From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

PREFACE:

This

operator's

manual has been prepared

to

guide

you

while

operating

the

MFC-7000 Series machines.

This

manual explains in detail

the

proper

settings

for

operation

of

the

machine.

Illustrations

are used

to

show

the

adjustments

and reference letters are used

to

point

out

specific

items

discussed.

Careful attention

to

the

instructions

and

cautions

for

operating and

adjusting

these

machines

will

enable you

to

maintain

the

superior

performance and reliability

designed

and

built

into

every

Union

Special machine.

Adjustments

andcautionsare presentedin

sequence

so

that

alogical

progression

is

accomplished.

Some

adjustments

performed

out

of

sequence may have an adverse

effect

on

the

function

of

the

other

related parts.

This

manual has been

comprised

on

the

basis

of

available

information.

Changes

in

design

and/or

improvements

may

incorporate

a

slight

modification

of

configuration

in

illustrations

or

cautions.

On

the

following

pages

will

be

found

illustrations

and

terminology

used

in

describing

operating

instructions

for

your

machine.

CONTENTS

PREFACE:

.................................................................................................................................................................2

SAFETY

RULES

..........................................................................................................................................................3

SPECIFICATIONS:

....................................................................................................................................................4

MOTOR

PULLEY

AND

V

BELT:

..................................................................................................................................4

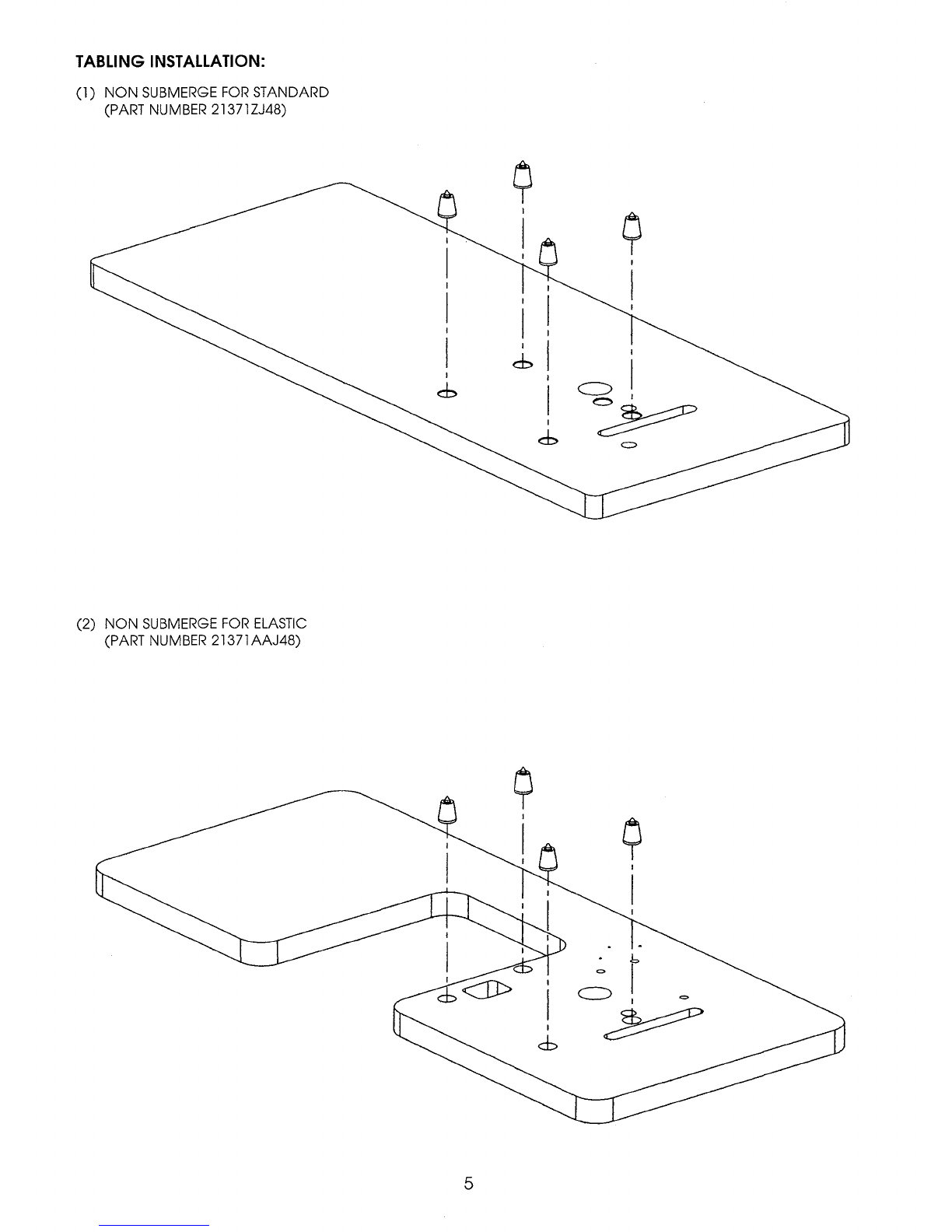

TABLING

INSTALLATION:

...................................

.-

..................................................................................................... 5

CAUTION

AREAS:

...................................................................................................................................................6

OPERATOR'S

DAILY

CHECK

UST:

.................................................................•........................................................... 7

ROTATION:

..............................................................................................................................................................7

OPERATING

CAUTIONS:

.........................................................................................................................................7

OPERATING

CAUTIONS

(CONT.): ..........................................................................................................................8

OPERATING

THE

PEDALS:

.........................................................................................................................................8

LUBRICATION:

.........................................................................................................................................................9

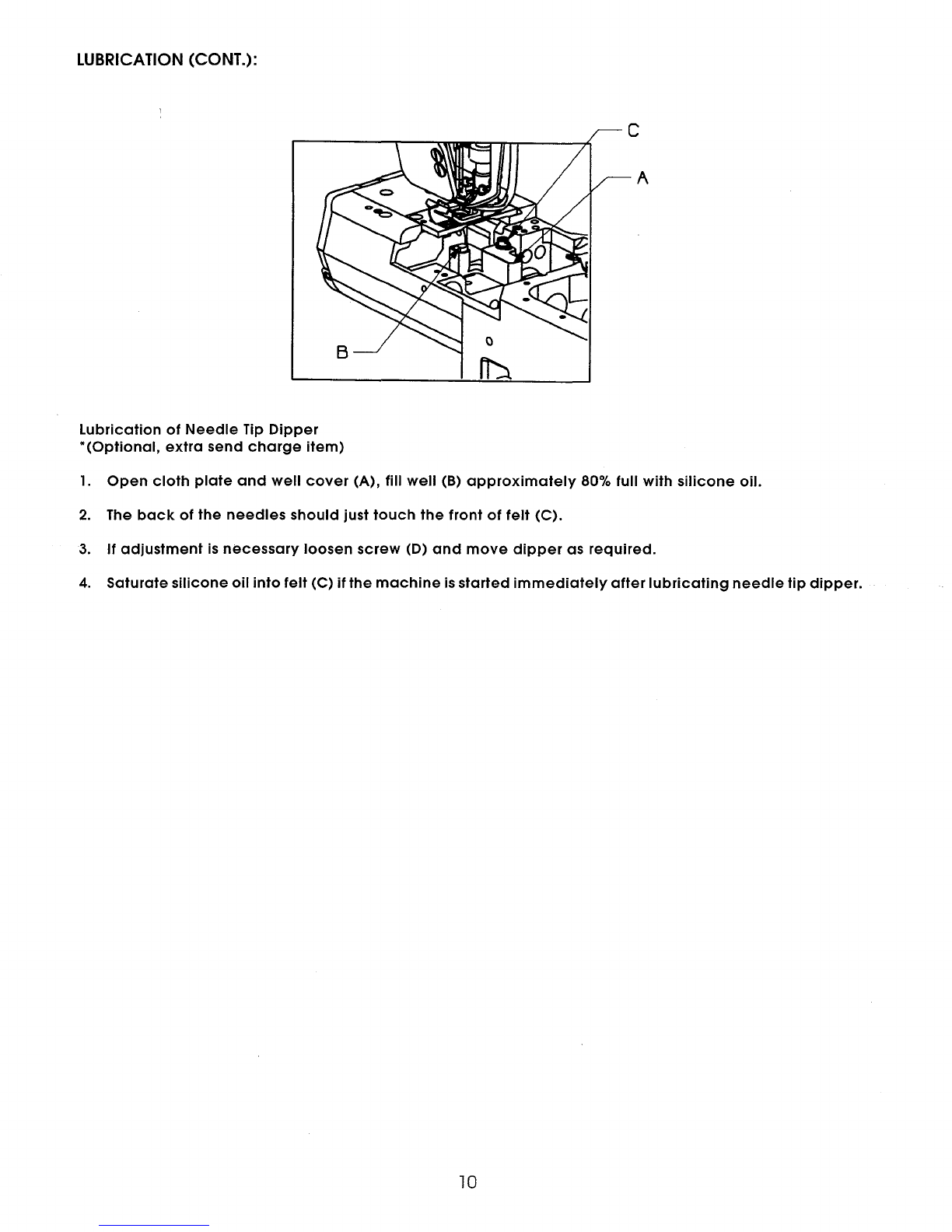

LUBRICATION

(CONT.):

........................................................................................................................................

10

INSERTING

NEEDLES:

.............................................................................................................................................

11

THREADING

THE

MACHINE:

.................................................................................................................................

12

THREADING

THE

MACHINE

(CONT.): ...................................................................................................................

13

DIFFERENTIAL

FEED

MECHANISM:

........................................................................................................................

14

ADJUSTING

THE

STITCH

LENGTH:

.........................................................................................................................

14

PRESSER

FOOT

PRESSURE

AND

LIFTER:

.................................................................................................................

15

ROLLER

PRESSURE

ADJUSTING

KNOB:

.................................................................................................................

15

PULLER

LIFTER

LEVER:

............................................................................................................................................

16

PULLER

STIITCH

LENGTH:

.......................................................................................................................................

17

ADJUSTMENT

OF

LOOPER

GAUGE:

......................................................................................................................

18

ADJUSTMENT

OF

NEEDLE

BAR

HEIGHT:

................................................................................................................

18

ADJUSTMENT

OF

LOOPER

AND

NEEDLE:

.............................................................................................................

19

ADJUSTMENT

OF

NEEDLE

GUARD:

.......................................................................................................................

19

ADJUSTMENT

OF

SPREADER:

................................................................................................................................

20

ADJUSTING

TAKE-UP

CAM: ..................................................................................................................................

21

ADJUSTMENT

OF

THREAD

GUIDE:

........................................................................................................................

22

MAINTENANCE:

....................................................................................................................................................

23

2