2.

Be sure

to

take

sufficientsafety measures

to

prevent falling ordropping beforelifting

or

moving the

machineIn

order

to protectagainst accident that can result

in

personal injuryor

death

.

3.

Once the machine has been

unpacked,

neverre-pack Itfortransportation

to

protectthe machineagainst

breaka~e

resulting from unexpected

accident

ordropping.

Unpackin_ I

1. Be sure

to

unpack

the

machine In

the

prescribed orderIn order

to

prevent accident

that

can result In

personal

injury

ordeath. In

the

case

the

machine ls,crated,

In

particular, be sure

to

carefully check nalls.

The nails have

to

be removed.

2. Be sure

to

check

the machine

for

the

position

of Its centerofgravity

and

take It out from the package

careful!

in

order

to

prevent

accident

that

can result In personal injuryordeath.

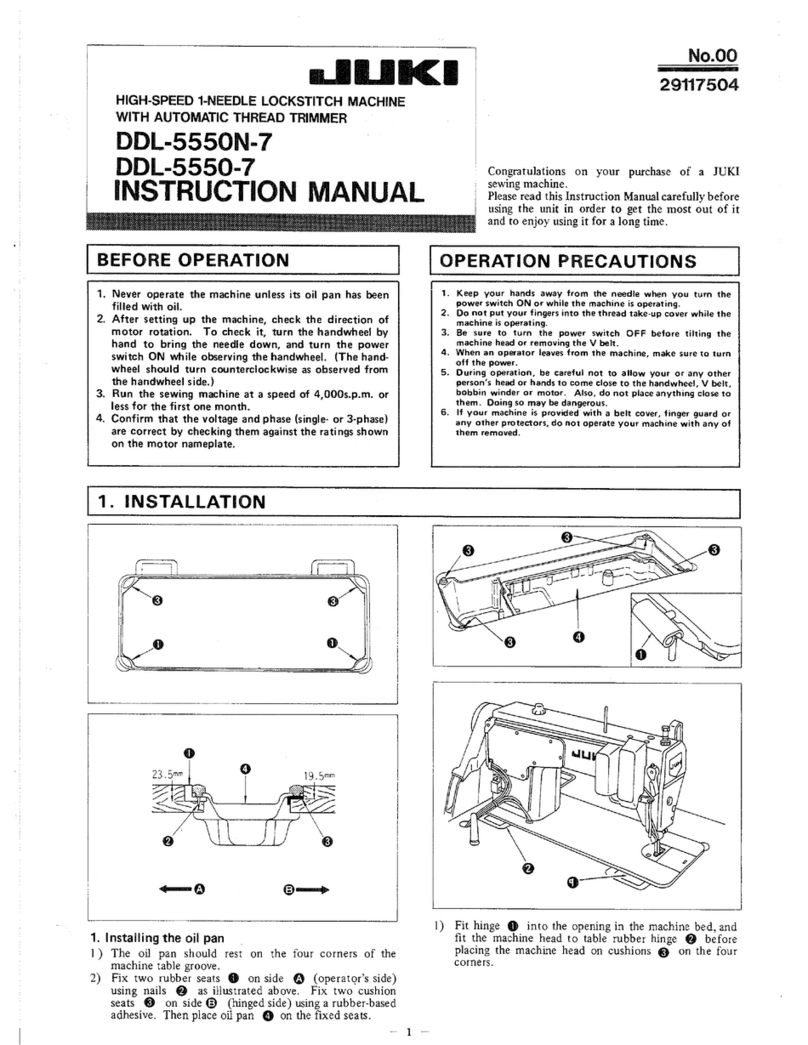

Installation

( I ) Table and

table

stand

1.

Be sureto useJUKI genuine table

and

table stand In orderto prevent accidentthat

can

result

In

per-

sonal injury

or

death. If ItIs Inevitable to use a table and table stand which

are

not

JUKI

genuineones,

selectthe table and tablestand which are able to supportthe machineweightand reaction force

during

operation.

2. Ifcasters are fitted

to

the table stand,

be

sure

to

use the casters

with

alocking mechanism and lock

them to secure the machine

during

the

operation, maintenance, inspection

and

repair in order

to

prevent

accident that can resultin personal

Injury

or

death.

(

n)

Cable and

wiring

1. Be sure to prevent an extra

force

from being applied

to

the cable during

the

use

in

order

to

prevent

electrical-shock, earth-leakage

or

fire

accident. In addition,

If

It is necessary to cablenear the operating

section such as the V-belt, be

sure

to

providea space

of

30

mm

or

morebetween the operating section

and thecable.

2. Be sure

to

avoid

starburstconnection In

order

to preventelectrical-shock, earth-leakage

or

fire accident.

3. Be sure to securely connect

the

connectors In order to prevent electrical-shock, earth-leakage

or

fire ac·

cident. In addition, besure to remove

the

connectorwhile holding

its

connectorsection.

(m)

Grounding

1.

Be

sure

to

have

an

electrical

expert

Install an appropriate power

plug

in

orderto prevent accident

caused by earth-leakage

or

dielectric strength voltage fault.

In

addition,besure

to

connect the

power

plug to the grounded outlet

without

exceptions.

2.

Be sure to

ground

the

earth cable In

order

to preventaccident caused

by

earth

leakage.

(l'l)

Motor

1.

Be

sure to

use

the specified rated

motor

(JUKI genuine product)

in

order

to

preventaccident caused by

burnout.

2. Ifa commercially available cluteh

motor

Is used with the machine, besure

to

select

one

with

an entan-

lement reventive pulley

cover

In

order

to

protectagainst being entangled

by

the V·belt

Before o eration ·

1.

Be

sure

~o

makesure that the

connectors

and cables are

fr~

from damage, dropout

and

looseness

be-

fore turnmg

the

poweron in

order

to

preventaccident resulting

in

personal Injury

or

death.

2. Never put

your

hand

Into

the

moving

sections

of

the machine in orderto prevent accld t th t It

in personal

injury

or

death. en • a can.resu

In addition, check to

be

sure that the direction

of

rotation of

the

pulley

agrees

with

th

h

3.

If

the

table

stand

with casters

is

used,

be

sure

to secure thetable stand by lockl e

atrrhow

s

own

on

~ulley

.

• • 1 • ng ecasters

or

w1th

adJUSters,

if

provided, m order

to

protectaga

nst

accedent caused

by

abrupt start f

th

D . . 1 o

emachlne

urmg

operatton I •

1.

Be

sure not

to

put

your

fingers,

hair

or

clothing

close

to

the moving sections such

as

th h

hand pulley and motor

or

place something nearthosesections while

the

machi . i e andwheel,

to

prevent accidentcaused by entanglement

that

can result in personal injury

0

~~~at~.operation

in

order

2.

Be

surenot

to

place

your

fingers near

the

surround area

of

the needleor Inside th th

cover when turning

the

power

on

or

while

the

machine

is

In

operation

in

orde t e read take-up lever

can result

in

personal Injury

or

death. r 0 prevent accident

that

3. The machine

runs

at a high speed. Never

bring

your

hands near

the

moving s ti

spreader, needlebar,

hook

and

cloth

trimming

knife duringoperation

In

order~

ons such

as

looper,

againstInjury. In addition,

be

sure

to

turn

the

power

off

and check

to

be

sure

th:r;~tect

yo~r

hands

ly stops before changing the thread. emach

me

complete·

4.

Be

careful

not

to

allow

your

fingers

or

any

other

parts

of

your body

to

be cau ht

be

and tablewhen removing the machine from

or

replacing Iton thetable

In

ord

g t

tween

the machine

can result

in

personal Injury

or

death.

er

0 prevent accident

that

5.

Be

sure to turn thepower offand check

to

be surethat the

machine

and

motor

co 1

lng the beltcover

and

V-belt

in

order to preventaccident

caused

by

abruptstart

0

~~

etelystop before remov-

6. If a servomotor

is

used with the machine,

the

motordoes not prOduce noise

wh

'le

mach

in

e or motor.

Be

surenot

to

forget

to

turn the power

off

In orderto prevent accident

caused~

e

~e

machine Is atrest.

7.

Never use

the

machine with

the

cooling

opening

of

the

motor

power

box

shleiJ~

1

rupt startof

the

motor.

accidentby overheat. n

Order

to prevent

fire