80

EN

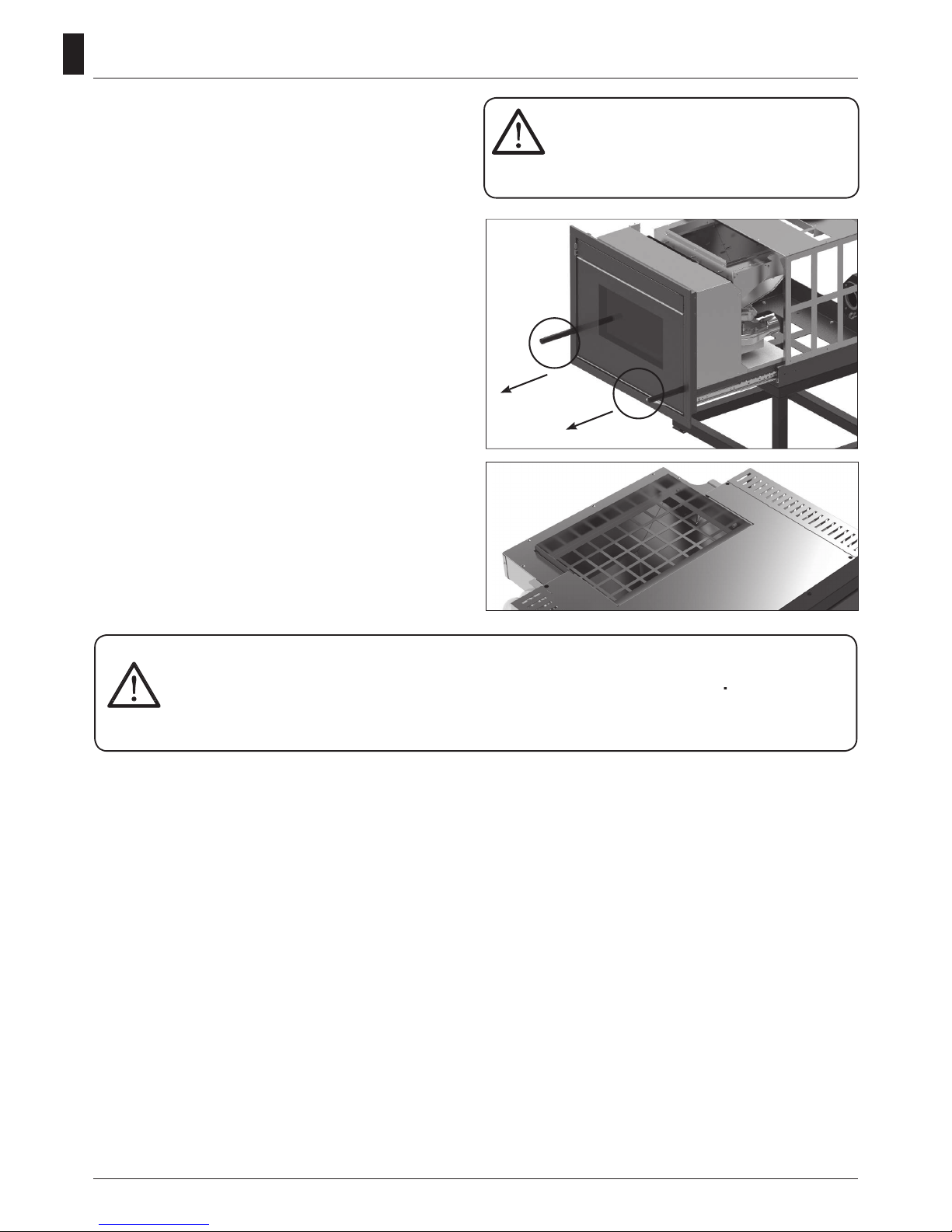

Operating area

How to place the Insert

For proper functioning and a good temperature

distribution, the Insert shoul be positioned

in a location where it is able to take in the air

necessary for combustion of the pellet (about

40 m3/h must be available), as laid down in

the standard governing the installation and in

accordance with local national standards.

The volume of the room must not be less than

30 m3.

The air must come in through permanent

openings made in walls (in proximity to the Insert)

which give onto the outside, with a minimum

cross-section area of 100 cm2.

These openings must be made in such a way

that it is not possible for then to be obstructed

in any way. Alternatively, the air can be taken

from rooms adjacent to the one which needs

ventilating, as long as they are provided with

an air intake from the outside, and are not used

as bedrooms or bathrooms, and provided there

is no re risk such as there is for example in

garages, woodsheds, and storerooms, with

particular reference to what is laid down in

current standards.

It is not permissible to install the

Insert in bedrooms, bathrooms, or

in a room where another heating

appliance is installed (Insert,

Insert etc.) which does not have its own

independent air intake. Locating the Insert

in a room with an explosive atmosphere

is prohibited. The oor of the room where

the Insert is to be installed must be strong

enough to take its weight. Keep a minimum

distance of 5 cm between the covering and

the replace insert. If walls are ammable,

maintain a minimum distance of 20 cm at

the rear , of 40 cm at the side and 100 cm

at the front. If the room contains objects

which are believed to be particularly

delicate, such as drapes, sofas and other

furniture, their distance from the Insert

should be considerably increased. The two

side walls of the chimney insert must be

accessible for maintenance by authorized

technicians.

Connection to the external air intake

It is essential that at least as much air must be

able to ow into the room where the Insert is

installed as is required for proper combustion in

the appliance and for the ventilation of the room.

This can be effected by means of permanent

openings in the walls of the room to be ventilated,

which give onto the outside, or by single or

collective ventilation ducts.

For this purpose, on the external wall near the

Insert, a hole must be made with a minimum free

cross-section of 100 cm2. (equivalent to a round

hole of 12 cm diameter or a square hole 10x10

cm) protected by a grille on the inside and the

outside.

The air intake must also: communicate directly

with the room where the Insert is installed be

protected by a grille, metal mesh or suitable

guard, as long as this does not reduce the area

below the minimum.

Be positioned in such a way as to be impossible

to obstruct.

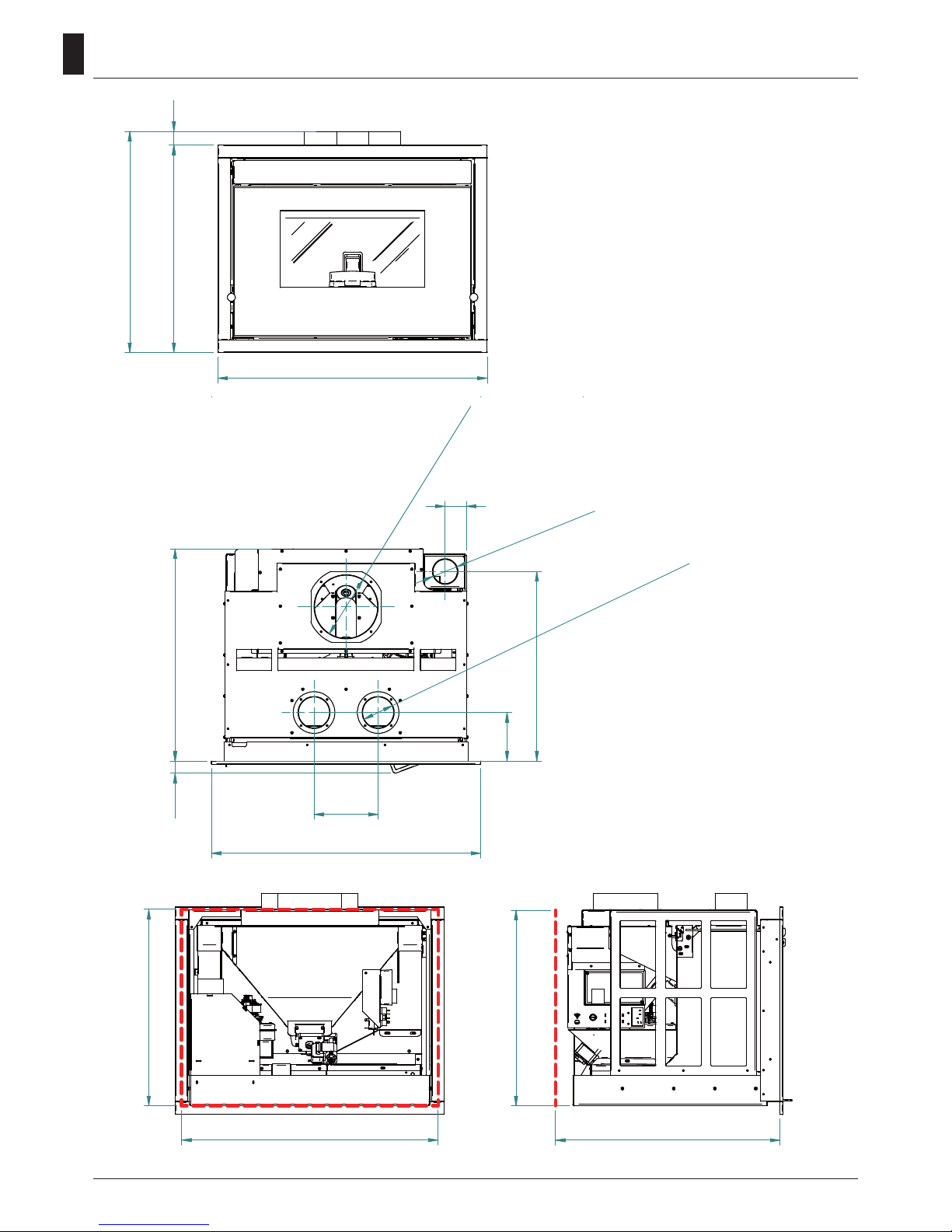

Distances to consider for the installation of stoves,

thermo-stoves, hydro and air inserts.

40 cm

20 cm

Min.

100 cm2

100 cm

20 cm

(A)

(B)