3

SAFETY AND PRECAUTION

• Keep bystanders and children away while operating the induction

heater.

• Keep a fully charged fire extinguisher or fire blanket at hand at all times

when using the induction heater.

• Ensure no flammable products are near the work area while using the

induction heater.

• If you have a cardiac pacemaker or any other kind of electronic or metal

surgical implant DO NOT operate the tool, and always stay at least 1

meter away from anybody operating a induction heater.

• Although the magnetic fields emitted by the tool only travel a few inch-

es, they pose a dangerous risk to the proper operation of all implanted

medical electronic devices in the user and any bystanders.

• Do not use the induction heater within 150mm of any air bag compo-

nent. The heat created by the induction heater can ignite the air bag

squib propellant causing it to explode without warning. Refer to the

vehicles service manual for precise air bag location before operating.

• Do not operate the induction heater while under the influence of

drugs, alcohol or any medication.

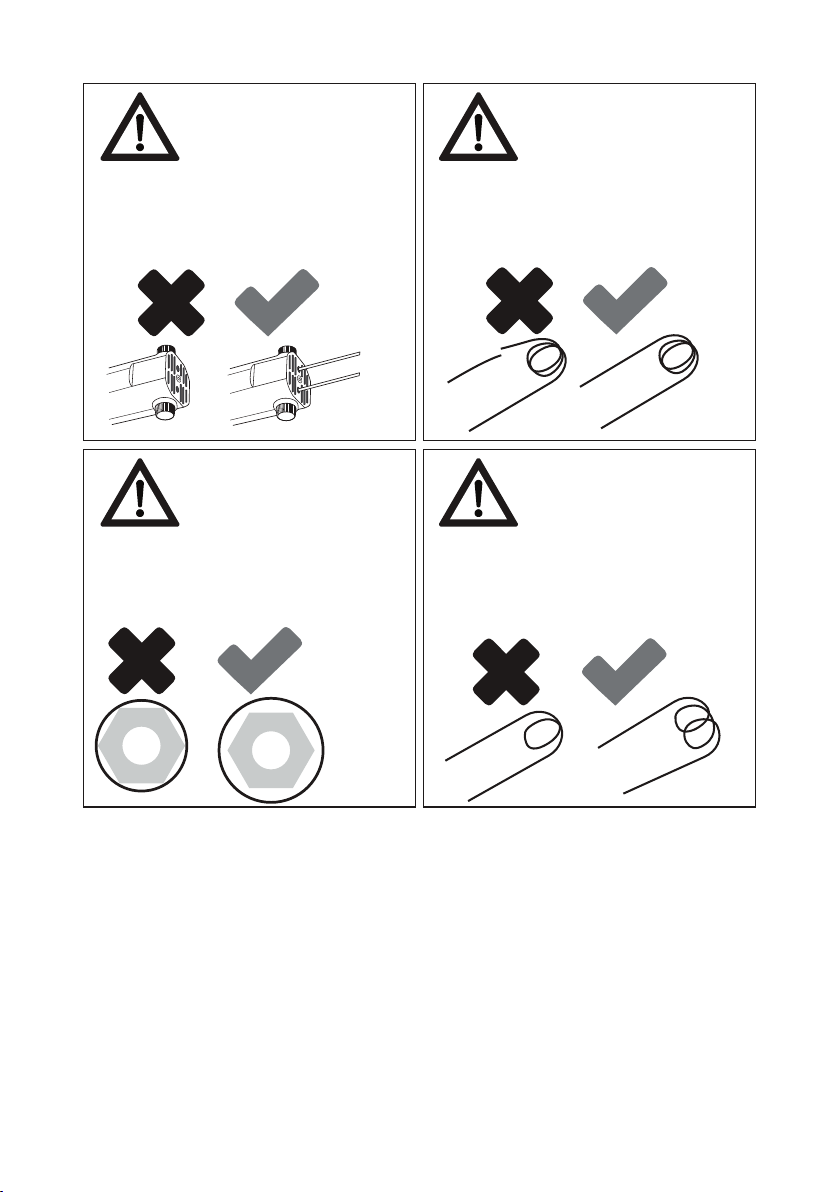

• Do not operate the induction heater while wearing any metallic items

such as jewellery, (including rings, watches, chains, identification tags,

body piercing) or belt buckles.

• Remove all loose coins, keys, chains, pocket knives, miniature tools, or

any other metallic object in, or, on your clothing before operating the

induction heater.

• Do not wear clothing that contains metallic rivets, waistband buttons,

pocket buttons or zips when operating the induction heater.

• The induction heater can heat these metallic objects very quickly and

cause serious burns or even ignite clothing.

• Always wear safety goggles when using the induction heater.

• Fumes and smoke from hot/burning adhesives are toxic. Wear an

appropriate dual filter (dust and fume) mask.

• Wear heat-resistant gloves when using the induction heater as it heats

metal very quickly. You can easily burn your hands and fingers when

trying to remove parts from hot metal surfaces.