2 3

inTroducTion:

This manual contains information to help you to learn about the safe and proper use of

the KL30105 Tractor Tire Handler (Fork Option). The instructions included in this manual

are not necessarily all-inclusive. K-Line® cannot anticipate all conceivable or unique

situations. You must make sure all conditions and procedures do not jeopardize your

personal safety.

DISCLAIMER: All information, images, and specications contained in this manual are

based on the latest information available at the time of publication. K-Line® reserves

the right to make changes at any time without notifying any person or organization of

such revisions or changes. K-Line® is not liable for incidental or consequential damages

(including lost prots) in connection with the furnishing, performance, or use of this

saFeTy precauTions:

Before using the KL30105 Tractor Tire Handler, read, understand, and follow the safety

precautions and operating instructions outlined in this manual. This equipment must be

operated by qualied personnel. The operator must be familiar with the vehicle this tool is be-

ing used on

ÂIf the operator cannot read English, operating instructions and safety precautions must

be read and discussed in the operator’s native language.

ÂSi el operador no puede leer inglés, las instrucciones de operación y las precauciones

de seguridad deberán leerse y comentarse en el idioma nativo del operador.

ÂSi l’utilisateur ne peut lire l’anglais, les instructions et les consignes de sécurité doivent

lui être expliquées dans sa langue maternelle.

Safety Icon termInology

The following safety icons can be found within this manual.

Read the Manual

Eye Protection

Ear Protection

Face Protection

Inspect Equipment

Do Not Weld

No Smoking

Prohibited Action

Crushing Hazard

Crushing Hazard (Foot)

Crushing Hazard (Hand)

Pinch Point

Fire Hazard

Safety Alert Symbol

Slipping Hazard

Tripping Hazard

Personal Protection/Important Information Hazard Avoidance

PerSonal ProtectIon/ImPortant InformatIon

To avoid eye injury, always

wear protective glasses

or face shield. Make sure

no one can be injured

by ying objects or debris when using tools or

working on a component.

To avoid personal injury or death,

carefully read and understand all

instructions before attempting to

operate any equipment or tools. Do

not operate or work on a machine unless you read

and understand the instructions and warnings in

this and all other applicable manuals.

WARNING

To prevent possible damage to your

hearing, always wear ear protection

when working around noise

generating tools.

Clean up all leaked

or spilled uids

immediately. Oil, fuel,

or cleaning uid leaked

or spilled onto any hot

surfaces or electrical components can cause a re,

resulting in personal injury or death.

Personal injury can

result from slips or falls.

DO NOT leave tools or

components laying

around the work area. Clean up all spilled uids

immediately.

ProhIbIted actIon

WARNING

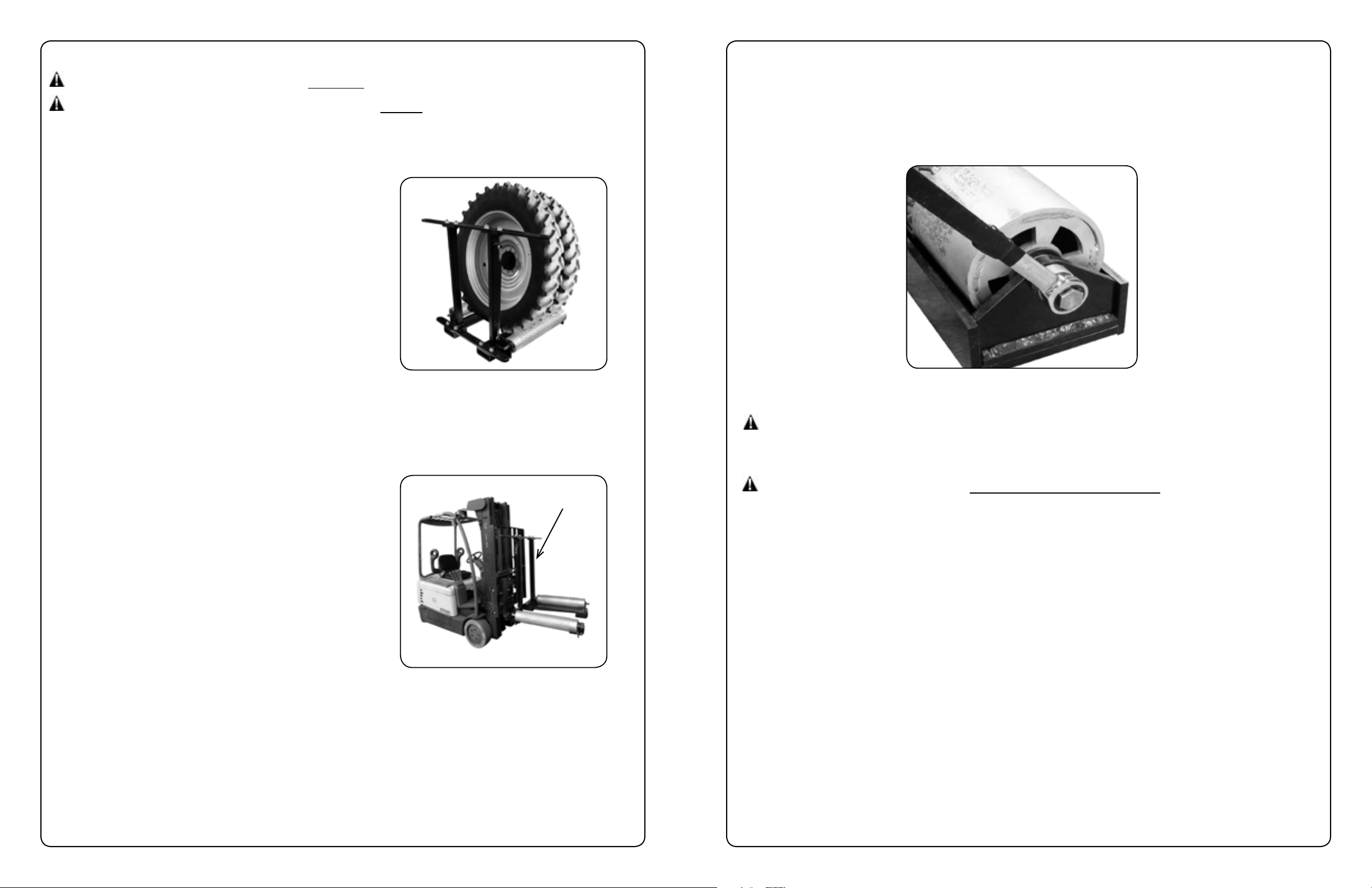

To avoid serious or fatal injury, only

use the KL30105 (Fork Option)

Tractor Tire Handler for its intended

purpose,whichis supportingTractor/

Truck tires during removal and installation.

To avoid serious or fatal injury, do

not exceed the Working Load Limit

(WLL) of 10,000 lbs for any wheel/

tire assembly being supported by

the KL30105 Tractor Tire Handler (Fork Option).

WARNING

hazard avoIdance

The complete KL30105

Tractor Tire Handler

weighs approximately

TBD lbs. Personal injury

can result from dropped tooling. Use caution

when transporting, installing, removing, and

storing the tooling.

Inspect prior to each use for dents,

cracks, bends, or worn parts. If

damage is found, discontinue use

until inspected and released by an

approved inspector at the dealership.

Personal injury can result from

pinch points. Use caution when

assembling, installing, and removing

the KL30105 Tractor Tire Handler

(Fork Option).

Personal injury or

death can result from

improper use of this tool

and supporting of the

vehicle. Make sure the

vehicle is properly supported using jack stands

before removing wheels/tires using the KL30105.

Do not work beneath any supported tool.

Potential pinch points. To avoid

serious injury, DO NOT place your

hand or any part of your body

between the KL30105 Tractor Tire

Handler (Fork Option) and the tractor components.

To avoid damage to the tooling, do

not weld on the components. Do

not modify the KL30105 Tractor Tire

Handler (Fork Option) in any way by

welding, heating with a torch, drilling, machining,

or grinding.