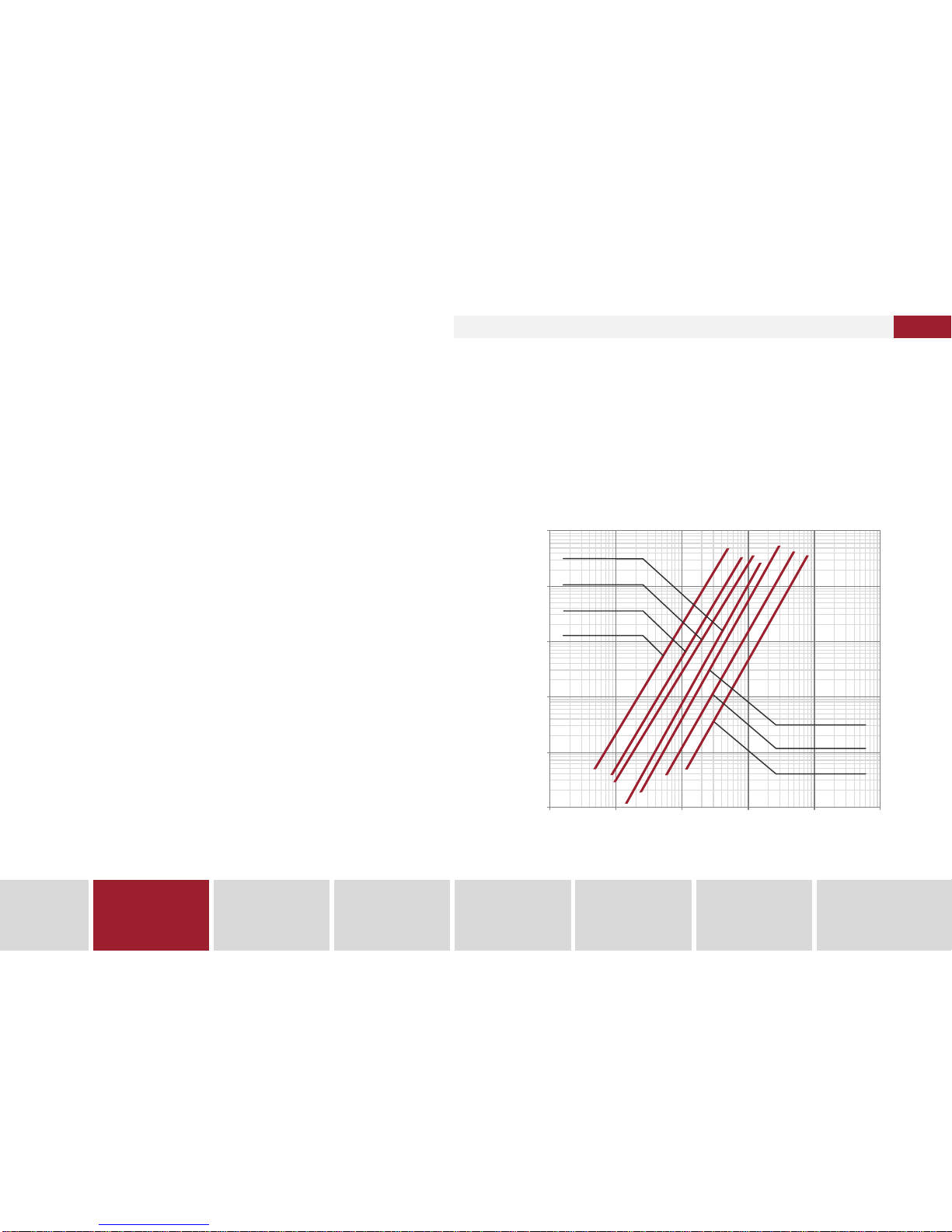

3

Flow rate, m /h

100

10

1

0,1

0,01

0,0010,01 0,1 110 100 1000

Pressure loss, MPa

Figure 1.3 – Pressure loss nomogram for KARAT-520 flowmeters

КАRАТ-520-20КАRАТ-520-20

КАRАТ-520-80КАRАТ-520-80

КАRАТ-520-25КАRАТ-520-25

КАRАТ-520-32КАRАТ-520-32

КАRАТ-520-40КАRАТ-520-40

КАRАТ-520-50КАRАТ-520-50

КАRАТ-520-65КАRАТ-520-65

1.3.2.Output signals parameters

Flowmeters of all design variants have 2 galvanically isolated pulse

outputs for transmission of measured values in the form of pulse

signalswiththespecifiedpulseweight(table1.2).

Pulsesignalhasthefollowingcharacteristics:

nminimumpulse-repetition interval...........................................…62;

npulse duration, ms ……………....................………................….31;

nvoltageinoutputcircuit,V,notmorethan………............…..…….50;

nminimumcurrent,providedin anoutputcircuit,mA.......................2;

nmaximumswitching current inanoutput circuit, mA…................10.

Flowmeter of KARAT-520-ХХ-3 design version has 2 analog elements

with current signal parameters according to GOST 26.011(“Measuring

and automation devices. Input and output current and voltage continu-

oussignals”):

nOutputcurrent,mA…....................................................…......4–20;

nSupply voltage, V ..................................................…....……12–36;

nMaximumloadresistance, Ohm…........................................…100.

FlowmetersofKARAT--520-ХХ-1,KARAT-520-ХХ-2designversions

withdigital outputRS-485, M-Bushavethe outputsignalparameters,

whichmeet therequirements, mentionedinstandards forthepresent

interfaces.

1.3.3.Powersupplycharacteristics

Inaccordancewith design version (table 1.1) flowmeters can be sup-

plied both from internal and external power sources according to de-

signversion.

Flowmeters of design version (it.1.2) are supplied from built-in lith-

ium battery of “C” dimension type with voltage equal to 3.6V ± 0,2V

and capacity equal to 7.2Ah. Battery life accounts to not less than 4

yearsofflowmetercontinuousrunning.

0

Flowmetersof , ,,designversionsaresuppliedfromexternaldirect

current source with output voltage from 12 to 36V. The output current

ofapowersourceshouldcorrespondtothefollowingcharacteristics:

nitshouldbenotlessthan100mAfor and designversions;

nnotlessthan50mAfor designversion;

nnotlessthan10mAfor4designversion.

1.3.4.Hydrauliccharacteristics

Diagrams of pressure loss dependence on the flow rate in flow tubes

fordifferentdimensiontypesaregivenonfigure1.3

1 2 3 4

1 2

3