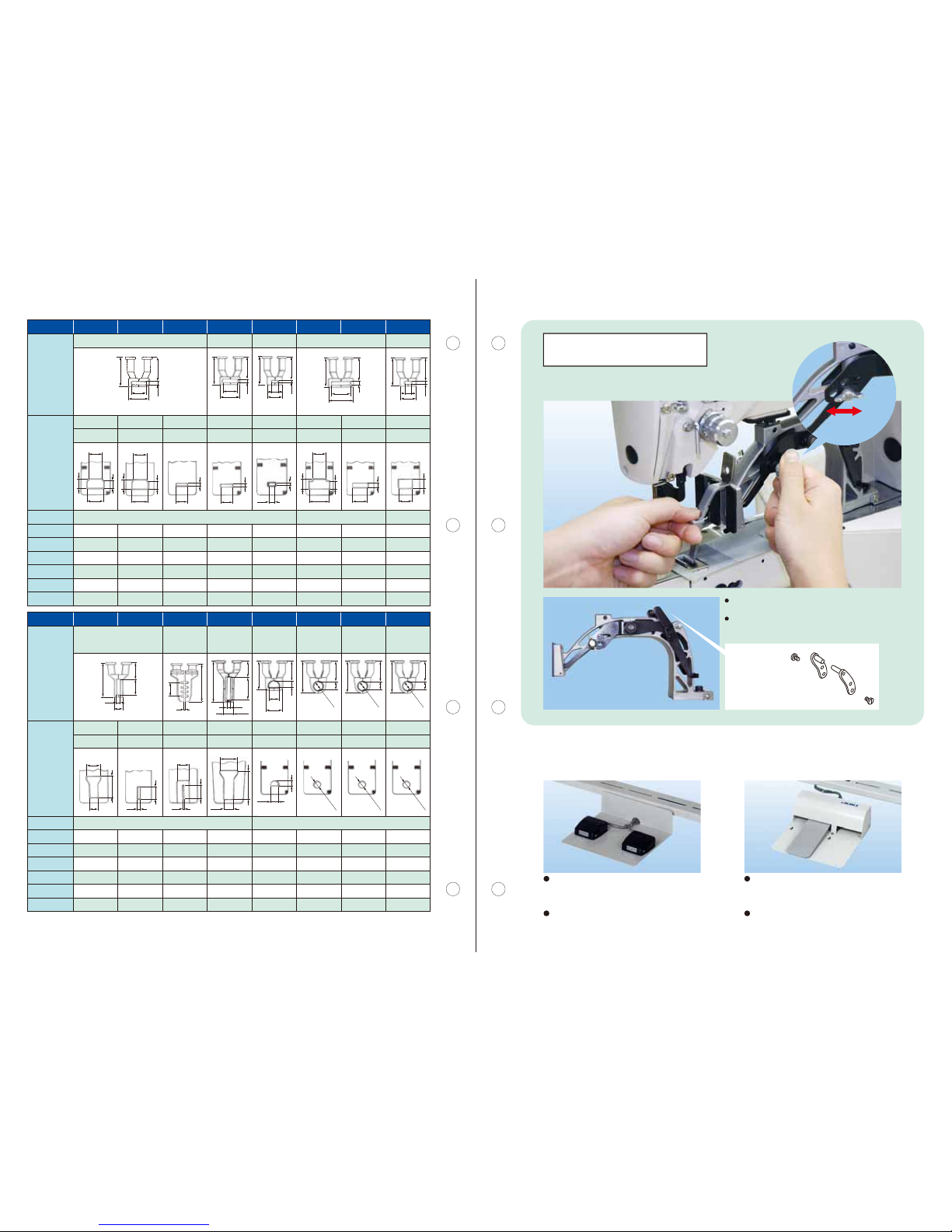

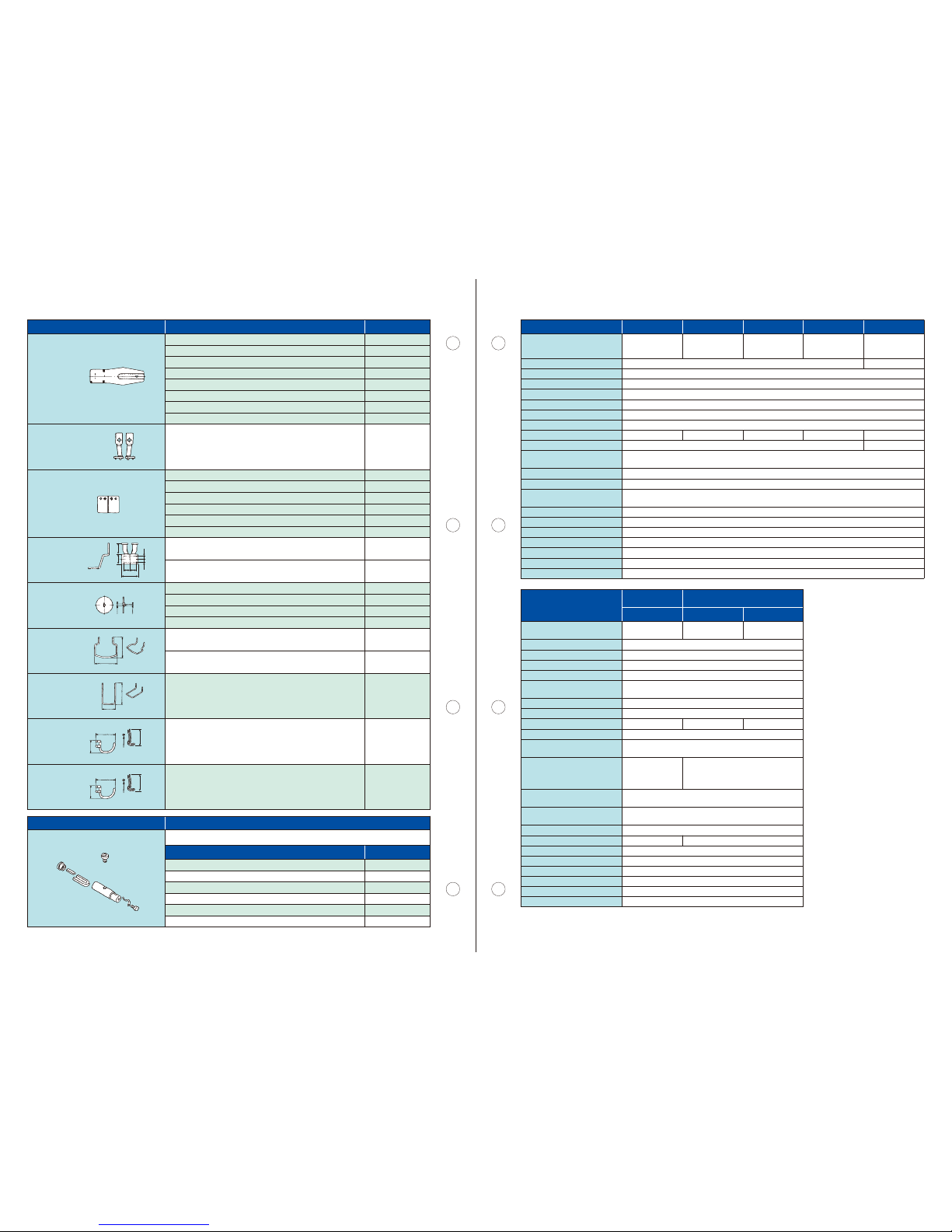

TABLE OF THE OPTIONAL PARTS

3,200sti/min✽2,700sti/min✽

Standard shuttle hook Large shuttle hook

20~200% (1% step), Pattern enlargement/reduction

can be done by increasing/decreasing the stitch length

Application Standard Standard For heavy-weight

materials

Lift of the work clamp foot

Applicable pattern number 11, 12, 13

17, 18 (19, 20, 21, 22*)

*This device has been factory-set to

“ invoking prohibited ”

status at the time of delivery.

Number of data that can be input 200 patterns

(for up to 150 patterns, sewing data can be added.)

20~200% (1% step), Pattern enlargement/reduction

can be done by increasing/decreasing the stitch length

✽

✽

✽

✽

“sti/min” stands for “Stiches per Minute”

CompactFlash™ or CFA specification compatible media.

“CompactFlash™” is a registered trademark of SanDisk Corporation, U.S.A.

Other company names and product names/brand names are trademarks or registered trademarks of the respective companies. 10

SPECIFICATIONS

LK-1900B-WSLK-1900B-MSLK-1900B-FSLK-1900B-HSLK-1900B-SS

Application Standard For heavy-weight

materials For foundation For knits and

knitted materials

With large hook

for heavy-weight

materials

Model name

DP×5 (#14) DP×17 (#21) DP×5 (#11) DP×5 (#11) DP×17 (#21)

30mm (L) × 40mm (W)

0.1~10mm (0.1mm step)

41.2mm

Standard 14mm (17mm when the reverse-rotation needle-up function)

Provided as standard (stepping motor type)

Active tension (electronic thread tension control system)

Max. 20,000 stitches

LK-1902B-HSLK-1902B-SSLK-1901B-SS

Model name

DP×5 (#14) DP×5 (#14) DP×17 (#21)

Eyelet buttonhole

bartacking machine

Belt-loop attaching machine

9

øA

øB

A

B

A

B

A

B

SM8040302TP

L

A

B

SM8040302TP

L

77

2422

14 14

36

Part name Type Part No.

Feed plate blank Without knurl/with plating

With knurl/with plating

Without knurl/stainless steel✽

Without knurl/with plating

Without knurl/without plating

Without knurl/stainless steel✽

With knurl/with plating

With knurl/without plating

Sewing area 20×40

Sewing area 20×40

Sewing area 20×40

Sewing area 30×40

Sewing area 30×40

Sewing area 30×40

Sewing area 30×40

Sewing area 30×40

14120109

14120307

14120505

40021855

40021856

40021857

40021858

40021859

Work clamp foot

face plate (asm.) Face plate for presser blank 14121263

Presser blank

With knurl/with plating (right)

With knurl/with plating (left)

40021869

40021870

A=66.5 B=43 For lengthwise bartacking 13573407

t=3.2

Part name Feature

Type Part No.

With knurl/with plating (right)

With knurl/with plating (left)

With knurl/with plating (right)

With knurl/with plating (left)

With knurl/without plating (right)

With knurl/without plating (left)

Sewing area 20×40

Sewing area 20×40

Sewing area 30×40

Sewing area 30×40

Sewing area 30×40

Sewing area 30×40

14121701

14121800

40021851

40021852

40021853

40021854

A=1.6 B=2.6 With relief slit Standard type

A=1.6 B=2.0 Without relief slit F and M types

A=2.3 B=4.0 Without relief slit for heavy-weight material

A=2.7 B=3.7 Without relief slit for extra heavy-weight material

B2426280000

D2426282C00

14109607

D2426MMCK00

Work clamp

foot blank

A=56.5 B=64

A=59 B=74 For extra-large bartacking

13533104

13548300

Finger guard (1)

Needle hole guide

Finger guard (2)

A=21.5 B=35.5 L=67 For lengthwise bartacking 14135305

Finger guard (3)

A=21.5 B=35.5 L=58.5 For specially ordered work clamp 14120000

Finger guard (4)

Silicon oil pipe The silicon oil pipe are the parts which cool the heat of a needle.

Silicon oil pipe

Rubber plug

Oil felt

Silicon oil thread guide

Screw 11/64 - 40 L5

Silicon oil pouring hole

40040910

TA1050504R0

13501705

B1127280000

SS4110515SP

13501408

t=1.2

✽Stainless steel t=0.5

Max. sewing speed

Sewing area

Stitch length

Needle bar stroke

Lift of the work clamp foot

Auto-lifter

Needle thread tension

Needle (at the time of delivery)

Hook

3,000sti/min✽

30mm (L) × 40mm (W)

0.1~10mm

41.2mm

Standard 14mm

(by using the reverse-rotation needle-up function 17mm)

Max. sewing speed

Sewing area

Stitch length

Needle bar stroke

Internal-organs memory

Provided as standard (up/down method)

Hook: minute-quantity lubrication

JUKI New Defrix Oil No.2 (equivalent to ISO VG32)

450W compact AC servomotor (direct-drive system)

250VA

Machine head (include motor) 42kg, Control box 5.6kg

Memory method

Material drawing amount

Bobbin thread counter

Lubrication

Lubricating oil

Sewing machine motor

Power consumption

Weight

Provided as standard (stepping motor type)

Active tension (electronic thread tension control mechanism)

Standard shuttle hook

Auto-lifter

Needle thread tension

Needle (at the time of delivery)

Hook

Max. 3mm —

Enlarging/Reducing facility

Max. 20,000 stitches

Number of stitches

that can be stored in memory

50 patterns

200 patterns (for up to 150 patterns, sewing data can be added.)

Number of standard patterns

Number of data that can be input

Internal-organs memory

Provided as standard (up/down method)

Hook: minute-quantity lubrication

JUKI New Defrix Oil No.2 (equivalent to ISO VG32)

450W compact AC servomotor (direct-drive system)

250VA

Machine head (include motor) 42kg, Control box 5.6kg

Memory method

Bobbin thread counter

Lubrication

Lubricating oil

Sewing machine motor

Power consumption

Weight

Number of stitches

that can be stored in memory

Enlarging/Reducing facility