Safety instructions ········································1-3

Contents························································4

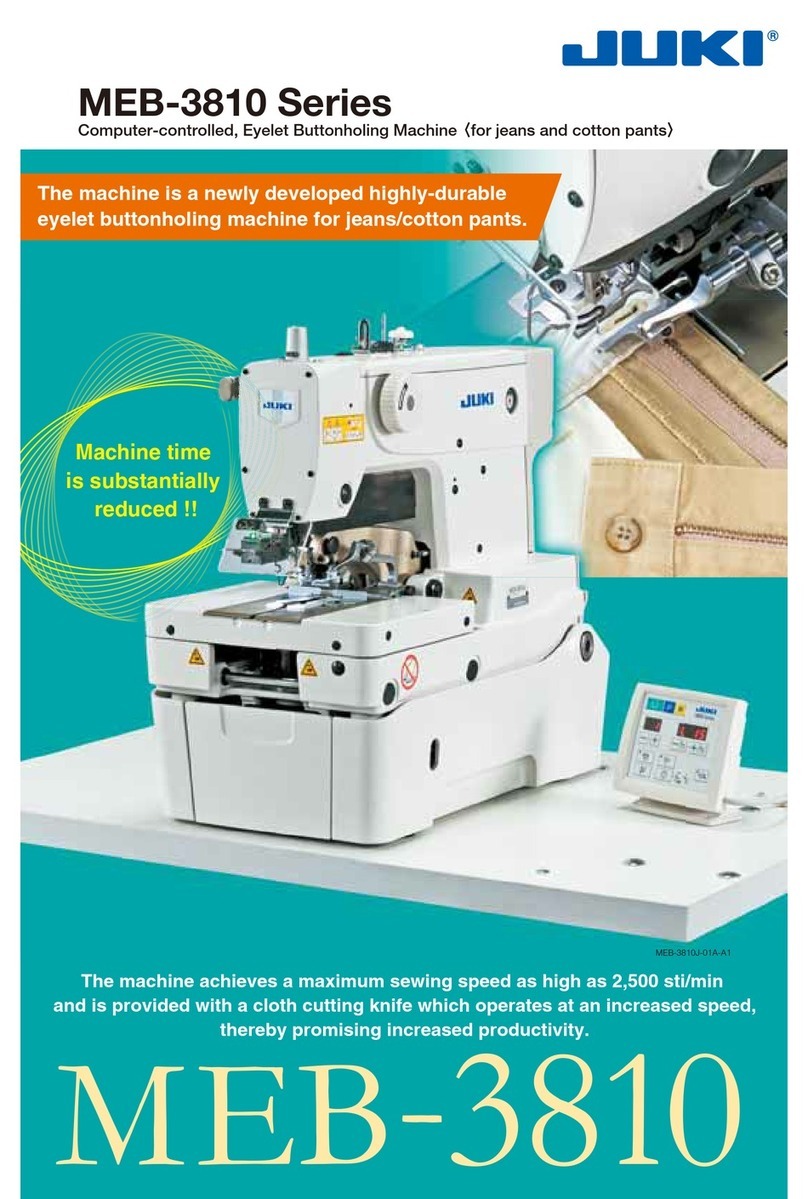

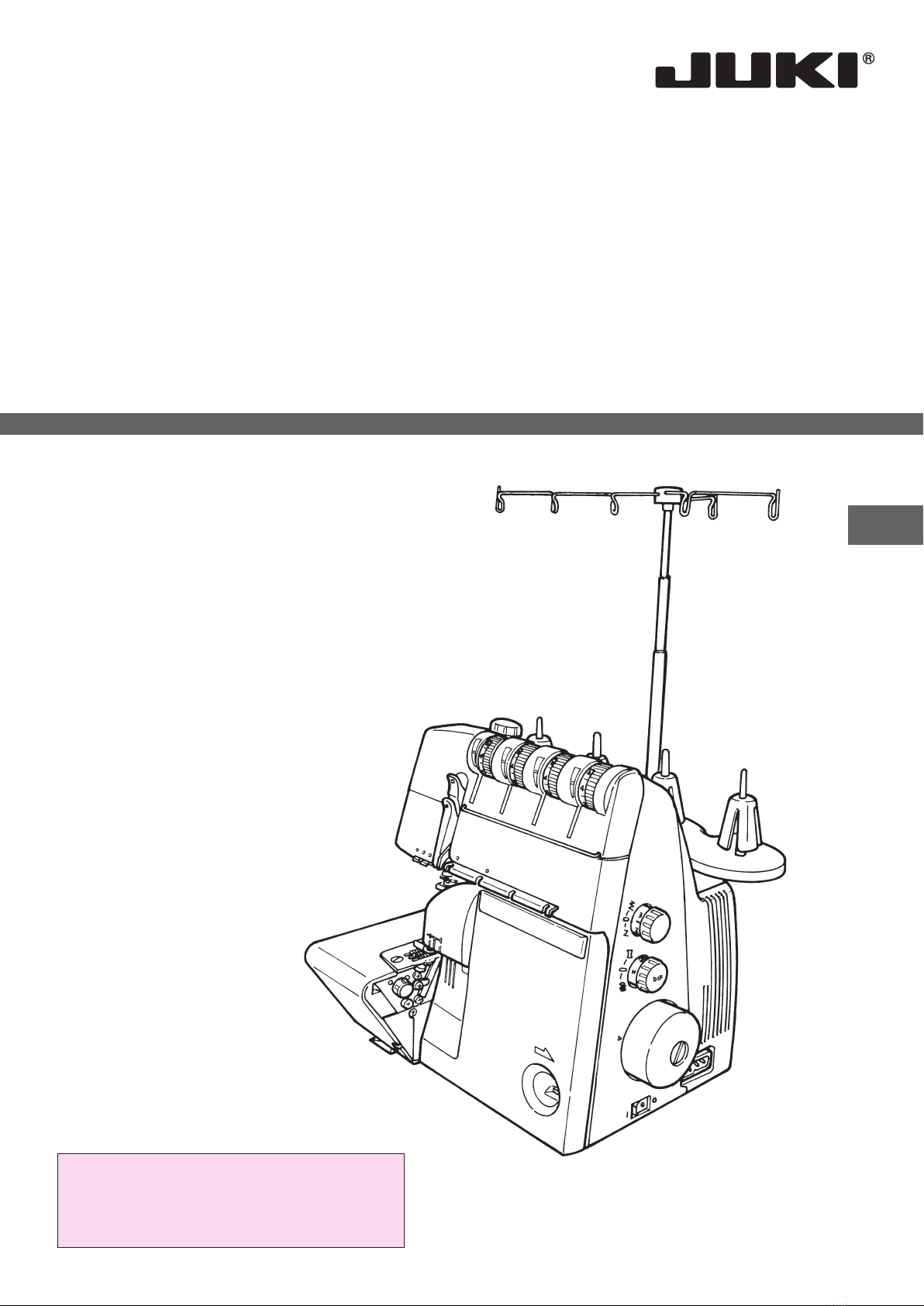

Details of the machine···································5-6

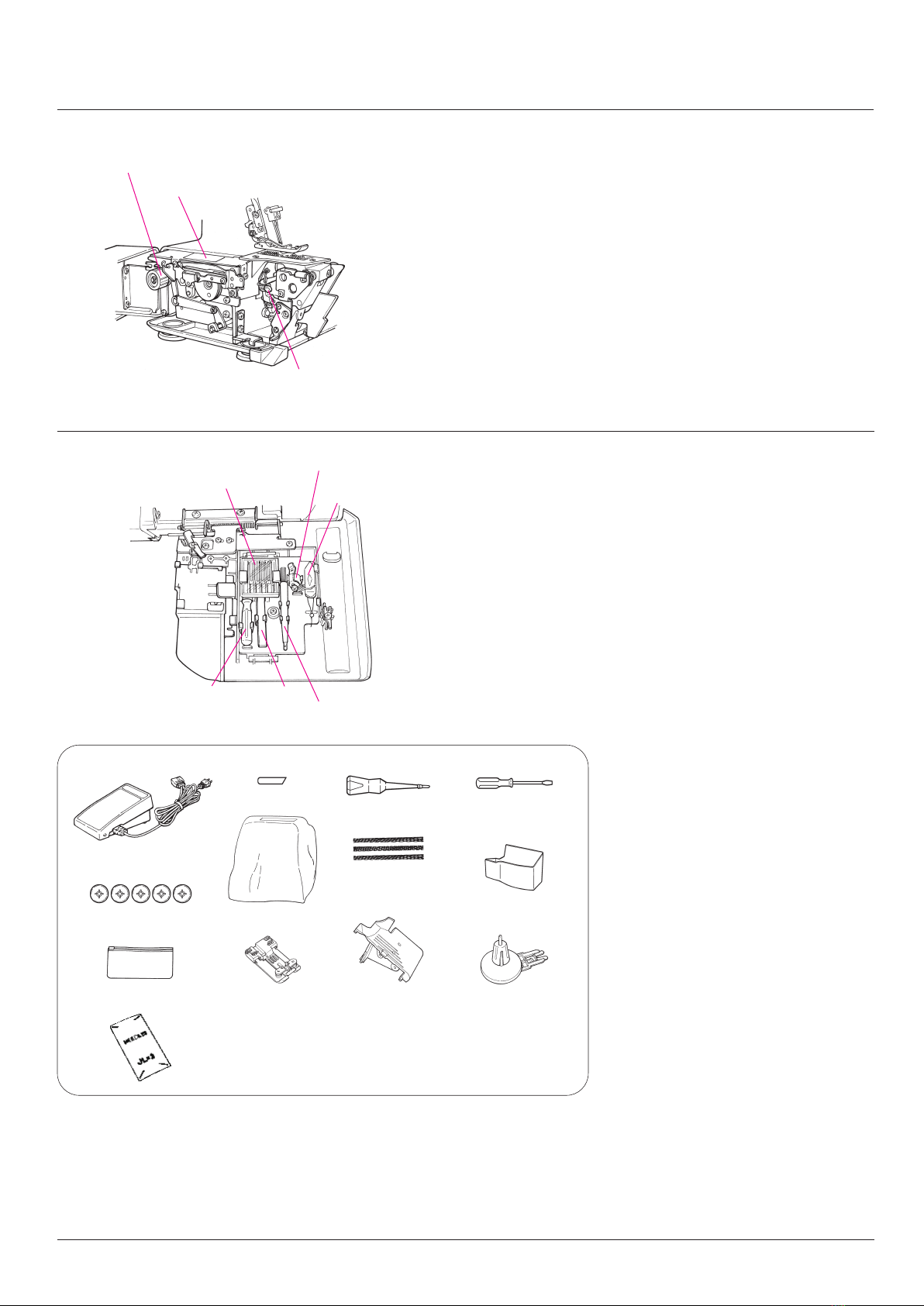

• Accessories·················································6

Preparing the machine / Using the machine ·······7-8

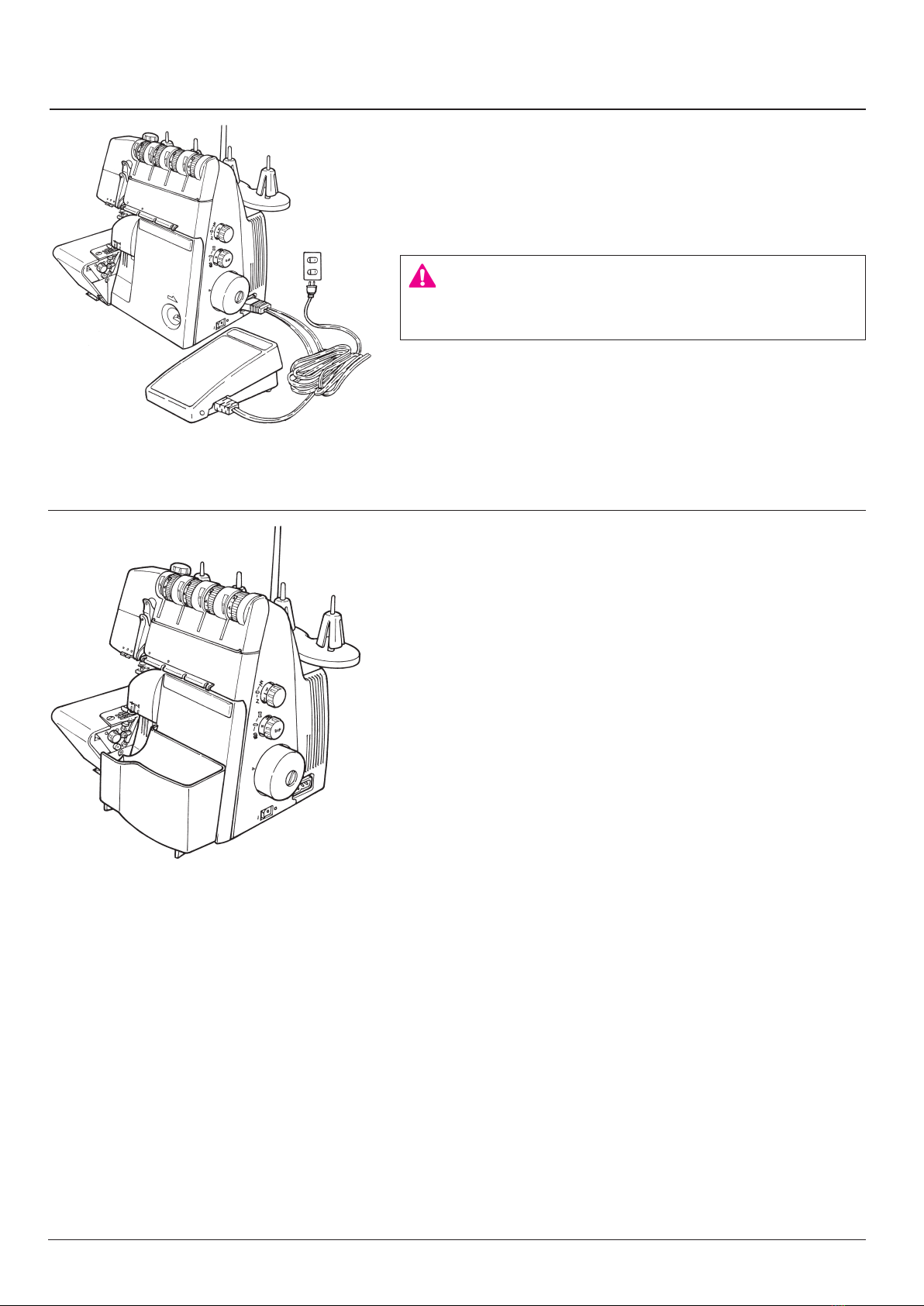

• Attaching the foot control································7

• Waste collector ············································7

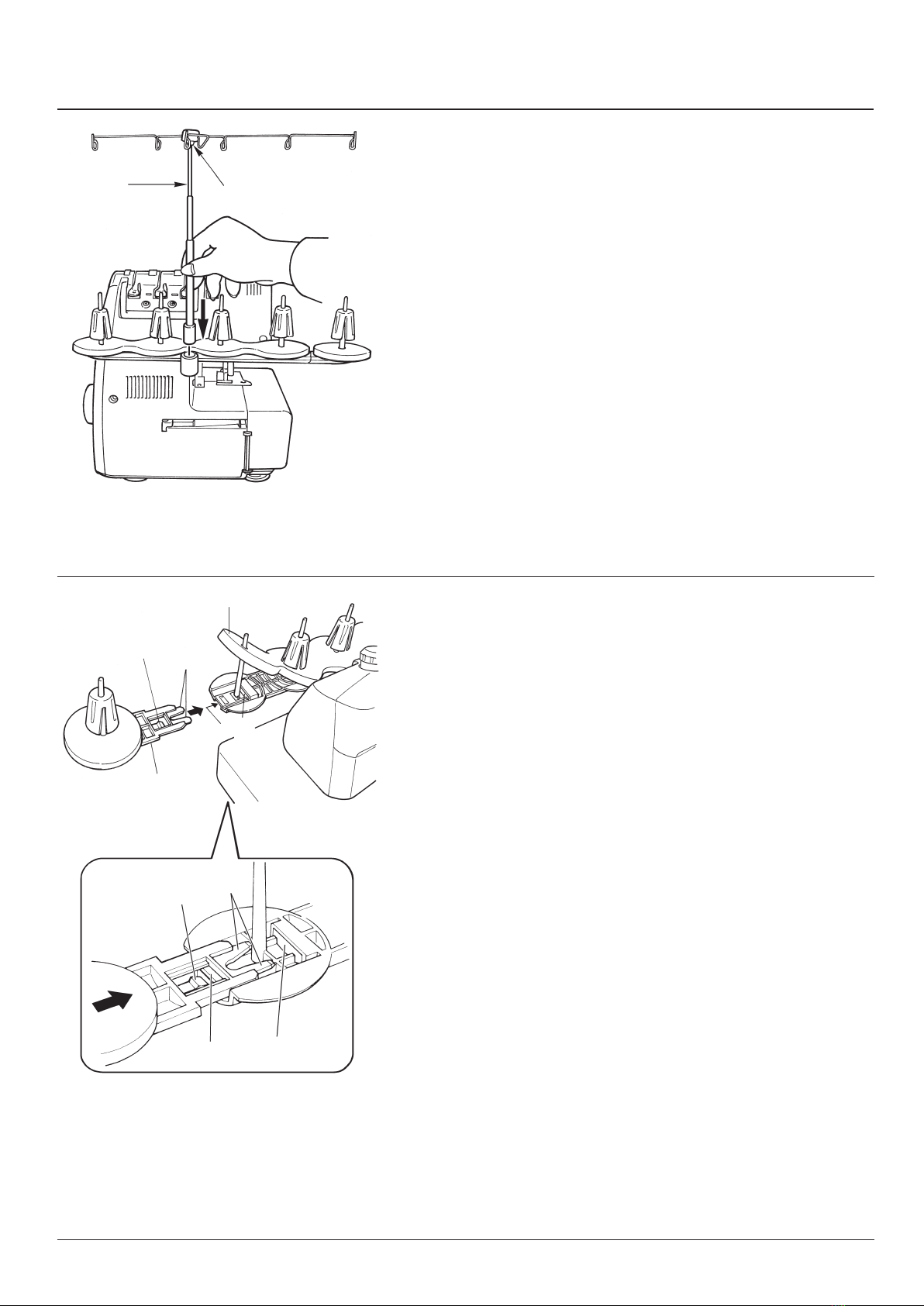

• Thread stand ···············································8

• Placing the spool holder for the chain thread ······8

• Thread / cones / spools··································9

Using the machine

• Power/light switch·········································9

• Raising the upper knife ··································9

• Two step presser foot lifter with integrated front

foot lift······················································10

• Changing the presser foot ···························· 10

• Looper cover ············································· 11

• Cloth plate ················································ 11

• Handwheel················································ 11

• Inserting the needles ··································· 12

Needle and thread·········································13

Adjustments and settings

• Stitch length ··············································14

• Cutting width ·············································14

• Dierential feed·········································· 15

• Gathering··················································16

• Upper looper converter ································ 16

• Roll hemming ············································17

Settings, practical sewing

• Presser foot pressure ·································· 17

• Sewing in tape ··········································· 18

• Thread breakage during sewing····················· 18

• Unpicking seams ········································18

Threading preparations / tips ···························19

Stitch chart·············································· 20-21

Threading 4/3 Thread OL

• Upper looper ·············································22

• Lower looper ·············································23

• Right-hand needle ······································24

• Left-hand needle ········································25

Threading, Chain stitch and OL ··················· 26-28

Contents

Trial sewing, thread tension ·····························29

Thread tension ········································ 29-30

Cover/chain stitch functions·····························31

Cover/chain stitch functions and

general operating instructions ····················· 32-33

Threading 4 thread cover stitch

• Threading cover stitch looper ························34

• Cover stitch R needle ·································· 35

• Cover stitch C needle ·································· 36

• Cover stitch L needle··································· 37

Threading 3 thread cover stitch (wide) ···············38

Threading 3 thread cover stitch (narrow) ············39

Threading chain stitch ····································40

Sewing test and tension adjustment ··················41

Tension adjustments ······································42

Practical Sewing-Cover stitch

• Securing the seam end, cover stitch ···············43

• Unpicking seams ········································43

• Stitch plate with seam guide lines ·················· 43

• Simple hem ···············································44

• Flat joining seam ········································ 44

• Edges with elastic······································· 45

• Binding·····················································45

Top stitching seams /ribbing/yokes····················46

Practical Sewing-Chain stitch

• Gathering with chain stitch···························· 46

• Binding·····················································46

Maintenance

• Changing the upper knife ····························· 47

• Changing the lower knife······························ 47

• Cleaning and lubricating······························· 47

Trouble shooting guide ···································48

Technical data ··············································49

Optional Accessories ·····································50

4