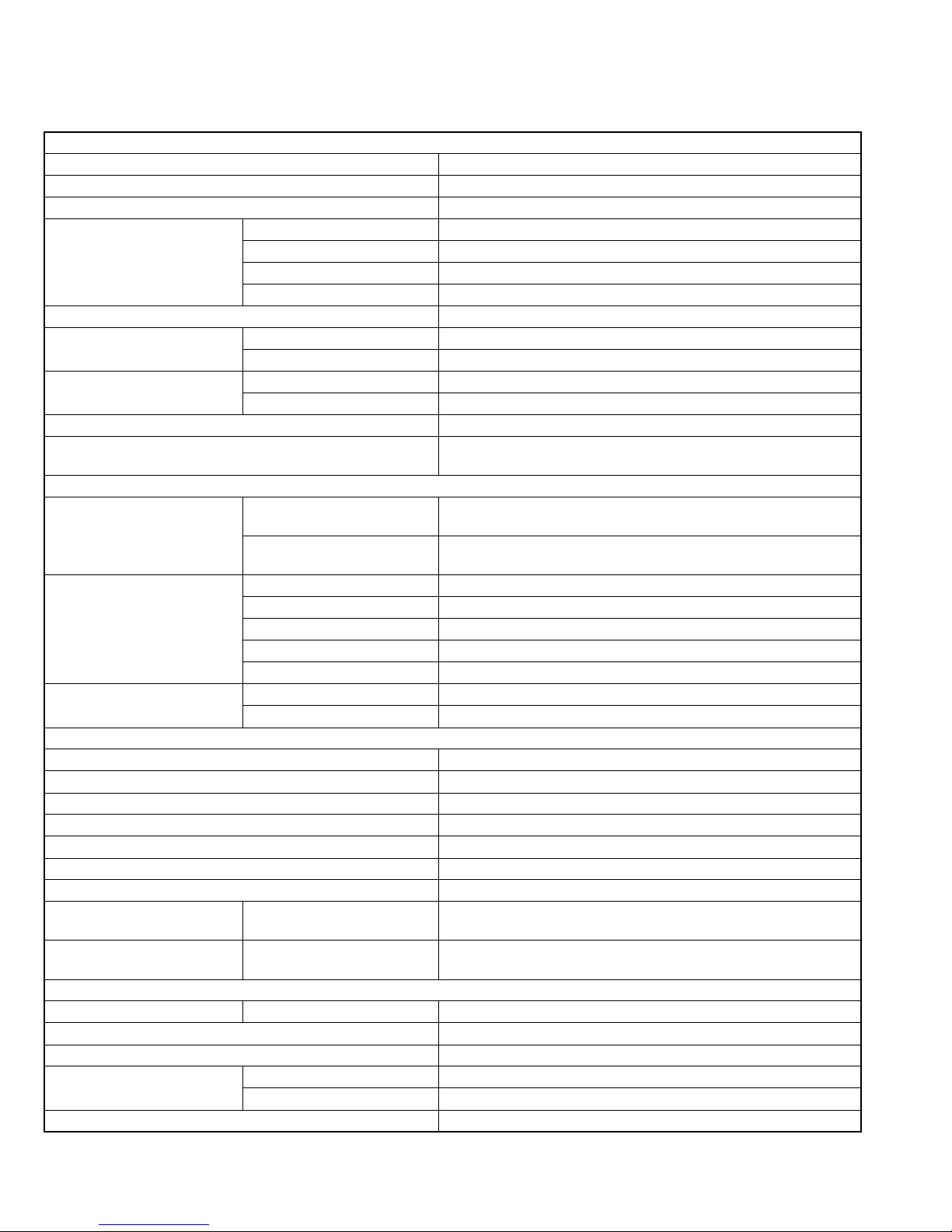

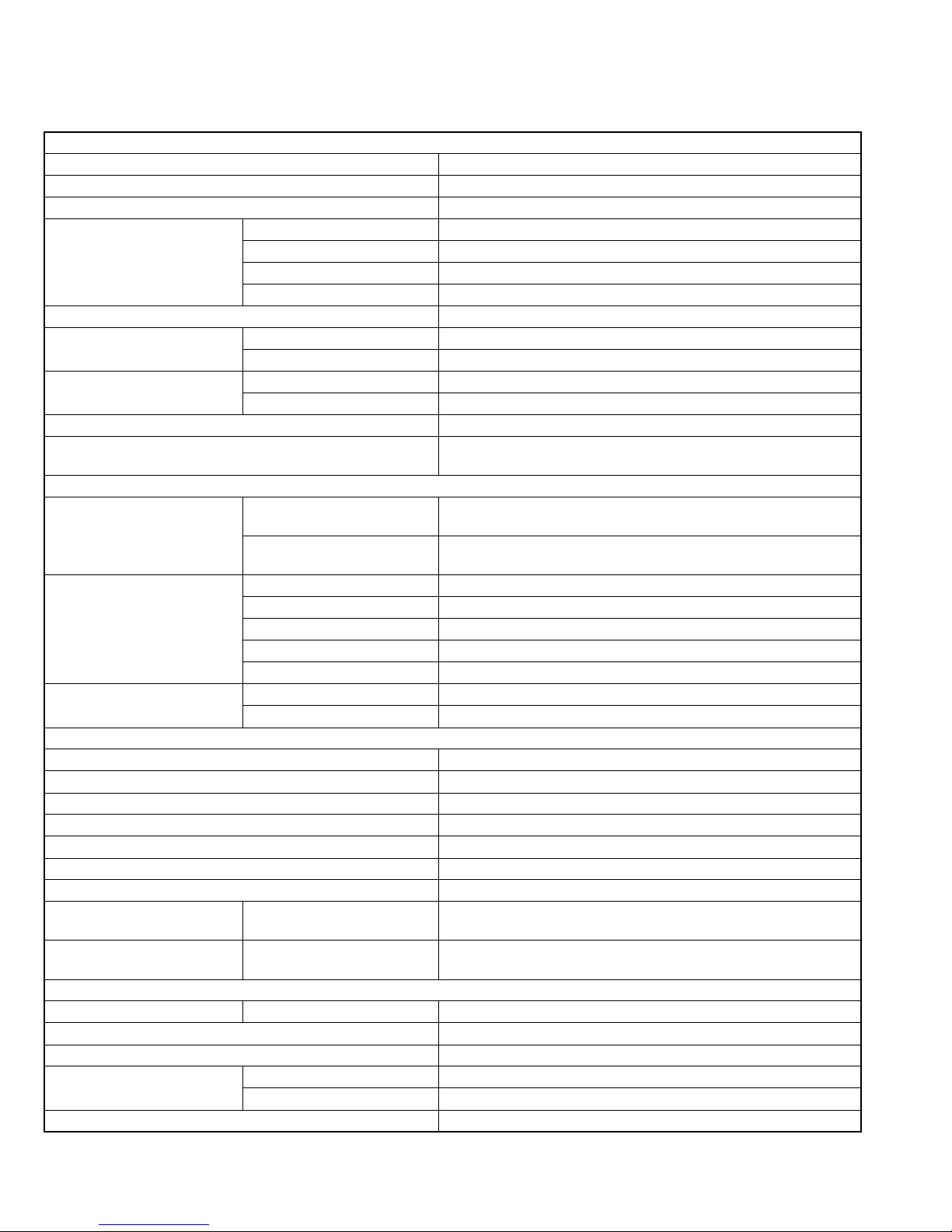

1-2 (No.MA376<Rev.002>)

SPECIFICATION

KD-AR390/KD-G340/KD-S25

Design and specifications are subject to change without notice.

AUDIO AMPLIFIER SECTION

Power Output 20 W RMS ×4 Channels at 4 Ωand < or = 1% THD+N

Signal-to-Noise Ratio 80 dBA (reference: 1 W into 4 Ω)

Load Impedance 4 Ω(4 Ωto 8 Ωallowance)

Tone Control Range Bass ±12 dB (60 Hz, 80 Hz, 100 Hz, 120 Hz)

Mid-range ±12 dB (500 Hz, 1.0 kHz, 1.5 kHz, 2.5 kHz)

Treble ±12 dB (7.5 kHz 10.0 kHz 12.5 kHz 15.0 kHz)

Q (band width) Q0.5 to Q2.0

Frequency Response 40 Hz to 20 000 Hz

Line-Out Level/Impedance KD-AR390 5.0 V/20 kΩload (full scale)

KD-G340/KD-S25 2.5 V/20 kΩload (full scale)

Subwoofer-Out Level/Impedance

KD-AR390 5.0 V /20 kΩload (full scale)

KD-G340/KD-S25 2.5 V/20 kΩload (full scale)

Output Impedance 1 kΩ

Other Terminal AUX (auxiliary) input jack CD changer jack Steering wheel remote

input (only for KD-AR390) Antenna

TUNER SECTION

Frequency Range FM

with channel interval set to 100 kHz or 200 kHz : 87.5 MHz to 107.9 MHz

with channel interval set to 50 kHz : 87.5 MHz to 108.0 MHz

AM with channel interval set to 10 kHz : 530 kHz to 1 710 kHz

with channel interval set to 9 kHz : 531 kHz to 1 602 kHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz)

65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

AM Tuner Sensitivity 20 µV

Selectivity 35 dB

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format

(MPEG1/2 Audio Layer 3)

Max. Bit Rate 320 kbps

WMA (Windows Media® Audio)

Decoding Format

Max. Bit Rate 192 kbps

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C (32°F to 104°F)

Dimensions (W

×

H

×

D) (approx.)

Installation Size 182 mm ×52 mm ×160 mm (7-3/16” ×2-1/16” ×6-5/16”)

Panel Size 188 mm ×58 mm ×6 mm (7-7/16” ×2-5/16” ×1/4”)

Mass 1.3 kg (2.9 lbs) (excluding accessories)