1-5

KS-FX711/KS-FX511

Prior to performing the following procedure, remove

the front panel assembly, the front chassis assembly,

the heat sink and the bottom cover.

Remove the screw B, the five screws C and the two

screws Dattaching the rear bracket on the back of

the body. Remove the rear bracket.

1.

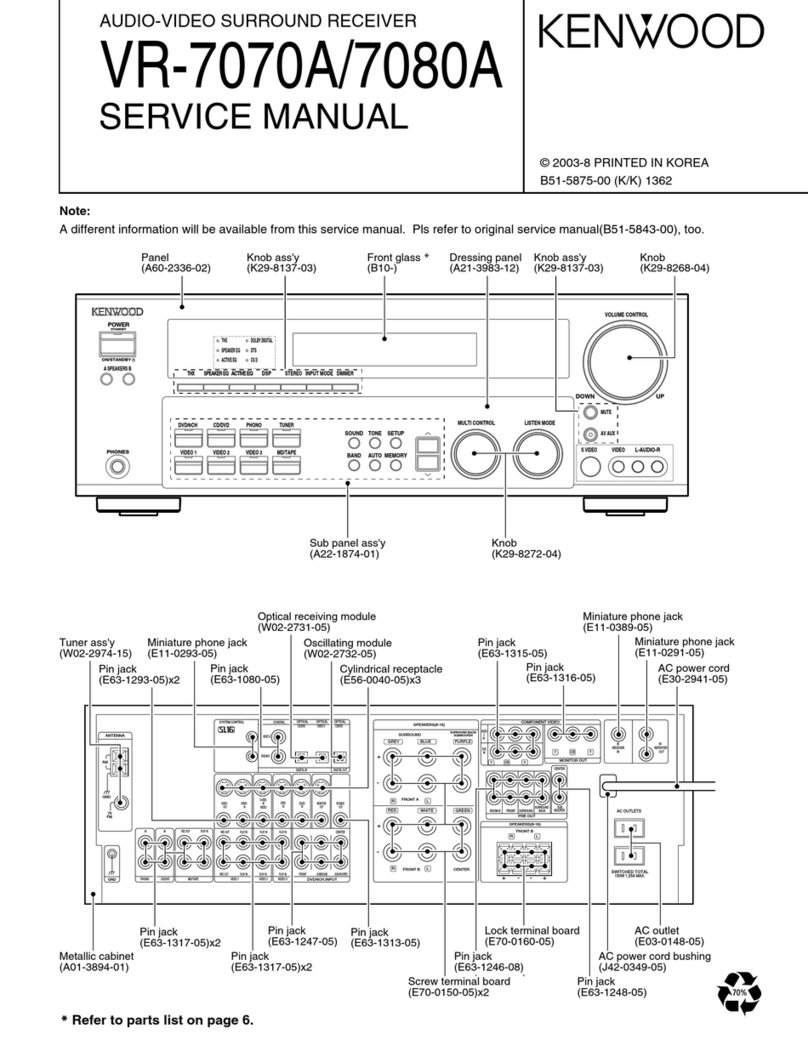

Removing the main board (See Fig.7)

Prior to performing the following procedure, remove

the front chassis, the heat sink, bottom cover and the

main amplifier board assembly.

Remove the four screws Fattaching the cassette

mechanism assembly from the top cover.

1.

Removing the cassette mechanism assembly

(See Fig.9)

Prior to performing the following procedure, remove

the front chassis, the heat sink, bottom cover and the

rear panel.

Remove the two screws E attaching the main

amplifier board assembly on the top cover.

Disconnect connector CP701 on the main amplifier

board assembly from the cassette mechanism

assembly.

1.

2.

Removing the main amplifier board assembly

(See Fig.8)

Fig.7

Fig.8

Fig.9

Rear bracket B

D

C

D

CC

Main board

E

E

CN701

Cassette mechanism assembly

F

F

FF Top chassis

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Q

Q

3

7

6

3

1

5

1

5

0

9

9

2

8

9

4

2

9

8

T

E

L

1

3

9

4

2

2

9

6

5

1

3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

http://www.xiaoyu163.com