Rooster CW Transceiver Rev3 Page 9 of 26 22nd Nov 2023

Stage 3 :- Side Tone

The Rooster has a sine wave sidetone generator, much more pleasant than many radios.

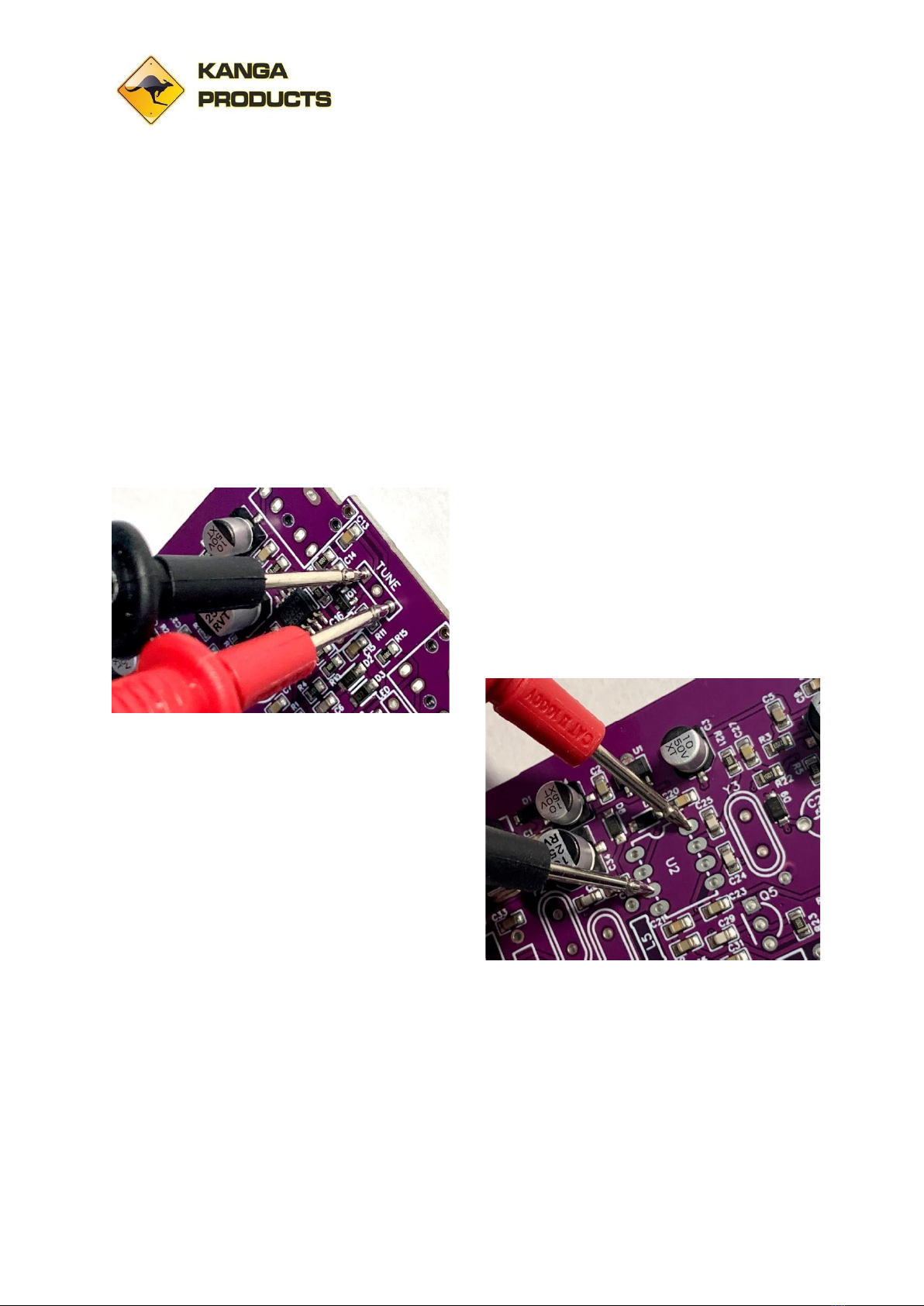

The first part we need to fit is a capacitor C16

C16 is a yellow capacitor with a 2.54mm pin spacing,

The value of this capacitor will adjust the volume of the

sidetone, we have used a value of 0.01uf for this.

CC16’s position is just

behind the Tune Control

location near the front of

the board.

Put this capacitor in its

location and slightly bend

the legs apart under the board, this will stop it falling out when you turn the board over to

solder it. Solder one lead first and re-check its still sat down correctly on the board. When

happy solder the second leg and trim the leads flush on the board.

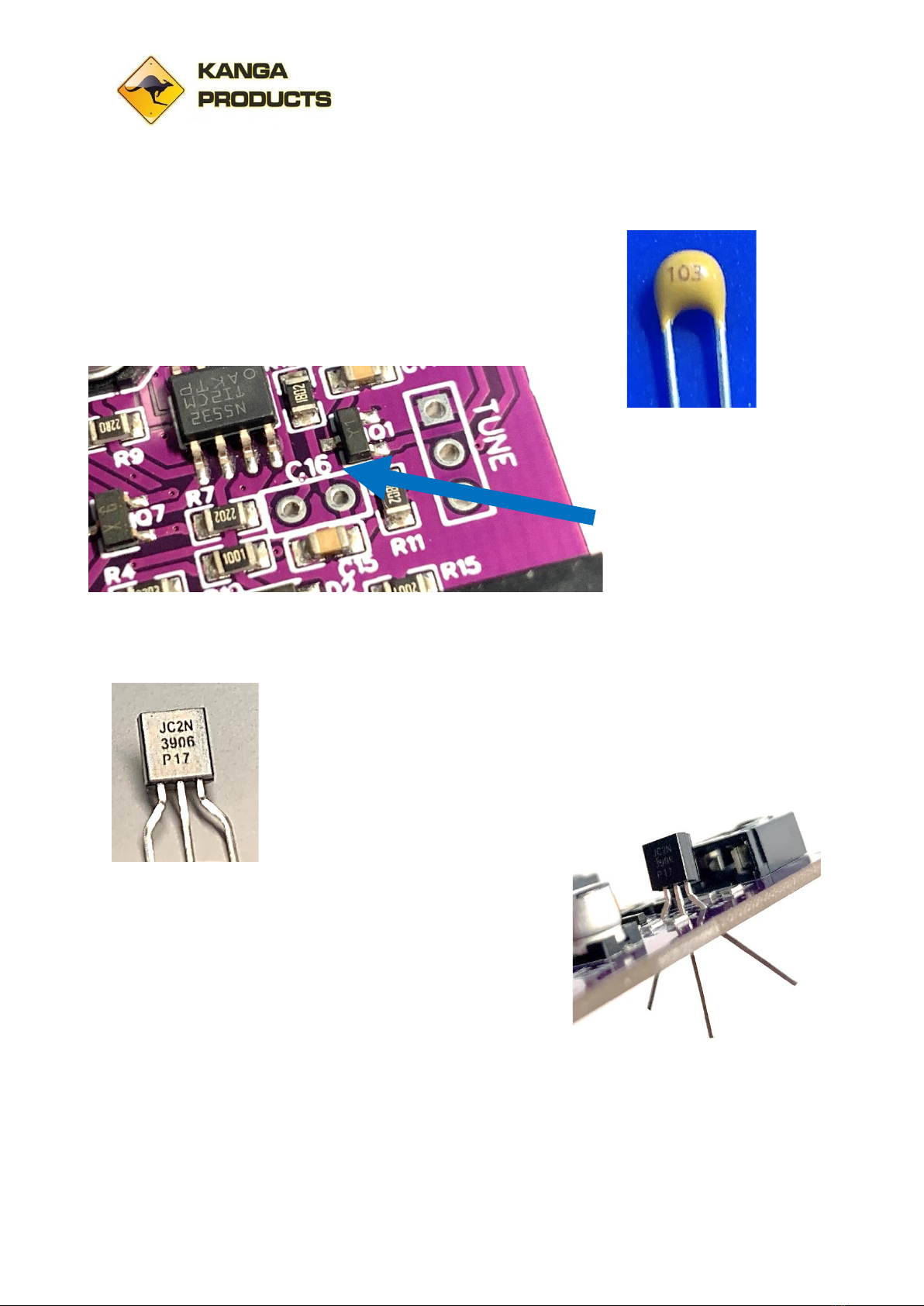

The next part is a transistor, IMPORTANT ! many different transistors

all look just the same, look on the flat side of the transistors in this kit

and check you select the right one for this, you need to find the

2N3906.

This transistor is to be fitted in

position Q4 on the board, it’s just

behind the KEY IN socket.

Make sure you put it the correct way round, the outline on

the PCB shows the way it must be fitted.

Push the part down to the natural stop point, don’t force

it! It will sit about 3mm above the board. Bend the two

outer legs outwards so the part doesn’t fall out when you

turn the board over.