1

CONTENTS

CONTENTS ........................................................................................................................................................................ 1

INTRODUCTION ................................................................................................................................................................. 3

IMPORTANT SAFETY INSTRUCTIONS..............................................................................................................................................................3

THE MACHINE AND THE PELLETS ................................................................................................................................. 4

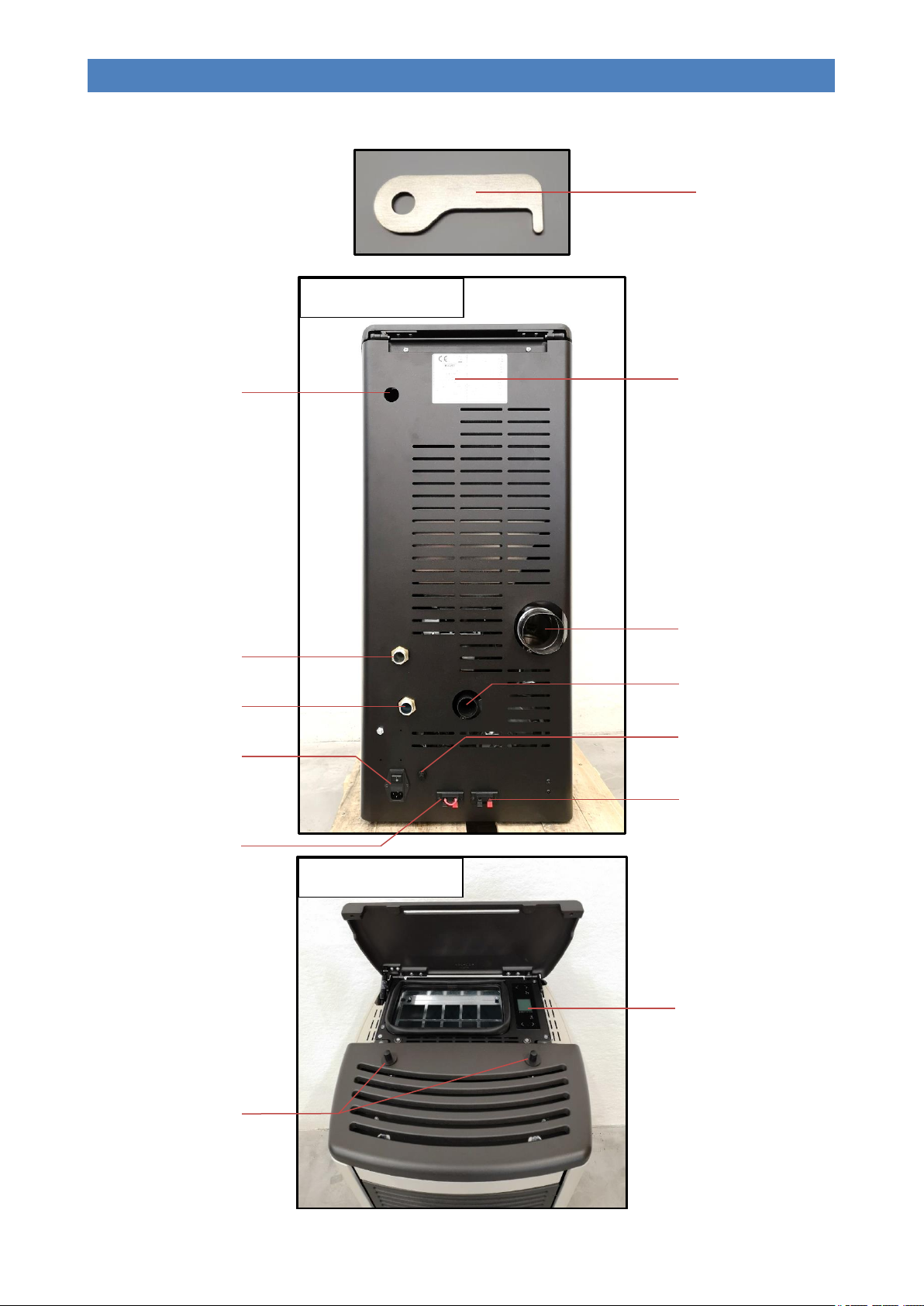

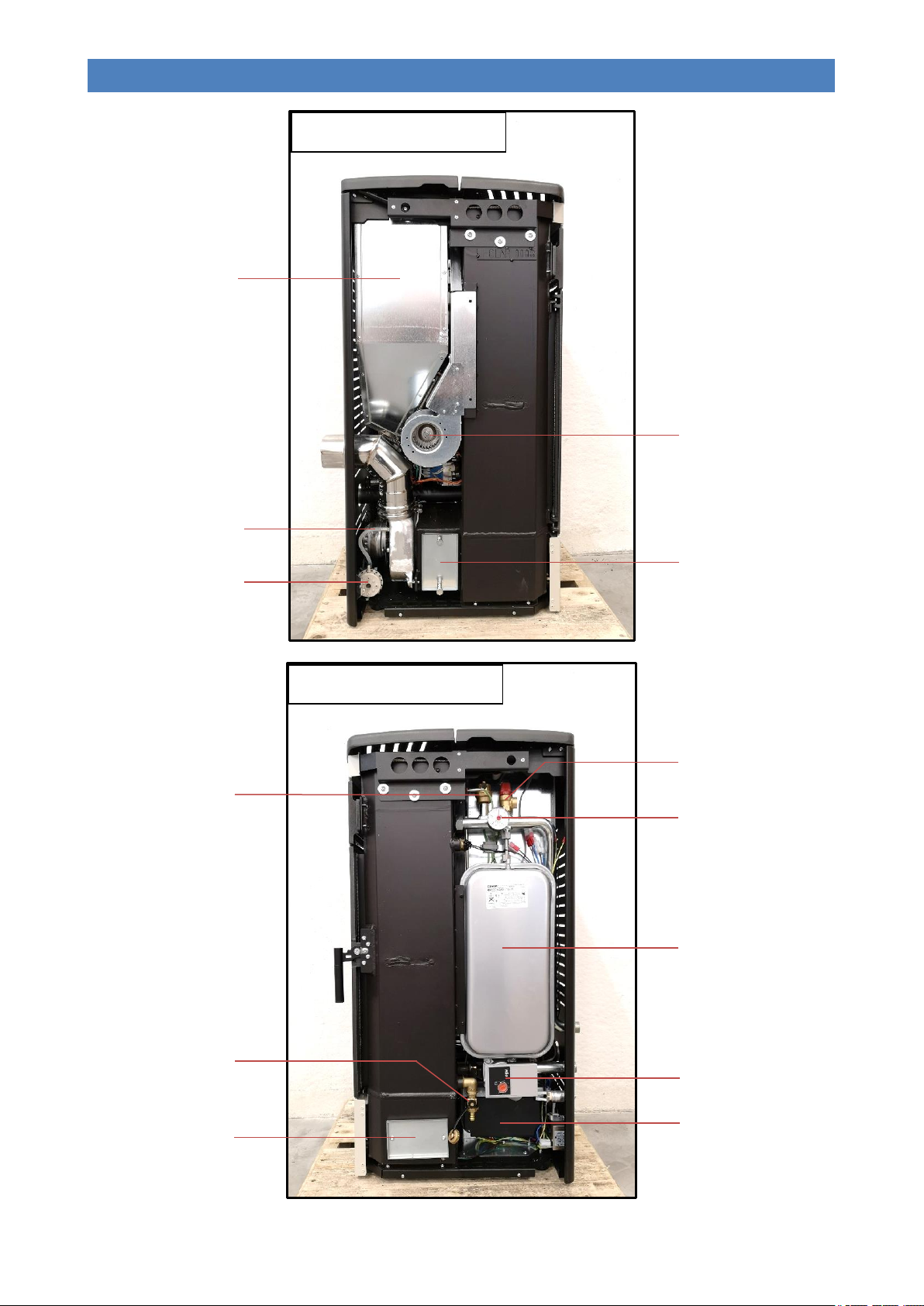

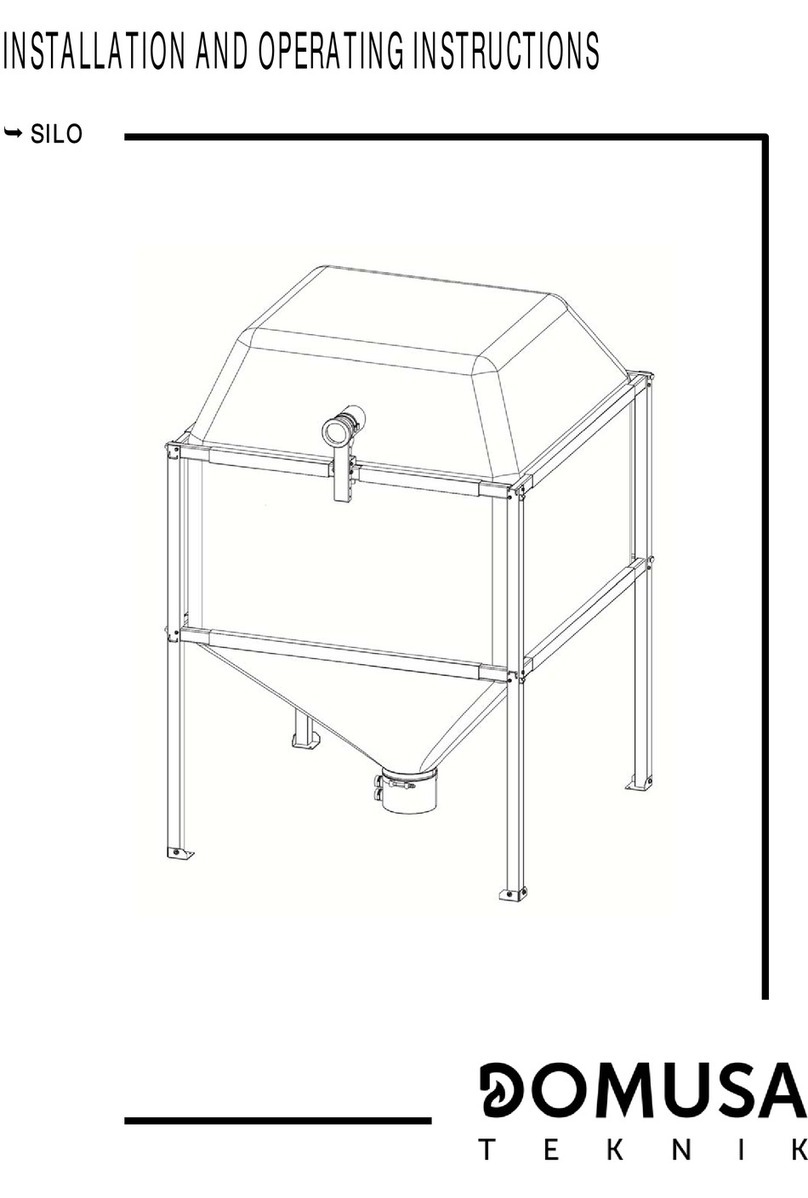

COMPONENTS OF THE APPLIANCE................................................................................................................................................................4

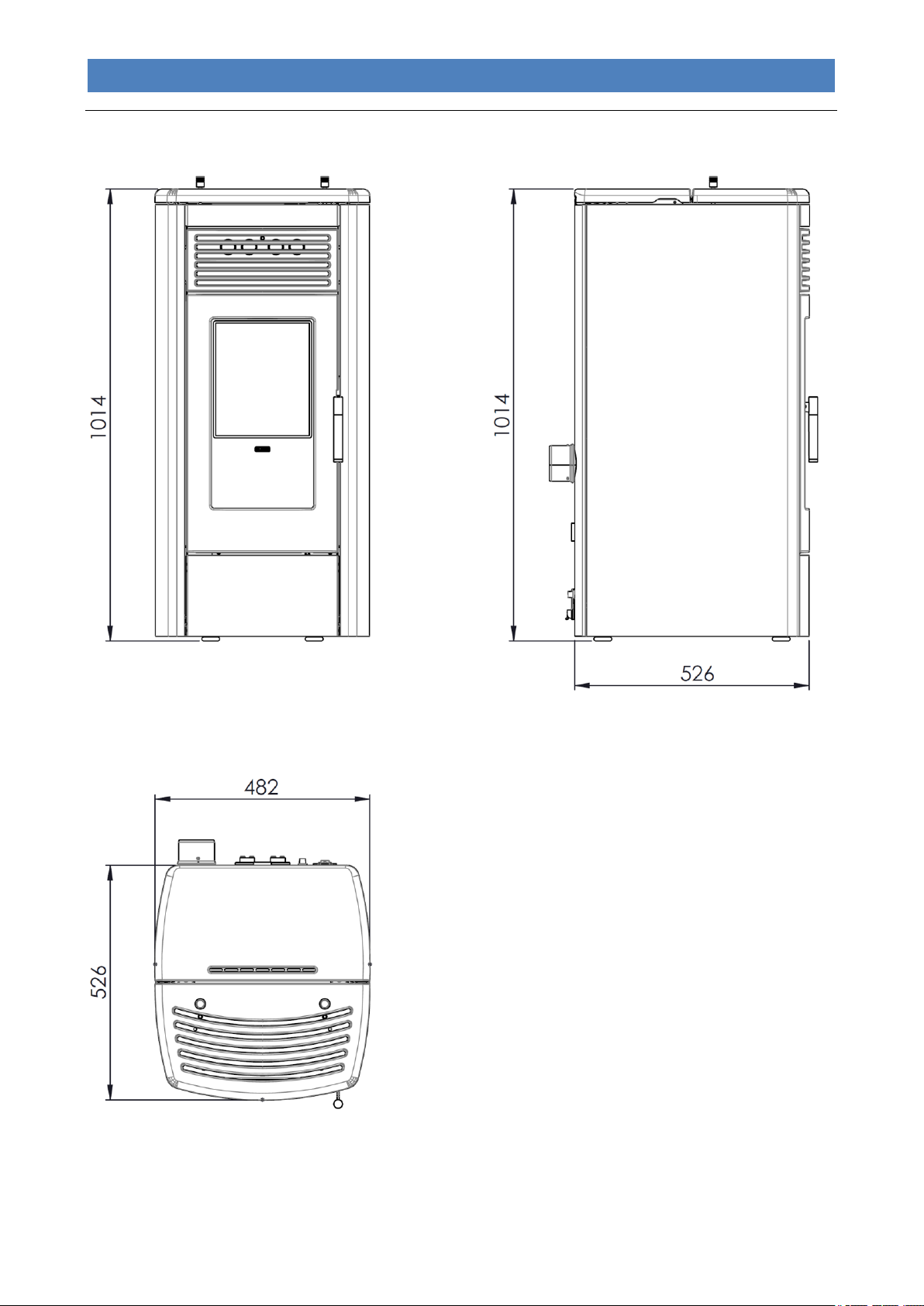

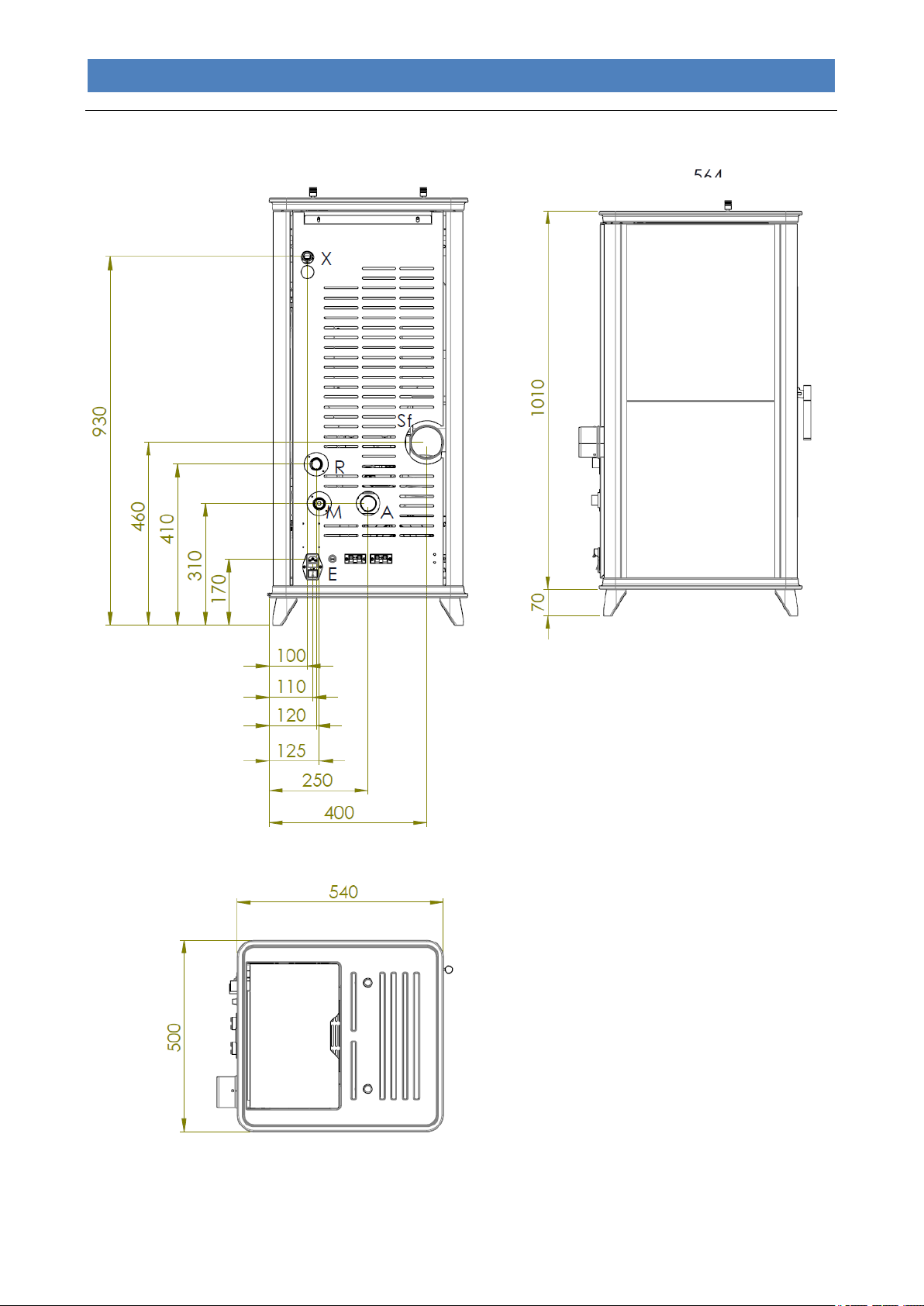

OVERALL DIMENSIONS FOR HRV VIKTOR...................................................................................................................................................7

OVERALL DIMENSIONS FOR HRV TORSBY....~............................................................................................................................................8

CONNECTIONS DATA SHEET FOR HRV VIKTOR...........................................................................................................................................9

CONNECTIONS DATA SHEET FOR HRV TORSBY.... ....................................................................................................................................10

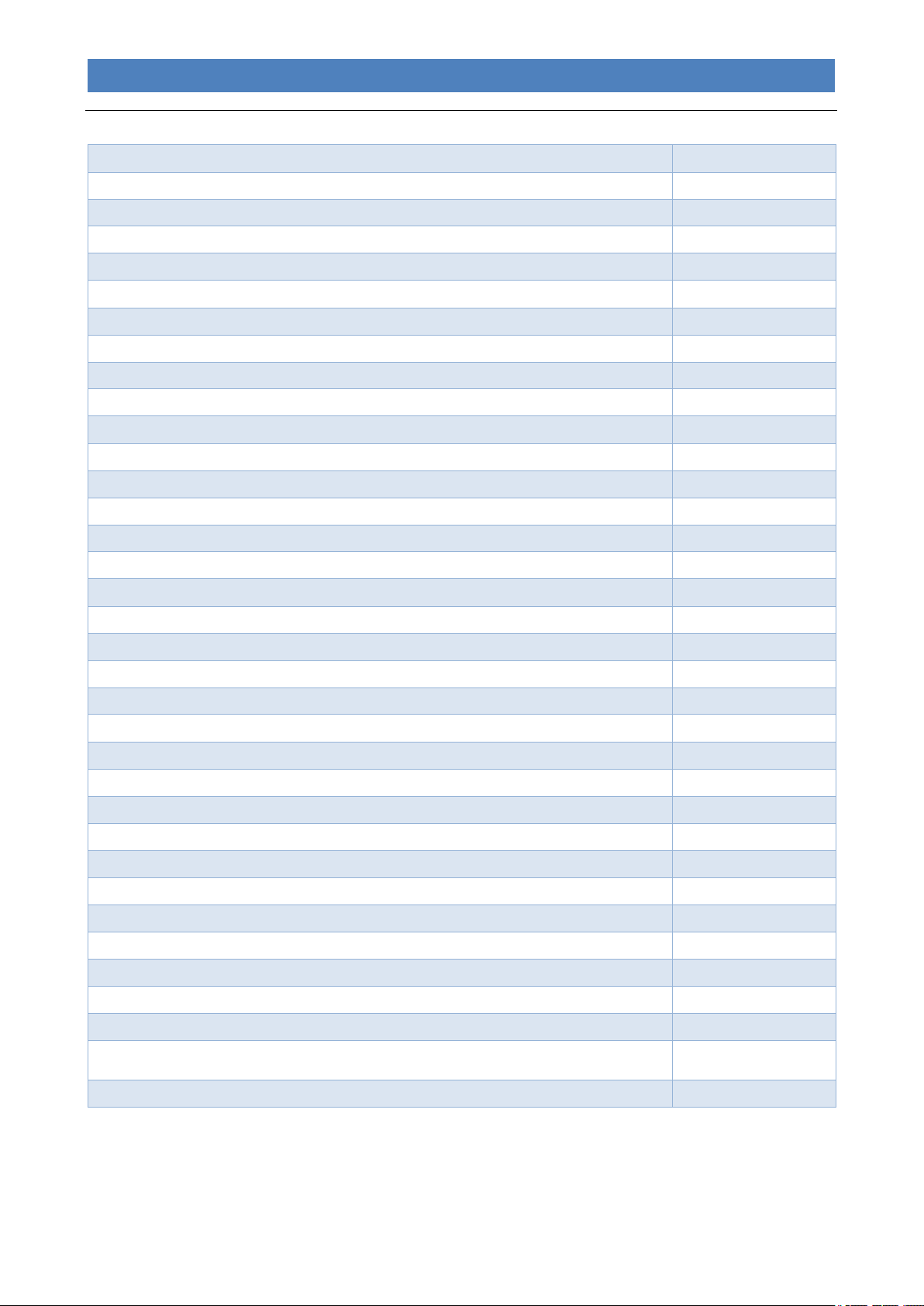

TECHNICAL SPECIFICATIONS.....................................................................................................................................................................11

PELLET PROPERTIES ................................................................................................................................................................................12

REQUIREMENTS OF THE PLACE OF INSTALLATION ................................................................................................. 12

POSITIONING ...........................................................................................................................................................................................12

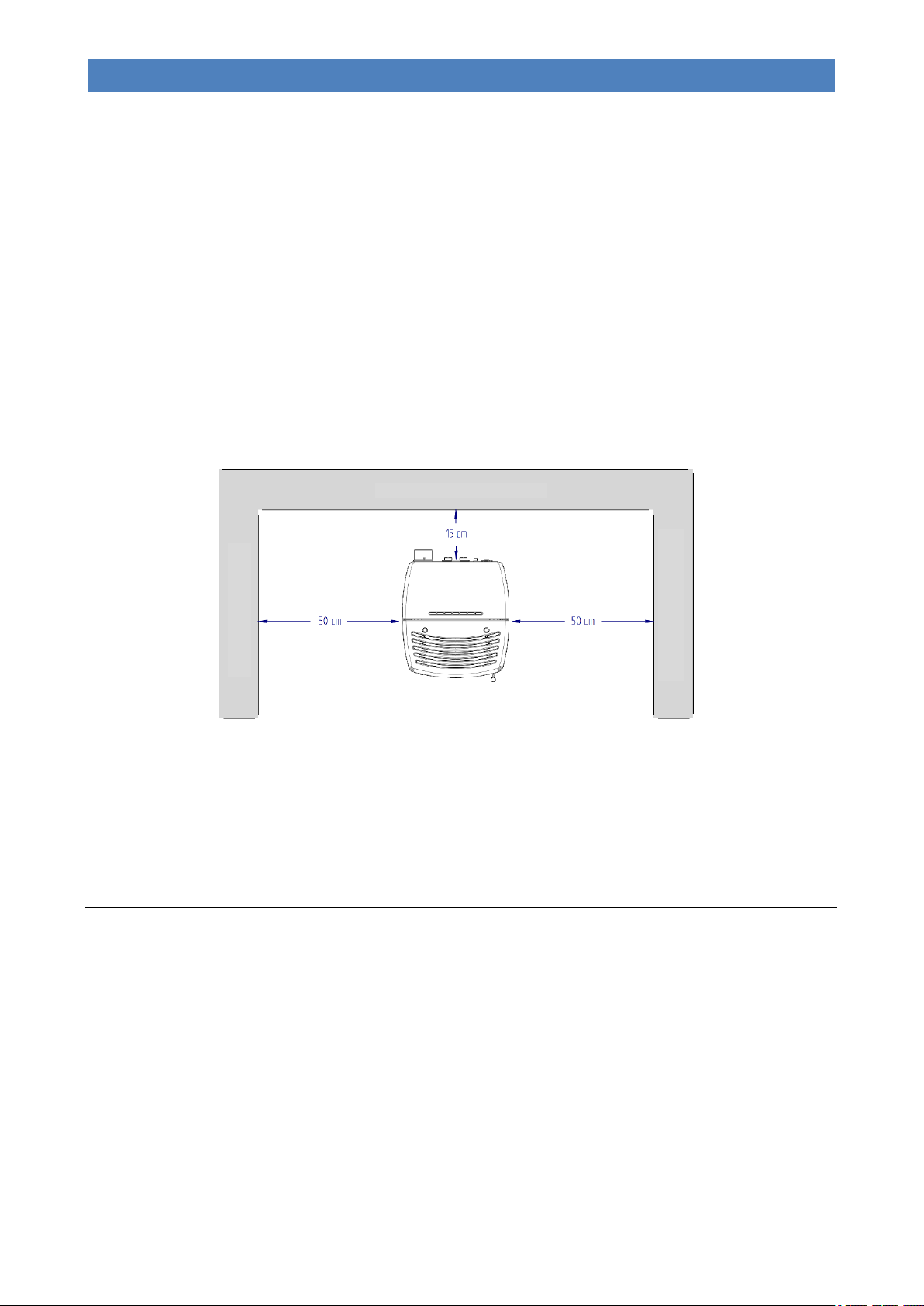

SPACES AROUND AND ABOVE THE APPLIANCE.............................................................................................................................................13

EXTERNAL AIR INTAKE ..............................................................................................................................................................................13

THE FLUE AND CONNECTION TO THE SAME .................................................................................................................................................14

CHIMNEY.................................................................................................................................................................................................15

ELECTRICAL CONNECTION .......................................................................................................................................... 16

CONTROL OF ANY COUPLED BOILER...........................................................................................................................................................16

CONTROL OF A POSSIBLE THREE-WAY MOTORIZED VALVE FOR DHW SYSTEM MANAGEMENT ..........................................................................17

CONNECTION TO THE ROOM THERMOSTAT..................................................................................................................................................17

HYDRAULIC CONNECTION ............................................................................................................................................ 18

THE DISPLAY .................................................................................................................................................................. 19

THE MENU ....................................................................................................................................................................... 21

INITIAL START-UP .......................................................................................................................................................... 25

SYSTEM CONFIGURATION..........................................................................................................................................................................25

INITIAL FILLING OF THE SYSTEM .................................................................................................................................................................27

PELLET LOADING AND CONNECTION TO THE MAINS POWER SUPPLY ..............................................................................................................27

IGNITION CYCLE .......................................................................................................................................................................................27

SWITCH-OFF CYCLE..................................................................................................................................................................................28

MODIFYING THE WORKING POWER.............................................................................................................................................................28

CHANGING THE WATER TEMPERATURE BOILER OR PUFFER ..........................................................................................................................28

CHANGING THE AIR FAN SPEED..................................................................................................................................................................29

PROBLEMS, ALARMS, USEFUL TIPS ........................................................................................................................... 30

USEFUL INFO…........................................................................................................................................................................................30

WHAT HAPPENS IF…................................................................................................................................................................................30

ALARM SIGNALS .......................................................................................................................................................................................31

CLEANING AND MAINTENANCE ................................................................................................................................... 32

PRECAUTIONS BEFORE CLEANING..............................................................................................................................................................32

ROUTINE CLEANING..................................................................................................................................................................................32

NON-ROUTINE CLEANING ..........................................................................................................................................................................33

ANNUAL CLEANING ...................................................................................................................................................................................35

CLEANING THE CERAMIC GLASS.................................................................................................................................................................37

CLEANING THE FLUE.................................................................................................................................................................................37

MAINTENANCE .........................................................................................................................................................................................37

PCB PARAMETERS ........................................................................................................................................................ 38

PARAMETERS TABLE.................................................................................................................................................................................38

WIRING DIAGRAM ........................................................................................................................................................... 40

STANDARD WARRANTY CONDITIONS ......................................................................................................................... 41