Introduction

The new sharpening platform, developed by KAINDl offers a genuine alternative to bigger and considerably more

expensive machines. Due to it’s new and worldwide unique conception, it is possible to sharpen many different

drills and saw blades No matter if SS or chrome vanadium-, even carbide tipped saw blades are sharpened with

very high precision, whatever the diameter or tooth pattern. SS and carbide drills are sharpened with the 4-facet

shape, which is favoured by DIY enthusiasts and craftsmen. This shape facilitates drilling of flat and- or rounded

surfaces. Web thinning becomes unnecessary.

This new type of diamond wheel covered on three sides, having cooling holes, granting a clean cut of any cutting

material without burning (loss of hardness) of the cutting edges.

1. Set up of the platform/ Connection with your drill machine

Fix the platform by using the designated boring holes on a fix and stable base (e.g. working table) Fix the drill

(not included) on the provided 43 mm neck. Fix the KAINDL diamond wheel in the drill chuck.

2. Sharpening of drills

Open both adjustment screws (11) and place the drill machine with the grinding wheel in correct position drill

grinding. Pay attention that the drill support (6) is in position “cutting angle” (upper stop dog picture 1)

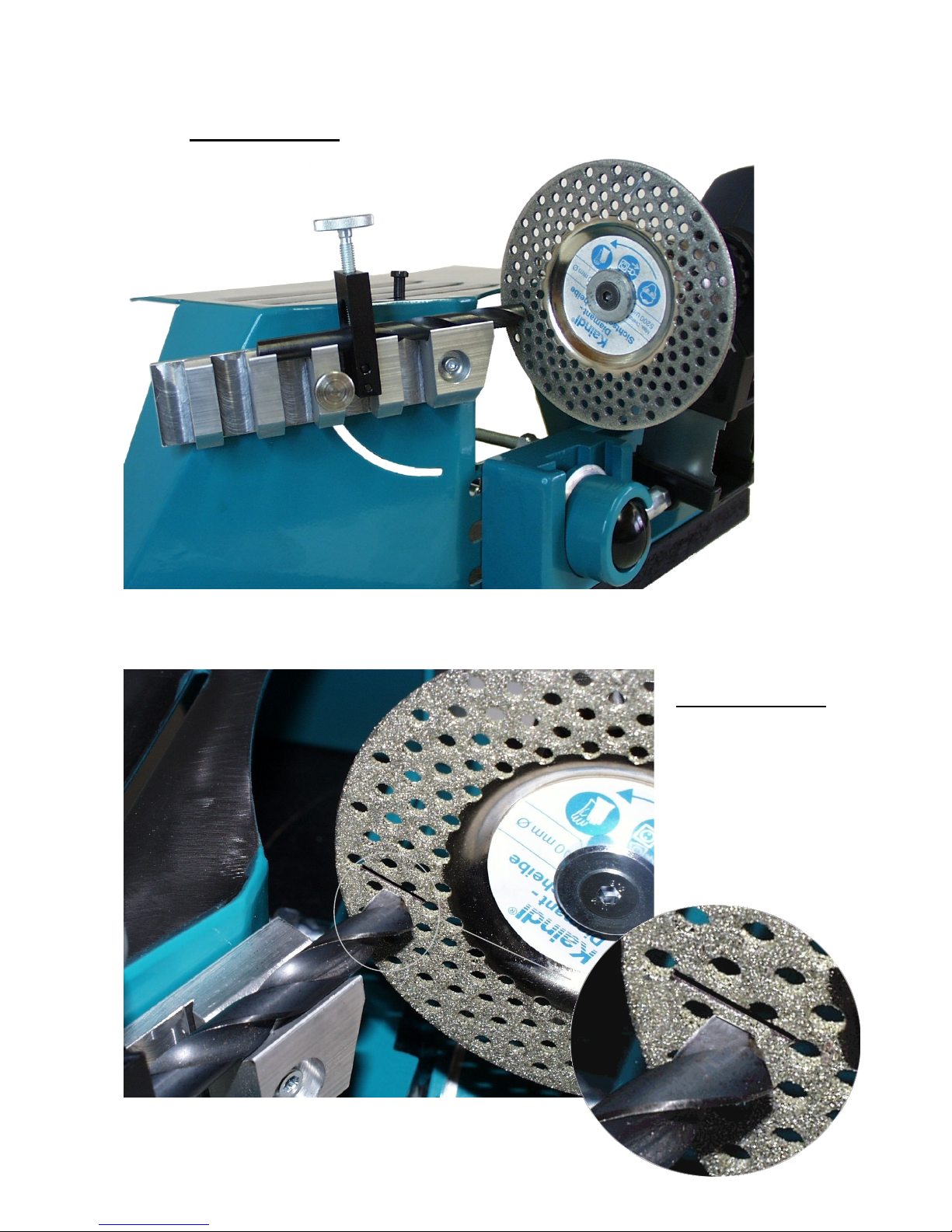

Fixation and adjustment of the drill

Place the drill as shown in picture (1) in the drill support (6).

Move the drill for adjustment towards the grinding wheel and align

the cutting edge parallel to the black adjustment marks (picture 2) on the

diamond grinding wheel. Now fix the knurled screw (4a) of the reversing

drill prism (4)

(Take care that the reversing drill prism (4) clamps the drill on the drill

shank and not the spiral of the drill. ).

Open the knurled screw (7) on the drill support (6) and move the prism

downward to the adjustment mark (5).

Slide the drill with the reversing prism forwards, direction grinding wheel

to the stop dog.

Advise: For getting best possible precision, pay attention, that while sharpening, the drill reversing prism (4)

fits tightly in the drill support (6) and the guidance groove is in accordance with the guidance notch.

Advise: The drills keeps fixed in the reversing prism (4) until the end of the grinding procedure. A change of

any adjustment is not requested.

Sharpening of the clearance angle surface (picture 4b)

Turn on the drill machine and move the grinding wheel using the feeding screw (8) to the drill, until the first side

of the drill is sharpened.

Now tear back the drill with the reversing prism (4),( away from the grinding wheel) and reverse the prism for

180°. Place the prism again in the same prism notch as before and pass the drill slowly in the prism notch (6a-d)

to the stop dog. Now your drill got 2 sides with a big clearance angle (picture 4b).

Sharpening of the cutting angle surface (picture 4a)

Take the drill with the prism out of the drill support (6) and turn the support by opening the knurled screw (7)

upward to the stop dog. Move back the grinding wheel with the feeding screw (8), in order the drill does not touch

the wheel when you place the drill in the drill support (6).

Important: take care that the reversing prism (4) fits tightly in the same prism notch as before (6a-d).

Slide the reversing prism (4) in the prism notch completely forwards to the stop dog. Turn on the drill machine

and move the grinding wheel forward with the feeding screw (8) towards the drill till one cutting edge is sharpened

approx. 2 mm. Now reverse the prism (4) with the drill for 180° , (Attention!) : same prism notch) and slide the re-

versing prism slowly to the stop dog.

This grants that both cutting edges are symmetric and equal.

Advise: the drill is then sharpened correctly, when he looks like as shown in picture 4