KS-FX621

(No.49825)1-5

2.1.7 Removing the cassette mechanism assembly

(See Fig.7)

• Prior to performing the following procedure, remove the front

panel assembly, bottom cover, front chassis, heat sink, rear

panel and main board.

(1) Remove the four screws Hattaching the cassette mecha-

nism assembly from the top chassis.

Fig.7

2.1.8 Removing the mecha board

(See Fig.8)

• Prior to performing the following procedure, remove the front

panel assembly, bottom cover, front chassis, heat sink, rear

panel, main board and cassette mechanism assembly.

(1) Disconnect the wire from the connectors CN402 and

CN403 on the mecha board.

(2) Remove the screw Jattaching the mecha board.

Fig.8

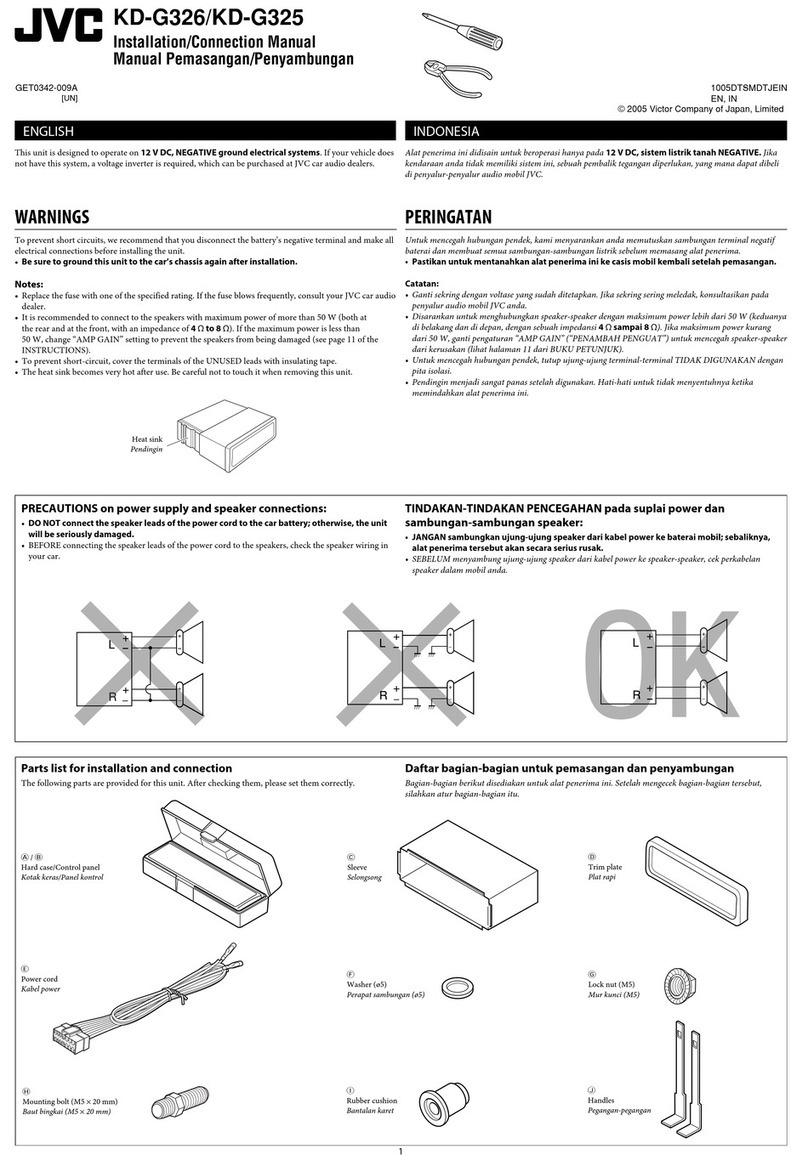

2.1.9 Removing the front board

(See Figs.9 to 11)

• Prior to performing the following procedure, remove the front

panel assembly.

(1) Remove the four screws Lattaching the rear cover on the

back of the front panel assembly. (See fig.9)

(2) Release the eleven joints f, the front panel and the rear

cover become separate. (See fig.10)

(3) Remove the front board from the front panel assembly.

(See fig.11)

Fig.9

Fig.10

Fig.11

HH

H H

Top chassis

Cassette mechanism assembly

J

CN402

CN401 CN403

K

K K

K

Joint h

Joint h

Joint h

Joint h

Front panel assembly

Rear cover

LCD & Key control board