the idle speed setting at regular intervals. STIHL

recommends you have this work done by a

STIHL servicing dealer.

Do not operate your power tool in the starting

throttle position – engine speed cannot be con‐

trolled in this position.

Be particularly alert and cautious when wearing

ear protection because your ability to hear warn‐

ings (shouts, alarms, etc.) is impaired.

Take breaks when you start getting tired or feel‐

ing fatigue – risk of accidents!

Work calmly and carefully – in daylight conditions

and only when visibility is good. Proceed with

caution, do not put others in danger.

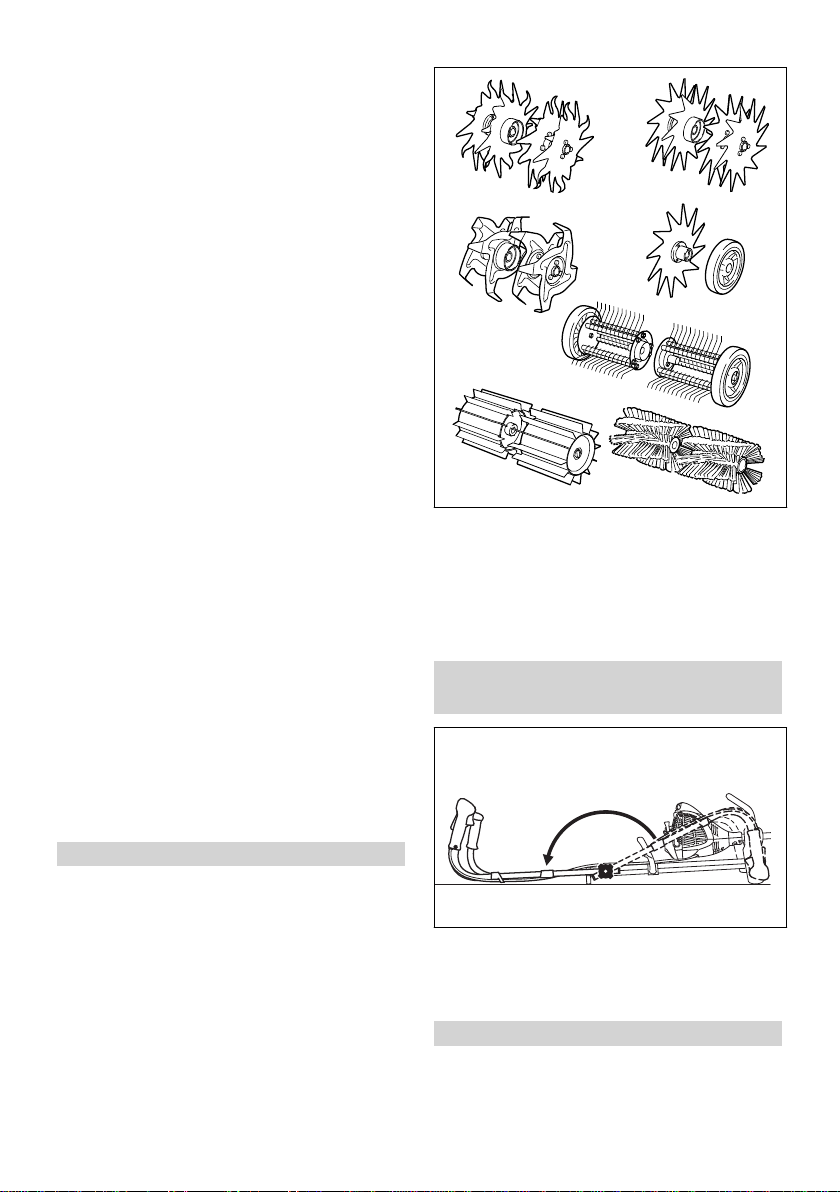

Use your power tool only for those applications

described in the MultiTool user manual.

As soon as the engine starts running,

the power tool generates toxic

exhaust gas. These gases may be

odorless and invisible and may con‐

tain unburned hydrocarbons and ben‐

zene. Never run the engine indoors or

in poorly ventilated locations, even if

your model is equipped with a cata‐

lytic converter.

To reduce the risk of serious or fatal injury from

breathing toxic fumes, ensure proper ventilation

when working in trenches, hollows or other con‐

fined locations.

Stop work immediately if you start suffering from

nausea, headaches, impaired vision (e.g. your

field of vision gets smaller), impaired hearing,

dizziness, or impaired concentration – these

symptoms may possibly be the result of too-high

exhaust gas concentration – Risk of accidents!

Operate your power tool in such a way that it

produces a minimum of noise and emissions –

do not run the engine unnecessarily, accelerate

the engine only when working.

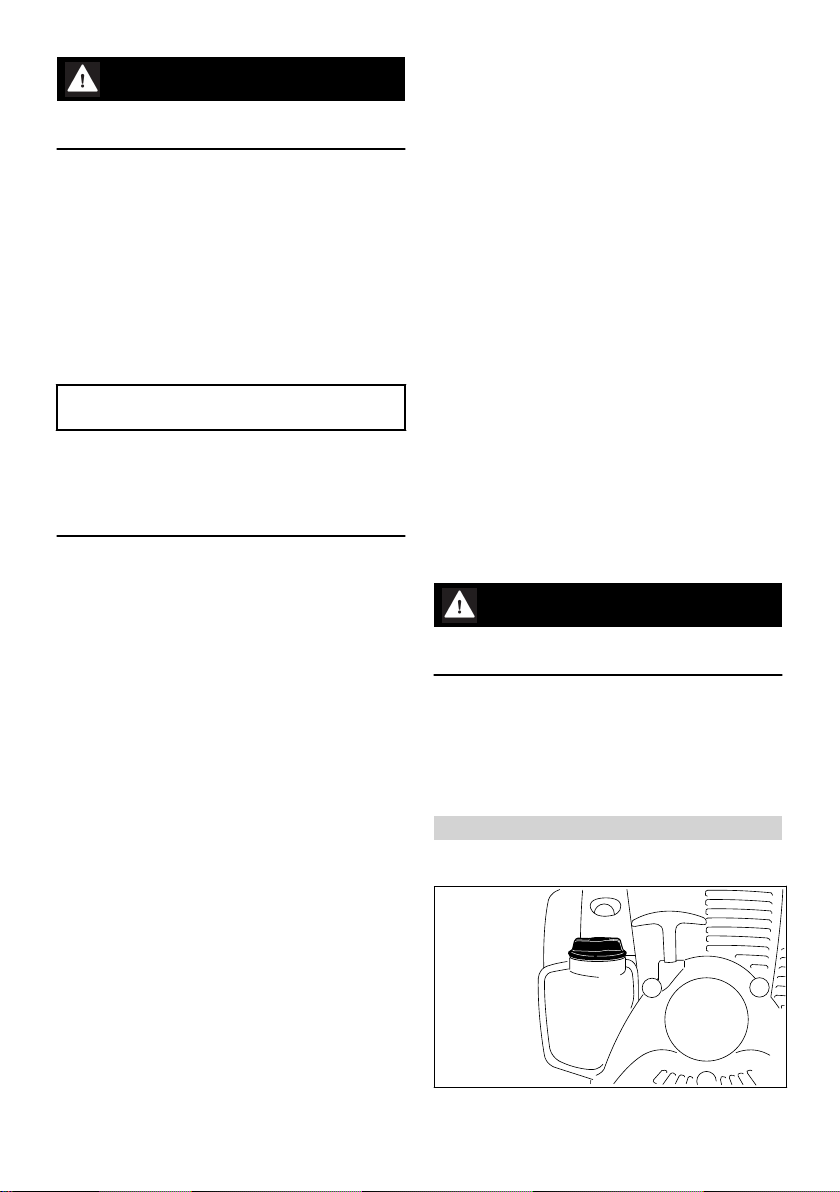

To reduce the risk of fire, do not smoke while

operating or standing near your power tool. Com‐

bustible fuel vapor may escape from the fuel sys‐

tem.

Dust, fumes and smoke produced while working

may be hazardous to health. Wear respiratory

protection in case of heavy dust or smoke emis‐

sion.

Never touch hot parts – risk of burns!

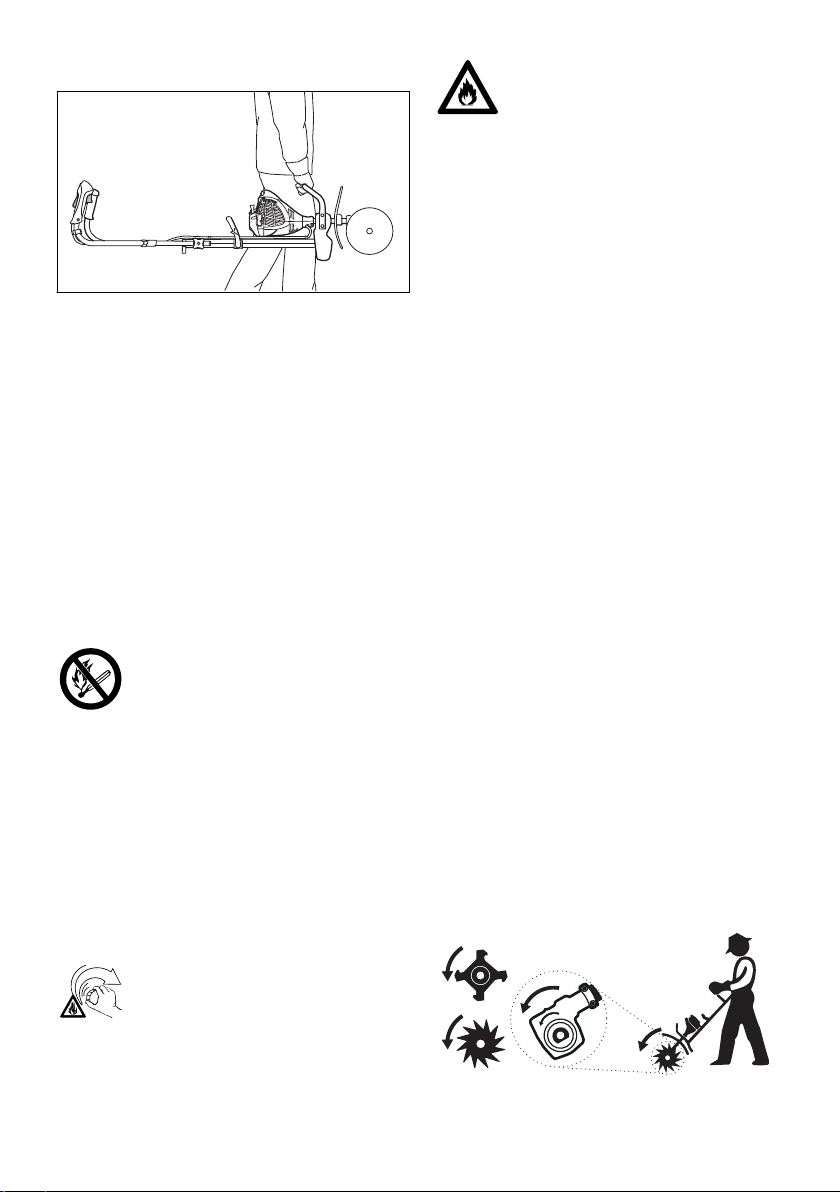

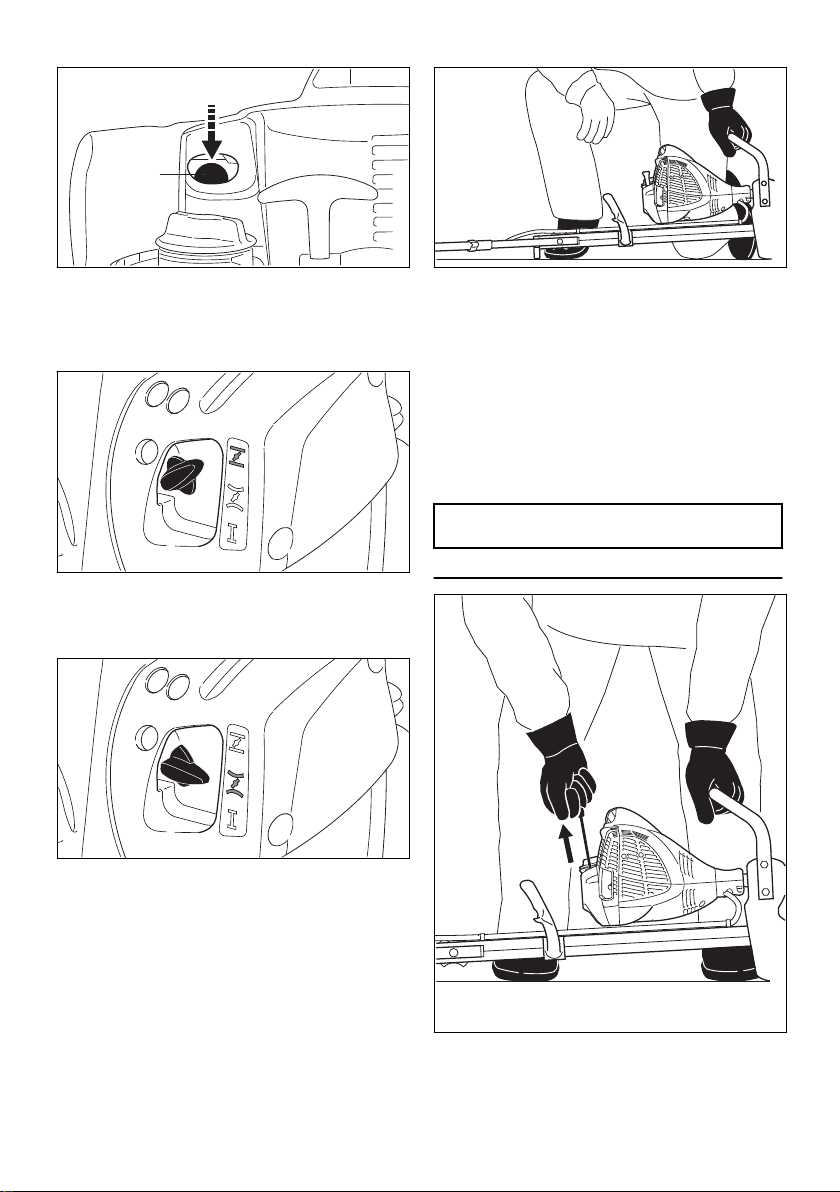

Keep your hands and feet well away

from the working tool. To reduce the

risk of injury, never touch a rotating

tool. Always stand behind the deflec‐

tor or to one side of the machine dur‐

ing operation – never in front of the

rotating tools.

If your power tool is subjected to unusually high

loads for which it was not designed (e.g. heavy

impact or a fall), always check that it is in good

condition before continuing work – see also

"Before Starting". Check in particular that the fuel

system has no leaks and the safety equipment is

fully operative. Never use a power tool that is no

longer safe to operate. In case of doubt, contact

a dealer.

To reduce the risk of injury, shut off the engine

before changing the attachment.

After finishing work or before leaving the power

tool unattended: Shut off the engine.

See also notes on "During Operation" in the user

manual of the MultiTool you are using.

3.8 Vibrations

Prolonged use of the power tool may result in

vibration-induced circulation problems in the

hands (whitefinger disease).

No general recommendation can be given for the

length of usage because it depends on several

factors.

The period of usage is prolonged by:

–Hand protection (wearing warm gloves)

–Work breaks

The period of usage is shortened by:

–Any personal tendency to suffer from poor cir‐

culation (symptoms: frequently cold fingers,

tingling sensations).

–Low outside temperatures.

–The force with which the handles are held (a

tight grip restricts circulation).

Continual and regular users should monitor

closely the condition of their hands and fingers. If

any of the above symptoms appear (e.g. tingling

sensation in fingers), seek medical advice.

3.9 Maintenance and Repairs

Service the machine regularly. Do not attempt

any maintenance or repair work not described in

the instruction manual. Have all other work per‐

formed by a servicing dealer.

STIHL recommends that you have servicing and

repair work carried out exclusively by an author‐

ized STIHL servicing dealer. STIHL dealers are

regularly given the opportunity to attend training

English 3 Safety Precautions and Working Techniques

6 0458-489-0121-C