6.

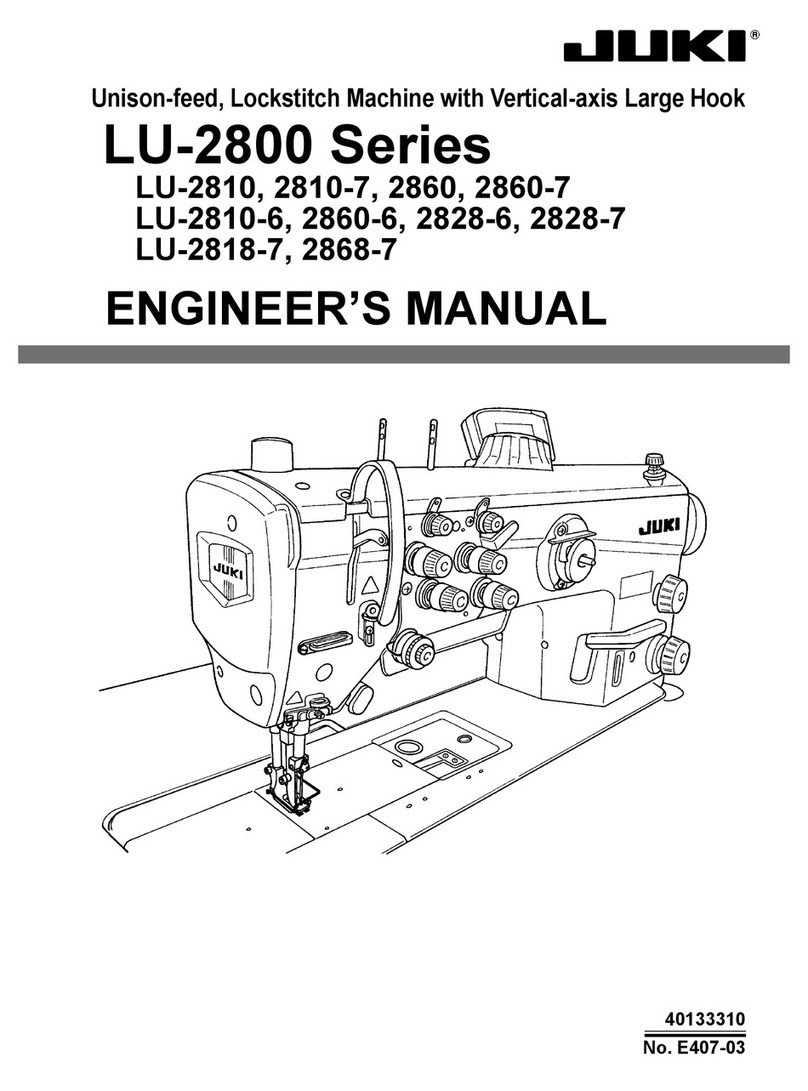

ADJUSTING THE VERTICAL STROKE OF THE TOP FEED

DOG

I

--

-

-

--

-

-

7

To change the vertical stroke of the top feed dog, move the side

cover back, loosen setscrew

@

of topfeed adjustor

@

attached

to knife driving arm shaft

0

.

and move adjustor

@

up to

increase the vertical stroke or down to decrease it. Be sure to

securely tighten setscrews

@

.

Adjust the position of felt

@

so that it is in slight contact with

link (A)

@

.

At this time, be careful not to allow felt

0

to

come into contact with other adjacent parts.

*

For MOJ-2500N models

Adjust the vertical stroke of the top feed dog within the range

in

which red marker line

@

engraved on knife drivingarm shaft

0

stays between two red marker lines

@

on top feed adjustor

@

.

When red marker line

@

is set to lower red marker line

@

,

the

maximum vertical stroke of

6.5

mm is provided.

When red marker Line

@

is set to upper red marker line

@

,

the

minimum vertical stroke of

4.5

mm is given.

(Caution) Never set red marker line

0

beyond the lower red

marker line engraved on the top feed adjust (Be sure

that the set vertical stroke does not exceed

6.5

mm).

*

For MOK-25001Umodels

Adjust the vertical stroke of the top feed dog within the range

in

which red marker line

0

engraved on knife drivingarmshaft

0

stays between two white marker lines

@

engraved on top feed

adjustor

@

.

When red marker line

0

is set to lower white marker line

@

,

the maximum vertical stroke of

6.5

mm is given, and when it is

set to upper white marker line

@

,

the minimum vertical stroke

of

5

mm is given.

1

7.

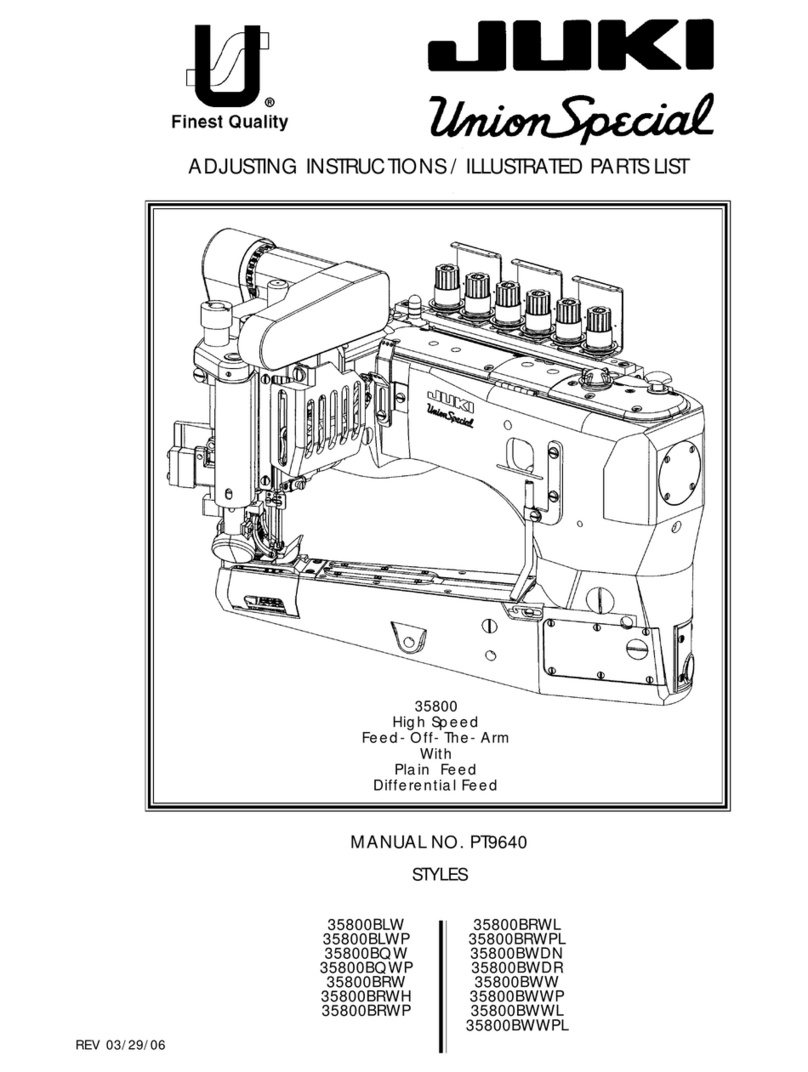

ADJUSTING THE TOP DIFFERENTIAL FEED RATIO

I

1

/e/

Top feed dog

Presser

foot

The top feed amount can be altered without changing the bottom

feed amount, by top-feed adjusting lever

.

1.

Turn lock nut

@

in the direction of arrow. Move top-feed

adjusting lever

0

to work the top differential feed mecha-

nism.

2.

When the lever is set to

"S",

the top feed amount will be

reduced. The top feed amount will increase as the adjusting

lever is set to a larger number on the scale.

3.

After adjustment, turn lock nut

@

in the opposite direction

from the arrow to lock top-feed adjusting lever

0

.

*

For MOJ-2500Nmodels

The Standard MOJ-2500N machine head is usuallv factorv-

adjusted to a

1

:2.8 (MOJ-2514N),

1:

1.8

(MOJ-2516~)(main

feed dog: top feed dog) top differential feed ratio. If other top

differential

feed

ratios are necessary, adjust as follows:

1.

Cut the front end of the top feed dog by

3

mm at a maximum

so a clearance of

1

mm or more is produced between the front

end of the top feed dog and the front end

of

the slot in the

presser foot when the top feed dog is in the most advanced

position.

2.

Then, loosen

@

of stopper

0

,and move the stopper down

to adjust clearance

0

as tabulated below:

Clearance

0

Max. top differential feed ratios

MOJ-2514N MOJ-2516N

1

:2.1 1:1.3

1

:2.8

1

:

1.8

Max. 1

:4.8

3.

If

a

top differential feed ratio other than those listed above is

required, perform the following adjustment:

Remove the cover from the adjusting hole in the rear of the

machine frame, loosen locknut

@

to release main feed arm

pin

Q

,

and move the main feed arm pin down. When the pin

is set at the lowest point, the maximum top differential feed

ratio of

1

:6

will be provided. After adjustment, securely

tighten nut

0

.