JVC KD-X2 User manual

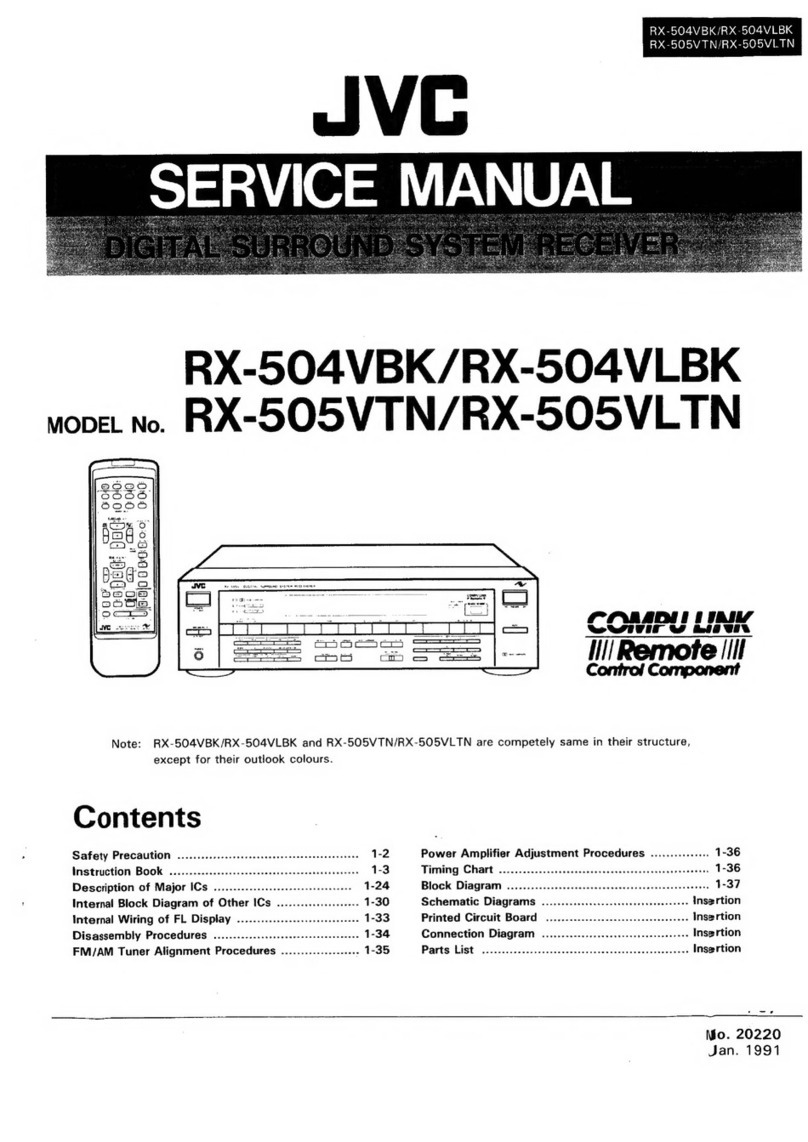

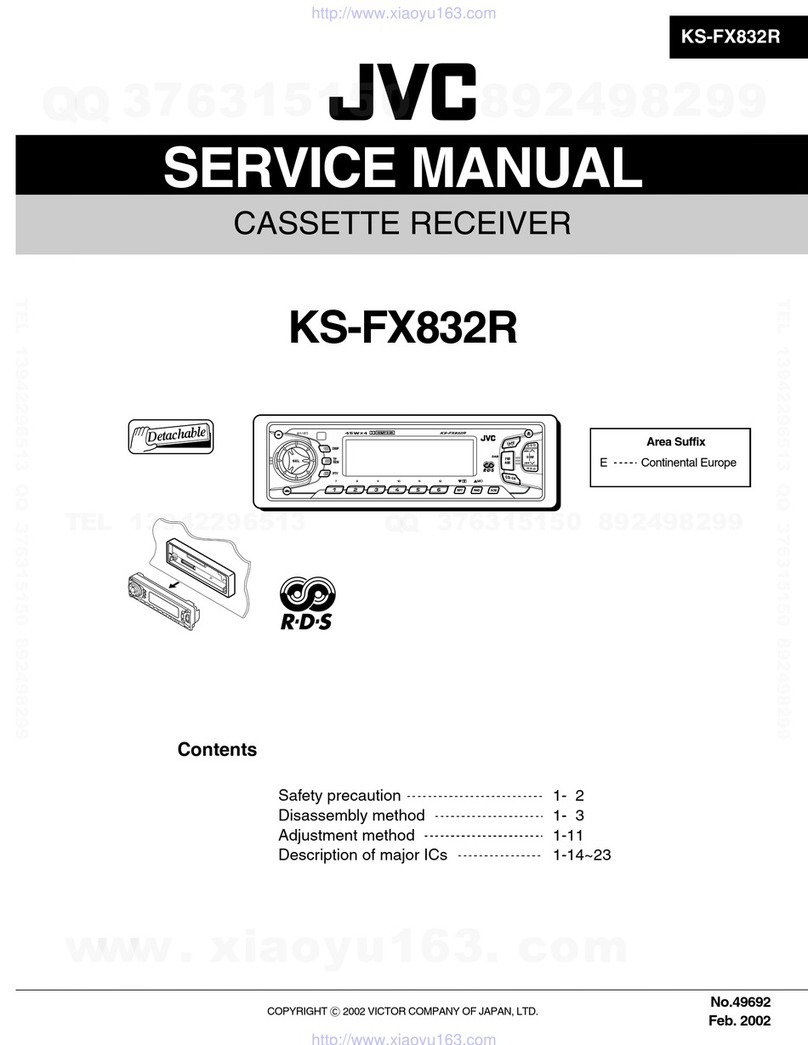

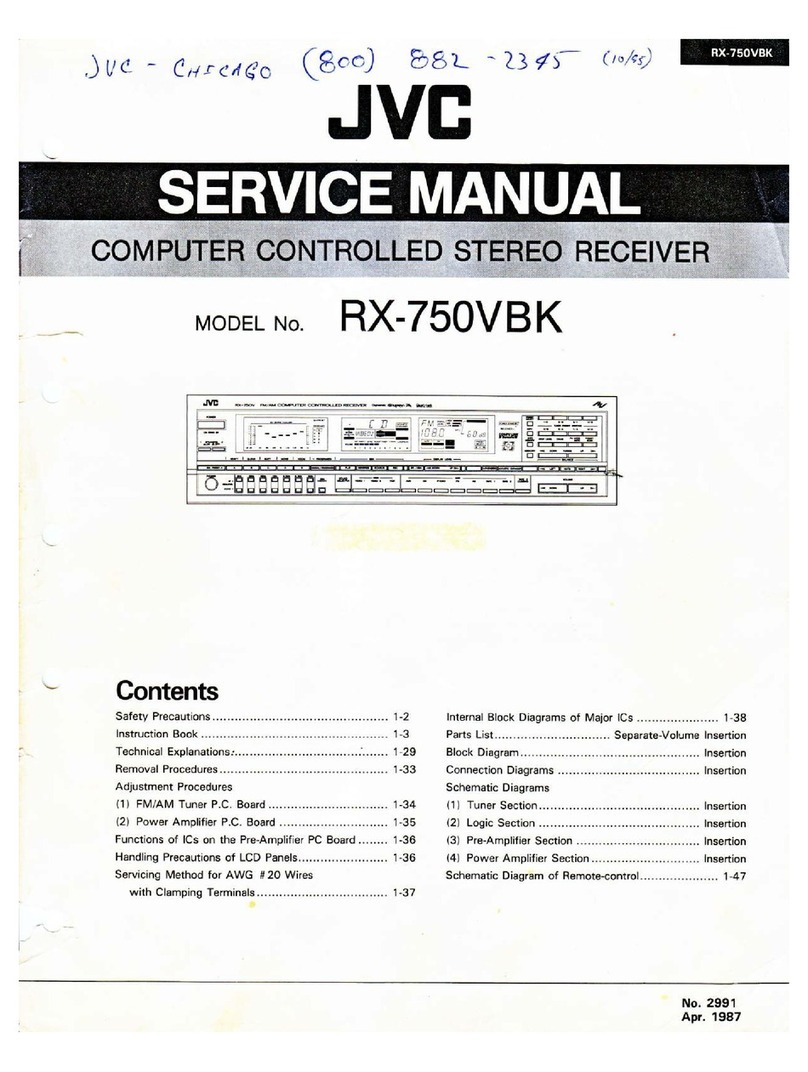

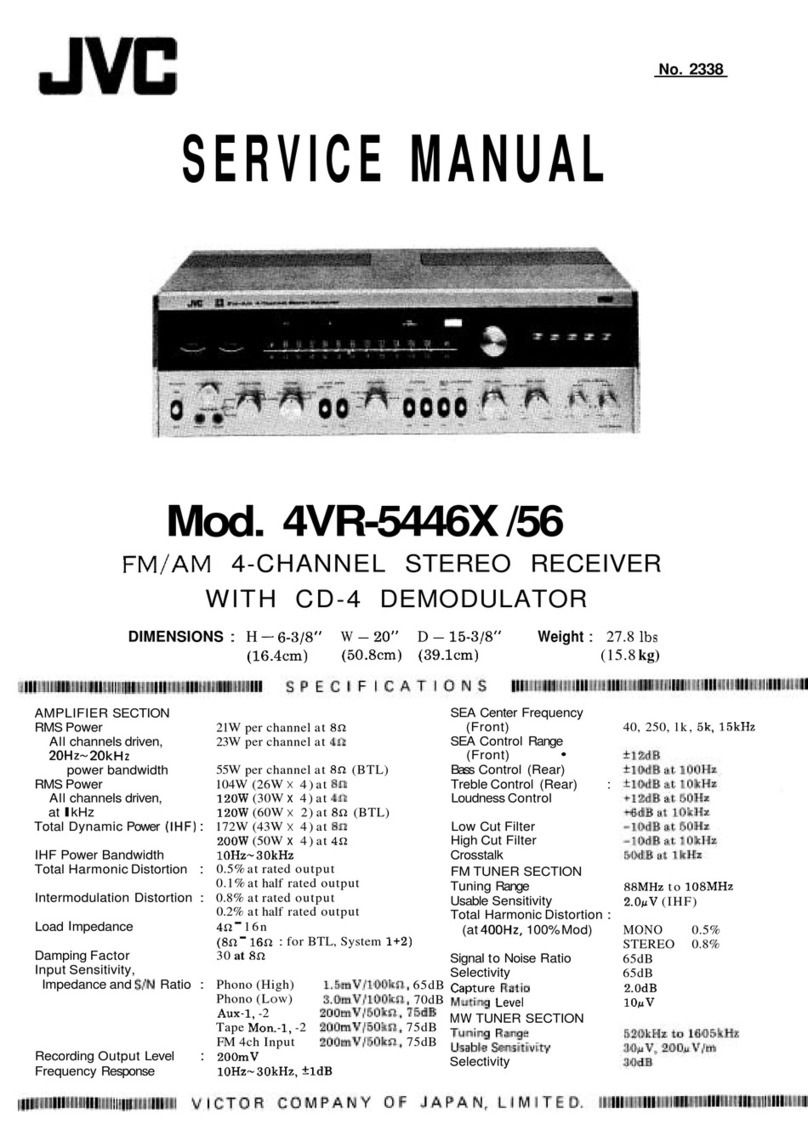

Other JVC Stereo Receiver manuals

Popular Stereo Receiver manuals by other brands

Pioneer

Pioneer SX-1000TA operating instructions

Yamaha

Yamaha MusicCast TSR-5B3D owner's manual

Sony

Sony STR-DE335 - Fm Stereo/fm-am Receiver operating instructions

Sony

Sony STR-DG500 - Multi Channel Av Receiver Service manual

Panasonic

Panasonic AJSD955B - DVCPRO50 STUDIO DECK Brochure & specs

Pioneer

Pioneer SX-838 Service manual