i

CONTENTS

I. IMPORTANT SAFETY INSTRUCTIONS ..................................................... 1

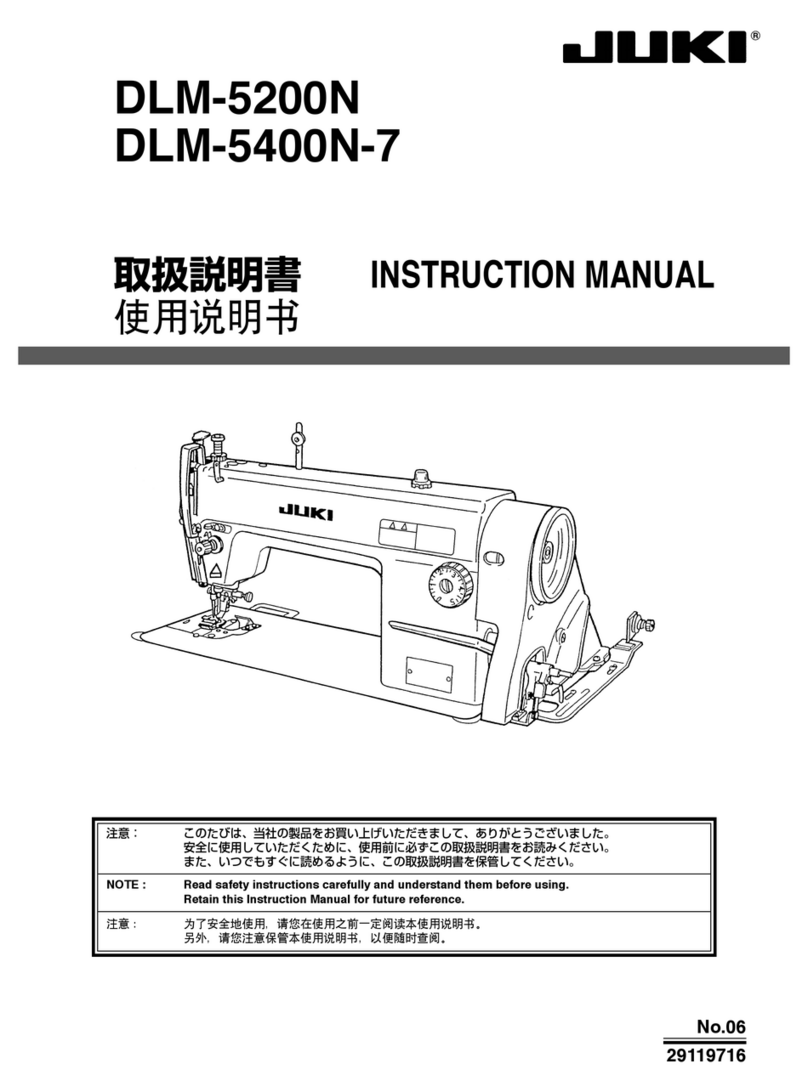

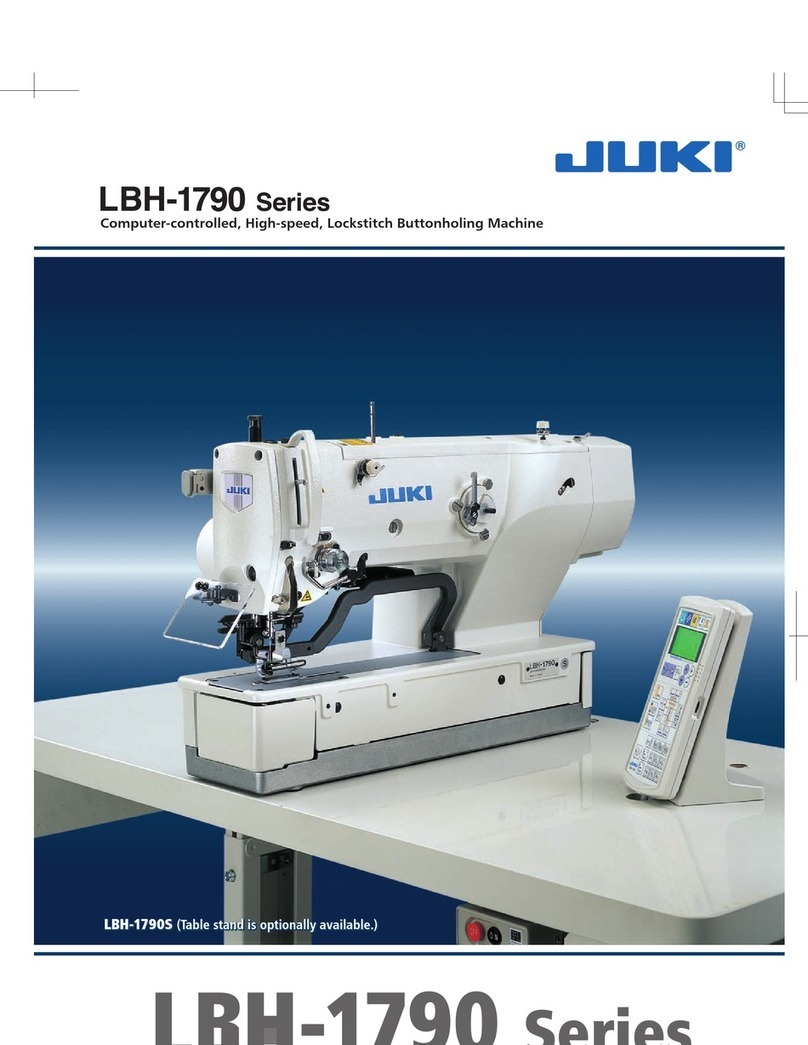

II. SPECIFICATIONS....................................................................................... 1

1. Specications.........................................................................................................................2

2. Standard sewing shape list...................................................................................................3

3. Conguration .........................................................................................................................4

III. INSTALLATION.......................................................................................... 5

IV. PREPARATION BEFORE OPERATION.................................................. 15

1. Lubrication ...........................................................................................................................15

2. Inserting the needle .............................................................................................................16

3. Threading the needle-thread...............................................................................................17

4. Threading the bobbin case .................................................................................................17

5. Adjusting the bobbin thread tension .................................................................................18

6. Installation of bobbin case..................................................................................................18

7. Installing the knife ...............................................................................................................19

8. Checking the sewing machine in the delivered state.......................................................19

V. OPERATION OF THE SEWING MACHINE.............................................. 20

1. Explanation of the operation panel switch........................................................................20

2. Basic operation of the sewing machine ............................................................................22

3. How to use the pedal ...........................................................................................................23

4. Input of the presser type .....................................................................................................25

5. Performing pattern selection ..............................................................................................26

6. Changing needle thread tension ........................................................................................27

7. Performing re-sewing ..........................................................................................................28

8. Winding bobbin thread........................................................................................................29

9. Using the counter ................................................................................................................31

10. Using the initial value pattern...........................................................................................34

11. Changing sewing data.......................................................................................................35

12. Method of setting sewing data with/without edit ............................................................37

13. Sewing data list..................................................................................................................38

14. Copying sewing pattern ....................................................................................................44

15. How to edit/check the data other than sewing data .......................................................45

16. Using parameter register key ...........................................................................................47

17. Performing continuous stitching .....................................................................................48

18. Performing cycle stitching................................................................................................51

19. How to change the name of cycle/continuous sewing data ..........................................53

20. Explanation of plural motions of knife.............................................................................54

21. Method of changing memory switch data .......................................................................55

22. Memory switch data list ....................................................................................................56

23. How to change the sewing speed while the sewing machine is engaged in sewing.. 60

24. How to adjust the pedal variable resistor........................................................................61