JVC TM-1500PS User manual

Other JVC Monitor manuals

JVC

JVC DDX5707S User manual

JVC

JVC 0509SKH-SW-MT User manual

JVC

JVC DT-V2000SU - Dtv Monitor User manual

JVC

JVC TM-A170G User manual

JVC

JVC KW-M180BT User manual

JVC

JVC LCT2142-001A-H User manual

JVC

JVC KW-M560BT User manual

JVC

JVC GD-F46L1 User manual

JVC

JVC DT-V21G2 User manual

JVC

JVC TM-A101GU - Multi-purpose Color Monitor User manual

JVC

JVC DT-U17 User manual

JVC

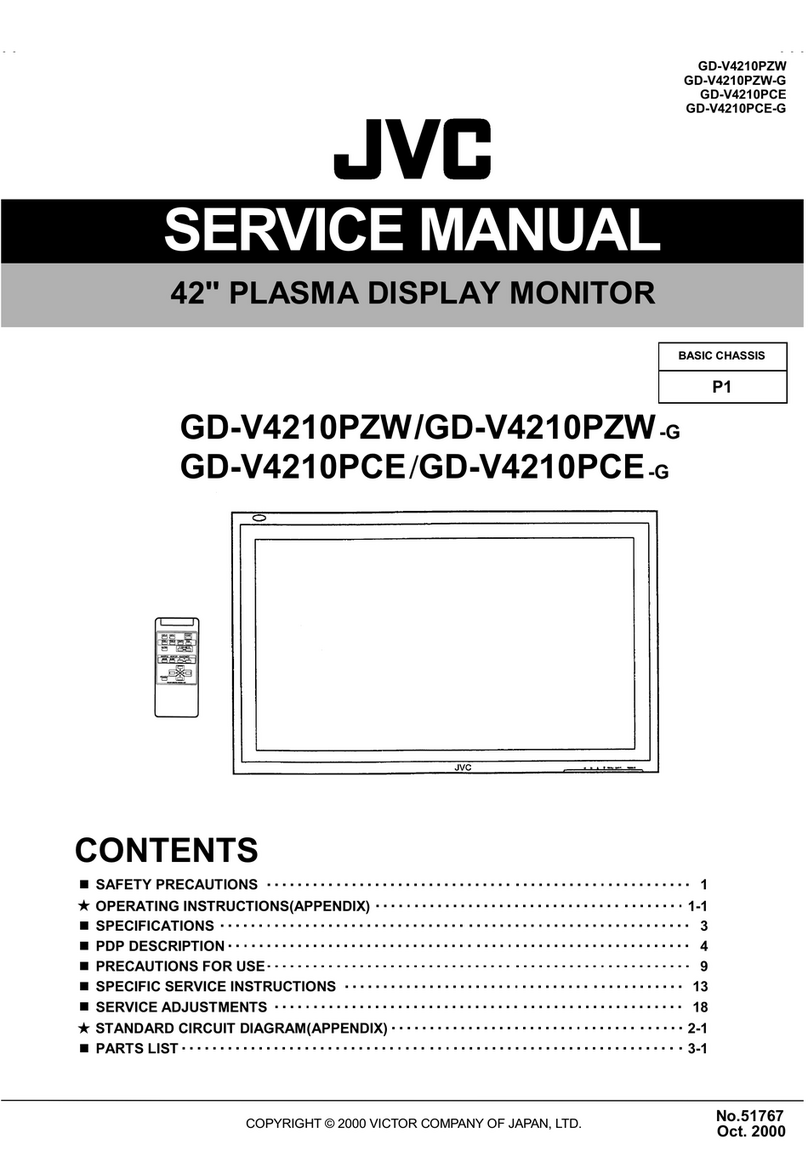

JVC GD-V4210PZW-G User manual

JVC

JVC VF-HP900 User manual

JVC

JVC LT-24CM69BE User manual

JVC

JVC DT-V1900CG/E User manual

JVC

JVC LT-55N7115AM User manual

JVC

JVC KV-MH6510 User manual

JVC

JVC DT-V1910CG/U User manual

JVC

JVC TM-A170G User manual

JVC

JVC TM-H1700GU - Color Monitor User manual