introduCtion:

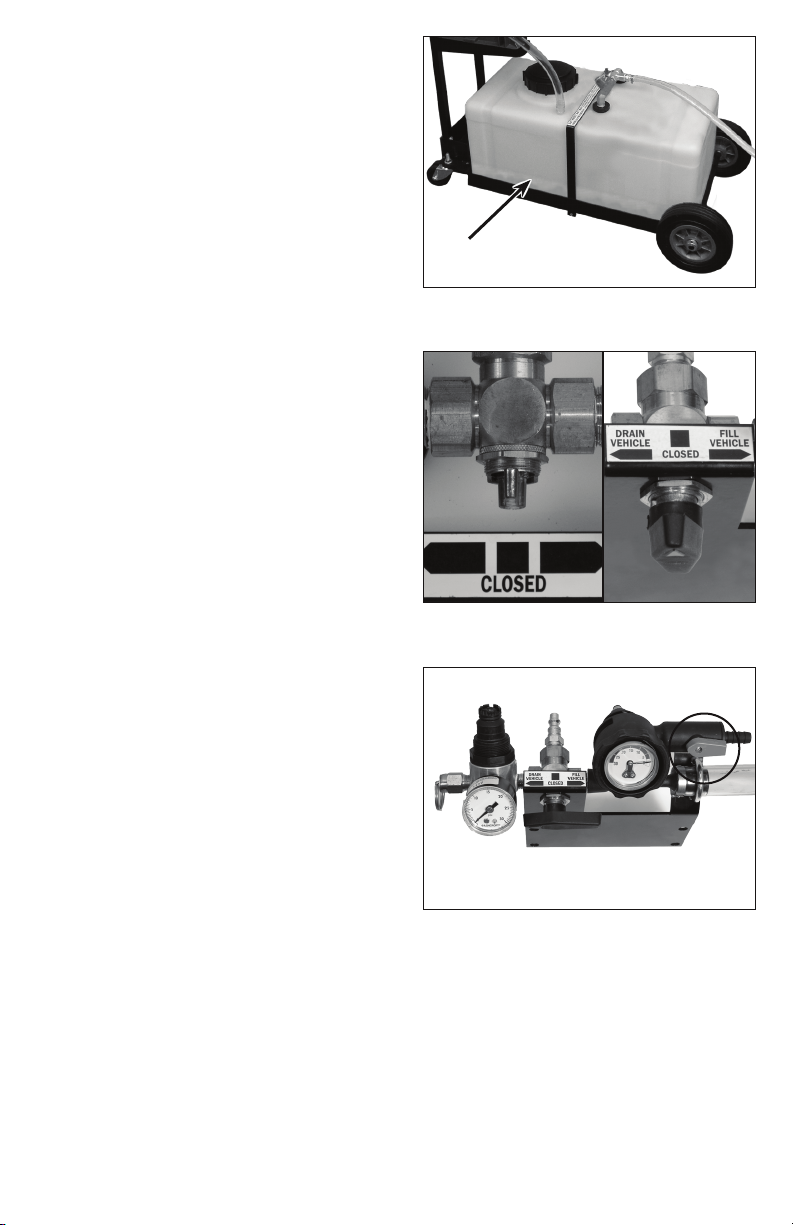

This manual contains information to help you to learn about the safe and proper use of

the KL34000 Coolant Management System. K-Line® Industries, Inc cannot anticipate all

conceivable or unique situations. The instructions and warnings included in this man-

ual are not necessarily all-inclusive. You must make sure all conditions and procedures

do not jeopardize your personal safety.

DISCLAIMER: All information, images, and specications contained in this manual are

based on the latest information available at the time of publication. K-Line® reserves

the right to make changes at any time without notifying any person or organization of

such revisions or changes. K-Line® is not liable for incidental or consequential damages

(including lost prots) in connection with the furnishing, performance, or use of this

material.

Safety preCautionS:

Before using the KL34000 Coolant Management System, read, understand, and

follow the safety precautions and operating instructions outlined in this manual.

This equipment must be operated by qualied personnel. The operator must be famil-

iar with vehicle cooling systems, coolants, and the dangers they present.

Personal Protection/

imPortant information

warning

To avoid personal injury, al-

ways wear protective gloves.

Hot antifreeze/coolant can burn

skin. If antifreeze/coolant comes in con-

tact with skin, thoroughly was area with

soap and water.

To avoid personal injury, care-

fully read and understand all

instructions before attempting

to operate any equipment or tools. Do

not operate or work on a machine unless

you read and understand the instructions

and warnings in this and all other appli-

cable manuals.

To avoid eye injury, always wear

protective glasses to guard

against possible ying particles

and/or debris. If contact with eyes occurs,

ush eyes with cold water for 30 minutes.

warning

To avoid inhaling mist or hot

vapors, use this product in a

well ventilated area. If inhaled,

move to fresh air and call a physician. If

swallowed, drink two glasses of water; in-

duce vomiting; and call a physician.

Hazard avoidance

Do not pressurize the vehicle

cooling system above its pres-

sure rating. Doing so may result

in cooling system failure and the release of

engine coolant.

To avoid personal in-

jury, allow engine to

cool completely. Hot

vehicle cooling systems are under pres-

sure. Opening a hot system can cause an

uncontrolled release of engine coolant.

Do not open the radiator cap, and do not

remove hoses from a hot system except as

directed in this manual.

2