–1 –

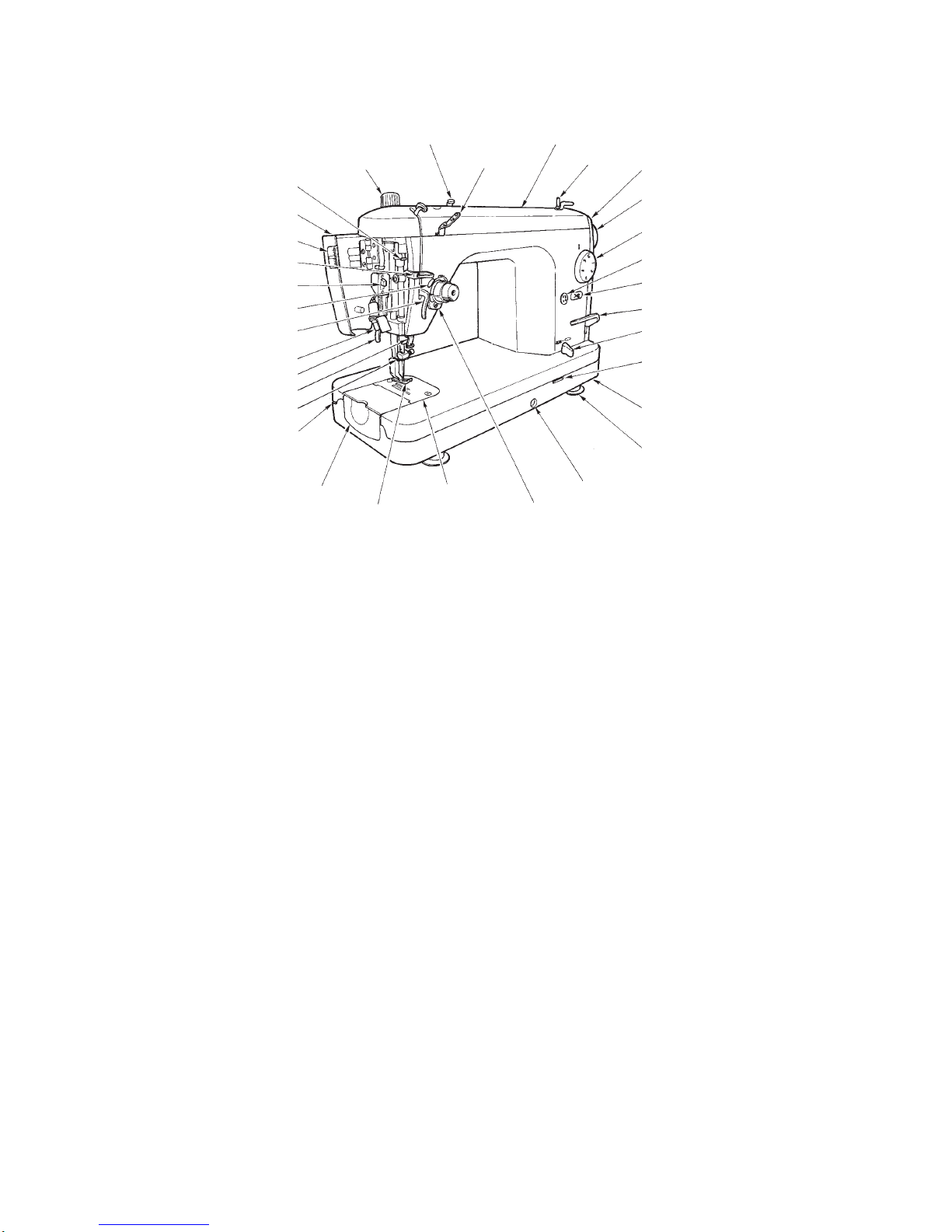

[1] Specifications of TL-98E

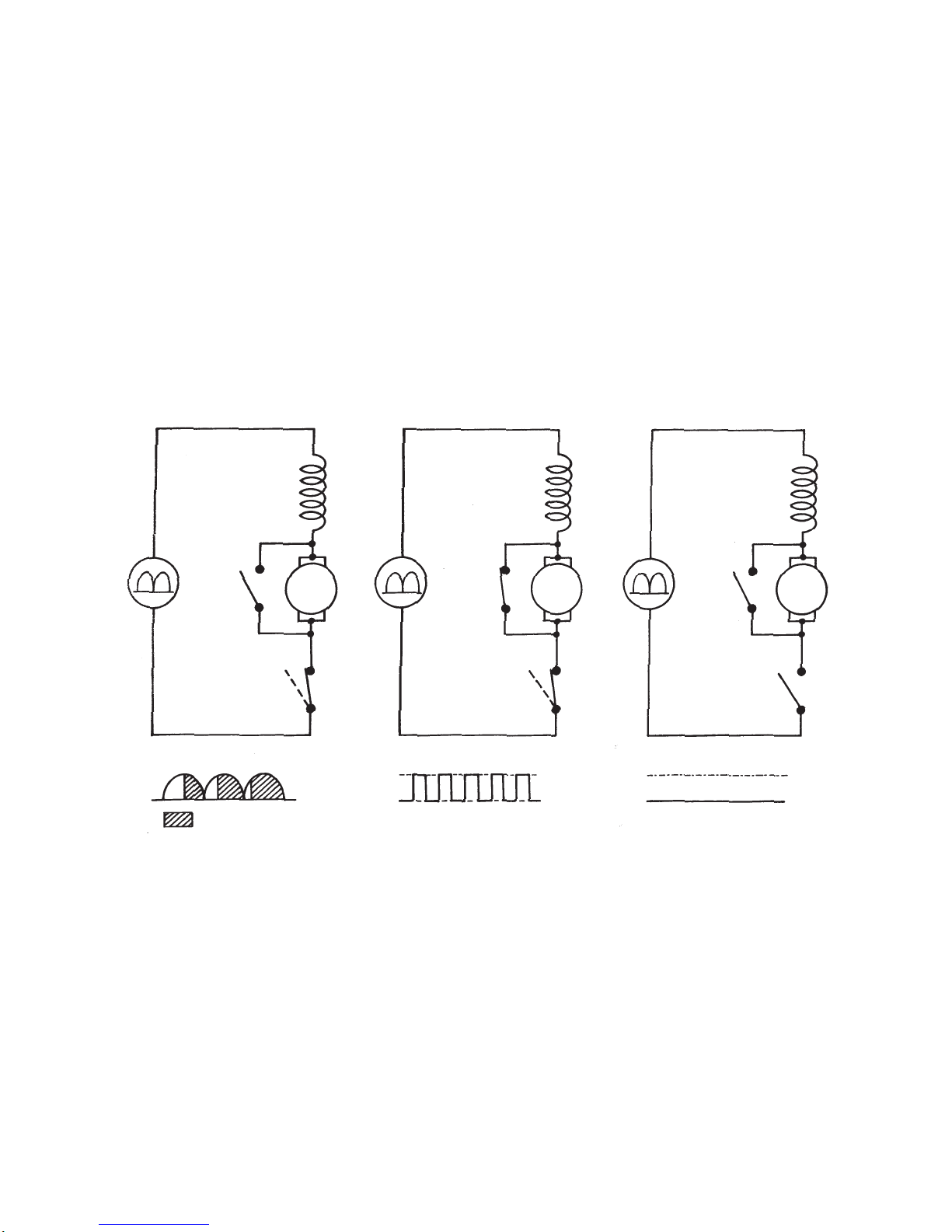

(1)Speed control device

Foot controller method : 80 to 1,500 rpm

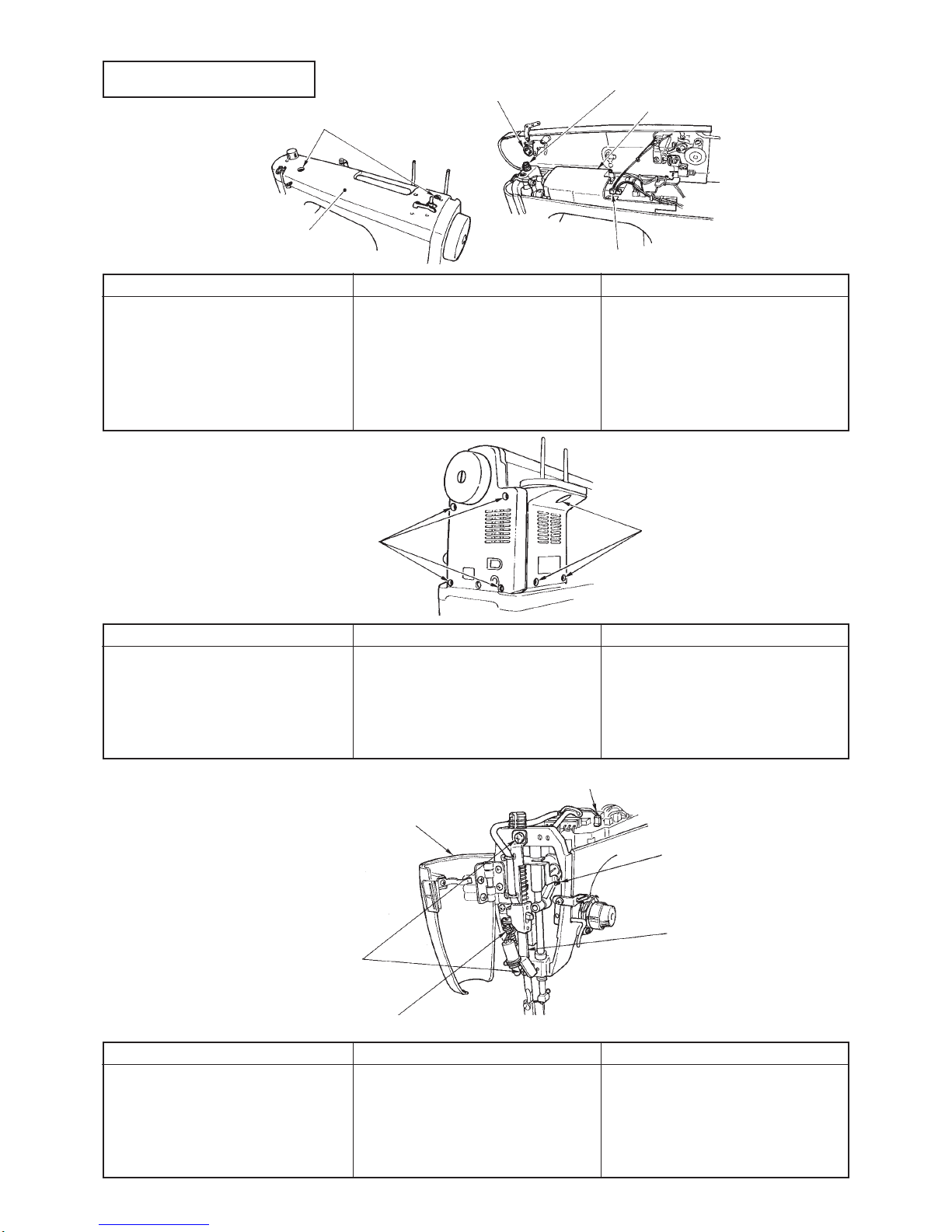

(2)Table and stand components

Main unit : Portable type main unit with soft case (Case is folded in two and packed with main unit.)

One-touch type auxiliary table knee lifter is provided as standard. (Packed together)

Handle : Pull-up/down from machine main unit type

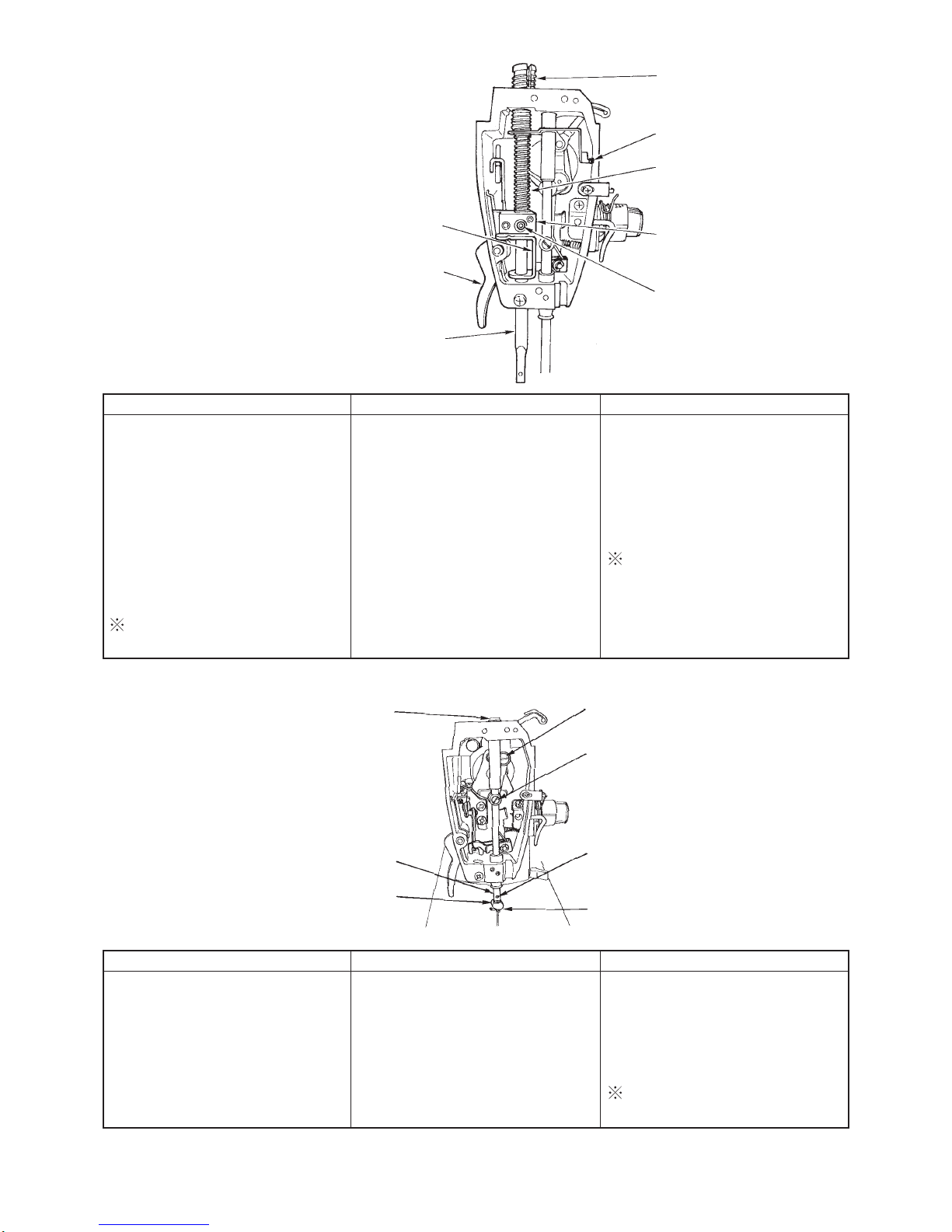

(3)General mechanism

1. Thread take-up : Slit type link thread take-up for one-touch threading

2. Hook : DB type horizontal full-rotary hook

3. Pressing pressure adjustment : Stepless adjusting screw with pressing pressure indicator method

4. Lighting device : Built in face cover Switch : Slide type

Lamp ...... Halogen lamp

5. Needle thread post : Thread guide of thread post is of tilting type and capable of one-touch

threading

6. Bobbin thread winder : One-touch action : Starting method by controller Automatic stop

when bobbin thread winding completed

7. Power switch : ON/OFF 2-step method

8. Lift of presser foot : By lever : 7 mm Max. by lever : 10 mm By knee lifetr : 12 mm

9. Thread tension : Disk pressure adjusting type with simplified disk pressure scale

10. Drop feed : 2-step changeover by knob method (Feed dog : UP : DOWN)

(4)Feed mechanism

1. Feed amount adjustment : Dial method ......Stepless 0 to 6 mm

2. Reverse feed stitch : Lever method ...... Feed amount conforms to that of normal feed stitch.

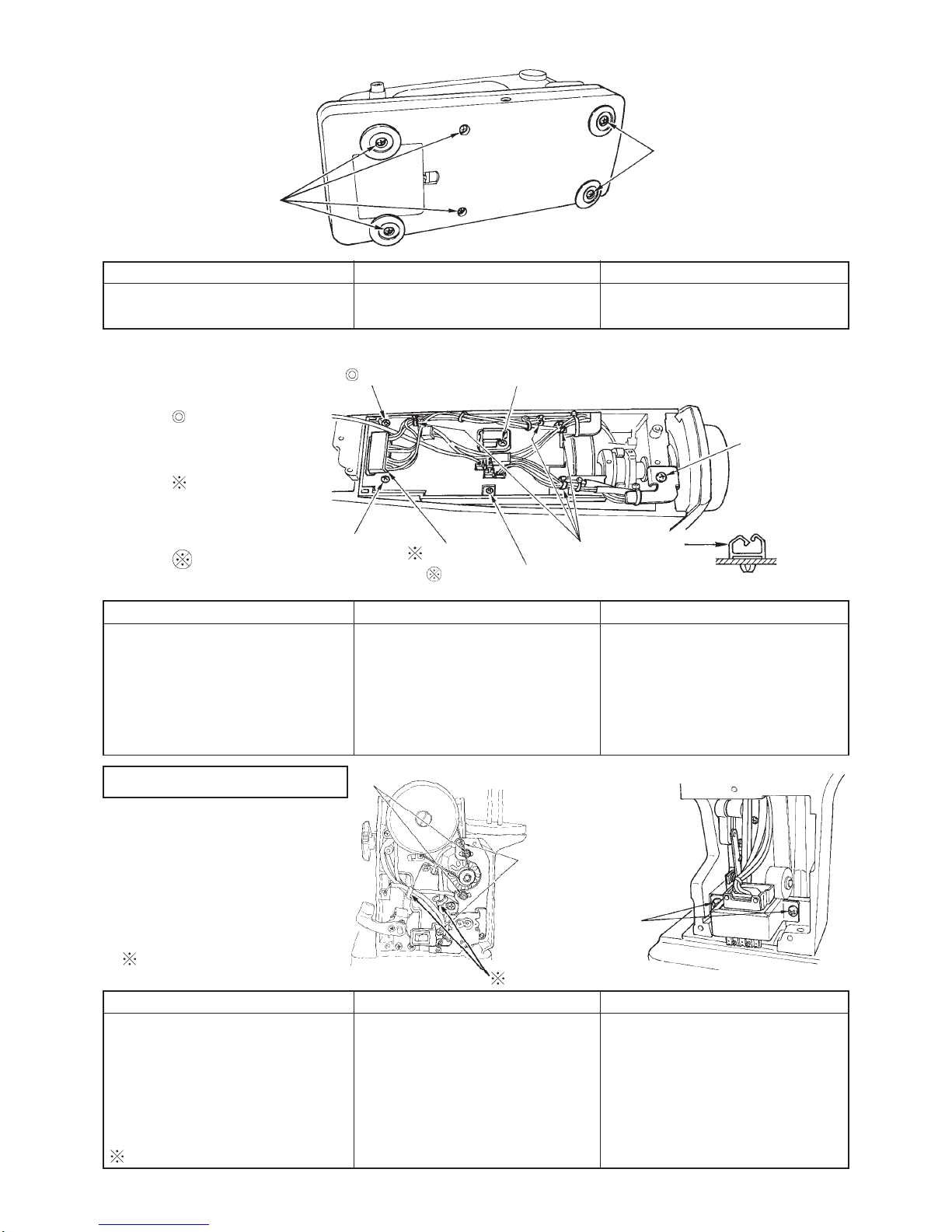

(5)Special mechanism

1. Automatic thread trimming : Thread trimming switch is used in common for pushbutton type and

for external foot pedal switch type.

2. Needle bar stop position : Electric brake stop method

Stop by controller : Down stop

Stop by automatic thread trimming : Up stop

Stop by bobbin winder : Up stop

3. Needle up/down switch : Switch is of pushbutton type and up/down stop by half rotation of

main shaft

4. Prevention of reverse setting of needle : Needle is attachable to normal direction only.

5. Motor protection

Overcurrent : When motor is locked for approximately one second due to sudden overload, motor power

is automatically turned OFF and returns to the ON state immediately.

Overheat : When motor temperature has abnormally risen, motor power is turned OFF (thermal cut)

and returns to the ON state when temperature has fallen.

(6)Dimensions and weight

Main unit : 452W x 219L x 319H (mm)

Weight : 11.3kg

(7)Power consumption

Whole sewing machine : 120V 1.4A/60Hz

Lamp : 12V 3W (Halogen lamp)