– 1 –

!. INTRODUCTION

1. Outline

ThisInstructionManualdescribestheproductionsupportfunctionwhichisenabledbyinstallingtheIP

(Intelligent Panel) on the sewing machine and operating it. The IP measures the operational status of

thesewingmachineandrecordsit.Inaddition,itvisuallyindicatestherecordeddatatohelpimprove

efciencyinsewingworkfromvariouspointsofview.Themeasuredandrecordeddataonthesew-

ingmachineoperationcanalsobeloadedintoapersonalcomputerbywayofamedium.Bycollecting

andloadingoperationdatafromtwoormoresewingmachinesintoapersonalcomputer,notonlythe

detailedanalysisoftheoperationalstatuswithSMDAA(SewingManagementDataAnalysisApplication

software)butalsotheaccumulationoftheanalyzeddataareenabled.Withthoseanalyzedandaccu-

mulateddata,efciencyimprovingactivitiesfortheentiresewingplantcanbecarriedoutcontinuously.

* RefertotheInstructionManualforSMDAAfortheSMDAA.

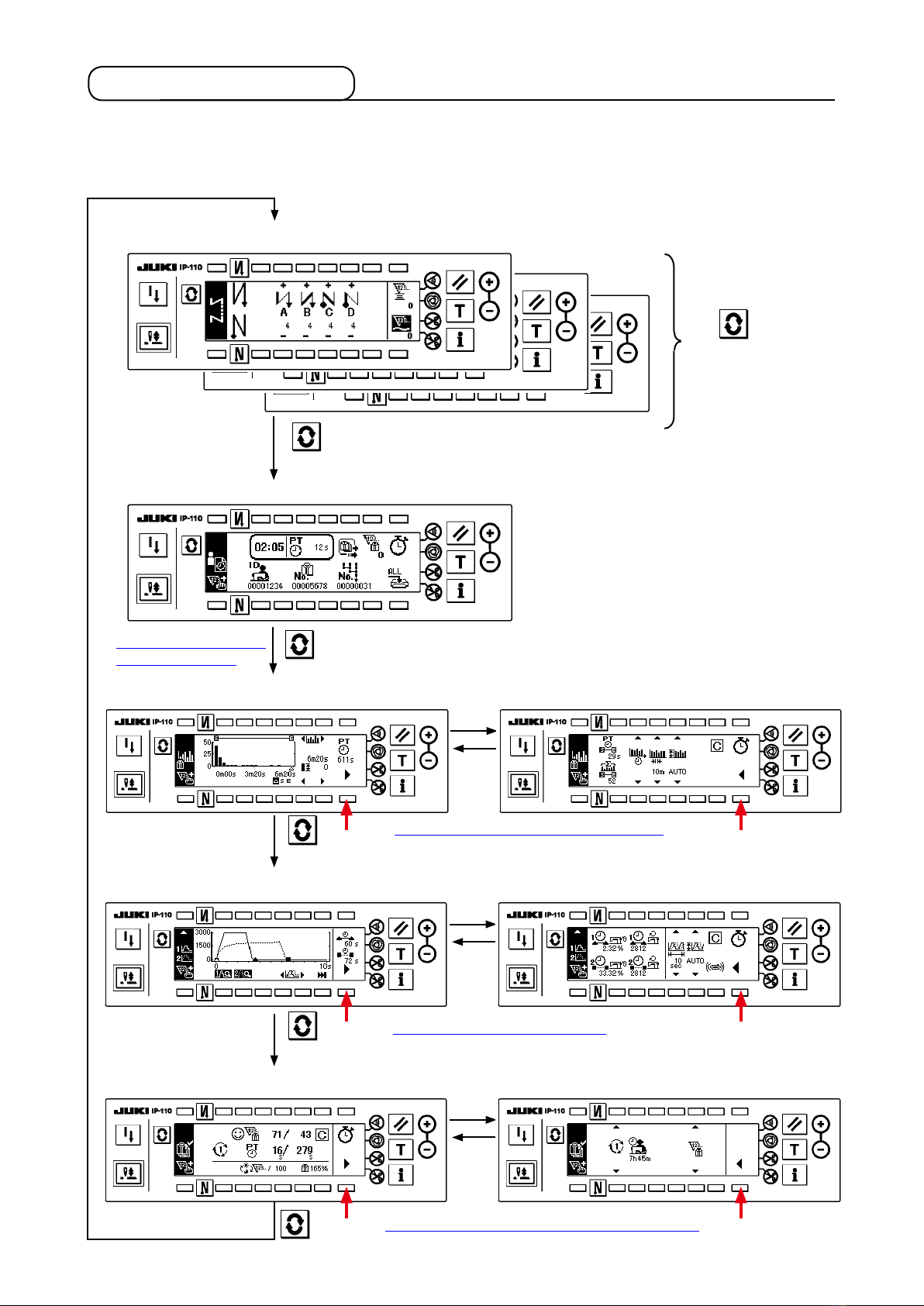

TheproductionsupportfunctionbymeansoftheIPiscategorizedintofourfunctionalparts,i.e.,work

management function, pitch time monitor function, sewing recorder function and production manage-

mentfunction.Eachofthemhasitsownsupportcapability.Usethembyselectinganappropriateone

accordingtoyourneeds.

* Itshouldbenotedthattheworkmanagementfunctioncannotbedisabledsinceitmanagesdataon

the sewing machine operation. Operation of the other three functions can be changed over between

the enable and disable.

(1) Work management function

Tousetheworkmanagementfunction,workhistorydatasuchastheoperatorID,productnumber

andprocessnumber,whicharetobeembeddedintheoperationdatarecordedbyeachsewing

machine,shouldbeentered.TheSMDAAcarriesoutoperationalstatusanalysisbasedonthose

pieces of data.

This function is also used when loading the operation data from the sewing machine into a personal

computer.

(2) Pitch time monitor function

Withthepitchtimemonitorfunction,itispossibletospecifyanarbitrarytargetsectiontomonitor

thetransitionoftheproductionvolume(i.e.,thequantityofsewnitems)perunittimeandthepitch

timedistributionanddisplaythemontheIPasabarchart.Inaddition,theoperationalstatussuch

asthetotalproductionvolumeandaveragepitchtimeinthespeciedsectioncanbeanalyzedand

indicatednumerically.Throughthesecapabilities,thesewingworkcanbemonitoredoveralong

timeandvisuallyanalyzedtoenabletrackingdownofthetimewhenaproblemhasoccurred.

(3) Sewing recorder function

Thesewingrecorderfunctioncontinuouslymeasuresthenumberofrevolutionsandthreadtrimming

timing of the sewing machine at all times to show the results on the IP as a line chart. The sewing

machineoperator'sskilllevelischeckedandtechnicaltrainingisprovidedbasedonthelinegraph.

Itispossibletodisplayanoperator'sskillleveltogetherwiththatofaskilledoperatororwithhis/her

workdataofthepastonascreenforthepurposeofcomparison,sothatthecomplicatedandhard-

to-understandsewingmachineoperationcanbevisualizedforeasieranalysis.

(4) Production management function

Theproductionmanagementfunctiondisplaysthetargetproductionvolumeforgivenworkinghours

andtheactualproductionvolumetonotifytheoperatorofadelayorprogressofsewingworkinreal

time.Withthisfunction,theoperatorisabletocarryouthis/herworkwhilecheckinghis/herwork

pace.Thisenhanceshis/hermotivationtoachievehis/hergoal,therebyleadingtoaincreasein

productivity.Inaddition,thisfunctionallowsearlydetectionofadelayinworkmakingitpossibleto

identifyaproblemandtakeanappropriatemeasureatanearlystage.