Technical manual OT-600-060/1

Page 8

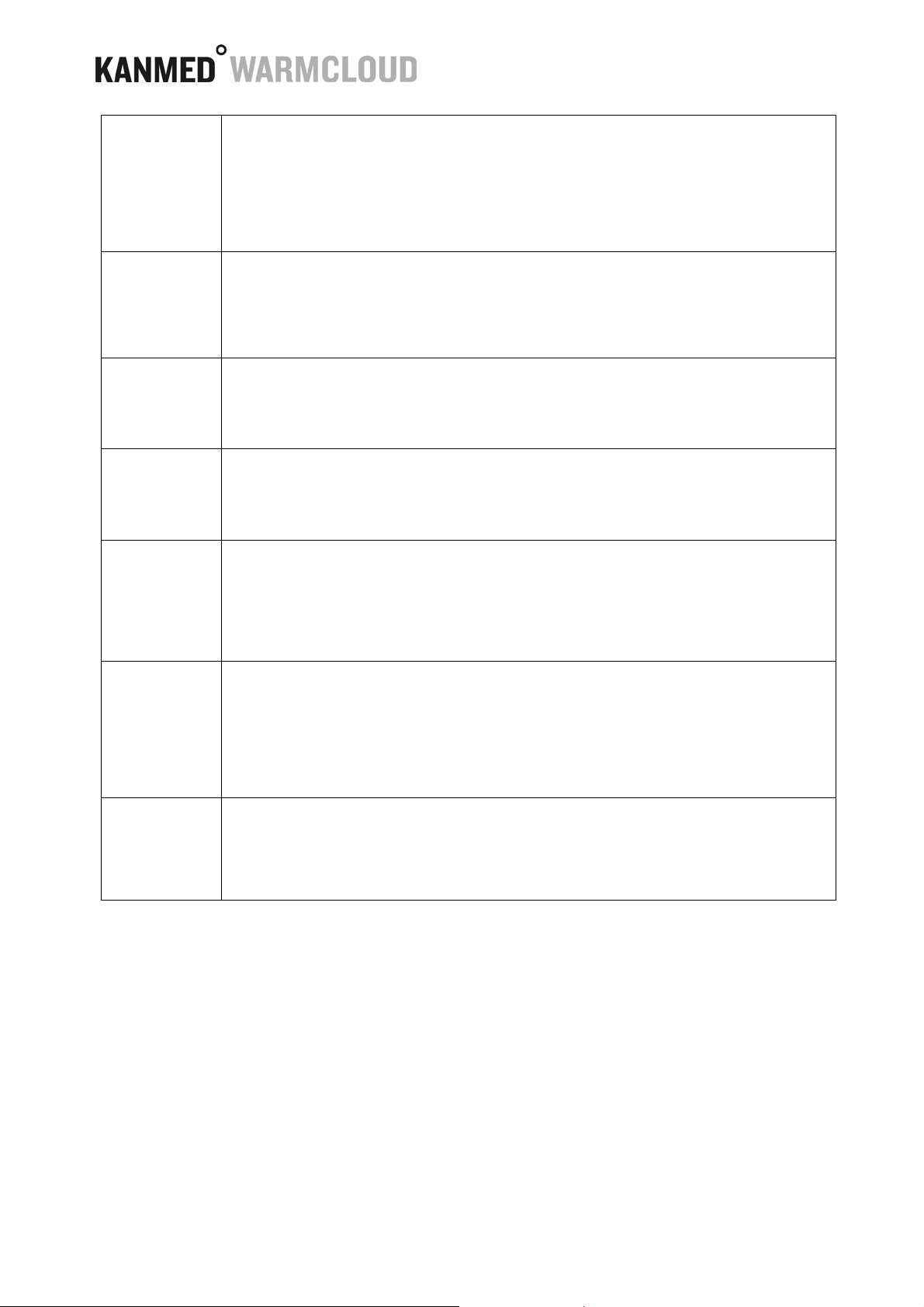

8. Trouble Shooting and Error codes

Error levels

A) Warning => Continued operation B) Serious error => Reduced heating

C) Major error => Heater OFF, Pressure ON D) Fatal error => System OFF

Alarm Code

and Level Description / Systems Actions

Err 001

C

High reading on temp sensor 1. Too high value detected. Probably sensor error or too

warm heating element. Can be caused by blocked air hose or channel in Mattress.

System actions: The heating will stop and the Hand Unit shows Err 001. After resetting the

alarm the temperature will display “---” and the alarm lamp will blink until the system is

stopped. This alarm is not active during the first 60 seconds after start.

User action required: Reset the alarm. Examine if the airflow is blocked by the patient

bottoming out, a blocked air hose or similar. If there is a natural cause for this alarm, correct

the condition and the system may be restarted. Otherwise contact a qualified technician to

examine the system.

Err 002

C

High reading on temp sensor 2. Too high value detected. Probably sensor error or too

warm heating element. Can be caused by blocked air hose or channel in Mattress.

System actions: The heating will stop and the Hand Unit shows Err 002. After resetting the

alarm the temperature will display “---” and the alarm lamp will blink until the system is

stopped. This alarm is not active during the first 60 seconds after start.

User action required: Reset the alarm. Examine if the airflow is blocked by the patient

bottoming out, a blocked air hose or similar. If there is a natural cause for this alarm, correct

condition and the system may be restarted. Otherwise contact a qualified technician to

examine the system.

Err 003

C

Air temperature exceeds safe value. The measured air temperature exceeds maximum

permitted value for more than 65 seconds. Can be caused by a blocked air channel or hose.

System actions: The alarm will switch off the warming and the display will show

Err 003. The alarm lamp will blink until the system is stopped. This alarm is not active during

the first 60 seconds after start.

User action required: Reset the alarm. Examine if the airflow is blocked by the patient

bottoming out, a blocked air hose or similar. If there is a natural cause for this alarm, correct

the condition and the system may be restarted. Otherwise contact a qualified technician to

examine the system.

Err 004

A

Set temp not reached, slow warming. The selected value has not been reached in 10

minutes. NOTE that this alarm may trigger if the unit is started in cold surroundings.

System actions: Err 004 will be displayed. When the alarm is silenced the lamp will stop

blinking and the unit will continue. If the alarm condition still exists after 10 minutes the alarm

will return.

User action required: Reset the alarm. Observe if the error returns, if it does, contact a

qualified technician to examine the system.

Err 005

A

Over pressure, measured air pressure exceeds selected value with more than 10mb.

Probably a fault on the electronic pressure relief valve or electronic error.

System actions: Err 005 is displayed. When the alarm is silenced the lamp will stop blinking

and the unit will continue. If the alarm situation still exists after 10 minutes the alarm will

come back.

User action required: Reset the alarm. Observe if the error returns, if it does, contact a

qualified technician to examine the system.

Err 006

C

Air leakage. The compressor is working continuously for more than 3 minutes. Probably a

major air leakage in the Mattress connection, the Mattress or the hoses.

System actions: Err 006 is displayed. If the system is in the phase of starting up a new

Mattress then it will go to stand by after silencing the alarm. If the situation occurs during

normal use the heating will be shut down but the compressor will continue to keep the

pressure. If the alarm condition still exists after 10 minutes the alarm will come back.

User action required: Reset the alarm. Examine the air hose connection. If there is a natural

cause for this alarm, correct the condition and the system may be restarted. Otherwise contact

a qualified technician to examine the system.