1-2 (No.MA057B)

SPECIFICATION

Design and specifications are subject to change without notice.

AUDIO AMPLIFIER SECTION

Maximum Power Output Front 50 W per channel

Rear 50 W per channel

Continuous Power Output (RMS) Front 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Rear 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Load Impedance 4 Ω(4 Ωto 8 Ωallowance)

Equalizer Control Range Low ±12 dB (60 Hz, 80 Hz, 100 Hz, 120 Hz)

Mid ±12 dB

High ±12 dB (8 kHz, 10 kHz, 12 kHz, 15 kHz)

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-Out Level/Impedance 2.0 V/20 kΩload (full scale)

Output Impedance 1 kΩ

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz

AM (MW) 522 kHz to 1 620 kHz

(LW) 144 kHz to 279 kHz

[FM Tuner] Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 30 dB

Capture Ratio 1.5 dB

[MW Tuner] Sensitivity 20 µV

Selectivity 35 dB

[LW Tuner] Sensitivity 50 µV

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 decoding format MPEG1/2 Audio Layer 3 Max. Bit Rate:320 Kbps

WMA (Windows Media Audio) decoding format Max. Bit Rate:192 Kbps

GENERAL

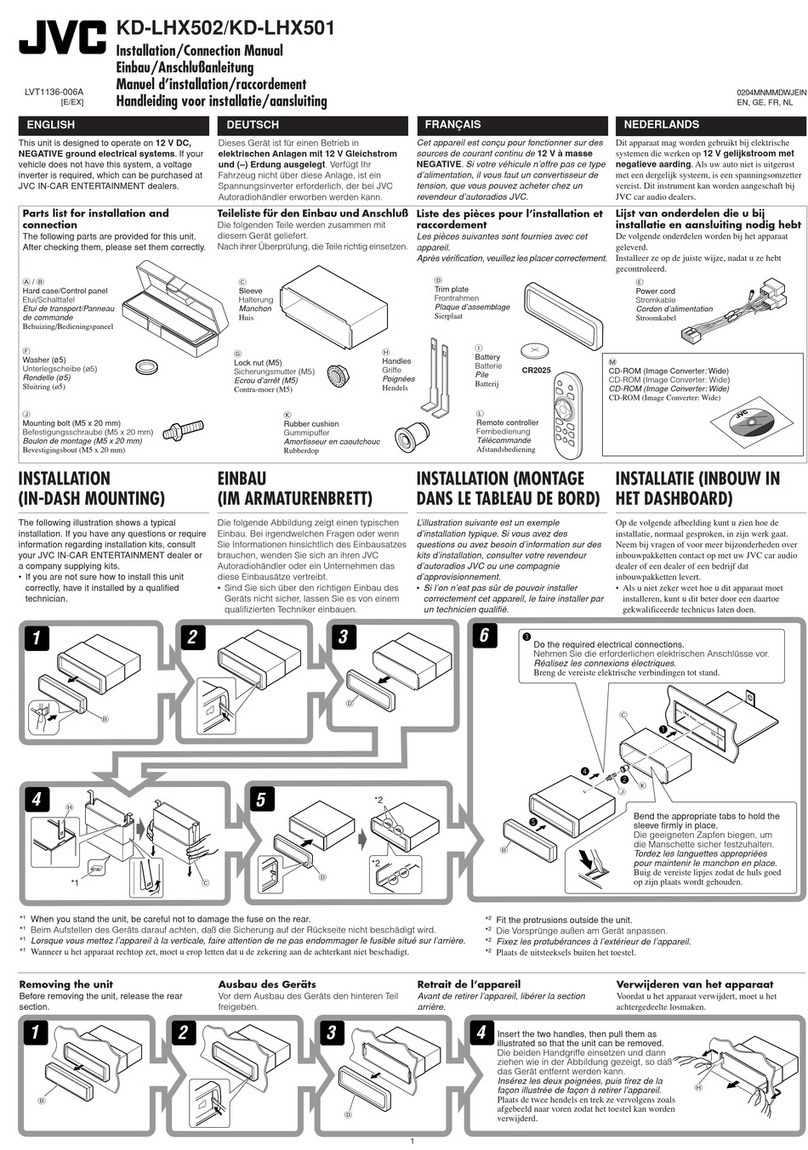

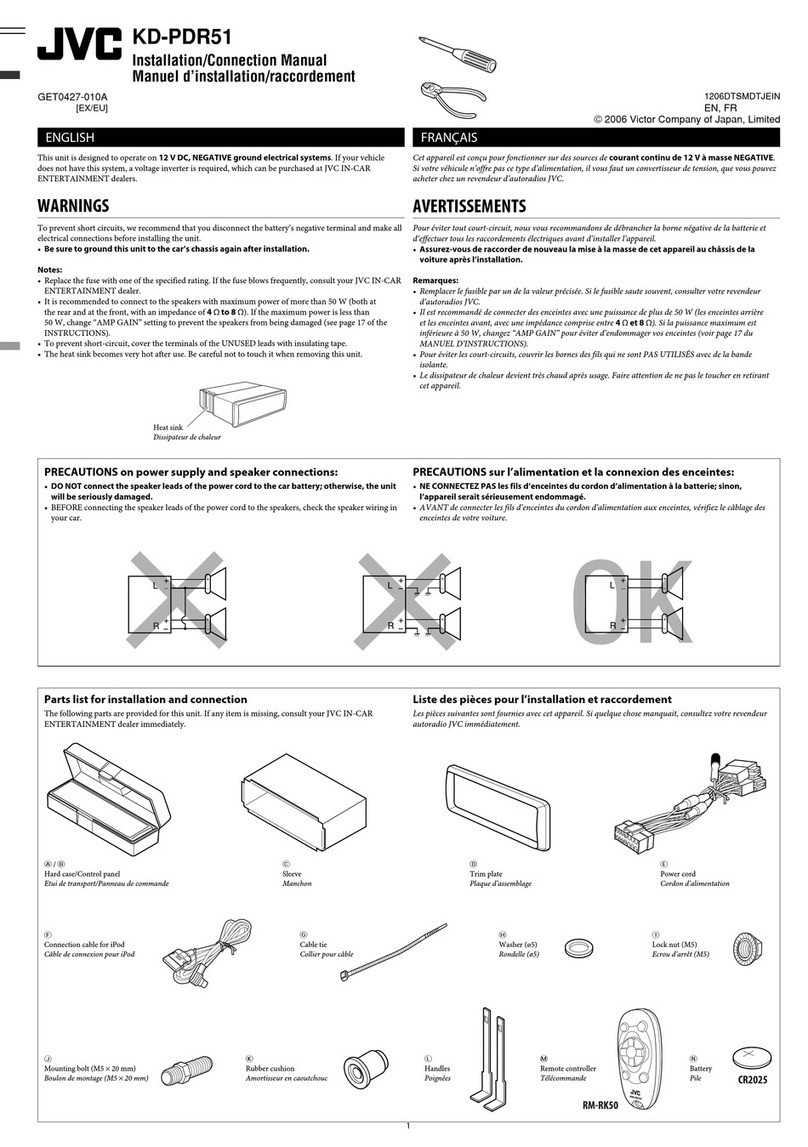

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System: Negative ground

Allowable Operating Temperature 0ºC to +40ºC

Dimensions (W ×H ×D) Installation Size (approx.) 182 mm ×52 mm ×159 mm

Panel Size (approx.) 188 mm ×58 mm ×12 mm

Mass (approx.) 1.5 kg (excluding accessories)