ABCBC

D

02

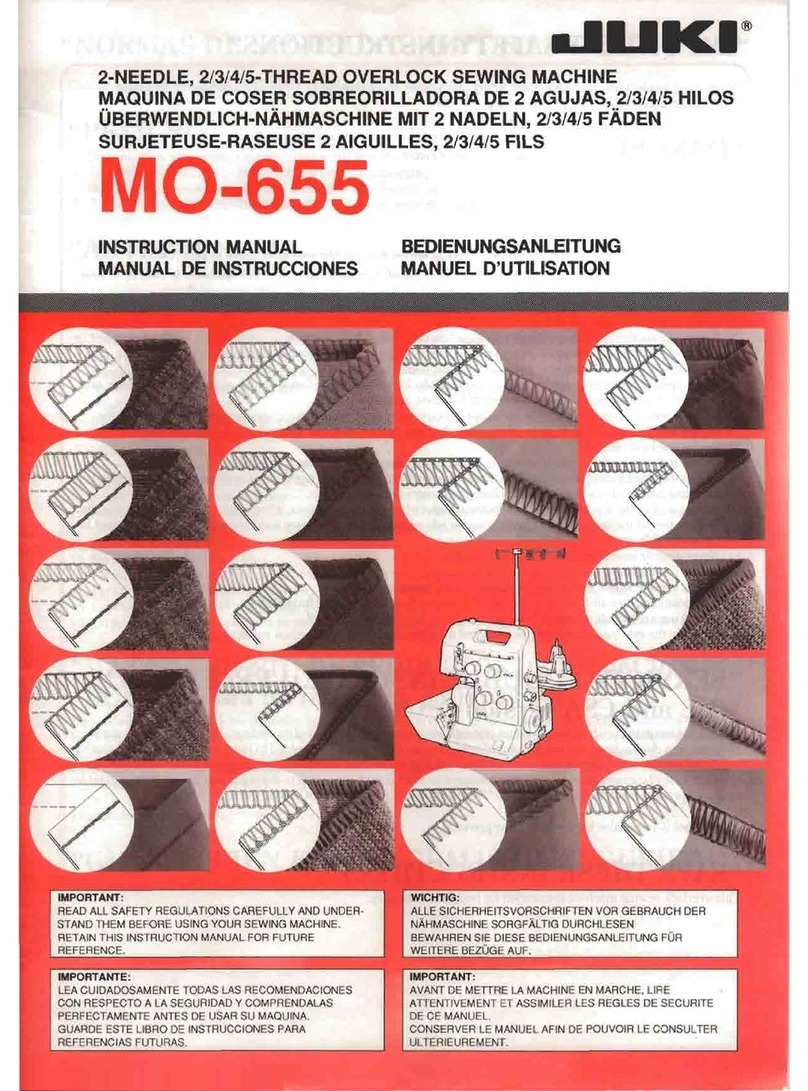

Soft-texture seam quality.

■Hook-driving shaft offset

mechanism

You can quickly create an original stitching pattern on the operation

panel and then try to sew it on a trial basis.

A wider variation in design enables the machine to respond to wider

applications, such as foundations, ladies' wear and men's wear.

The machine requires neither a programming device nor ROM writer.

Abundant variation in stitching.

●Custom patterns

• Original sewing patterns can be quickly

created and stored in memory.

• Max. 20 patterns, Max. 500 stitches /pattern.

●Mirroring of scallop stitches

• The machine produces beautifully finished

scallop stitches on front part of a girdle. etc.

• For the scallop stitch, the starting position for

sewing can be selected between the top and

bottom of a scallop.

●Setting the number of stitches

for a blind stitching pattern

• The user can set the

number of stitches

for a pattern.

(3 to 250 stitches.)

●Setting of the left and right stopping positions

• The left and right

stopping positions of the

needle can be controlled.

•

These settings are

effective when

performing corner

stitching for label

attachment or decorative

stitching on the fronts of

●Continuous stitching

• Custom patterns can be

joined.

• Max. 10 patterns,

Max. 20 steps / pattern, and

Max. 500 stitches / step

●Program stitching

• As many as 20 different constant-dimension

stitch patterns can be programmed.

The maximum number of stitches that can be

set for one step is 500.

●Cycle sewing

• The machine is able to sew different patterns

while changing them in sequence.

• Max. 10 patterns, Max. 20 steps / pattern, and

Max. 500 stitches / step

●Multi-layer stitching

• It is used for reinforcing

fastening stitches or bartacks.

●Condense custom patterns ✽Automatic reverse feed function is required.

• The user can specify original condense custom patterns.

This type of pattern is very effective at producing improved

bartacks and keeping seams from being left undone.

• Start and end of sewing: A maximum of

20 different patterns, with a max. of 64

steps/pattern.

• The machine, with its automatic thread

trimmer, is able to leave shorter thread

after thread trimming as compared with

the conventional machines.

(Example)

(Example)

Bartacks

(Example)

Stop the sewing machine

and press mirror

inversion switch.

Mirror inversion

operation LED

lights up.

Afterwards

inversion

operation

The position at which the

blade point of the hook

tacks the thread is almost

uniform.

Scallop: 1 pattern

Stitching direction

Mirror inversion switch

(Example)

(Example)

Blind stitch: 1

pattern 6 stitches

10 stitches

(Example)

(Example) Start point Step 1

Step 2

Step 3

Step 4

Pattern combining

patterns A, C, B and C

A

C

B

C

Custom patterns can be created

on the operation panel with ease.

Keeping seams from

being left undone

Shorter length of

thread remaining

after thread trimming

Left stopping position

of the needle

Right stopping position

of the needle

Stitching

direction

Stitching

direction

Left Right

✱

✱

✱

✱

✱

The thread tension mechanism, bobbin

case and feed timing have been improved

to produce soft-textured seams.

The machine is equipped with a hook-

driving shaft-offset mechanism which

places the hook-rotating shaft off-center

from the center of zigzag stroke of the

needle. This mechanism allows the blade

point of the hook to catch the needle

thread every time regardless of the needle

throwing direction. As a result, the

machine is immune to sewing troubles

such as stitch skipping and thread

breakage, annoyances likely to occur with

the conventional machine, especially

when the needle throws to the right.

For the minute-quantity lubrication type hook,

the inner hook is finished with titanium to keep it

from becoming hot. The machine requires only a

very small quantity of oil. This prevents oil stains

on the material and the improves durability of the

hook. In addition, the hook configuration is

carefully designed to avoid needle breakage.

!