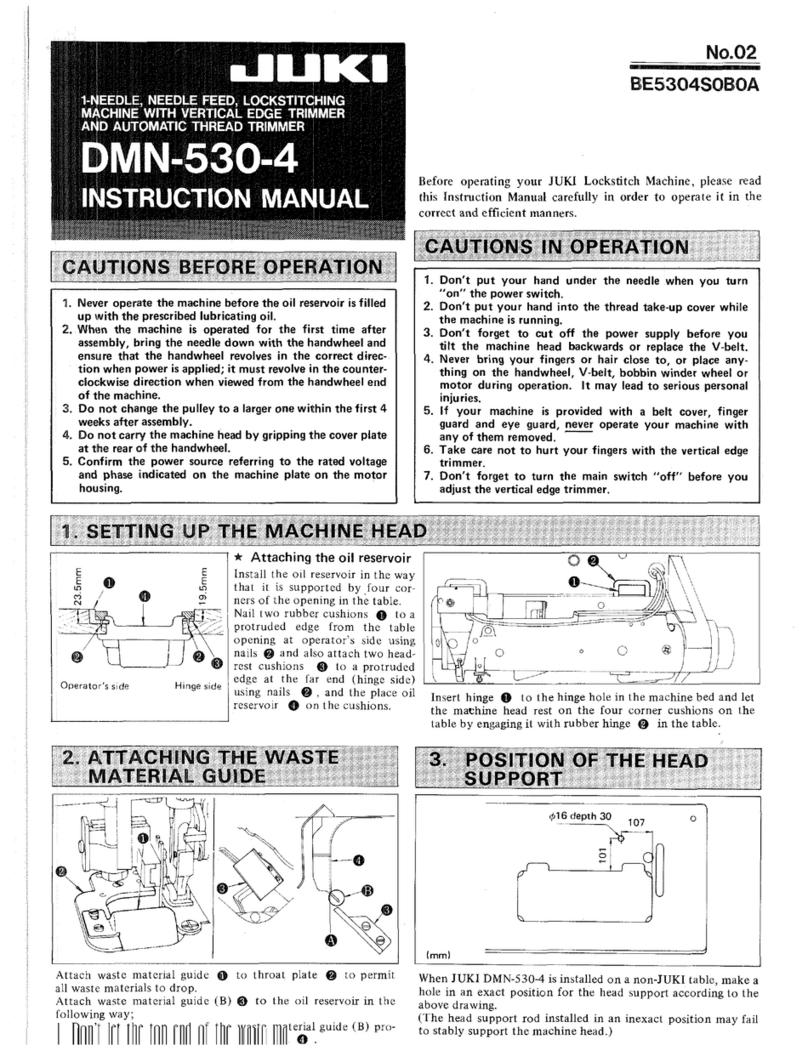

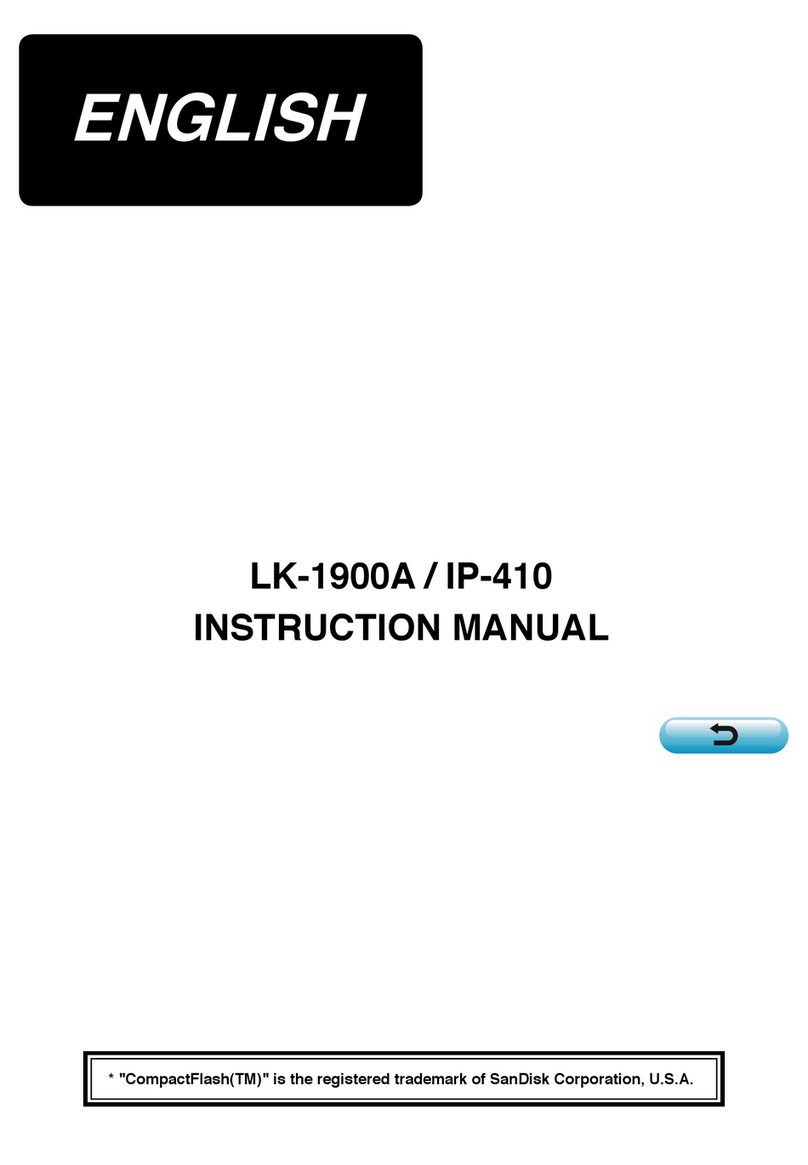

qTopstitching

wBlind edge stitch

at the far side of

the front facing

wBlind edge stitch

on the front body

qTopstitching on the

front pocket mouths

q

w

e

qTopstitching on the

left top-center plait

wSide topstitching

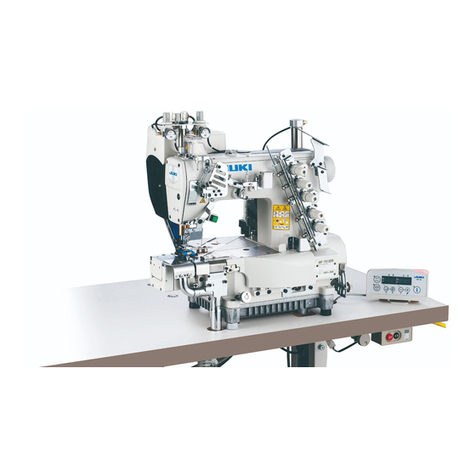

MP-200NL

This pinpoint stitch machine is used for topstitching on

the front facing of men's wear, as well as front flies, pocket

mouths and trouser sides, as a cost-effective topstitching

machine that offers increased productivity. In addition,

its applicable working range has been widened to include

various materials and other processes, such as the

topstitching of collars for shirts, blouses and knits.

The MP-200N has the newly added capability of sewing

wider stitches and using thicker thread. It can be used

for a wider range of applications requiring narrower to

wider stitch widths.

Excellent seam quality

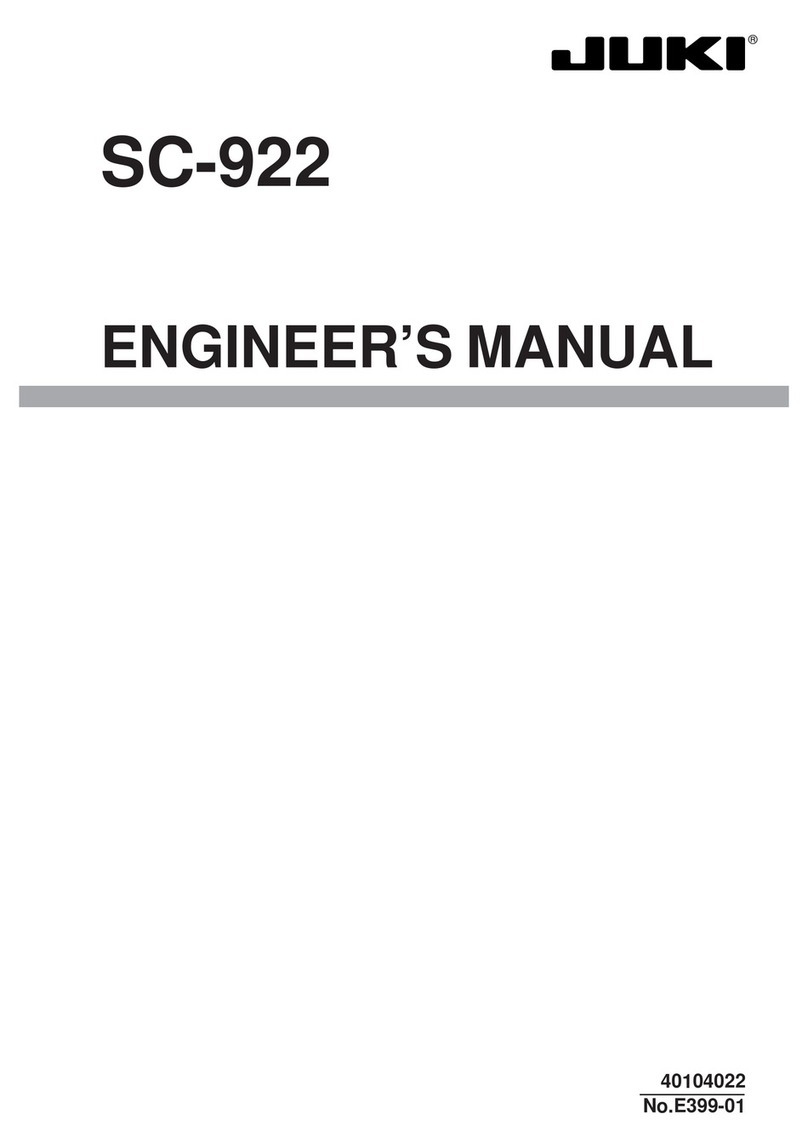

REPLACEABLE PARTS OF GAUGES

OPTIONS

Uses of pinpoint stitching

Needle clamp spacer

Needle clamp

Needle holder

Needle Hook-needle

Feed pitch

Right sideReverse side Right sideReverse side

Wider range of applicable needle

gauges and yarn counts

Positioning of needles

with increased accuracy

Pinpoint stitching MP-200NS

(Needle gauge 1.6mm)

MP-200NL

(Needle gauge 5.0mm)

Replaceable parts

Part No. Description

Quantity

231-24100 Needle clamp S 1

231-24308 Needle clamp spacer (1.2mm) 1

231-24407 Needle clamp spacer (1.6mm) 1

231-24506 Needle clamp spacer (2.0mm) 1

231-24605 Needle clamp spacer (2.5mm) 1

231-24803 Needle clamp (3mm) 1

231-24902 Needle clamp (4mm) 1

231-25008 Needle clamp (5mm) 1

231-24209 Needle holder S 1

SS-8090540-SP Screw 1

231-25107 Needle holder (3mm) 1

231-25206 Needle holder (4mm) 1

231-25305 Needle holder (5mm) 1

SS-7090530-SP Needle clamp screw 1

231-25404 Needle clamp hook 1

SS-5060310-SP Screw 1

231-22658 Presser S (asm.) 1

231-22757 Presser L (asm.) 1

231-23003 Throat plate (1.4×3.0) 1

231-23102 Throat plate (1.6×4.2) 1

231-23201 Throat plate (1.6×4.7) 1

231-23300 Throat plate (2.2×5.6) 1

231-23409 Throat plate (2.2×6.6) 1

231-23508 Throat plate (2.2×7.6) 1

231-25750 Spreader fitting base (asm.) 1

231-38209 Spreader (JC1023) 1

SM-4020301-SC Screw 1

231-25800 Spreader (3mm) 1

231-25909 Spreader (4mm) 1

231-26006 Spreader (5mm) 1

231-36104 Looper clank 1

231-21502 Looper clank B 1

SM-8060612-TP Screw 2

Remarks

1.2 1.6 2.0 2.5 3.0 4.0 5.0

mm mm mm mm mm mm mm

▼◎▼▼ S type, common

○S type, exclusive to 1.2mm

◎S type, exclusive to 1.6mm

●S type, exclusive to 2.0mm

○S type, exclusive to 2.5mm

○L type, exclusive to 3.0mm

○L type, exclusive to 4.0mm

◎L type, exclusive to 5.0mm

▼◎▼▼ S type, common

▼◎▼▼ S type, common

○L type, exclusive to 3.0mm

○L type, exclusive to 4.0mm

◎L type, exclusive to 5.0mm

○○◎L type, common

○○◎L type, common

○○◎L type, common

▼◎▼▼ S type, common

▼▼◎L type, common

○S type, exclusive to 1.2mm

◎▼ S type, common to 1.6~2.0mm

○S type, exclusive to 2.5mm

○L type, exclusive to 3.0mm

○L type, exclusive to 4.0mm

◎L type, exclusive to 5.0mm

▼◎▼▼○ S type, common/L type 3.0mm

▼◎▼▼ S type, common

▼◎▼▼○ S type, common/L type 3.0mm

○L type, exclusive to 3.0mm

○L type, exclusive to 4.0mm

◎L type, exclusive to 5.0mm

▼◎▼▼ S type, common

▼▼◎L type, common

▼◎▼▼▼▼◎Common to types and sizes

Part number of gauge set

Part No. Description

231-24357 Needle gauge size 1.2mm S set

Not prepared Standard specifications

Not prepared Needle clamp spacer

(accessory parts)

231-24654 Needle gauge size 2.5mm S set

231-24861 Needle gauge size 3.0mm L set

231-24960 Needle gauge size 4.0mm L set

Not prepared Standard specifications

◎Standard parts for S and L types (gauge set is not prepared)

●Accessory parts for S type (gauge set is not prepared)

○Parts to be purchased (included in a gauge set) at the time of changing sizes

▼Parts not to be purchased (not included in a gauge set) at the time of changing

sizes since they are included in S or L type machine as accessories.

✽

In order to be applicable to a wider range of materials, various types of needle bar cranks with different thread take-up timings have been prepared.

●Needle bar crank

Part No. Thread take-up timing Type Remarks

231-21106 Standard

231-21205 Standard −10°

231-21304 Standard +10°

231-21403 Stepless setting

Hook-needle

✽

The [length of thread that appears on the right side of the material]

is shorter than the needle gauge by approximately 0.5mm

(depending on the material and sewing conditions).

Model name Needle Gauge ✽Applicable yarn

gauge count

1.2mm Option

MP-200NS 1.6mm Provided as standard

(Needle gauge To be replaced with the needle

1.6mm) 2.0mm clamp spacer supplied

with the machine

2.5mm Option

MP-200NL 3.0mm Option

(Needle gauge 4.0mm Option

5.0mm) 5.0mm Provided as standard

✽Refer to "Replaceable parts of gauges" for a correspondence between gauges and

needle gauges.

[Length of thread that

appears on the right

side of the material]

Reverse side

(Right side of the

material during sewing)

Right side

(Reverse side of the

material during sewing)

●Men's coats and jackets

qTopstitching on the front facing

wBlind edge stitch at the far side of the

front facing, and blind edge stitch on

the front body (for preventing uneven

material feed)

●Trousers

qTopstitching on the front pocket

mouths and left top-center plait

wSide topstitching

––

Thread is applied with a higher tension as

compared with the standard needle bar crank

Thread is applied with a lower tension as

compared with the standard needle bar crank

––

Standard timing (provided as standard)

Type timing, of which is earlier than that of the

standard needle bar crank by 10°

Type timing, of which is later than that of the

standard needle bar crank by 10°

A Needle bar crank which has a flat shaft to permit

the stepless setting of thread take-up timing.

Note, however, that the needle bar stroke changes

according to the thread take-up timing.

Needle gauges support, using replacement parts, stitch widths from as

narrow as 1.2mm to as wide as 5.0mm.

The applicable range of yarn counts has been widened from #60 to #8

(B33, Nm = 120/3) for both Tetron and spun thread. This allows the

machine to be used for topstitching a wider range of items.

●

●

In addition to balloon-stitching (to produce seams with a

hand-stitched touch), smooth sewing of chain-off

stitches, and having other outstanding seam quality

features of the highly regarded Columbia 100, the

MP-200N achieves more improved sewing capabilities

and a wider adjustment range.

The machine comes with a box type feed that permits a

split adjustment in both horizontal and vertical directions,

thereby responding to the sewing of various types of

materials. Additionally, the inclination of the feed dog is

also adjustable in accordance to the material.

●

●

Gauges that are determined by the combination of

needles and spacers are of the Columbia type.

This improves the accuracy of the installation of needle

positions, which determines the seam quality.

●

●Miscellaneous

qTopstitching on collars of coats,

ladies' cut and sewn garments,

knit shirts, etc.

wTopstitching on the top-

center plaits of coats,

ladies' wear, shirts,

etc.

eVarious kinds of

topstitching on

coats, ladies'

wear, shirts, etc.

Tetron, Spun

#60~#30,

B33~B46,

Nm=120/3~60/3

Tetron, Spun

#30~#8,

B46~B92,

Nm=60/3~30/3

S type

(1.6mm, standard)

L type

(5.0mm, standard)