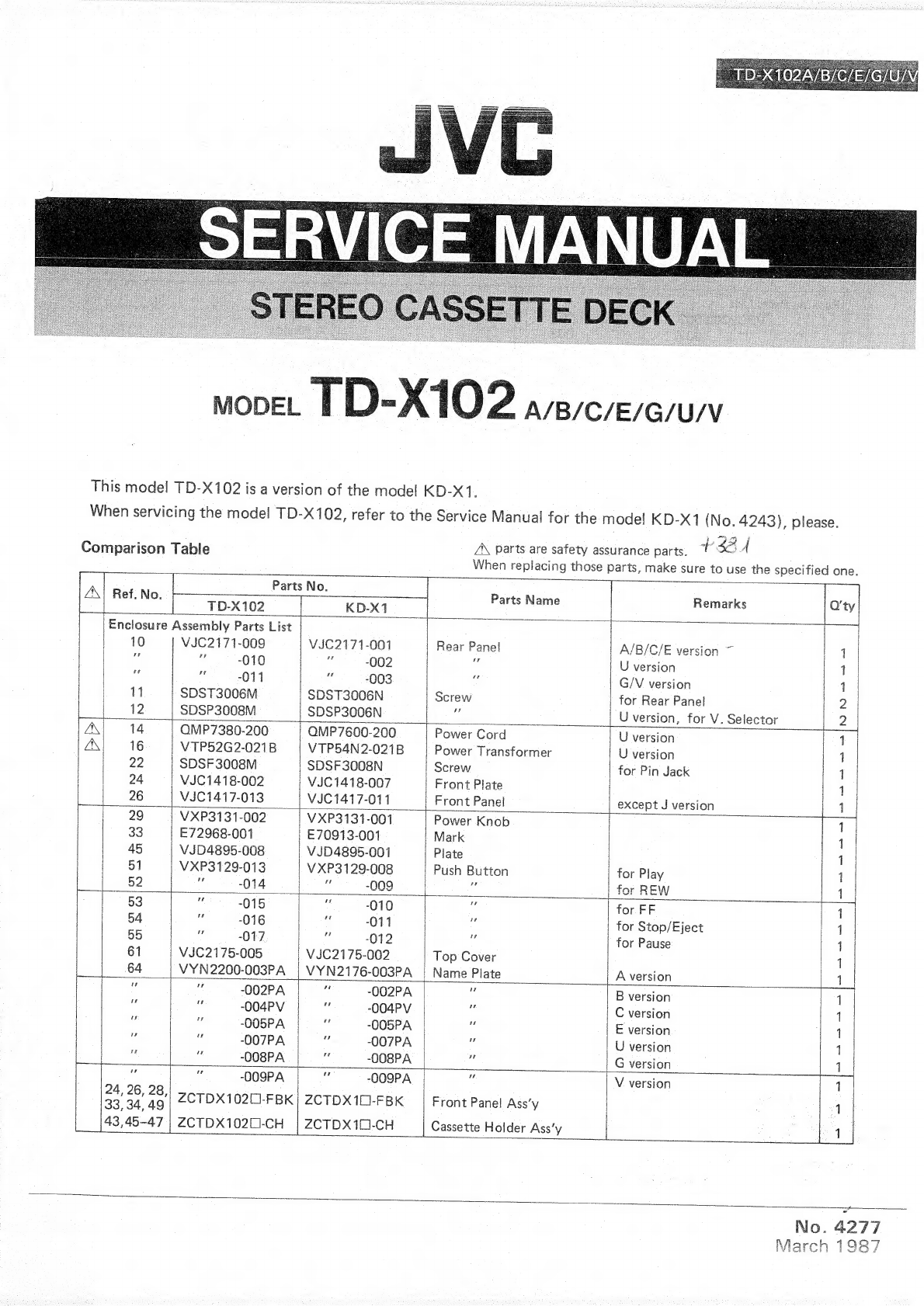

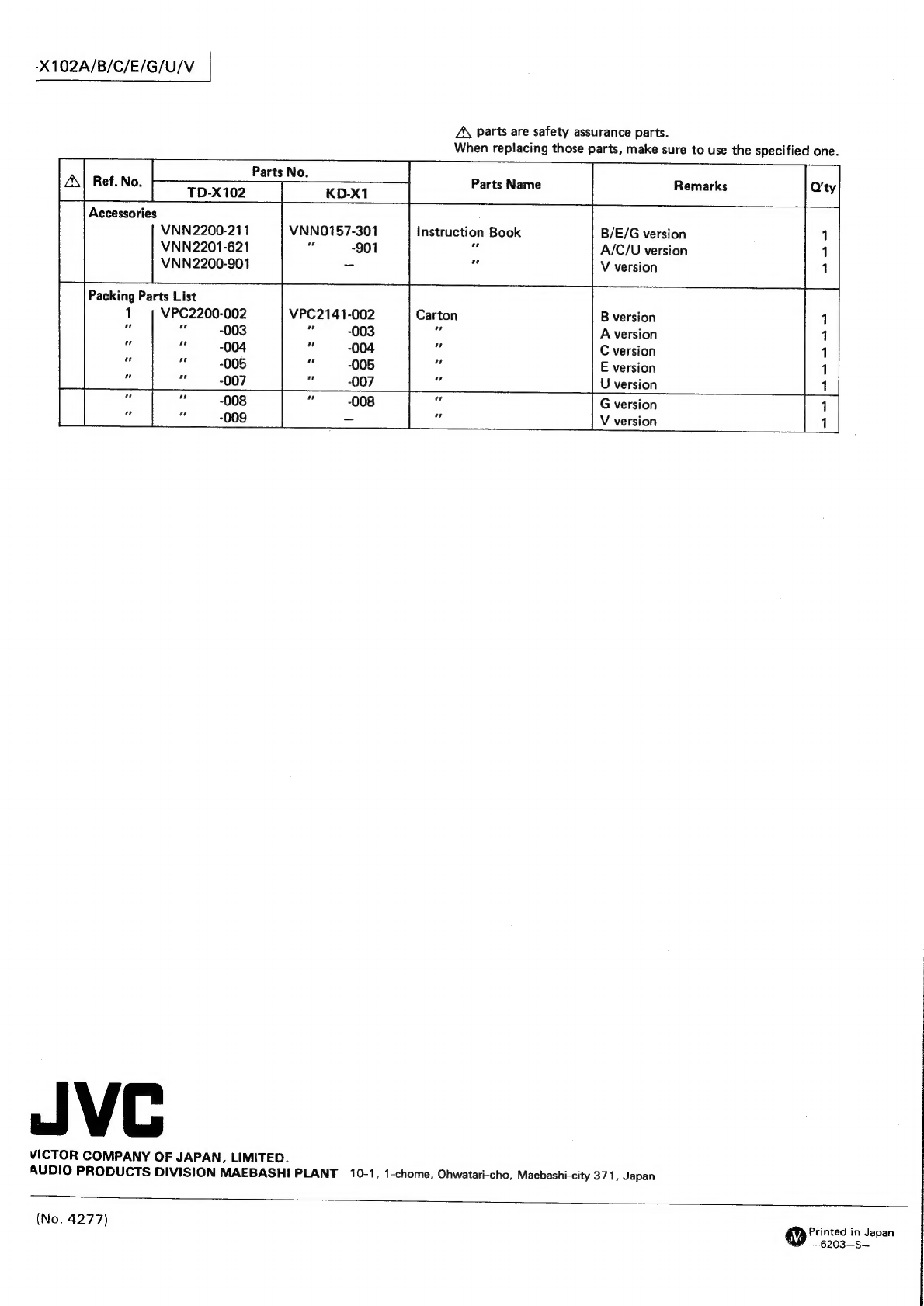

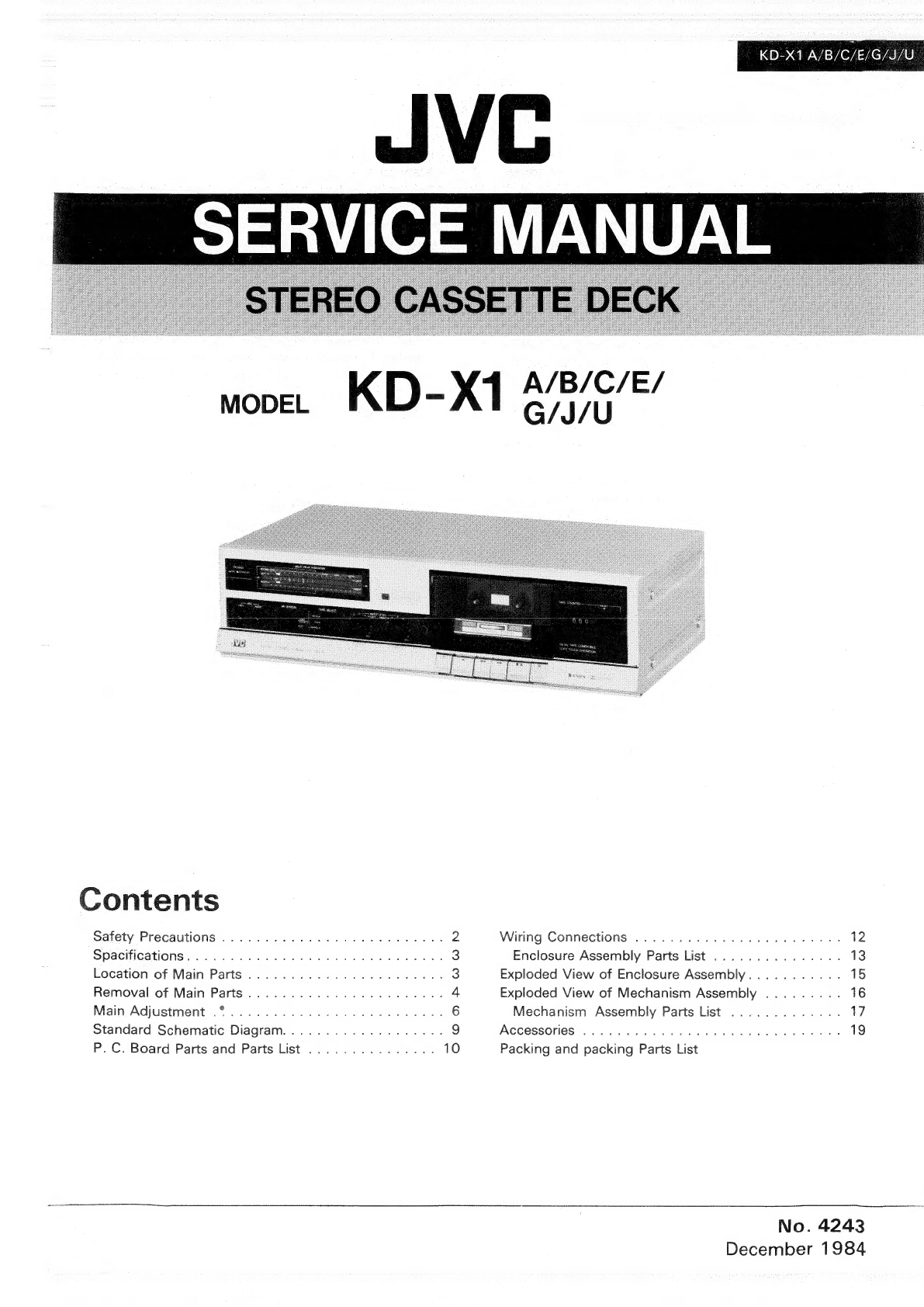

JVC TD-X102 User manual

Other JVC Cassette Player manuals

Popular Cassette Player manuals by other brands

Sony

Sony CFS-B15 - Am/fm Stereo Cassette Recorder operating instructions

Sony

Sony WMFS220 - Portable Sports AM/FM Cassette... operating instructions

Aiwa

Aiwa HS-TA21 operating instructions

Sanyo

Sanyo MCD-ZX700F Service manual

Aiwa

Aiwa CS-P77 Service manual

Sony

Sony Pressman TCM-465V operating instructions