i

CONTENTS

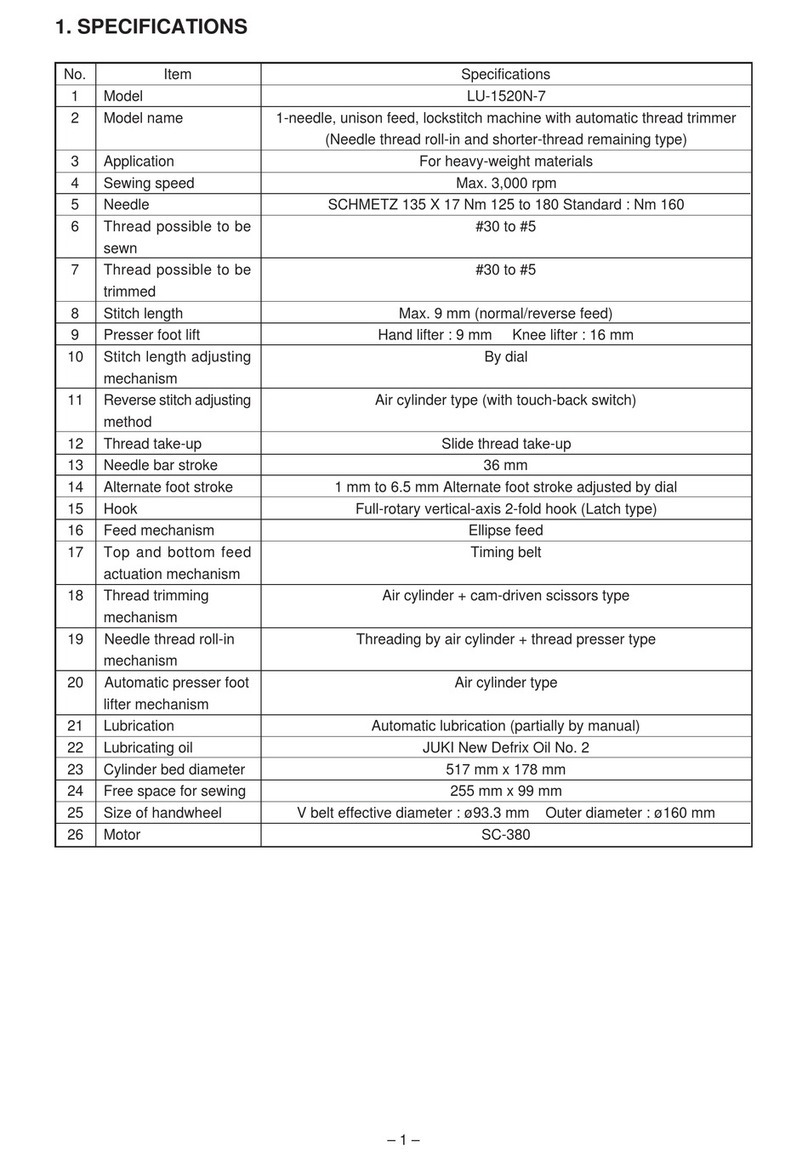

1. SPECIFICATIONS............................................................................................................ 1

2. NAME OF EACH COMPONENT ..................................................................................... 3

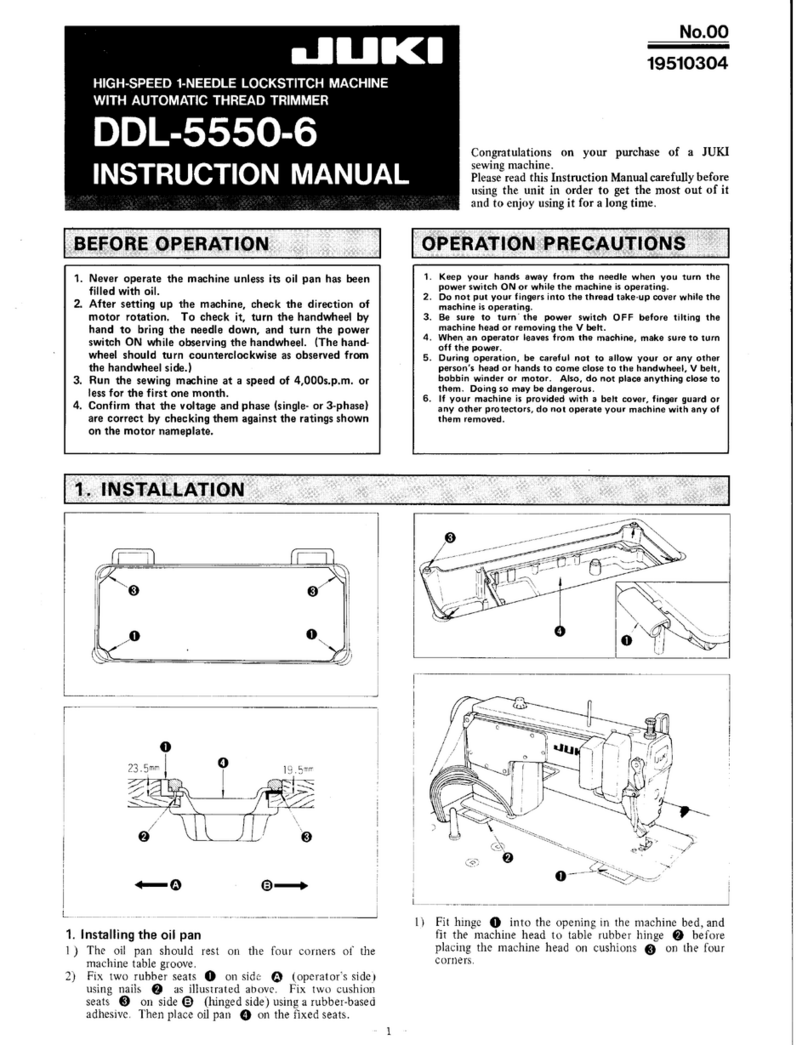

3. INSTALLATION................................................................................................................ 4

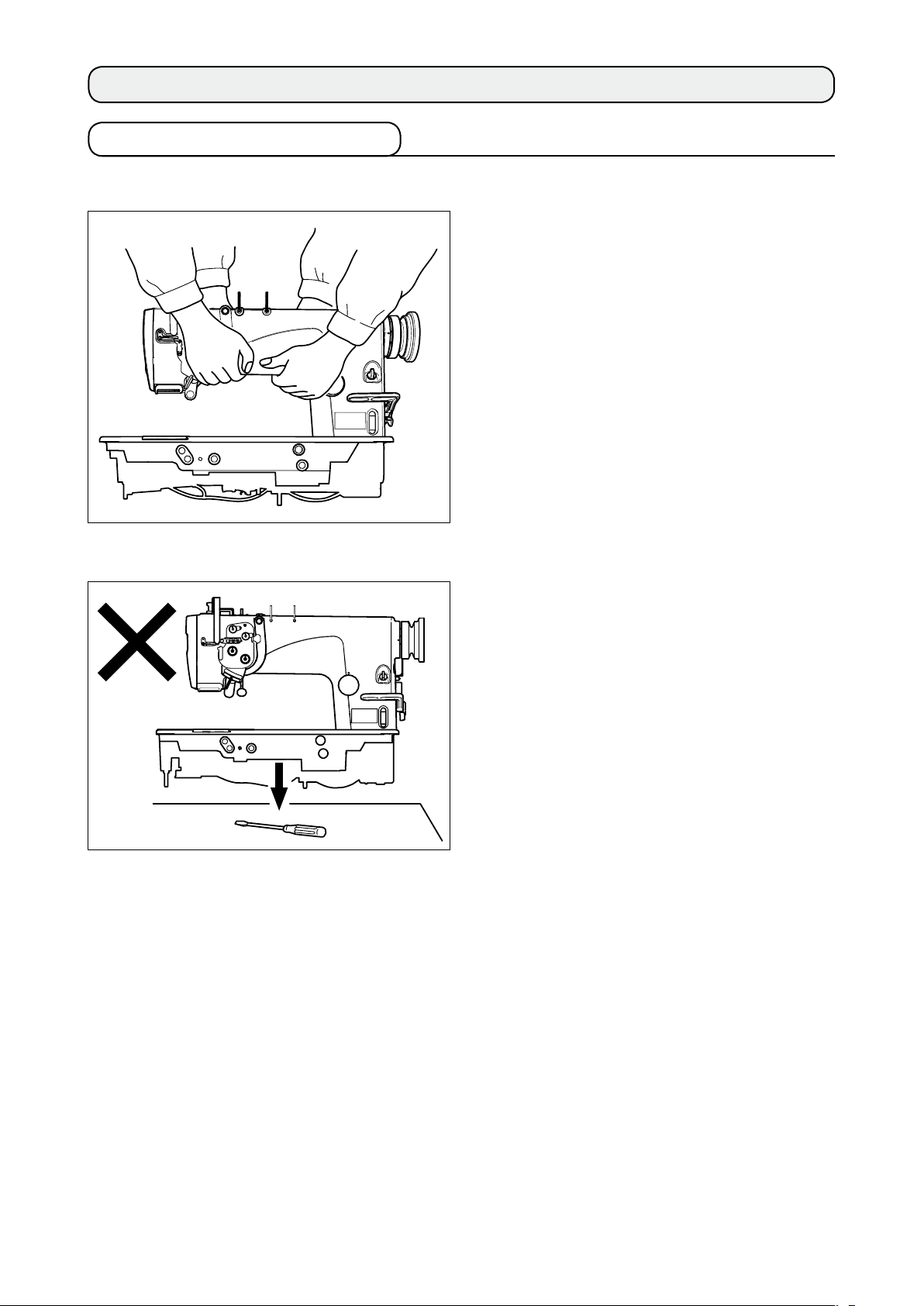

3-1. Caution at the time of set-up ................................................................................................................................ 4

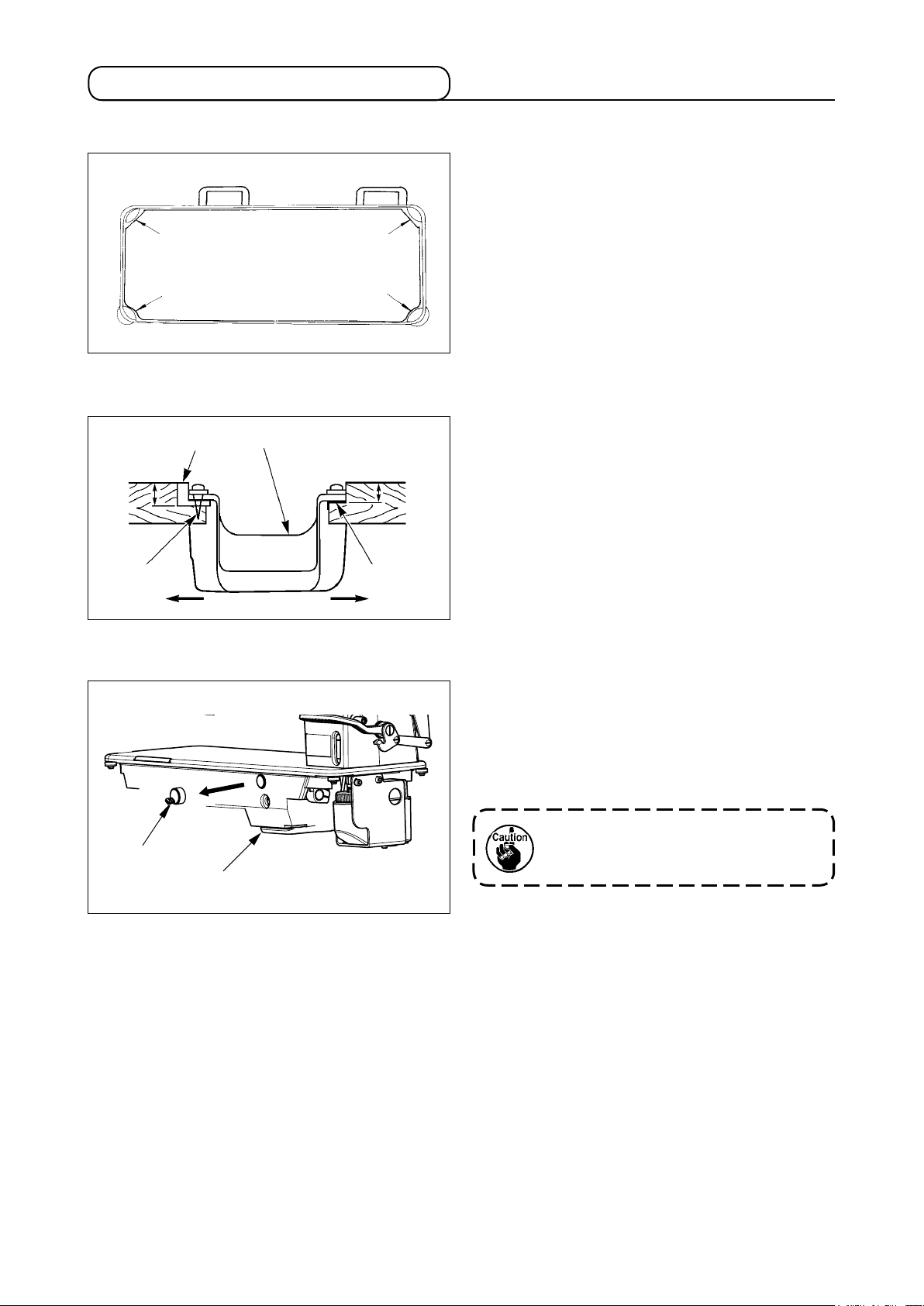

3-2. Installation of the sewing machine ...................................................................................................................... 5

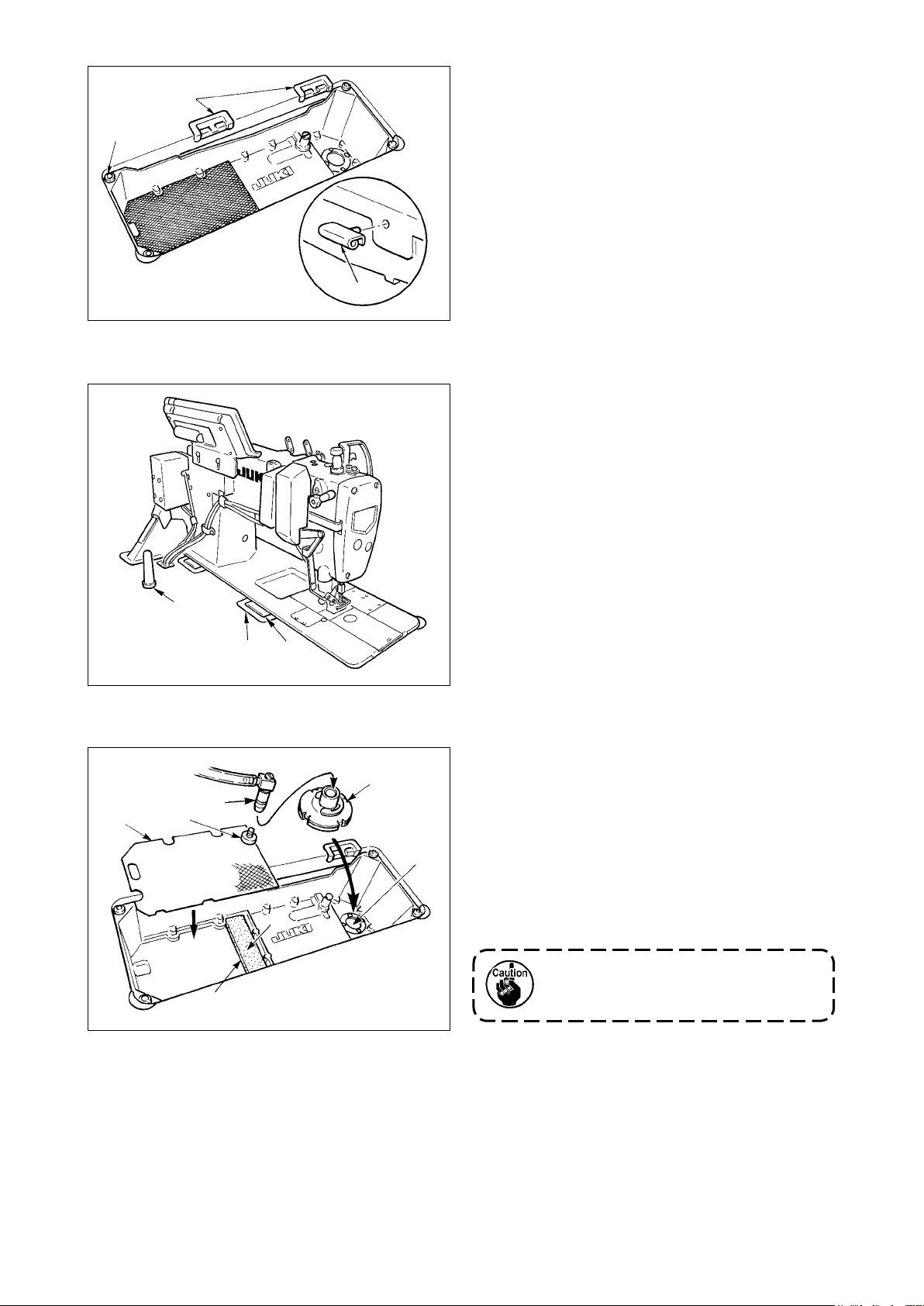

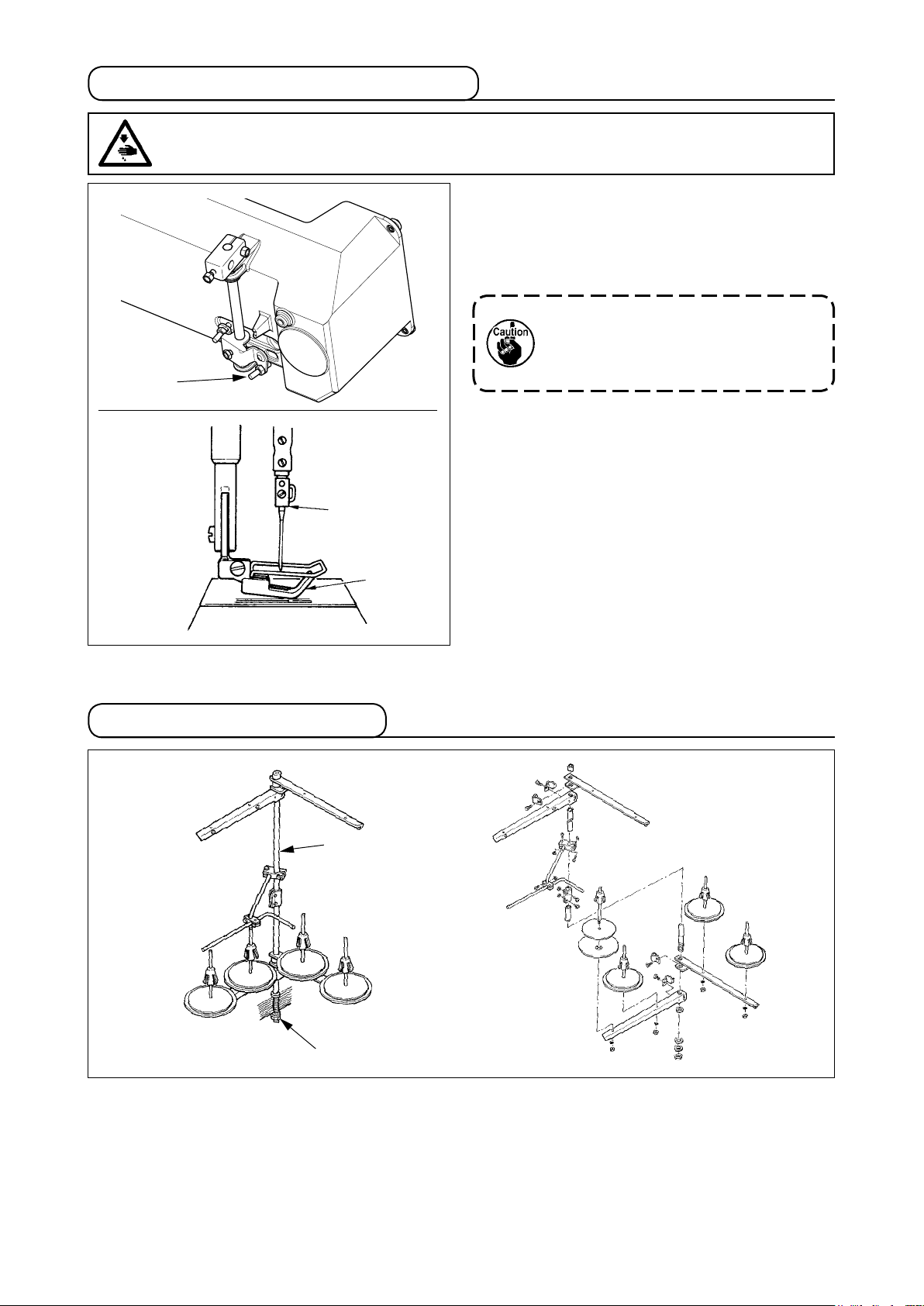

3-3. Adjusting the height of the knee lifter ................................................................................................................. 7

3-4. Installation of thread stand................................................................................................................................... 7

4. PREPARATION OF THE SEWING MACHINE ................................................................8

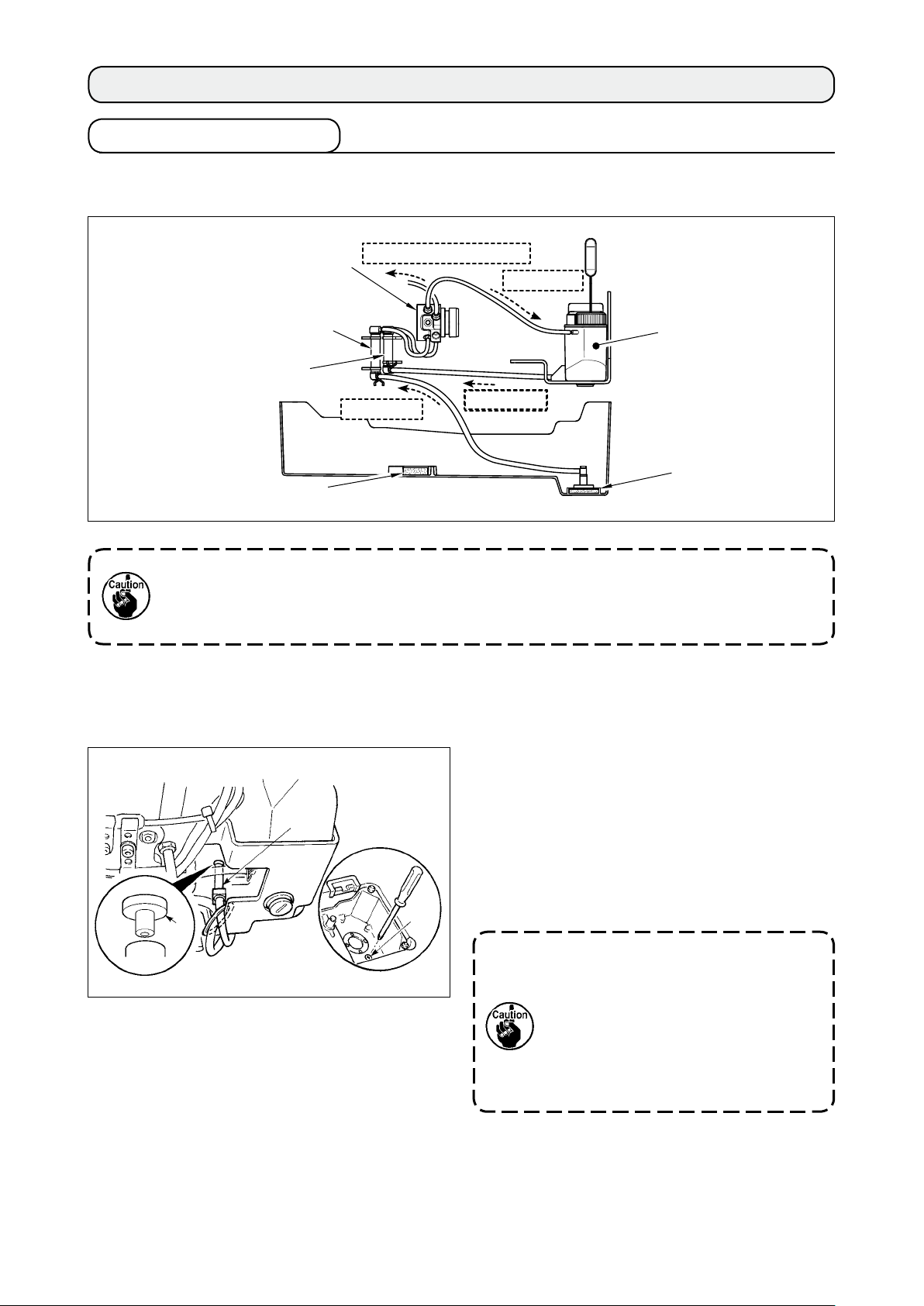

4-1. Method of lubrication ............................................................................................................................................ 8

4-2. Lubrication to the oil tank..................................................................................................................................... 9

4-3. Draining of oil from the oil tank ......................................................................................................................... 10

4-4. Adjusting the amount of oil in the hook ............................................................................................................ 10

4-5. Oil in the feed box ............................................................................................................................................... 12

4-6. Applying grease................................................................................................................................................... 13

4-7. Installing the belt cover and the bobbin thread winder ................................................................................... 16

4-8. Attaching the needles ......................................................................................................................................... 16

4-9. How to take out the bobbin case ....................................................................................................................... 17

4-10. Insertlng a bobbin in a bobbin case ................................................................................................................ 17

4-11. Threading the machine head ............................................................................................................................ 18

4-12. Thread tension................................................................................................................................................... 19

4-13. Thread take-up spring....................................................................................................................................... 20

4-14. Adjusting the stitch length ............................................................................................................................... 21

4-15. Needle-to-hook relation .................................................................................................................................... 21

4-16. Adjusting the needle stop position.................................................................................................................. 23

4-17. Pedal pressure and pedal stroke ..................................................................................................................... 24

4-18. Adjustment of the pedal.................................................................................................................................... 24

5. OPERATION OF THE SEWING MACHINE .................................................................. 25

5-1. Pedal Operation ................................................................................................................................................... 25

5-2. Hand lifter............................................................................................................................................................. 25

5-3. Adjusting the pressure of the presser foot ....................................................................................................... 26

5-4. Micro-lifter ............................................................................................................................................................ 26

5-5. Thread tension release changeover when using the knee lifter ..................................................................... 27

5-6. One-touch manual reverse feed (One-touch reverse feed type)..................................................................... 27

6. MAINTENANCE ............................................................................................................. 28

6-1. Changing procedure to bottom feed and the adjustment (for LH-3528 only)................................................ 28

6-2. Changing procedure to needle feed and the adjustment (for LH-3528 only)................................................. 29

6-3. Adjusting the hook needle guard....................................................................................................................... 30

6-4. Adjusting the inner hook guide.......................................................................................................................... 30

6-5. Adjusting the height and the inclination of the feed dog ................................................................................ 31

6-6. Replacing the gauge ........................................................................................................................................... 32

6-7. Adjusting the thread presser spring.................................................................................................................. 33

6-8. Adjusting the position of the moving knife....................................................................................................... 34

6-9. Position of the wiper ........................................................................................................................................... 35

6-10. Caution when installing the attachments........................................................................................................ 35

6-11. Replacing the bobbin thread slack preventer sprlng (For LH-3568, 3568-7, 3588, 3588-7) ........................ 36

6-12.

Stop of the needle bars and angle of corners for corners stitching (For LH-3568, 3568-7, 3588, 3588-7)....

36

7. STITCH-TO-ANGLE TABLE BY GAUGE (PITCH AND mm CONVERSION TABLE).. 37

8. GAUGE SETS................................................................................................................ 38

9. TROUBLES AND CORRECTIVE MEASURES ............................................................. 47

10. MOTOR PULLEY AND BELT ...................................................................................... 48