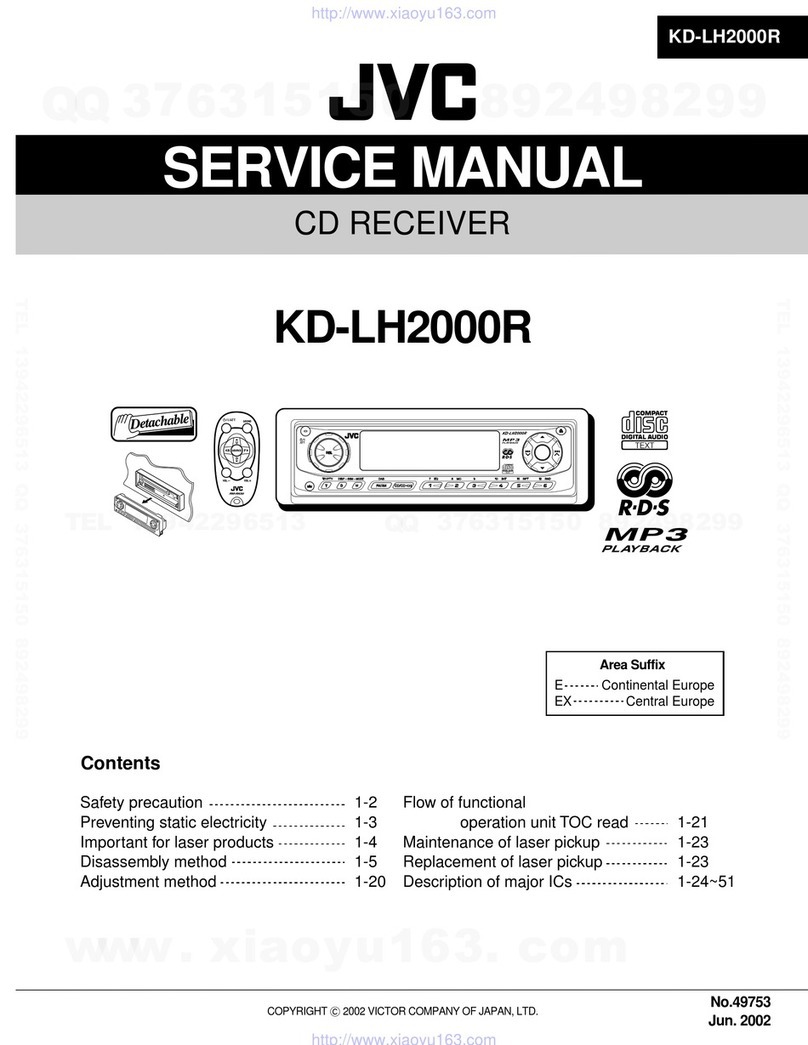

(No.MA596<Rev.005>)5/28

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purpos-

es. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be per-

formed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteris-

tics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by us-

ing replacement components rated for higher voltage, watt-

age, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Ser-

vice Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety charac-

teristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassem-

bling.

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of pre-

forming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

1.5 Remote control

The Lithium battery is in danger of explosion if replaced incor-

rectly. Replace it only with the same or equivalent type.

1.6 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electric-

ity stored in the body, fabric, etc. is discharged, can destroy the

laser diode in the traverse unit (optical pickup). Take care to pre-

vent this when performing repairs.

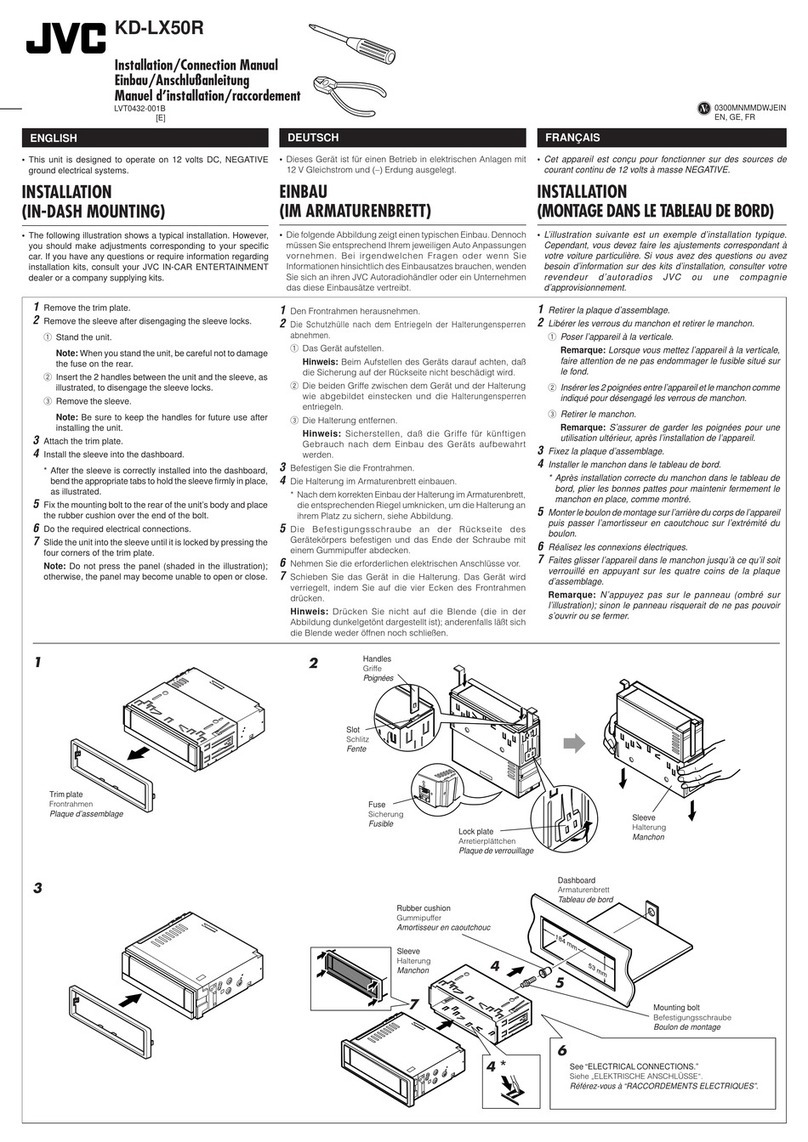

1.6.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup

(laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are

being performed.

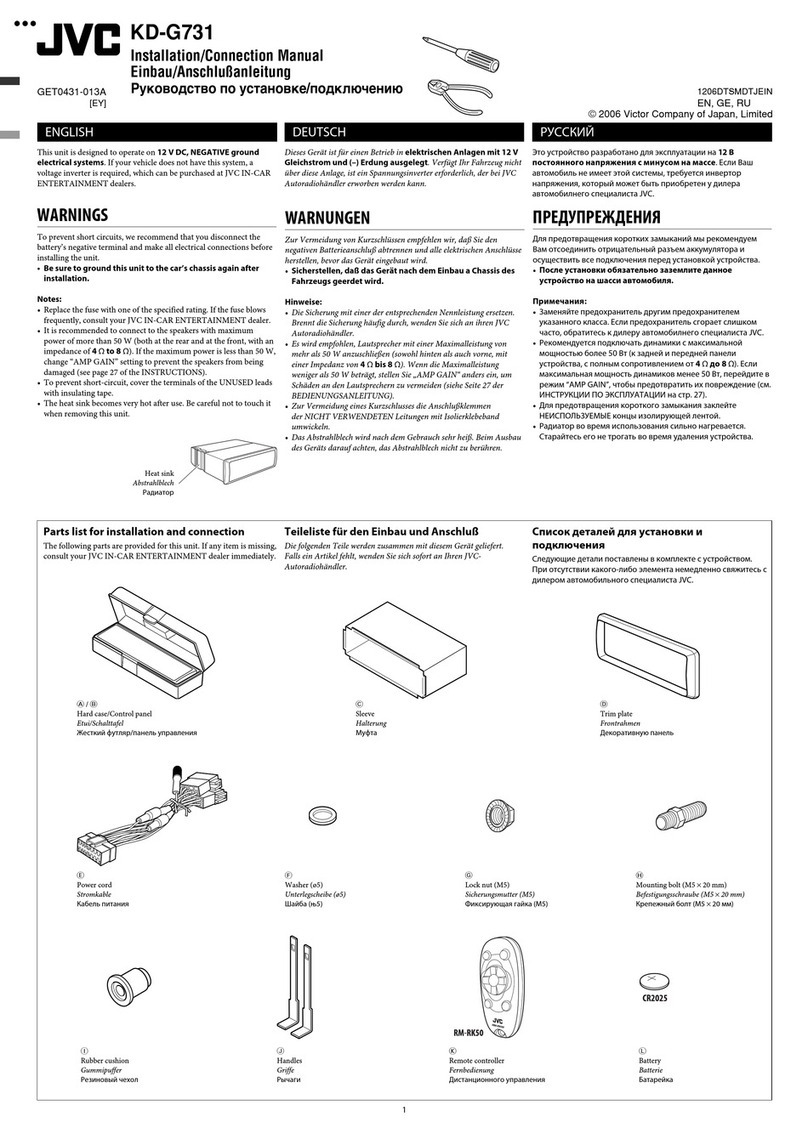

(1) Ground the workbench

Ground the workbench by laying conductive material (such

as a conductive sheet) or an iron plate over it before plac-

ing the traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity

built up in your body.

(3) Handling the optical pickup

• In order to maintain quality during transport and before

installation, both sides of the laser diode on the replace-

ment optical pickup are shorted. After replacement, re-

turn the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser di-

ode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

1M

Conductive material

(conductive sheet) or iron plate

(caption)

Anti-static wrist strap