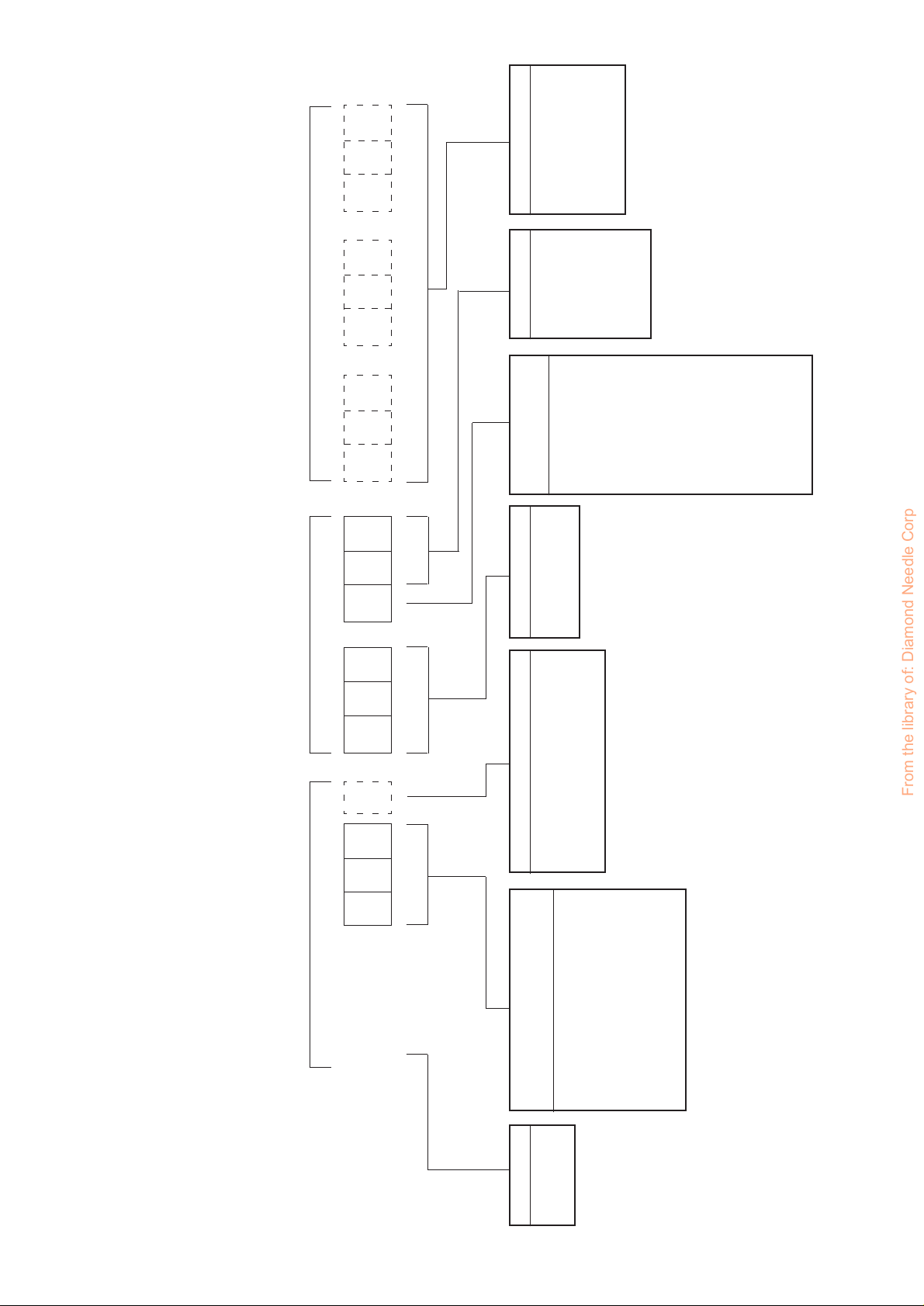

CONTENTS

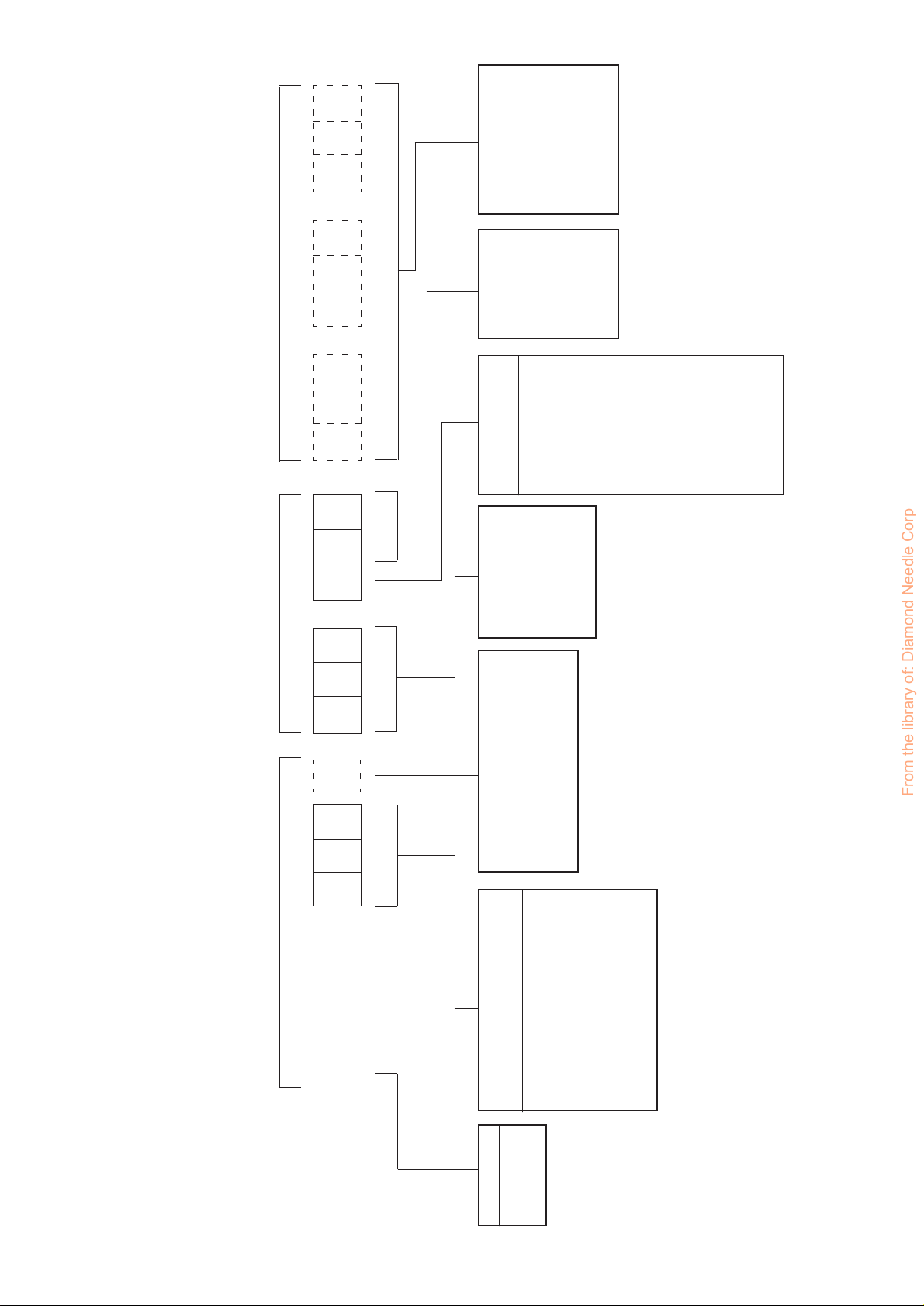

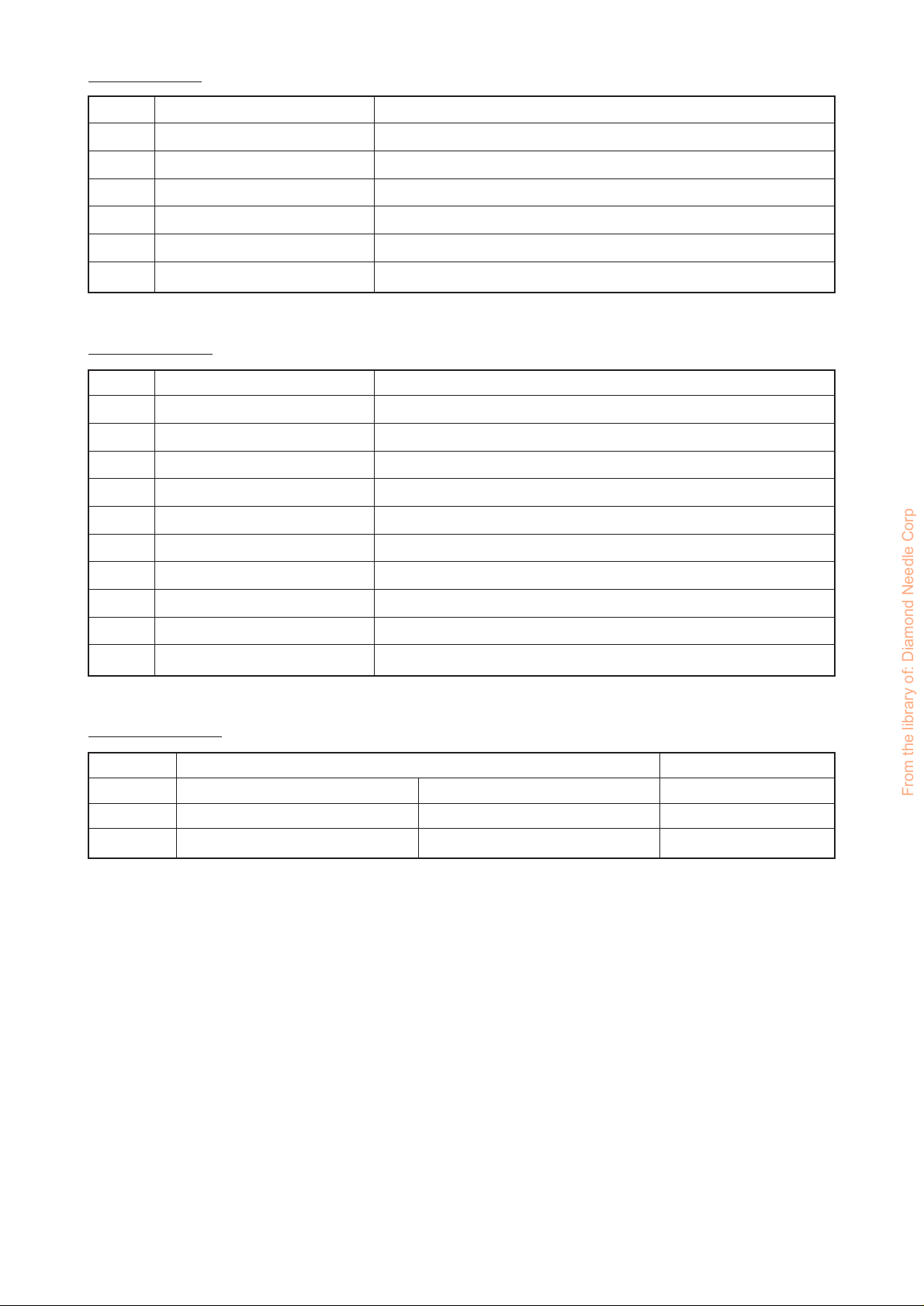

1. SPECIFICATIONS ....................................................................................................................... 1

2. MOTOR AND BELT..................................................................................................................... 2

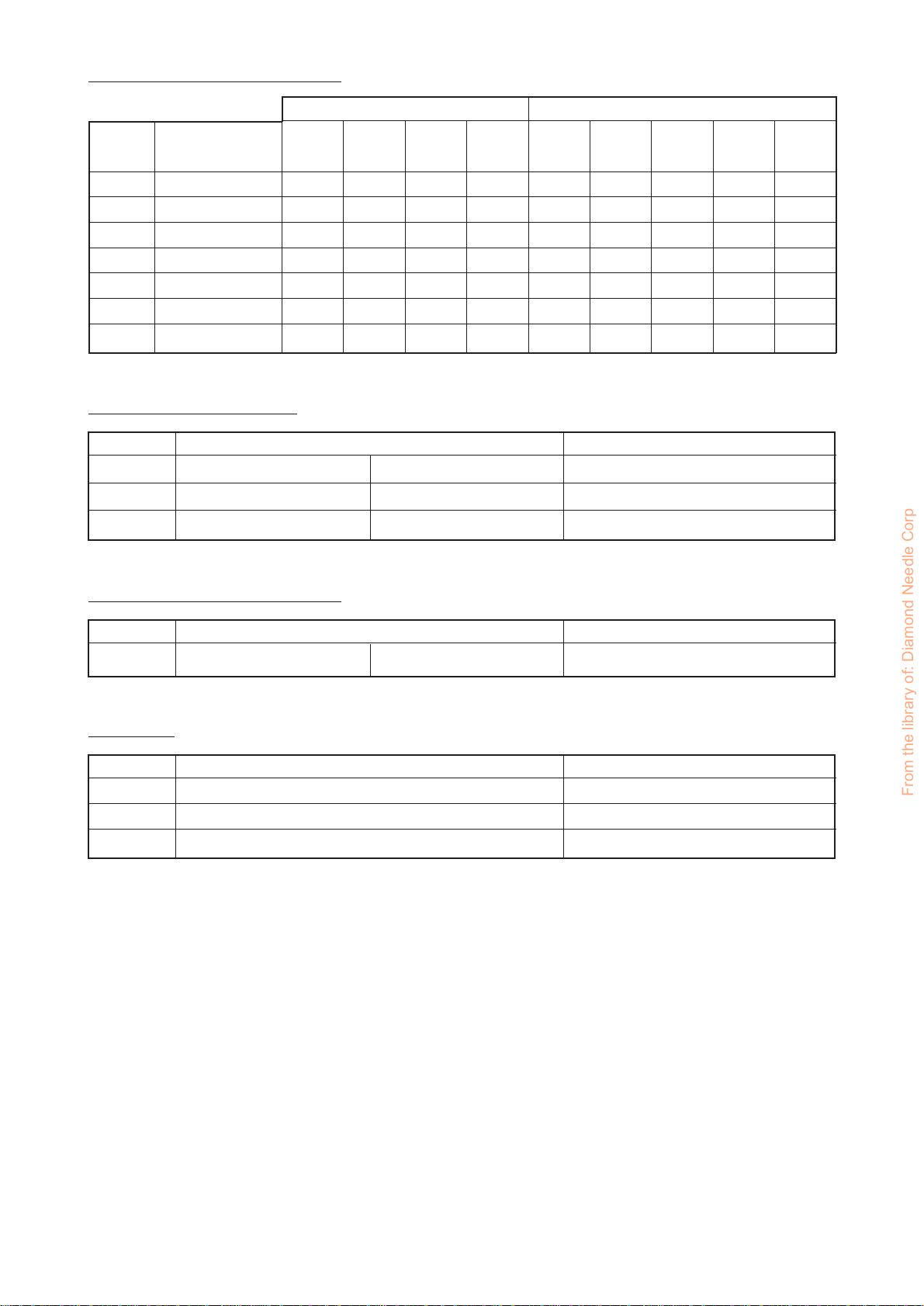

3. MODEL NUMBERING SYSTEM ................................................................................................. 3

4. STANDARD ADJUSTMENT ....................................................................................................... 7

(1) MF ............................................................................................................................................................................ 7

1) Timing relation between the needle and the feed .............................................................................................. 7

2) Adjusting the timing relation between the needle bar and looper (synchronization) : Without gauges ........................... 7

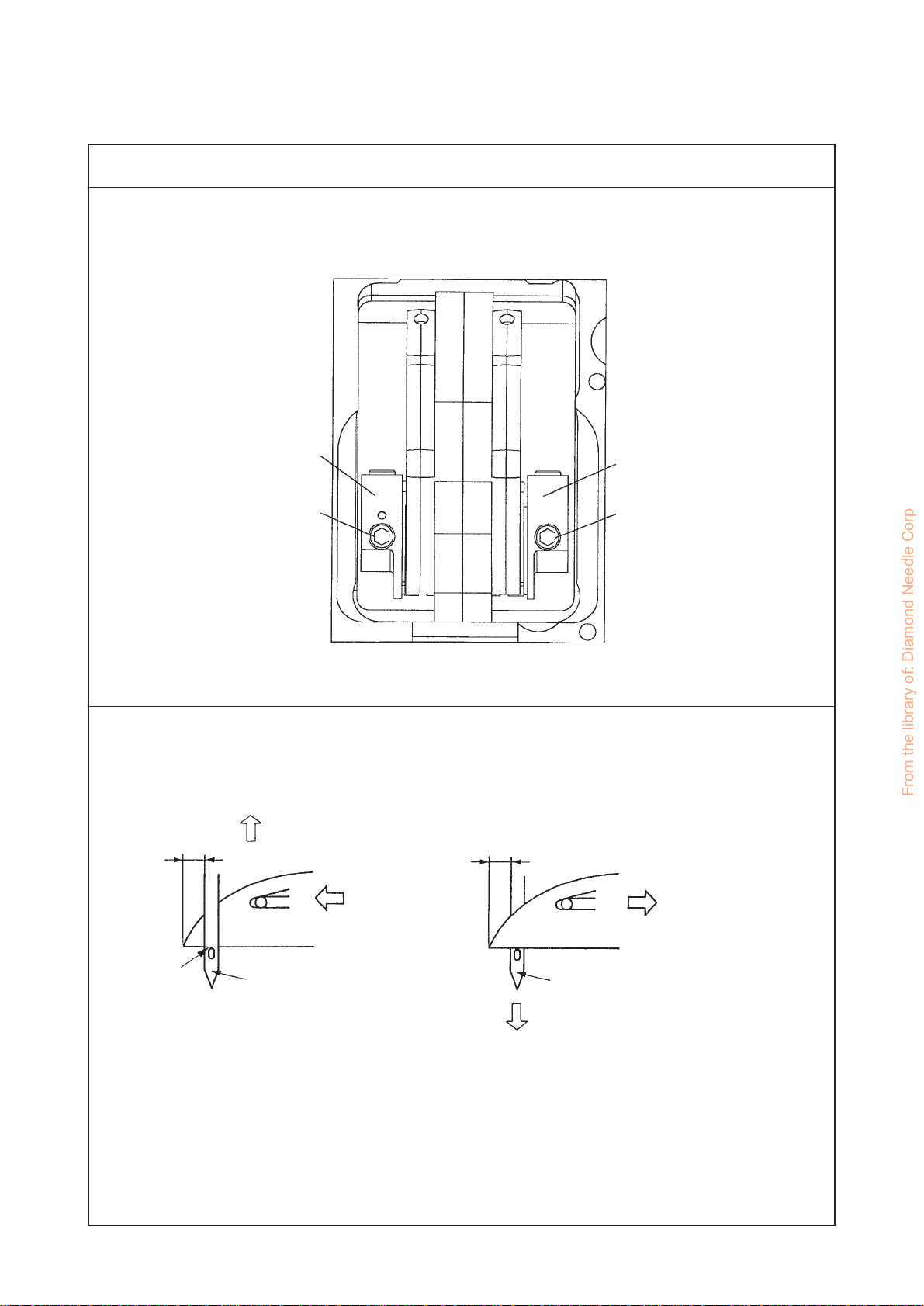

3) Returning amount of the looper ......................................................................................................................... 9

4) Height of the needle bar..................................................................................................................................... 9

5) Clearance between the looper and needle ...................................................................................................... 11

6) Adjusting amount of the looper-avoid .............................................................................................................. 11

7) Position of the needle guard ............................................................................................................................ 13

8) Position of the feed dog ................................................................................................................................... 15

9) Spreader .......................................................................................................................................................... 17

10) Looper thread cam ........................................................................................................................................... 19

11) Position of the presser bar ............................................................................................................................... 21

12) Position of the needle thread tension release (without thread trimmer)........................................................... 21

13) Position and height of the presser foot ............................................................................................................ 23

14) Position of the thread guide ............................................................................................................................. 23

(2) Thread trimmer device (MF) ................................................................................................................................ 27

1) Adjustment of the thread trimmer device ......................................................................................................... 27

2) Thread tension release (Looper thread trimmer device) .................................................................................. 29

(3) MFC ....................................................................................................................................................................... 31

1) Timing relation between the needle and the feed ............................................................................................ 31

2) Adjusting the timing of the needle bar and looper (Synchronization) : Without gauges................................... 31

3) Returning amount of the looper ....................................................................................................................... 33

4) Height of the needle bar................................................................................................................................... 33

5) Position of the needle guard ............................................................................................................................ 35

6) Clearance between the looper and needle ...................................................................................................... 35

7) Adjusting amount of the looper-avoid .............................................................................................................. 37

8) Position of the feed dog ................................................................................................................................... 39

9) Spreader .......................................................................................................................................................... 41

10) Looper thread cam ........................................................................................................................................... 43

11) Looper thread wrap-up preventing cam (Old type) .......................................................................................... 43

12) Position of the presser bar ............................................................................................................................... 45

13) Position of the needle thread tension release (without thread trimmer)........................................................... 45

14) Position and height of the presser foot ............................................................................................................ 47

15) Position of the thread guide ............................................................................................................................. 47

(4) Thread trimmer device (MFC) ............................................................................................................................. 51

1) Stroke adjustment (common to both elctromagnetic and pneumatic type) ...................................................... 51

2) Adjustment of the right position of movable knife (return)................................................................................ 51

3) Adjustment of stationary knife and looper thread clamp spring ....................................................................... 53

4) Adjustment of the position of movable knife’s pointed end .............................................................................. 53

5) Adjustment of operating speed of thread trimmer (pneumatic type) ................................................................ 55

6) Confirmation of thread trimming....................................................................................................................... 55

7) Adjustment of pneumatic lifter.......................................................................................................................... 57

8) Adjustment of tension release (equipped with thread trimmer)........................................................................ 59

9) Adjustment of proximity switch......................................................................................................................... 59

10) Adjustment of top covering thread trimmer ...................................................................................................... 61

5. ASSEMBLING AND ADJUSTMENT OF FIXED CAM THREAD TAKE-UP ............................. 63

(1) Parts used............................................................................................................................................................. 63

(2) Needle bar cam plate and needle bar fork thread take-up ............................................................................... 65

(3) Needle thread guide and medium thread path base......................................................................................... 65

(4) Spreader thread guide ......................................................................................................................................... 67

1) Parts used ........................................................................................................................................................ 67

2) Assembling and adjustment of spreader thread guide..................................................................................... 67

6. OTHER PRECAUTIONS ........................................................................................................... 68

(1) Points to which Locktite is applied .................................................................................................................... 68

7. TROUBLES AND CORRECTIVE MEASURES......................................................................... 69

8. DRAWING OF TABLE............................................................................................................... 84

(1) Semi-submerged type for MF ............................................................................................................................. 84

(2) Desktop type for MF ............................................................................................................................................ 86

(3) Desktop type for MF with fabric under trimmer ................................................................................................ 87

(4) Desktop type for MFC .......................................................................................................................................... 88

(5) Semi-submerged type for MFC ........................................................................................................................... 89

(6) Semi-submerged down table for MFC ............................................................................................................... 90

(7) Table for MFC with tension roller ....................................................................................................................... 91

From the library of: Diamond Needle Corp