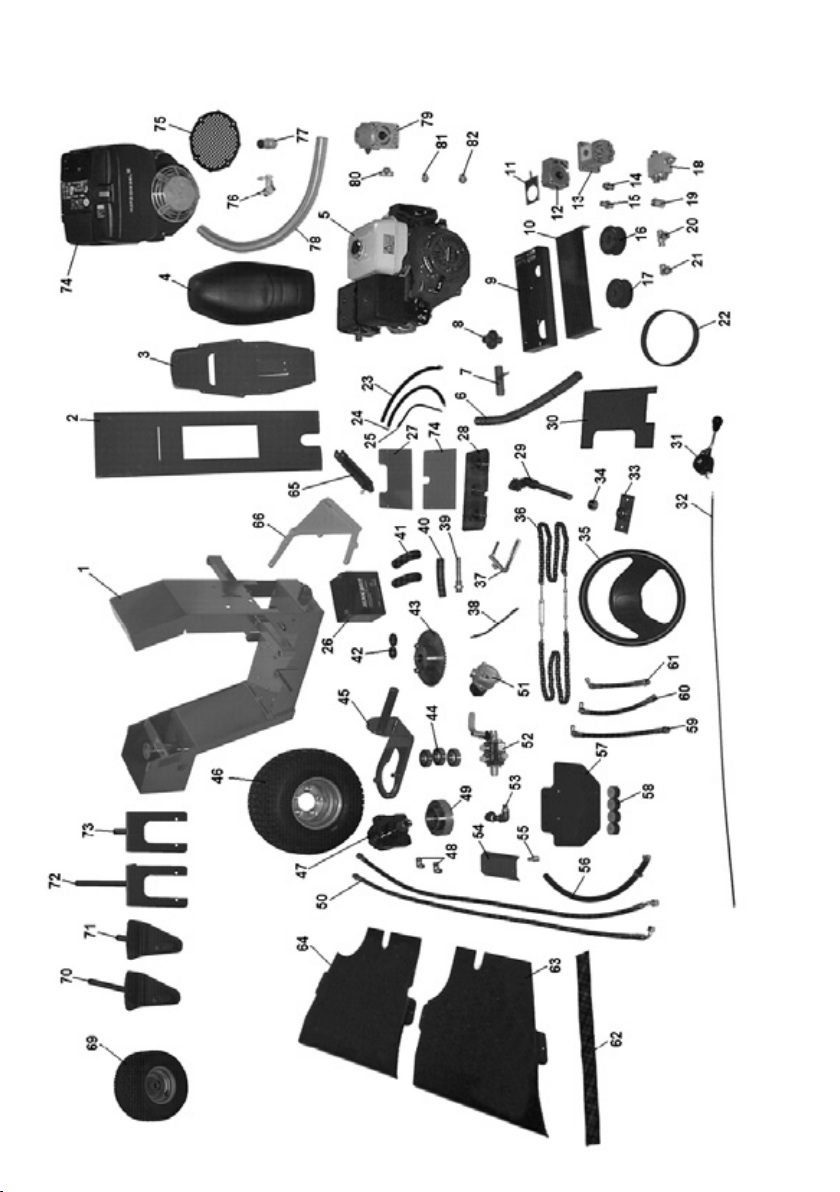

8

Cleaning

Always keep engine clean - use com-

pressed air if necessary. Avoid blow-

ing directly into air filter. Replace air

filter often to avoid reducing engine

power due to dust in air. The machine

can also be cleaned by high pressure

washer, but never aim jet directly at

air filter, breather pipe for hydraulics

under seat, diesel filler cap, wiring

and electronics.

Tightening up and damage

Tightening up screws and bolts must

be done regularly.

Always repair any damage immedi-

ately after discovery.

Weekly check

Check there is sufficient oil in engine

(W15-40).

Monthly check

Check level of hydraulic oil in sight

glass on right side of machine

(HV32).

Lubrication

Lubricate steering chain with oil

(spray-on chain oil is recommended).

Lubricate ball joints with no grease

nipple and universal joint on steering

column with oil. kugleled som ikke har

nipler smøres også med olie.

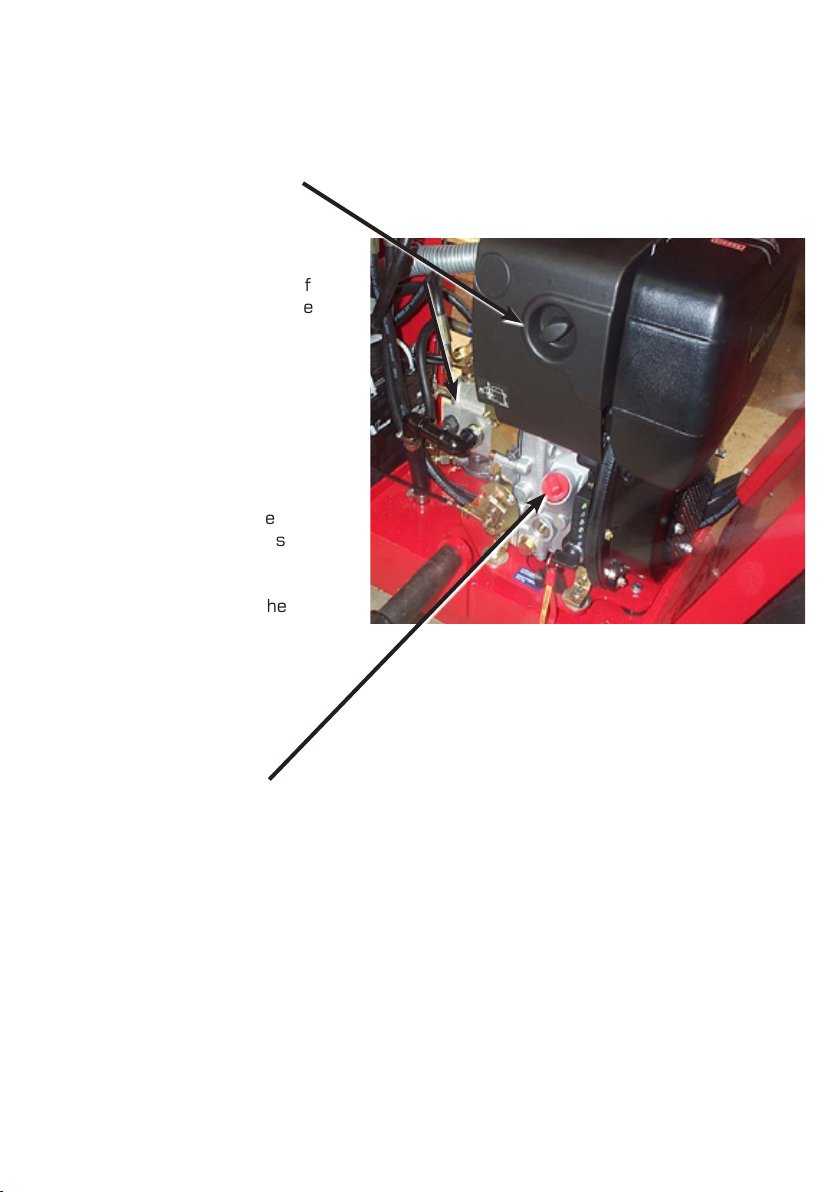

Hydraulic oil

Hydraulic oil level must be in centre of

sight glass.

Replace hydraulic oil after analysis or

2000 hours.

Fill hydraulic oil (HV32) at filter on

right side of hydraulic oil tank.

Hydraulic oil filter

Change hydraulic oil filter first time

after 50 hours and thereafter every

500 hours or once annually. NB: if oil

colour is milky white, there is water in

the system. Change oil.

Steering

Back wheel is turned by chains from

steering wheel passing under seat.

Remove seat and top panel to adjust.

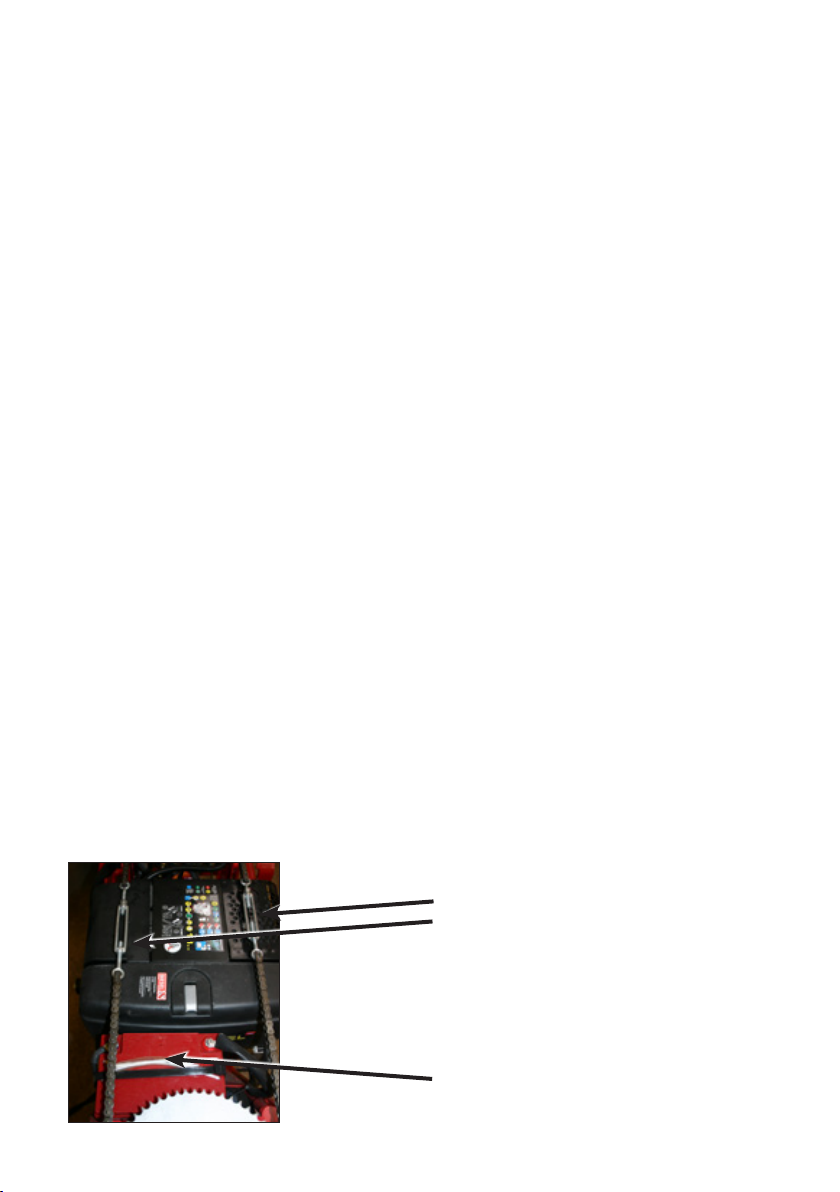

Battery

12 V sealed battery.

Keep terminals clean.

Maintenance