KALAMAZOO

INDUSTRIES, INC.

KALAMAZOO, MI

PH: (269) 382-2050 www.kalamazooind.com

KI

WARNING!

TO REDUCE THE RISK OF FIRE OR SHOCK HAZARD,

DO NOT EXPOSE THIS EQUIPMENT TO RAIN, ANY LIQUID OR MOISTURE.

INSPECTION

If these goods are damaged in transit, the DELIVERING TRANSPORTATION COMPANY is required by

law to make notation of damages on the freight bill. If in your opinion, there may be concealed damage, they are

required to make an inspection after goods are unpacked. Transportation rates are made in proportion to damage.

Therefore, the carrier and NOT the shipper should be charged with any loss or damage. Any claim should be

lled with the delivering TRANSPORTATION COMPANY. PLEASE DO NOT RETURN GOODS TO

US WITHOUT OUR RGA NUMBER AND SHIPPING INSTRUCTIONS.

NOTE: SEE NEXT PAGE FOR RETURN POLICY AND WARRANTY.

IMPORTANT

Read Operating Instructions before using equipment.

OPERATING INSTRUCTIONS

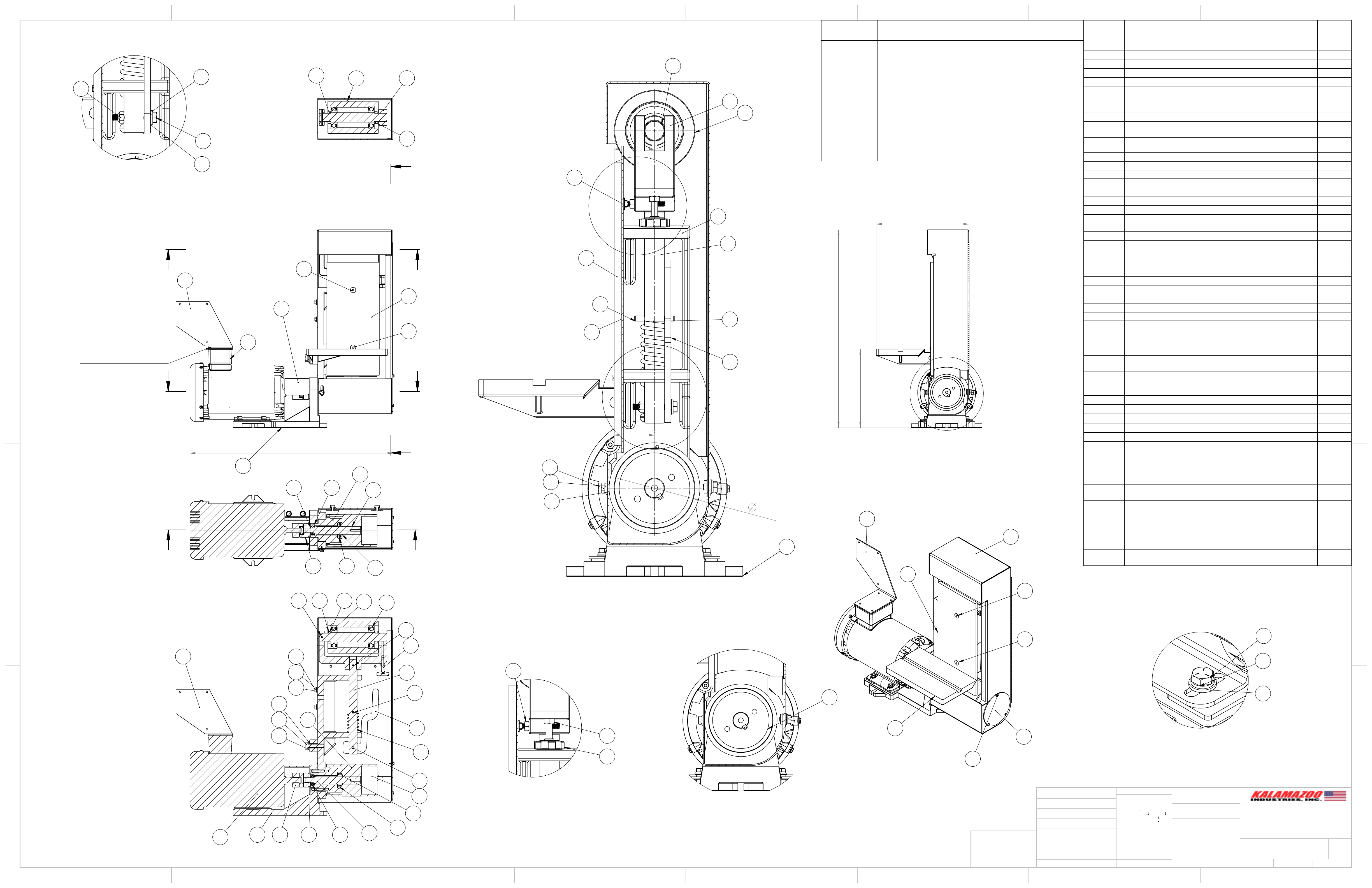

1. Abrasive belt rotation is counter-clockwise. If the abrasive belt is lap spliced be sure of the correct belt

rotation. Butt spliced belts bi-directional.

2. Belt tension is pre-set with internal spring (9). No belt tension adjustment is required. The yoke assembly is

spring loaded for constant belt tension. The tension lever (10) tightens and loosens belt tension.

3. To change belt disconnect power: open belt guard (43) and locate the tension lever (10) between the sander

frame (7). Pull down tension lever (10) to compress tension spring and release belt tension. Remove and

replace sanding belt. Be sure of correct belt rotation. Look inside belt for arrows showing you correct

rotation. Lift tension lever (10) to allow re-tensioning of belt. Check tracking of belt short on/off of motor

before letting the machine run. Spinning the belt by hand with power off will also check rough tracking be

for running machine. Be sure sanding belt stays centered on platen.

4. Belt tracking: tracking the sanding belt is done with the tracking knob (22) on yoke assembly. Tightening

knob (22) raises idler spindle and the belt moves toward the motor. Loosening the tracking knob drops the

idler spindle (17) and the sanding belt moves away from the motor. When the belt is centered on the platen

(16), tighten jam nut on tracking knob to lock in belt position.

TROUBLE SHOOTING AND TRACKING PROBLEMS

• Drive pulley lost its crown (curvature of pulley)

• Sanding belt are not spliced square.

• Upper pulley assembly not squre to platen. (Use carriage bolts to square yoke with platen.)