−5−

Adjustment Procedures Results of Improper Adjustment

Adjustment Procedures Results of Improper Adjustment

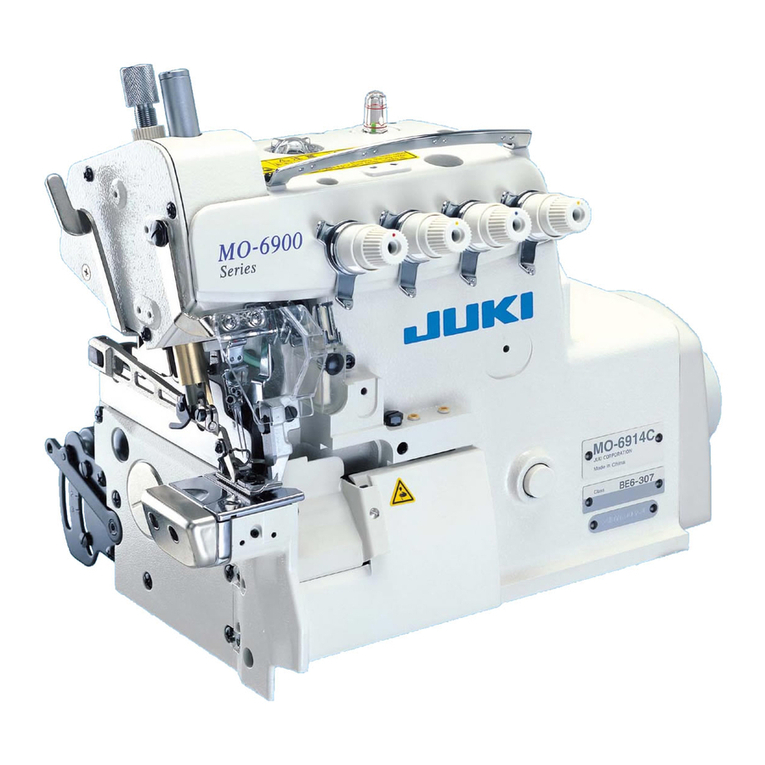

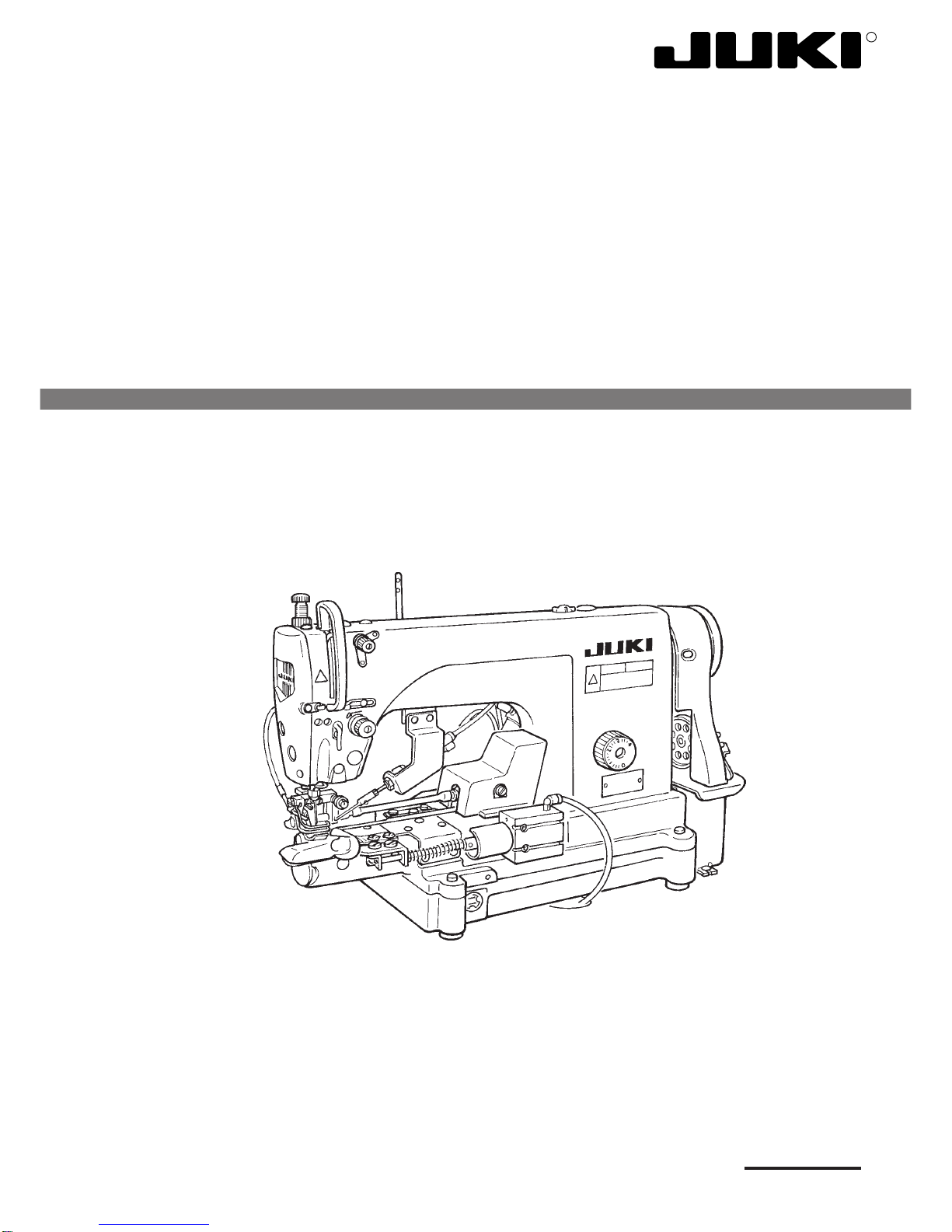

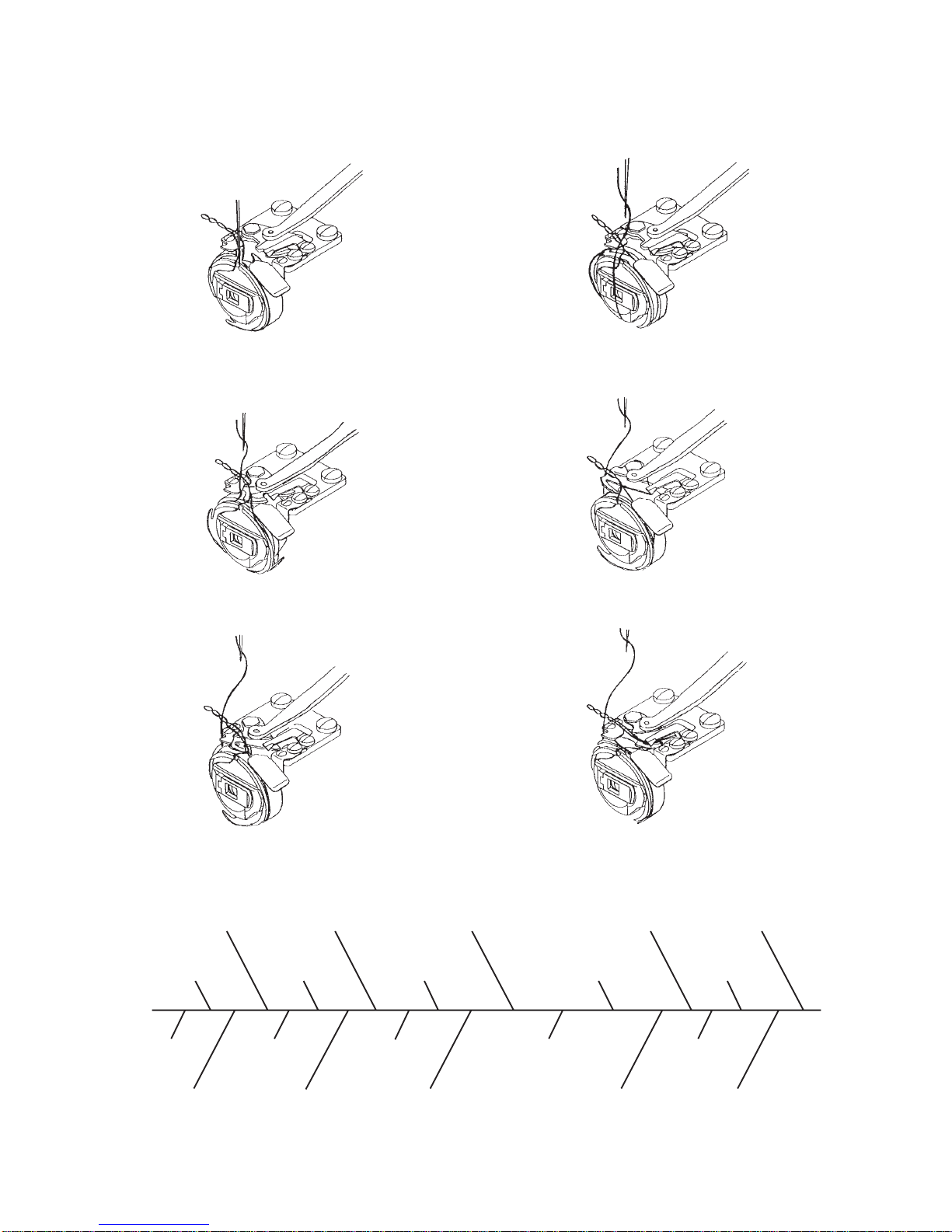

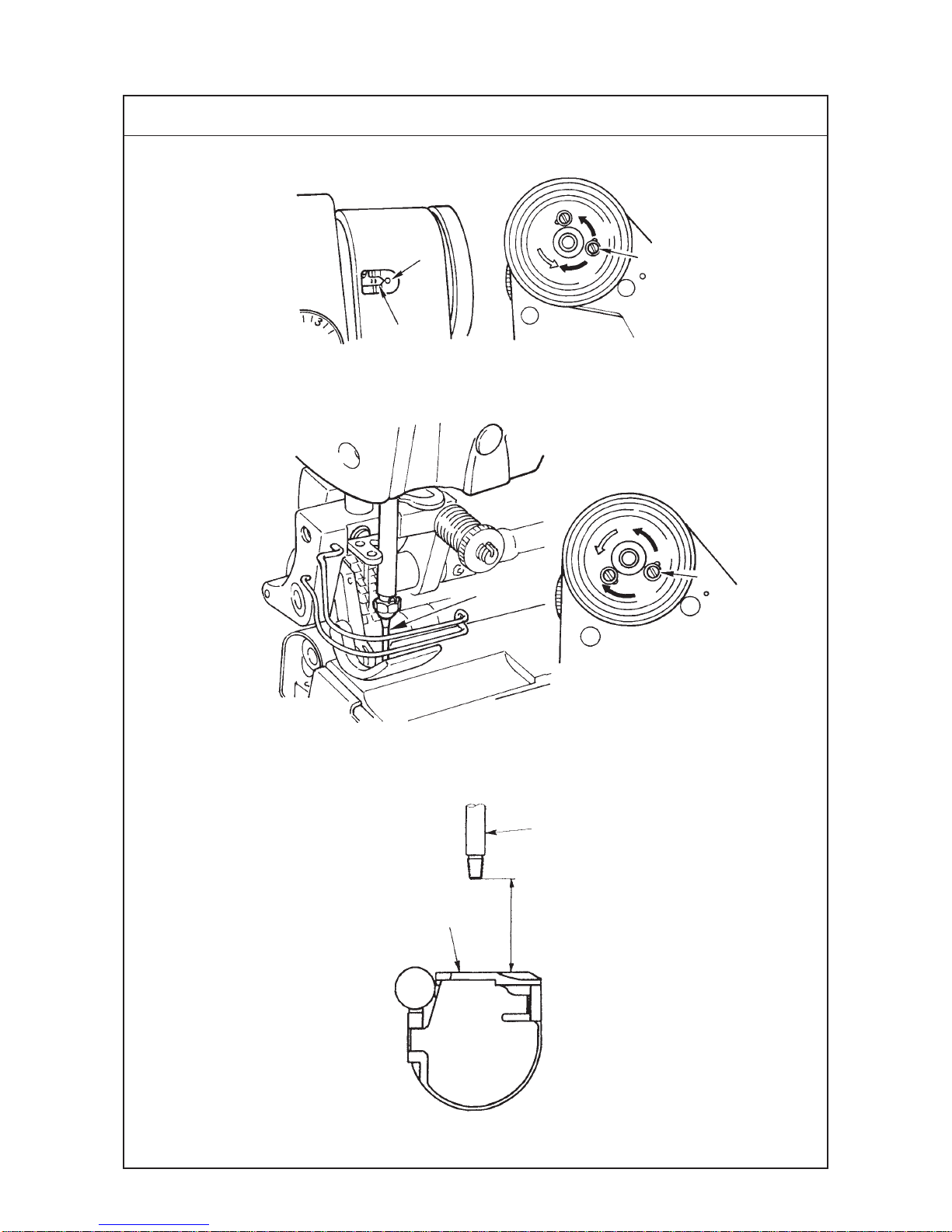

1) Turn the handwheel to bring the needle bar to the lowest position

of its stroke, and loosen setscrew 1in the needle bar bracket.

2) Set needle bar height gauge 2supplied with the machine as

accessories to installing plane 3of the throat plate as shown

in the figure, and make bottom end 4of the needle bar come

in contact with plane A(engraved A marking) of needle bar

height gauge 2. Then tighten setscrew 1in the needle bar

bracket.

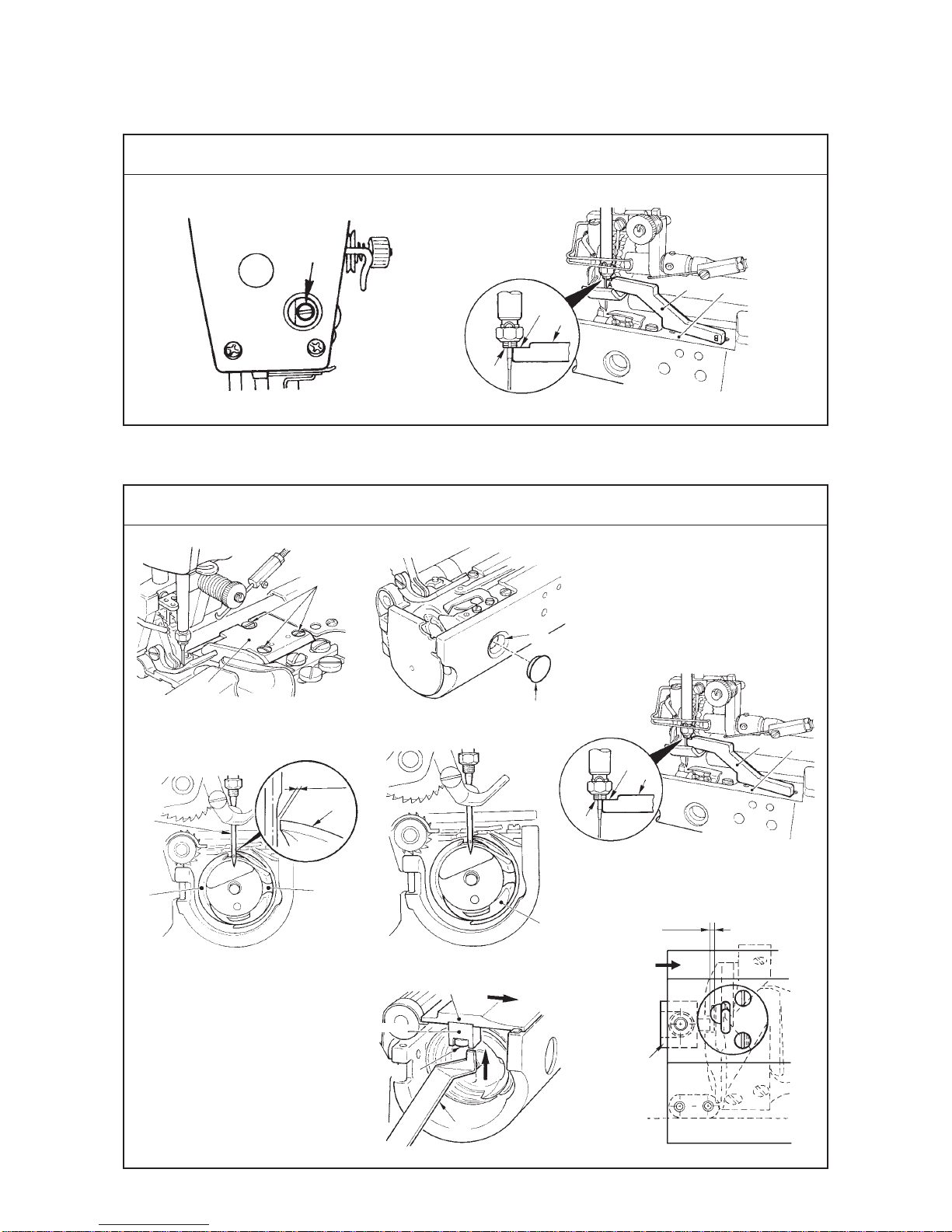

1) Remove setscrews 1and remove throat plate 2.

2) Remove cap 3, and put a screwdriver from hole 4to loosen

three setscrews in the hook. Turn the handwheel in the direction

where needle bar goes up, set needle bar height gauge 5to

installing plane 6of the throat plate as shown in the figure,

and adjust the position so that plane B(engraved B marking)

of needle bar height gauge 5enters bottom end 7of the

needle bar.

3) Adjust blade point 8of hook ato the center of needle 9.

Then adjust so that the clearance provided between the needle

and the hook is 0 to 0.06 mm (standard), and securely tighten

three setscrews in the hook. (Tightening torque : 2 to 4N.m)

* Adjust inner hook bat the position as shown in the figure.

4) Install cap 3and throat plate 2, and securely tighten setscrews

1. (Tightening torque : 1.5 to 3N.m)

* Adjust the convex of bobbin case holder !0 to the concave of

inner hook bwhen installing the throat plate.

* Tighten setscrews 1and install throat plate 2while pushing

throat plate 2by hand in the direction of arrow mark cwhen

installing throat plate 2.

5) Adjust clearance Dprovided between the convex of the bobbin

case holder and the concave of the inner hook with gauge !2

supplied with the sewing machine as accessories. (Standard :

0.8 mm)

* Put gauge !2 supplied as accessories in clearance Dand

tighten setscrew !1while lightly pushing bobbin case holder !0

in the direction E. (Tightening torque : 1.5 to 2.5N.m)

* Check that gauge !2 can go in clearance Dand come out

from it with light resistance.

™Thread breakage will be caused

even when the height of the

needle is excessively high or

low.

™When hook timing is excessively

retarded (return amount is large)

Contact of the blade point of the

hook with the belly of needle is

increased resulting in stitch

skipping or thread breakage at

the time of sewing of overlapped

section.

™When hook timing is excessively

advanced (return amount is

small)

Thread loop becomes smaller

resulting in stitch skipping or

thread breakage at the time of

sewing of overlapped section.