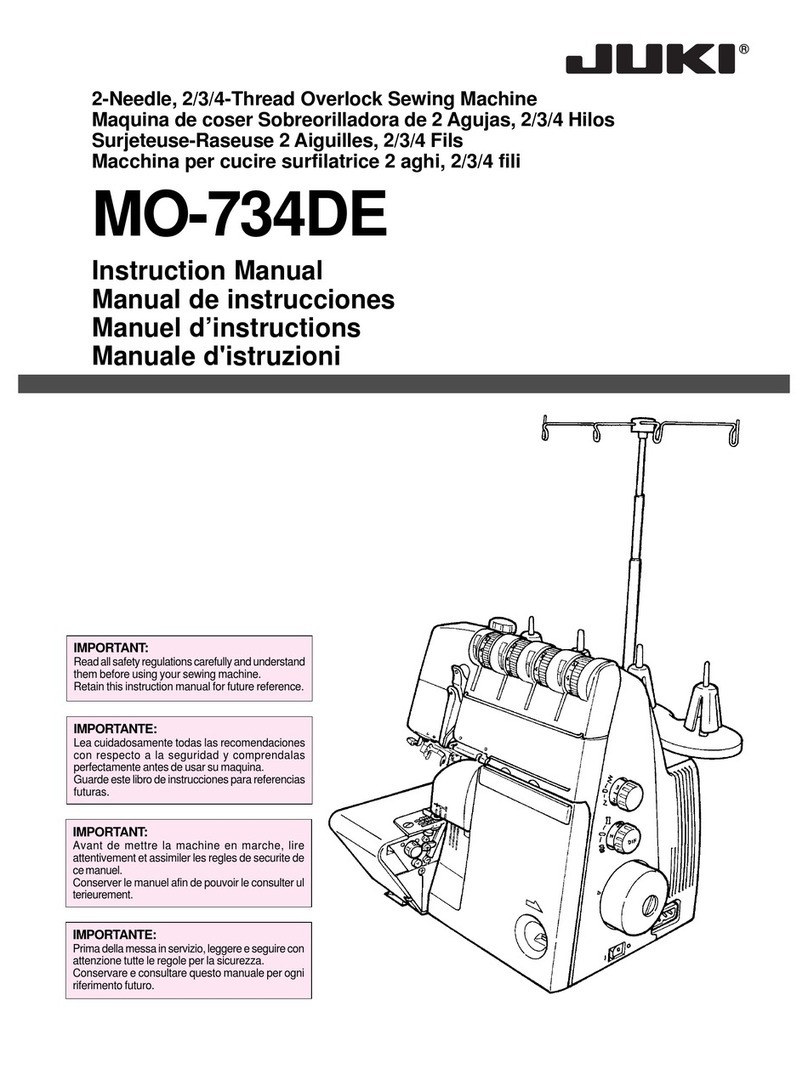

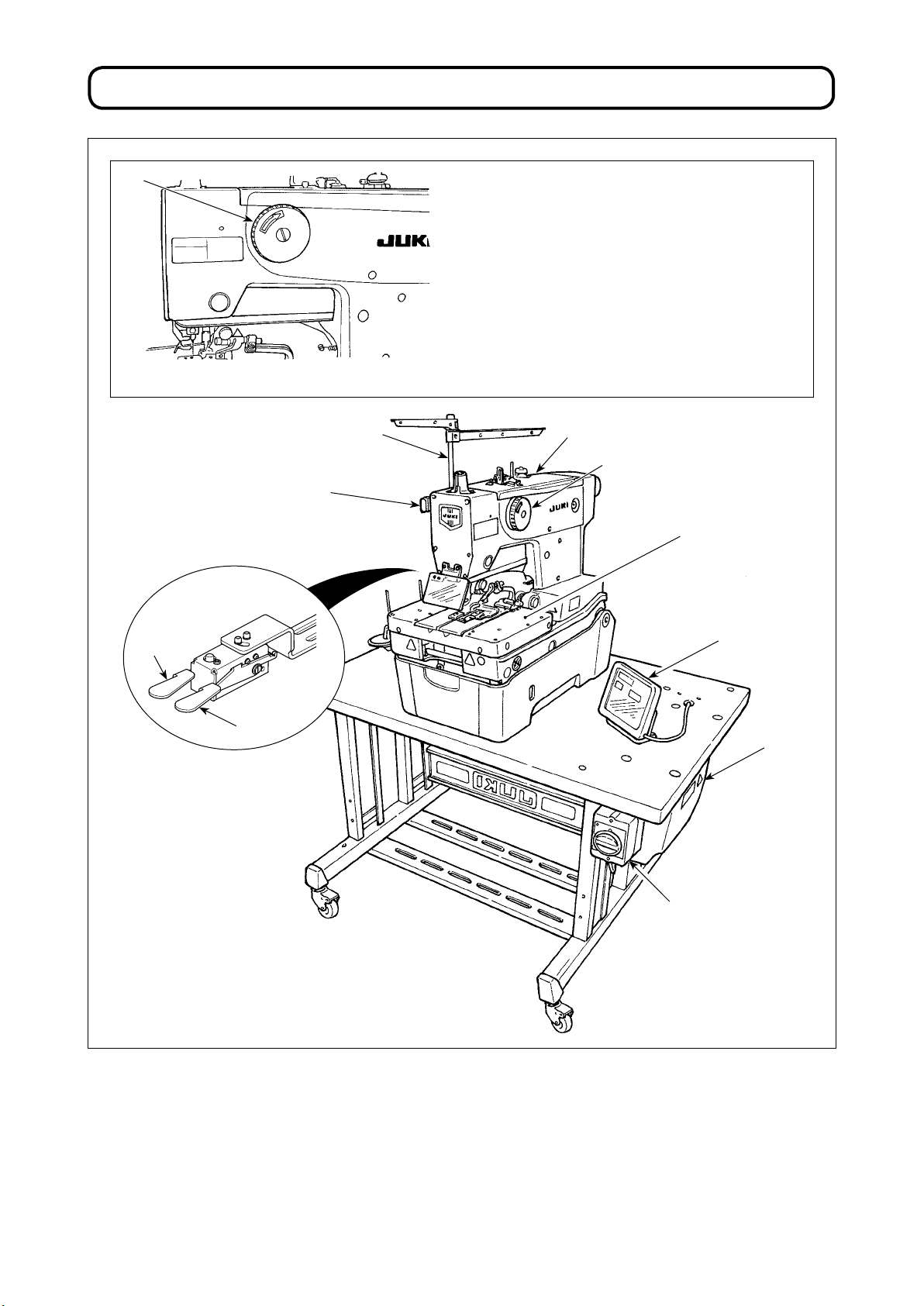

2. NAME OF EACH COMPONENT ......................2

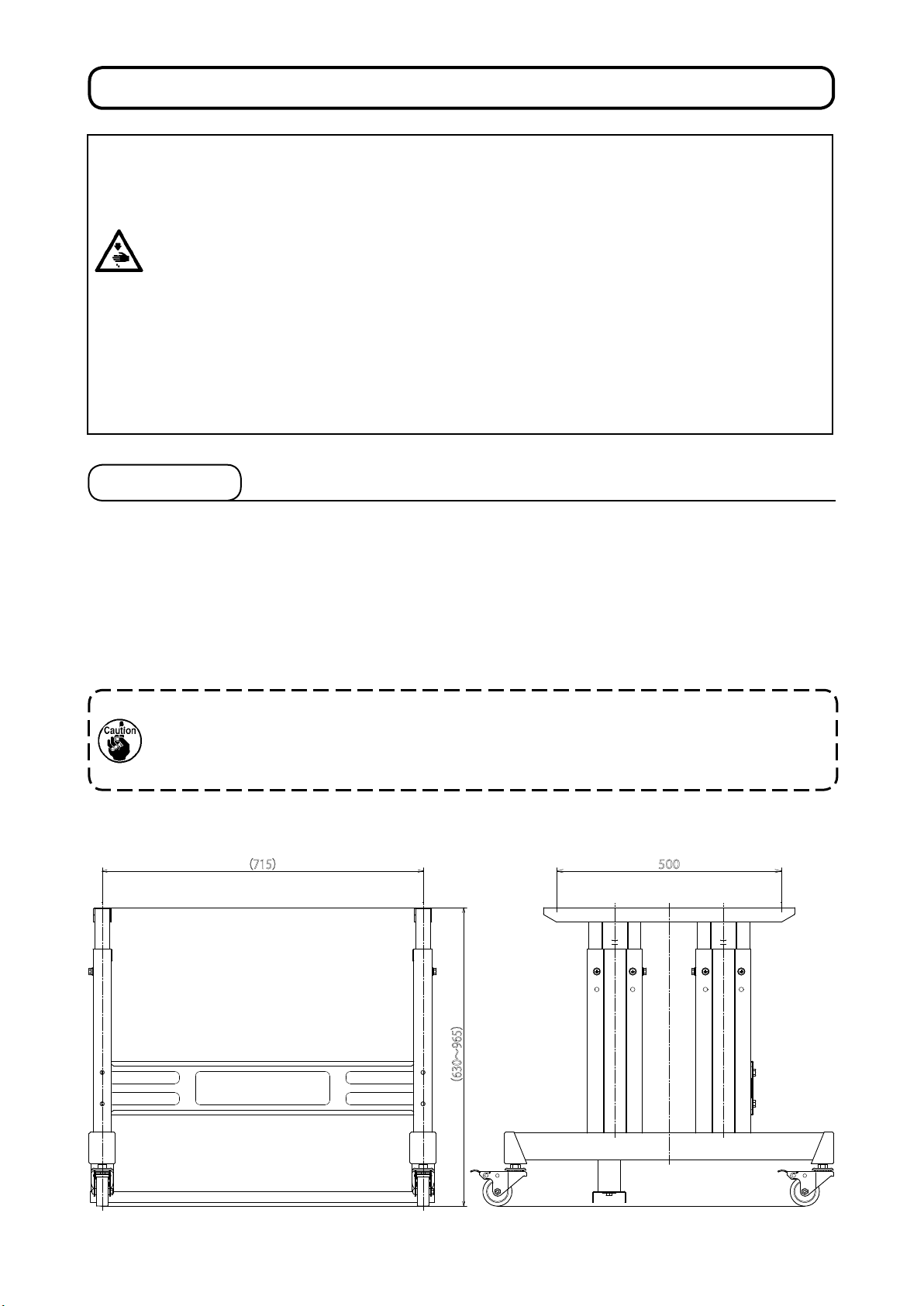

3. INSTALLATION.................................................3

3-1. Table.............................................................................3

(1) Drawing of the stand....................................................... 3

(2) Drawing of the table(Table-xed type) .......................... 4

(3) Drawing of the table (Semi-sunken type)...................... 5

3-2. Installing the control box ...........................................6

3-3. Installing and connecting the power switch ............ 6

3-4. Taking out the sewing machine................................. 8

3-5. Installing the sewing machine................................... 9

(1) In the case of the table-xed type machine head......... 9

(2) In the case of the semi-sunken type machine head....11

3-6. Raising and returning the sewing machine............ 16

3-7. Installing the poly oiler............................................. 19

3-8. Installing the operation panel.................................. 19

3-9. Installing the regulator and the manifold ............... 20

3-10. Connecting the cords............................................. 22

3-11. Handling the cords..................................................23

3-12. Installing the foot pedal switch (optional)............ 24

3-13. Connecting the air supply...................................... 25

(1) Connecting the regulator and the manifold................ 25

(2) Connecting the air tubes .............................................. 26

3-14. Installing the air hose............................................. 27

3-15.

Cautions for the compressed air supply (source

of supply air) facility................................................. 28

3-16. Installing the thread stand .....................................29

3-17. Installing the thread guides ...................................30

3-18. Installing the eye protection cover and the

nger guard ............................................................. 31

3-19. Installing the cloth chip bag ..................................32

3-20. Installing/removing the presser unit..................... 33

4. PREPARATION BEFORE OPERATION.........34

4-1. Lubrication of the machine and how to lubricate.. 34

(1) Lubricating the arm oil tank ......................................... 34

(2) Lubricating the bed oil tank ......................................... 34

(3) Lubricating the looper and spreader components .... 35

(4) Lubricating the looper bracket oil tank....................... 35

(5) Lubricating the needle bar and the gear section ....... 36

4-2. Attaching the needle................................................. 37

4-3. Threading the machine head ...................................38

(1) Threading the upper thread (needle thread)............... 38

(2) Threading the lower thread (looper thread)................ 39

(3) Threading the machine with gimp ............................... 40

4-4. How to set the cloth on the sewing machine ......... 40

5. STRUCTURE OF THE OPERATION

SWITCH ..........................................................41

5-1. Structure of the operation panel ............................. 41

5-2. Temporary stop switch.............................................43

5-3. Hand switch............................................................... 43

5-4. Foot switch (optional)............................................... 43

6. HOW TO USE THE OPERATION PANEL ......44

6-1. Basic operation of the sewing machine ................. 44

6-2. Setting the thread tension........................................ 44

6-3. Temporarily stopping the sewing machine ............ 45

6-4. Performing re-sewing............................................... 46

6-5. Performing threading ...............................................47

6-6. How to use the counter ............................................47

6-7. When dropping of the knife is temporarily not

desired .....................................................................48

6-8. Changing the operation mode................................. 48

6-9. Changing procedure of the sewing pattern............ 50

6-10. Conrming the pattern shape................................ 50

7. SETTING PROCEDURE OF THE SEWING

DATA ...............................................................51

7-1. Setting the knife No. .................................................52

7-2. Setting the cut length ...............................................52

7-3. Setting the cut-before/cut-after knives ................... 53

7-4. Setting the number of stitches of the parallel

section...................................................................... 53

7-5. Setting the number of stitches of the eyelet .......... 53

7-6. Setting the cut space................................................ 54

7-7. Setting the eyelet space........................................... 54

7-8. Knife position compensation................................... 54

7-9. Number of stitches of sewing end compensation. 55

7-10. Turning angle compensation ................................. 55

7-11. Turning angle compensation at the parallel sec-

tion............................................................................ 55

7-12. Compensation of eyelet in lateral direction ......... 56

7-13. Compensation of eyelet in longitudinal direction 56

7-14. Compensation of eyelet, left in longitudinal

direction ...................................................................56

7-15. Compensation of left parallel section of a but-

tonhole .....................................................................57

7-16. Compensation of cutting space, left..................... 57

7-17.

Setting the needle throwing width of the

right bottom of eyelet .........................................57

7-18.

Setting the needle throwing width of the left

bottom of eyelet .................................................58

7-19. Setting the needle throwing width ........................ 58

7-20. Setting the type of bartack..................................... 58

7-21. Setting the length of taper bar............................... 59

7-22. Setting the number of stitches of taper bar ......... 59

7-23. Setting the offset of taper bar................................ 59

7-24. Setting the number of stitches of slant section

of taper bar .............................................................. 60

7-25. Compensation of the number of stitches of the

right side taper bar.................................................. 60

7-26. Setting the straight bar length............................... 60

7-27. Setting the number of stitches of straight bar..... 61

7-28. Setting the overlapping amount of straight bar... 61

7-29. Setting the needle throwing width of straight bar61

7-30. Setting the number of stitches of round bar........ 62

7-31. Setting the number of overlapping stitches of

round bar 2 .............................................................. 62

7-32. Setting the needle throwing width of the round

bar............................................................................. 62

7-33. Setting the needle throwing width at the upper

section of eyelet bar ............................................... 63

7-34. Setting the reduced sewing speed for straight/

round bar ................................................................. 63

7-35. Setting the sewing speed....................................... 63

7-36. Setting the reduction speed of eyelet................... 63

i