Be sure to observe the following to protect against a re, electrical shock, injury or damaged components.

* Be sure to unplug the machine before disassembly, assembly or adjustment of the machine.

* Be sure to use the proper genuine parts when changing any of the machine parts.

CAUTION:

CONTENTS

1. Specications ..................................................................................................1

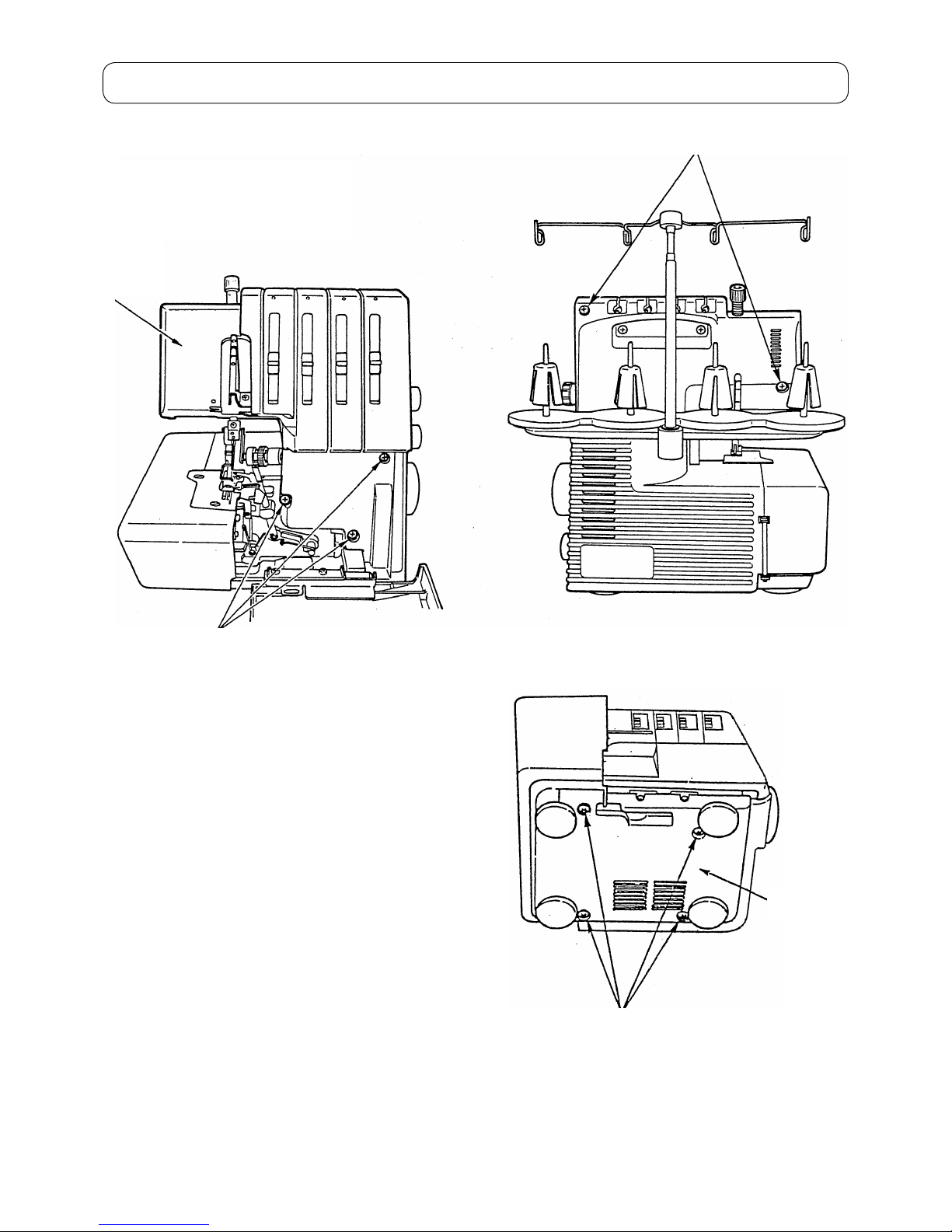

2. Removing order of covers ..............................................................................2

2-1. Front cover ...................................................................................................................2

2-2. Base plate .....................................................................................................................2

2-3. Rear cover ....................................................................................................................3

2-4. Cloth plate ....................................................................................................................3

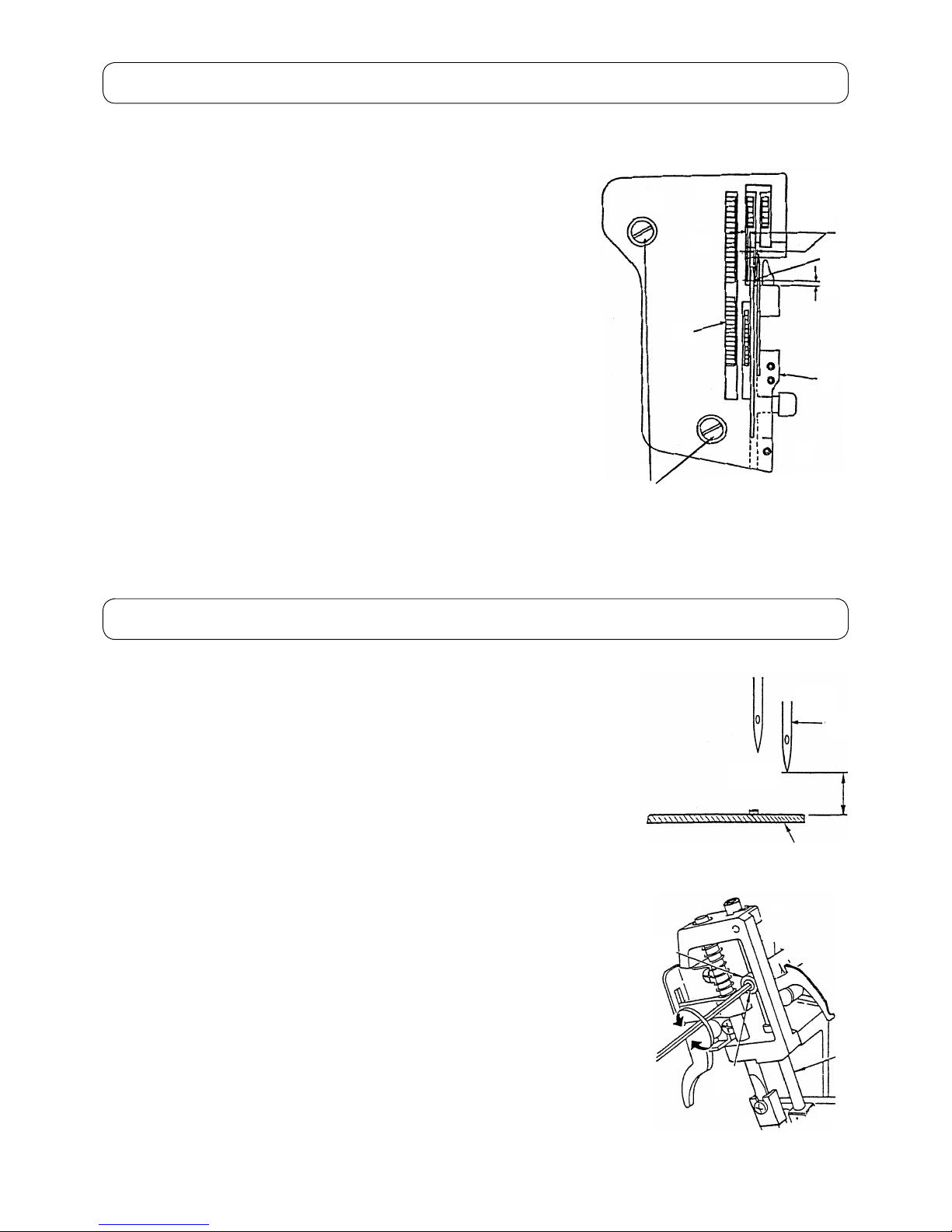

3. Installation of throat plate ..............................................................................4

4. Height of needle bar ........................................................................................4

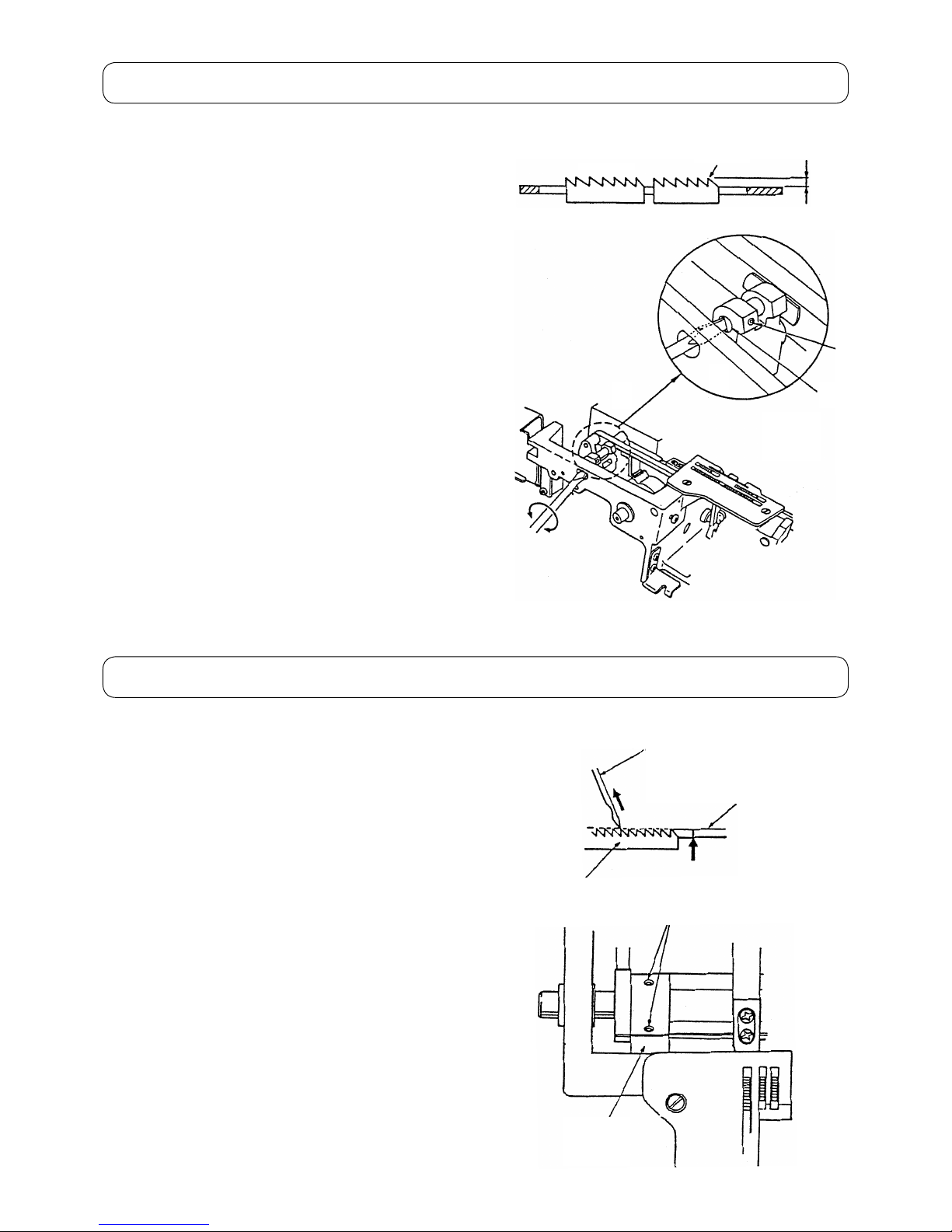

5. Position of feed dog ........................................................................................5

6. Adjusting stroke of main feed dog ................................................................6

7. Adjusting stroke of sub feed dog (MO-114D) ................................................7

8. Height of feed dog ...........................................................................................8

9. Feed dog timing ...............................................................................................8

10. Position of balance weights and cams..........................................................9

11. Projecting amount of upper looper ................................................................9

12. Radius of lower looper ..................................................................................10

13. Adjusting lower looper thread guide lever ..................................................10

14. Adjusting loop lift ..........................................................................................11

15. Timing between upper and lower looper .....................................................12

16. Installation of needle guards ........................................................................13

17. Position of upper looper thread take-up .....................................................13

18. Height and lateral position of presser foot .................................................14

19. Adjusting oating amount of thread tension disk ......................................15

20. Thread tension controller .............................................................................16

21. Position of needle thread take-up ................................................................17

22. Belt tension ....................................................................................................18

23. Position of lower knife ..................................................................................18

24. Engagement of upper knife with lower knife ..............................................19

25. Position of cloth plate ...................................................................................20

26. Adjusting presser foot pressure ..................................................................20