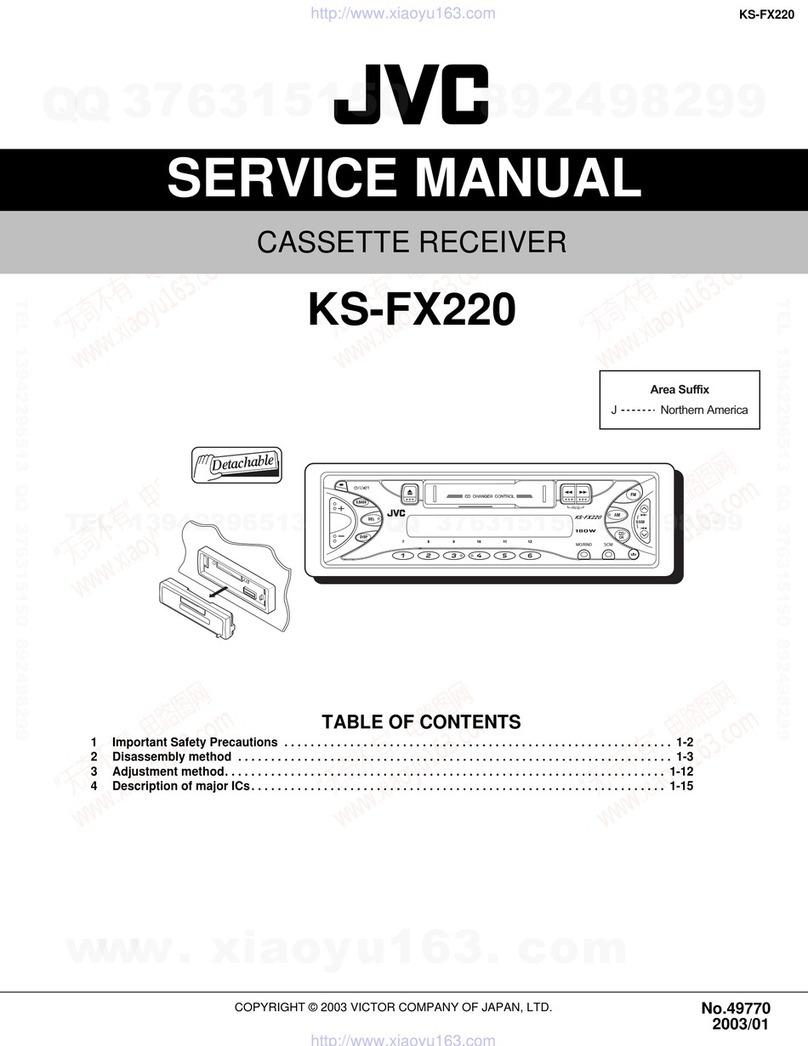

1-2 (No.MA158)

SPECIFICATION

Design and specifications are subject to change without notice.

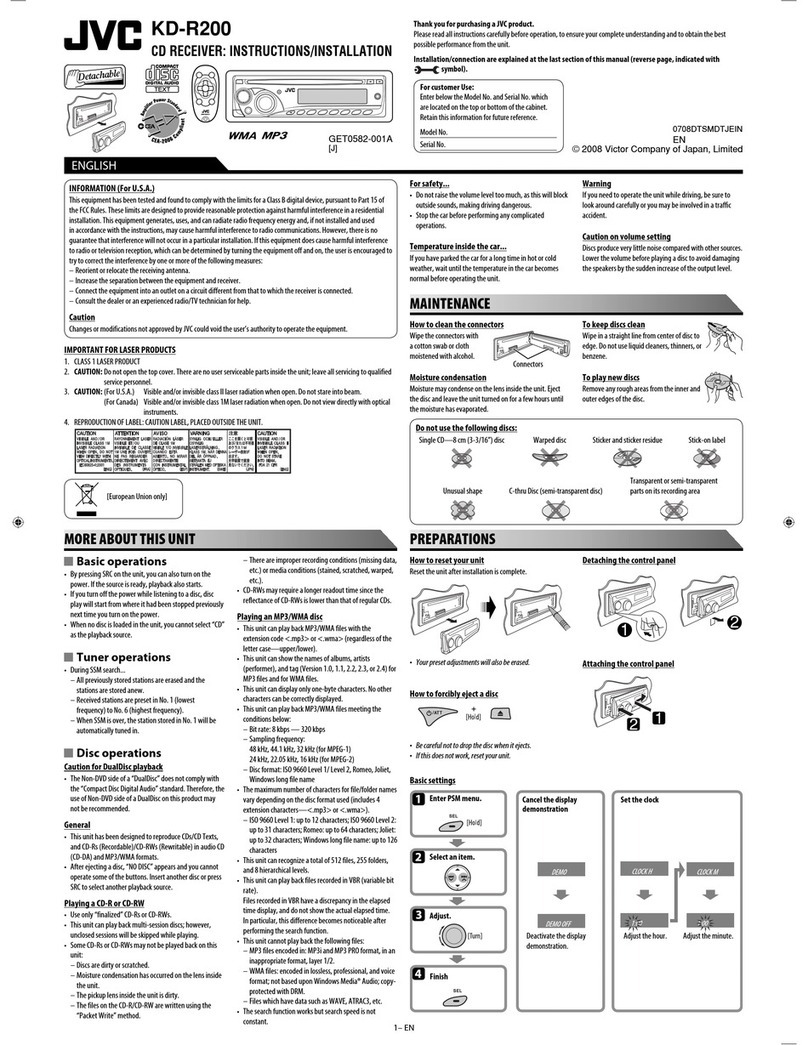

AUDIO AMPLIFIER SECTION

Maximum Power Output Front 50 W per channel

Rear 50 W per channel

Continuous Power Output (RMS) Front 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Rear 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Load Impedance 4 Ω(4 Ωto 8 Ωallowance)

Equalizer Control Range Frequencies 60 Hz, 150 Hz, 400 Hz, 1 kHz, 2.4 kHz, 6 kHz, 15 kHz

Level ±10 dB

Signal-to-Noise Ratio 70 dB

Audio Output Level Analog (2nd AUDIO OUT) 6 mW (at 16 Ω)

Digital (DIGITAL OUT: Optical) Signal wave length : 660 nm

Output level : -21 dBm to -15 dBm

Line-Out Level/Impedance 5.0 V/20 kΩload (full scale)

Output Impedance 1 kΩ

Subwoofer-Out Level/Impedance 2.0 V/20 kΩload (full scale)

Color System PAL/NTSC

Video Output (composite) 1 Vp-p/75 Ω

Other Terminals LINE IN, CD changer

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz

AM 531 kHz to 1 602 kHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

Capture Ratio 1.5 dB

AM Tuner Sensitivity 20 µV

Selectivity 35 dB

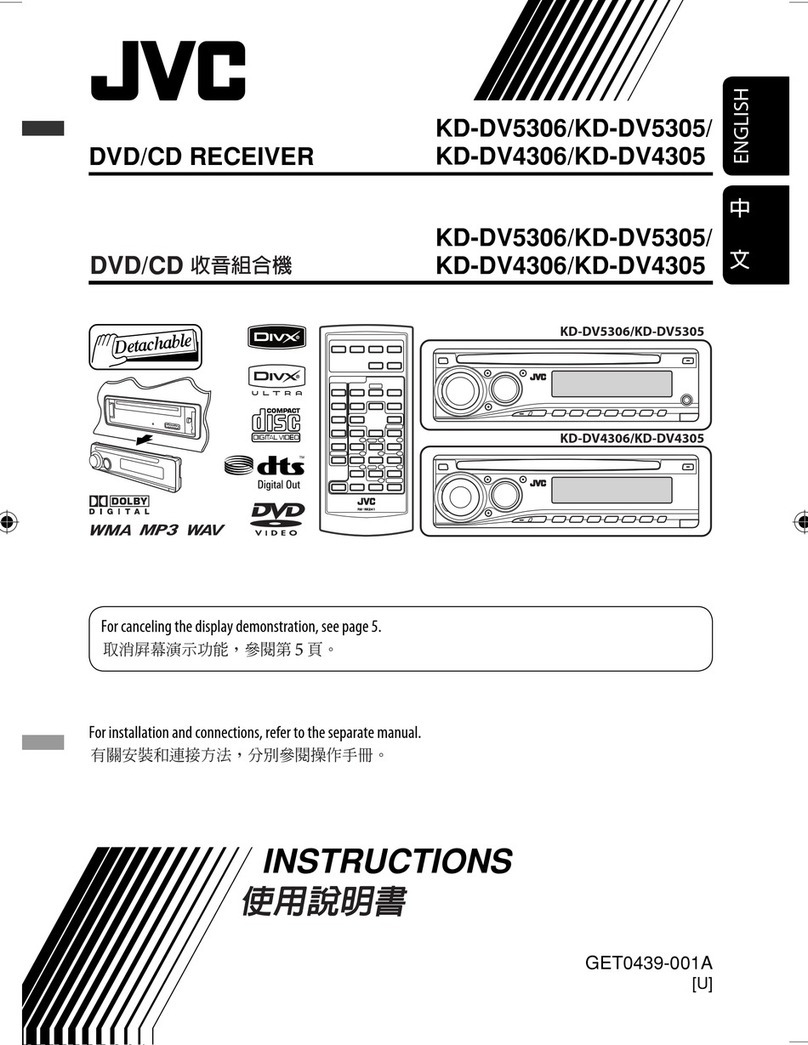

DVD/CD PLAYER SECTION

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response DVD, fs=48 kHz/96 kHz 16 Hz to 22 000 Hz

VCD, CD, MP3, WMA 16 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 (MPEG Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media Audio) Max. Bit Rate: 192 kbps

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W ×H ×D) Installation Size (approx.) 182 mm ×52 mm ×158 mm

Panel Size (approx.) 188 mm ×58 mm ×11 mm

Mass (approx.) 1.7 kg (excluding accessories)

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Q

Q

3

7

6

3

1

5

1

5

0

9

9

2

8

9

4

2

9

8

T

E

L

1

3

9

4

2

2

9

6

5

1

3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

http://www.xiaoyu163.com