Niagara FC User manual

Model FC - Mass Flow Computer 990272 Rev. A 05/04/12

Model FC

Mass Flow Computer

Installation, Operation

Manual

FC Flow Computer

SAFETY INSTRUCTIONS .............................................................................................................1

1. INTRODUCTION

1.1UnitDescription............................................................................................................2

1.2Specications...............................................................................................................3

2. INSTALLATION

2.1GeneralMountingHints................................................................................................8

2.2MountingDiagrams......................................................................................................8

3. APPLICATIONS

3.1SteamMass................................................................................................................13

3.2SteamHeat................................................................................................................. 11

3.3SteamNetHeat..........................................................................................................13

3.4SteamDeltaHeat.......................................................................................................14

3.5CorrectedGasVolume...............................................................................................15

3.6GasMass...................................................................................................................16

3.7GasCombustionHeat................................................................................................17

3.8CorrectedLiquidVolume............................................................................................18

3.9LiquidMass................................................................................................................19

3.10LiquidCombustionHeat...........................................................................................20

3.11LiquidSensibleHeat.................................................................................................21

3.12LiquidDeltaHeat......................................................................................................22

3.13Steam–CondensateHeat.......................................................................................23

4. WIRING

4.1TerminalDesignations................................................................................................24

4.2TypicalWiringConnections........................................................................................25

4.2.1FlowInput...................................................................................................25

4.2.2StackedDPInput........................................................................................25

4.2.3PressureInput............................................................................................25

4.2.4TemperatureInput......................................................................................26

4.2.5Temperature2Input...................................................................................26

4.3WiringInHazardousAreas.........................................................................................29

4.3.1FlowInput...................................................................................................27

4.3.2PressureInput............................................................................................27

4.3.3TemperatureInput......................................................................................27

5. UNIT OPERATION

5.1FrontPanelOperationConceptforOperateMode.....................................................28

5.2GeneralOperation......................................................................................................29

5.3PasswordProtection...................................................................................................29

5.4RelayOperation..........................................................................................................29

5.5PulseOutput..............................................................................................................29

5.6AnalogOutputs...........................................................................................................29

5.7FunctionKeys;DisplayGrouping...............................................................................29

5.8RS-232SerialPortOperation.....................................................................................30

5.8.1PCCommunications...................................................................................30

5.8.2OperationofRS-232SerialPortwithPrinters............................................30

5.9RS-485SerialPortOperation.....................................................................................30

5.10PauseComputationsPrompt....................................................................................30

6. PROGRAMMING

6.1FrontPanelOperationConceptforProgramMode....................................................31

6.2EZSetup....................................................................................................................32

6.3DetailedMenuDescriptions........................................................................................34

6.4SystemParameters....................................................................................................35

6.5Display........................................................................................................................40

6.6SystemUnits..............................................................................................................42

6.7FluidData...................................................................................................................49

6.8FlowInput...................................................................................................................54

6.9OtherInput..................................................................................................................66

6.10PulseOutput.............................................................................................................69

6.11CurrentOutput..........................................................................................................70

6.12Relays.......................................................................................................................74

6.13Communication.........................................................................................................78

6.14NetworkCard............................................................................................................85

6.15Service&Analysis....................................................................................................86

CONTENTS

FC Flow Computer

7. PRINCIPLE OF OPERATION

7.1General.......................................................................................................................92

7.2SquareLawFlowmeterConsiderations......................................................................92

7.3FlowEquations...........................................................................................................92

7.3.1FlowInputComputation..............................................................................92

7.3.2PressureComputation................................................................................93

7.3.3TemperatureComputation..........................................................................93

7.3.4Density/ViscosityComputation...................................................................93

7.3.5CorrectedVolumeFlowComputation.........................................................94

7.3.6MassFlowComputation.............................................................................95

7.3.7CombustionHeatFlowComputation..........................................................95

7.3.8HeatFlowComputation..............................................................................96

7.3.9SensibleHeatFlowComputation...............................................................96

7.3.10LiquidDeltaHeatComputation.................................................................96

7.3.11ExpansionFactorComputationforSquareLawFlowmeters...................96

7.3.12UncompensatedFlowComputation.........................................................98

7.3.13ILVAFlowMeterEquations.......................................................................99

7.4ComputationoftheD.P.Factor................................................................................100

8. RS-232 SERIAL PORT

8.1RS-232SerialPortDescription.................................................................................101

8.2InstrumentSetupbyPCOverSerialPort................................................................101

8.3OperationofSerialCommunicationPortwithPrinters.............................................101

8.4FCRS-232PortPinout.............................................................................................101

9. RS-485 SERIAL PORT

9.1RS-485SerialPortDescription.................................................................................102

9.2General.....................................................................................................................102

9.3OperationofSerialCommunicationPortwithPC....................................................102

9.4FCRS-485PortPinout.............................................................................................102

10. FLOW COMPUTER SETUP SOFTWARE

10.1SystemRequirements............................................................................................103

10.2CableandWiringRequirements.............................................................................103

10.3InstallationforWindows™3.1or3.11.....................................................................103

10.4UsingtheFlowComputerSetupSoftware.............................................................103

10.5FileTab...................................................................................................................104

10.6SetupTab...............................................................................................................104

10.7ViewTab.................................................................................................................105

10.8Misc.Tab................................................................................................................105

11. GLOSSARY OF TERMS

10GlossaryOfTerms.....................................................................................................106

12. Diagnosis and Troubleshooting

12.1ResponseofFConErrororAlarm.........................................................................109

12.2DiagnosisFlowchartandTroubleshooting..............................................................109

12.3ErrorMessages...................................................................................................... 110

Appendix A

FluidPropertiesTable..................................................................................................... 113

Appendix B - Setup Menus

SetupMenuswithOperatorCodeAccess...................................................................... 114

SetupMenuswithSupervisorCodeAccess................................................................... 115

Appendix C - RS-485 Modbus Protocol

Description...................................................................................................................... 116

WiringPinoutandInstallation......................................................................................... 117

RegisterandCoilUsage................................................................................................. 119

CONTENTS

FC Flow Computer

1

!

SAFETY INSTRUCTIONS

The following instructions must be observed.

• Thisinstrumentwasdesignedandischeckedinaccordancewith

regulationsinforceEN60950(“Safetyofinformationtechnology

equipment,includingelectricalbusinessequipment”).

Ahazardoussituationmayoccurifthisinstrumentisnotusedfor

itsintendedpurposeorisusedincorrectly.Pleasenoteoperating

instructionsprovidedinthismanual.

• Theinstrumentmustbeinstalled,operatedandmaintainedby

personnelwhohavebeenproperlytrained.Personnelmustread

andunderstandthismanualpriortoinstallationandoperationofthe

instrument.

• Themanufacturerassumesnoliabilityfordamagecausedbyincorrect

useoftheinstrumentorformodicationsorchangesmadetothe

instrument.

Technical Improvements

• Themanufacturerreservestherighttomodifytechnicaldatawithout

priornotice.

FC Flow Computer

2

1. Introduction

PeakDemandOption

Thereareapplicationswherecustomerchargesaredetermined

inpartbythehighesthourlyaveragedowrateobservedduring

abillingperiod.

ThepeakdemandoptionfortheFCisintendedforapplica-

tionswhereitisimportanttocomputesuchanhourlyaverage

owrate,tonotethevalueofthepeakoccurrenceandthecor-

respondingtimeanddateofthatevent.

Thedemandlasthourrateiscomputedbasedonthecurrent

totalandthetotal60minutesprior.Thisvalueisrecomputed

every5minutes.

Thepeakdemandisthehighestvalueobservedinthedemand

lasthour.

Thetimeanddatestampisthetimeanddateatwhichthehigh-

estpeakdemandoccurred.

TheDemandLastHourand/orPeakDemandcanbedirectly

viewedonthedisplaybypressingtheRATEkeyandthen

scrollingthroughtherateswiththe^/varrowkeyuntilthede-

sireditemisviewed.

ThePeakTimeandDatestampcanbeviewedonthedisplay

bypressingtheTIMEandthenscrollingthroughthetimere-

latedparametersusingthe^/varrowkeysuntilthedesireditem

isviewed.

Alloftheseitemscanbeincludedintothescrollingdisplaylist

alongwiththeotherprocessvaluesandtotalizersinauser

selectablelist.

ThepeakdemandmaybeclearedbypressingtheCLEARkey

whileviewingthePEAKDEMANDorbymeansofacommand

ontheserialport.

ThePeakTimeandDatestampcanbeviewedonthedisplay

bypressingtheTIMEandthenscrollingthroughthetimere-

latedparametersusingthe^/varrowkeysuntilthedesireditem

isviewed.

TheDemandLastHourandPeakDemandcanbeassigned

tooneoftheanalogoutputs.Thedemandlasthourorpeak

demandcouldthuslybeoutputonarecordingdevicesuchas

astripchartrecorderorfedintoabuildingenergyautomation

system.

TheDemandLastHourandPeakDemandcanbeassigned

tooneoftherelays.Thecustomercanbenotiedthatheis

approachingorexceedingacontracthighlimitbyassigningthe

demandlasthourtooneoftherelaysandsettingthewarn-

ingpointintothesetpoint.Awarningmessagewouldalsobe

displayed.

Thepeakdemandmaybeusedinconjunctionwiththeprintlist

anddataloggertokeeptrackofhourlycustomerusageproles.

TheDemandLastHour,PeakDemand,andTimeandDate

Stampinformationcanbeaccessedovertheserialports.The

PeakDemandmayalsoberesetovertheserialports.

Thepeakdemandoptionmayalsobeusedasaconditionto

calloutinremotemeteringbymodem.

EZ Setup

TheunithasaspecialEZsetupfeaturewheretheuserisguided

through a minimum number of steps to rapidly congure the

instrumentfortheintendeduse.TheEZsetuppreparesaseries

ofquestionsbasedonowequation,uid,andowmetertype

desiredintheapplication.

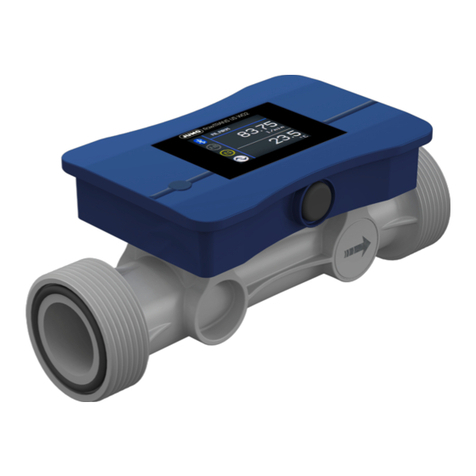

1.1 Unit Description:

The FC Flow Computer satises the instrument requirements

foravarietyofowmetertypes inliquid,gas,steamand heat

applications. Multiple ow equations are available in a single

instrumentwithmanyadvancedfeatures.

Thealphanumericdisplayoffersmeasuredparametersineasyto

understandformat.Manualaccesstomeasurementsanddisplay

scrollingissupported.

TheversatilityoftheFlowComputerpermitsawidemeasureof

applicationswithintheinstrumentpackage.Thevarioushardware

inputsandoutputscanbe“soft”assignedtomeetavarietyof

commonapplicationneeds.Theuser“softselects”theusageof

eachinput/outputwhileconguringtheinstrument.

Theisolatedanalogoutputcanbechosentofollowthevolume

ow,correctedvolumeow,massow,heatow,temperature,

pressure,ordensitybymeansofamenuselection.Mosthardware

featuresareassignablebythismethod.

TheusercanassignthestandardRS-232SerialPortfordata

logging,ortransactionprinting,orforconnectiontoamodemfor

remotemeterreading.

APCCompatiblesoftwareprogramisavailablewhichpermitsthe

usertorapidlyredenetheinstrumentconguration.

Languagetranslationoptionfeaturesalsopermittheusertodene

hisownmessages,labels,andoperatorprompts.Thesefeatures

maybeutilizedattheOEMleveltocreativelycustomizetheunit

foranapplicationoralternatelytoprovideforforeignlanguage

translations.BothEnglishandasecondlanguageresidewithin

theunit.

NX-19option

AdvancedorderingoptionsareavailableforNaturalGascalculations

wheretheuserrequirescompensationforcompressibilityeffects.

Compensationforthesecompressibilityeffectsarerequiredat

mediumtohighpressureandareafunctionofthegasspecic

gravity,%CO2,%Nitrogen,aswellastemperatureandpressure.

ThecompressibilityalgorithmusedisthatforNX-19.

Stackeddifferentialpressuretransmitteroption

ThisoptionpermitstheuseofalowrangeandhighrangeDP

transmitteronasingleprimaryelementtoimproveowtransducer

andmeasurementaccuracy.

Peakdemandoption

Thisoptionpermitsthedeterminationofanhourlyaveragedow

rate.Demandlasthour,peakdemandandtime/datestampingfor

applicationsinvolvingpremiumbilling.

Dataloggingoption

Thisoptionprovidesdatastorageinformationin64kofbattery

backedRAM.Itemstobelogged,conditionstoinitiatethelogand

avarietyofutilitiestoclearandaccessthedataviatheRS-232

portareprovided.

FC Flow Computer

3

1.2 Specications:

Environmental

OperatingTemperature:0to+50C

StorageTemperature:-40to+85C

Humidity:0-95%Non-condensing

Materials:UL,CSA,VDEapproved

Approvals: CEApprovedLightIndustrial,UL/CSAPending

Display

Type:2linesof20characters

Types:BacklitLCDandVFDorderingoptions

CharacterSize:0.3"nominal

Userselectablelabeldescriptorsandunitsofmeasure

Keypad

KeypadType:MembraneKeypad

KeypadRating:SealedtoNema4

Numberofkeys:16

RaisedKeyEmbossing

Enclosure

EnclosureOptions:Panel,Wall,ExplosionProof

Size:SeeChapter2;Installation

Depthbehindpanel:6.5"includingmatingconnector

Type:DIN

Materials:Plastic,UL94V-0,Flameretardant

Bezel:Texturedpermattnish

EquipmentLabels:Model,safety,anduserwiring

NX-19 Compressibility Calculations

Temperature -40to240F

Pressure 0to5000psi

SpecicGravity 0.554to1.0

Mole%CO2 0to15%

Mole%Nitrogen 0to15%

Power Input

The factory equipped power options are internally fused.

Aninternallinetolineltercapacitorisprovidedforadded

transientsuppression.MOVprotectionforsurgetransientis

alsosupported

UniversalACPowerOption:

85to276Vrms,50/60Hz

Fuse:TimeDelayFuse,250V,500mA

DCPowerOption:

24VDC(16to48VDC)

Fuse:TimeDelayFuse,250V,1.5A

TransientSuppression:1000V

Flow Inputs:

Flowmeter Types Supported:

Linear:

Vortex,Turbine,PositiveDisplacement,Magnetic,

GilFlo,GilFlo16point,ILVA16Point,MassFlow

andothers

SquareLaw:

Orice,Venturi,Nozzle,V-Cone,Wedge,Averaging

Pitot,Target,Verabar,Accelabarandothers

Multi-PointLinearization:

Maybeusedwithallowmetertypes.Including:16

point,UVCanddynamiccompensation.

Analog Input:

Ranges

Voltage:0-10VDC,0-5VDC,1-5VDC

Current:4-20mA,0-20mA

BasicMeasurementResolution:16bit

UpdateRate:2updates/secminimum

Accuracy:0.02%FS

AutomaticFaultdetection: Signalover/under-range,

CurrentLoopBroken

Calibration: Operatorassisted learnmode. LearnsZero

andFullScaleofeachrange

FaultProtection:

FastTransient:1000VProtection(capacitiveclamp)

ReversePolarity:Noilleffects

Over-VoltageLimit: 5 0 V D C O v e r v o l t a g e

protection

Over-CurrentProtection: Internallycurrentlimited

protectedto24VDC

Optional:StackedDPtransmitter0-20mAor4-20mA

Pulse Inputs:

NumberofFlowInputs:one

InputImpedance:10kΩnominal

TriggerLevel:(menuselectable)

HighLevelInput

LogicOn: 2to30VDC

LogicOff: 0to.9VDC

LowLevelInput(magpickup)

Selectablesensitivity:10mVand100mV

MinimumCountSpeed:0.25Hz

MaximumCountSpeed:Selectable:0to40kHz

OvervoltageProtection:50VDC

FastTransient:Protectedto1000VDC(capacitiveclamp)

Temperature, Pressure, Density Inputs

The compensation inputs usage are menu selectable for

temperature, temperature 2, pressure, density, steam trap

monitorornotused.

Calibration:Operatorassistedlearnmode

Operation:Ratiometric

Accuracy:0.02%FS

ThermalDrift:Lessthan100ppm/C

BasicMeasurementResolution:16bit

UpdateRate:2updates/secminimum

AutomaticFaultdetection:

SignalOver-range/under-range

CurrentLoopBroken

RTDshort

RTDopen

TransientProtection:1000V(capacitiveclamp)

ReversePolarity:Noilleffects

Over-VoltageLimit(VoltageInput):50VDC

Over-CurrentLimit(Internallylimitedtoprotectinputto

24VDC)

AvailableInputRanges

(Temperature/Pressure/Density/TrapMonitor)

Current:4-20mA,0-20mA

Resistance:100OhmsDINRTD

100OhmDINRTD(DIN43-760,BS1904):

ThreeWireLeadCompensation

InternalRTDlinearizationlearnsicepointresistance

1mAExcitationcurrentwithreversepolarityprotection

TemperatureResolution:0.1°C

TemperatureAccuracy:0.5°C

FC Flow Computer

4

Datalogger (optional)

Type:BatteryBackedRAM

Size: 64k

Initiate:Key,IntervalorTimeofDay

ItemsIncluded:SelectableList

DataFormat:PrinterorCSVAccessviaRS-232command

Stored Information (ROM)

Steam Tables (saturated & superheated), General Fluid

Properties, Properties of Water, Properties of Air, Natural

Gas

User Entered Stored Information (EEPROM / Nonvolatile

RAM)

TransmitterRanges,SignalTypes

FluidProperties

(specific gravity, expansion factor, specific heat,

viscosity,

isentropicexponent,combustionheatingvalue,Zfactor,

RelativeHumidity)

UnitsSelections(English/Metric)

RS-232 Communication

Uses:Printing,Setup,Modem,Datalogging

BaudRates:300,1200,2400,9600

Parity:None,Odd,Even

DeviceID:0to99

Protocol:Proprietary,Contactfactoryformoreinformation

ChassisConnectorStyle:DB9Femaleconnector

PowerOutput: 8V(150mAmax.)providedtoModem

RS-485 Communication(optional)

Uses:NetworkCommunications

BaudRates:300,600,1200,2400,4800,9600,19200

Parity:None,Odd,Even

DeviceID:1to247

Protocol:ModBusRTU

ChassisConnectorStyle:DB9Femaleconnector(standard)

Excitation Voltage

24VDC@100mAovercurrentprotected

Relay Outputs

Therelayoutputsusageismenuassignableto(Individually

for each relay) Hi/Lo Flow Rate Alarm, Hi/Lo Temperature

Alarm,Hi/LoPressureAlarm,PulseOutput(pulseoptions),

WetSteamorGeneralpurposewarning(security).

(Peakdemandanddemandlasthouroptional)

Numberofrelays:2(3optional)

ContactStyle:FormCcontacts(FormAwith3relayoption)

ContactRatings:240V,1amp

FastTransientThreshold:2000V

Analog Outputs

Theanalogoutputusageismenuassignabletocorrespond

tothe HeatRate, UncompensatedVolume Rate,Corrected

Volume Rate, Mass Rate, Temperature, Density, or

Pressure.

(Peakdemandanddemandlasthouroptional)

NumberofOutputs:2

Type:IsolatedCurrentSourcing(sharedcommon)

IsolatedI/P/C:500V

AvailableRanges:0-20mA,4-20mA(menuselectable)

Resolution:16bit

Accuracy:0.05%FSat20DegreesC

UpdateRate:5updates/sec

TemperatureDrift:Lessthan200ppm/C

MaximumLoad:1000ohms

ComplianceEffect:Lessthan.05%Span

60Hzrejection:40dBminimum

EMI:Noeffectat10V/M

Calibration:OperatorassistedLearnMode

Averaging: UserentryofDSPAveragingconstantto

causeansmoothcontrolaction

Isolated Pulse output

TheisolatedpulseoutputismenuassignabletoUncompensated

VolumeTotal,CompensatedVolumeTotal,HeatTotalorMass

Total.

IsolationI/O/P:500V

PulseOutputForm(menuselectable):OpenCollectorNPNor

24VDCvoltagepulse

NominalOnVoltage:24VDC

MaximumSinkCurrent:25mA

MaximumSourceCurrent:25mA

MaximumOffVoltage:30VDC

SaturationVoltage:0.4VDC

PulseDuration:Userselectable

Pulseoutputbuffer:8bit

Real Time Clock

TheFlowComputerisequippedwitheitherasupercapora

batterybackedrealtimeclockwithdisplayoftimeanddate.

Format:

24hourformatfortime

Day,Month,Yearformatfordate

DaylightSavingsTime(optional)

Measurement

The Flow Computer can be thought of as making a series

ofmeasurementsofow,temperature/densityandpressure

sensors and then performing calculations to arrive at a

result(s)whichisthenupdatedperiodicallyonthedisplay.The

analogoutputs,thepulseoutput,andthealarmrelaysarealso

updated.Thecyclethenrepeatsitself.

Step1: Updatethemeasurementsofinputsignals-

Raw Input Measurements are made at each input using

equationsbasedoninputsignaltypeselected.Thesystem

notesthe“outofrange”inputsignalasanalarmcondition.

Step2: ComputetheFlowingFluidParameters-

Thetemperature,pressure, viscosityanddensity equations

arecomputedasneededbasedontheowequationandinput

usageselectedbytheuser.

FC Flow Computer

5

Step3:ComputetheVolumetricFlow-

Volumetricowisthetermgiventotheowinvolumeunits.

The value is computed based on the owmeter input type

selected and augmented by any performance enhancing

linearizationthathasbeenspeciedbytheuser.

Step4:ComputetheCorrectedVolumeFlowatReference

Conditions-

Inthecaseofacorrectedliquidorgasvolumeowcalculation,

the corrected volume ow is computed as required by the

selectedcompensationequation.

Step5:ComputetheMassFlow-

Allrequiredinformationisnowavailabletocomputethemass

owrateasvolumeowtimesdensity.Aheatowcomputation

isalsomadeifrequired.

Step6:CheckFlowAlarms-

The ow alarm functions have been assigned to one of

the above ow rates during the setup of the instrument.A

comparisonisnowmadebycomparingthecurrentowrates

againstthespeciedhiandlowlimits.

Step7:ComputetheAnalogOutput-

Thisdesignatedowratevalueisnowusedtocomputethe

analogoutput.

Step8:ComputetheFlowTotalsbySummation-

A ow total increment is computed for each ow rate. This

incrementiscomputedbymultiplyingtherespectiveowrate

byatimebasescalerandthensumming.Thetotalizerformat

alsoincludesprovisionsfortotalrollover.

Step9:PulseOutputService-

Thepulseoutputisnextupdatedbyscalingthetotalincrement

whichhasjustbeendeterminedbythepulseoutputscalerand

summingittoanyresidualpulseoutputamount.

Step10:UpdateDisplayandPrinterOutput-

Theinstrumentnallyrunsatasktoupdatethevarioustable

entries associated with the front panel display and serial

outputs.

Instrument Setup

Thesetupispasswordprotectedbymeansofanumericlock

outcodeestablishedbytheuser.Thehelplineandunitsof

measurepromptsassureeasyentryofparameters.

An EZ Setup function is supported to rapidly congure the

instrument for rst time use. A software program is also

available which runs on a PC using a RS-232 Serial for

connectiontotheFlowComputer.Illustrativeexamplesmay

bedownloadedinthismanner.

The standard setup menu has numerous subgrouping of

parameters needed for ow calculations. There is a well

conceived hierarchy to the setup parameter list. Selections

made at the beginning of the setup automatically affect

offeringsfurtherdowninthelists,minimizingthenumberof

questionsaskedoftheuser.

In the setup menu, the ow computer activates the correct

setup variables based on the instrument conguration, the

ow equation, and the hardware selections made for the

compensation transmitter type, the ow transmitter type,

andmeterenhancements(linearization)optionsselected.All

requiredsetupparametersareenabled.Allsetupparameters

notrequiredaresuppressed.

Alsonotethatinthemenuareparameterselectionswhichhave

preassignedindustrystandardvalues.Theunitwillassume

thesevaluesunlesstheyaremodiedbytheuser.

Mostoftheprocessinputvariableshaveavailablea“default”

oremergency valuewhich mustbe entered.Theseare the

valuesthattheunitassumeswhenamalfunctionisdetermined

tohaveoccurredonthecorrespondinginput.

It is possible to enter in a nominal constant value for

temperature or density, or pressure inputs by placing the

desirednominal value intothe default valuesand selecting

"manual".Thisisalsoaconveniencewhenperformingbench

toptestswithoutsimulators.

Thesystemalsoprovidesaminimumimplementationofan

“audittrail”whichtrackssignicantsetupchangestotheunit.

This feature is increasingly being found of benet to users

or simply required by Weights and Measurement Ofcials

in systems used in commerce, trade, or “custody transfer”

applications.

Simulation and Self Checking:

Thismodeprovidesanumberofspecializedutilitiesrequired

forfactory calibration,instrumentcheckoutonstart-up, and

periodiccalibrationdocumentation.

A service password is required to gain access to this

specializedmodeof operation.Normallyquality, calibration,

andmaintenancepersonnelwillndthismodeofoperation

veryuseful.

Manyofthese tests maybe used duringstart-upof a new

system.Outputsignalsmaybeexercisedtoverifytheelectrical

interconnectsbeforetheentiresystemisputonline.

ThefollowingactionitemsmaybeperformedintheDiagnostic

Mode:

PrintCalibration/MaintenanceReport

ViewSignalInput(Voltage,Current,Resistance,Frequency)

ExamineAuditTrail

PerformaSelfTest

PerformaServiceTest

ViewErrorHistory

PerformPulseOutputCheckout/Simulation

PerformRelayOutputCheckout/Simulation

PerformAnalogOutputCheckout/Simulation

CalibrateAnalogInputsusingtheLearnFeature

CalibrateAnalogOutputusingtheLearnFeature

ScheduleNextMaintenanceDate

Notethatacalibrationoftheanaloginput/outputwilladvance

the audit trail counters since it effects the accuracy of the

system.

FC Flow Computer

6

Operation of Steam Trap Monitor

In applications on Saturated Steam, the otherwise unused

CompensationInputmaybeconnectedtoasteamtrapmonitor

thatoffersthefollowingcompatibleoutputsignallevels:

4mA=trapcold

12mA=trapwarmandopen(blowing)

20mA=trapwarmandclosed

Innormaloperationasteamtrapiswarmandperiodicallyopens

andclosesinresponsetotheaccumulationofcondensate.A

coldtrapisindicationthatitisnotpurgingthecondensate,a

trapthatisconstantlyblowingisanindicationthatitisstuck

open. To avoid a false alarm, the FC permits the user to

programadelay,ortimeperiod,whichshouldbeconsidered

normalforthetraptobeeithercold,oropen.Analarmwill

onlybeactivatedifthetrapisdetectedascontinuouslybeing

intheabnormalstatesforatimeperiodgreaterthanthisTRAP

ERRORDELAYtime.

The user selects to use the Compensation Input for Trap

Monitoringbyselecting“4-20mATRAPSTATUSastheINPUT

SIGNALforOTHERINPUT1.

Theusercan programtheERROR DELAYtime in HH:MM

formatintoboththeTRAPERRORDELAY(coldtraperror)

menu and the TRAP BLOWING DELAY (trap stuck open)

menu.

The FC will warn the operator of a TRAP ERROR when

an abnormal condition is detected. The error can be

acknowledged by pressing the ENTER key. However, the

problem may reassert itself if there is a continued problem

withthesteamtrap.

Inaddition,theeventisnotedintheERRORLOG.

Itisalsopossiblefortheusertoprogramatrapmalfunction

asoneoftheconditionsworthyofaCALLOUTofaproblem

byselectingthiserrorintheERRORMASK.

TheData-LoggingoptionoftheFCcanalsobeusedtologthe

performanceofthetrapbystoringthe%oftimethetraphas

beencold,and/orblowingopenduringthedataloginterval.

Datalogging Option

The Datalogging Option for the FC permits the user to

automaticallystoresetsofdataitemsasarecordonaperiodic

basis.Adatalogrecordmaybestoredastheresultofeithera

PRINTkeydepression,oranINTERVAL,oraTIMEOFDAY

requestforadatalog.

Theuserdenesthelistofitemstobeincludedineachdatalog

byselectingtheseinthePRINTLISTmenulocatedwithinthe

COMMUNICATIONSSUBMENU.

Theuserselectswhatwilltriggeradatalogrecordbeingstored

inthePRINTINITIATEmenu.ThechoicesarePRINTKEY,

INTERVAL,andTIMEOFDAY.

The user can select the datalog store interval in a HH:MM

formatinthePRINTINTERVALmenu.

Theusercanalsoselectthestoretimeofdayina24hrHH:

MMformatinthePRINTTIMEmenu.

Theusercanalsodenewhetherhejustwantsthedatastored

intothedatalogger,orifhewantsthedatabothstoredinthe

dataloggerandsentoutovertheRS232portintheDATALOG

ONLYmenu.

Theusercandenetheformathewishesthedatatobeoutput

inusingtheDATALOGFORMATmenu.ChoicesarePRINTER

andDATABASE.PRINTERformatwilloutputthedatarecords

inaformsuitabletodumptoaprinter.DATABASEformatwill

outputthevaluesinaCSV,orCommaSeparatedVariablewith

Carriagereturndelimitingofeachrecord.

Anumberofserialcommandsarealsoincludedtoaccessand

manipulateinformationstoredwithinthedatalogger.Among

theseRS232commandcapabilitiesarethefollowingactions:

ClearDataLogger

SendallDatainDatalogger

SendOnlyNewDatasinceDataloggerwaslastRead

SendDataforthedateincludedintherequest

SendthecolumnheadingtextfortheCSVdataelds

SendthecolumnunitsofmeasuretextfortheCSVdata

elds

Storeonenewrecordintodataloggernow

ReadNumberofNewRecordsinthedatalogger

Readnumberofrecordscurrentlyinthedatalogger

Read the maximum number of records capacity of the

datalogger

MovePointerBackNrecords

DumpRecordatPointer

Dumprecordsnewerthanpointer

DumpdatafromNrecordsback

ThedataloggeroptionisusedinconjunctionwiththeRS-232

portinremotemeteringapplications.

The technical details associated with the serial commands

arelistedinUniversalSerialProtocolManualavailableupon

request.

RS-232 Serial Port

TheFlowComputerhasa generalpurposeRS-232Port

whichmaybeusedforanyoneofthefollowingpurposes:

TransactionPrinting

DataLogging

RemoteMeteringbyModem

ComputerCommunicationLink

CongurationbyComputer

PrintSystemSetup

PrintCalibration/MalfunctionHistory

Instrument Setup by PC’s over Serial Port

ADisketteprogramisprovidedwiththeFlowComputerthat

enablestheusertorapidlyconguretheFlowComputer

usinganPersonnelComputer.Includedonthedisketteare

commoninstrumentapplicationswhichmaybeusedasa

startingpointforyourapplication.Thispermitstheuserto

haveanexcellentstartingpointandhelpsspeedtheuser

throughtheinstrumentsetup.

FC Flow Computer

7

Operation of Serial Communication Port with Printers

TheFlowComputer’sRS-232channelsupportsanumber

of operating modes. One of these modes is intended to

support operation with a printer in metering applications

requiringtransactionprinting,dataloggingand/orprinting

ofcalibrationandmaintenancereports.

Fortransactionprinting,the userdenestheitemsto be

includedintheprinteddocument.Theusercanalsoselect

whatinitiatesthetransactionprintgeneratedaspartofthe

setupoftheinstrument.Thetransactiondocumentmaybe

initiatedviaafrontpanelkeydepression.

Indatalogging,theuserdenestheitemstobeincludedin

eachdatalogasaprintlist.Theusercanalsoselectwhen

orhowoftenhewishesadatalogtobemade.Thisisdone

duringthesetupoftheinstrumentaseitheratimeofdayor

asatimeintervalbetweenlogging.

The system setup and maintenance report list all the

instrument setup parameters and usage for the current

instrument configuration. In addition, the Audit trail

informationispresentedaswellasastatusreportlistingany

observedmalfunctionswhichhavenotbeencorrected.

Theuserinitiatestheprintingofthisreportatadesignated

point in the menu by pressing the print key on the front

panel.

Operating Serial Communication Port with Modems

TheFCoffersanumberofcapabilitiesthatfacilitateitsuse

withmodems.TheFC’sRS232portcanbeconnectedto

amodeminordertoimplementaremotemeteringsystem

that uses either the phone companies standard phone

linesorcellulartelephone system.Inadditionto remote

meter readings, the serial commands may also be used

toexamineand/ormakesetupchangestotheunit,andto

checkforproperoperationorinvestigateproblems.Several

hundredcommandsaresupported.Acompatibleindustrial

modemaccessoryandinterconnectingcablingisofferedin

theMPP2400NspecicallydesignedforusewiththeFC.

TheFCandModemcanbeusedtogethertocreatesystems

withoneormoreofthefollowingcapabilities:

1. PolltheFCunitforinformationfromaremotePC.

2. CallOutfromtheFCunittoaremotePConascheduled

readingtimeand/orcrisisbasis

3. Somecombinationoftheabovetwodescriptionswhere

theunitispolledbyonePCandcallsintotoadifferent

PCifaproblemisdetected.

Infact,uptoveFCunitscansharethesamemodem.Each

FCmusthaveauniqueDEVICEID.Thismultidroppingof

owcomputersonasinglemodemispopularwhenthere

areseveralowcomputersmountedneareachother.

In most applications using modem communications, the

FC’sRS232USAGEisrstsetequaltoMODEM.EachFC

onasharedmodemcableisgivenauniqueserialdevice

addressorDEVICEID.TheBAUDRATEiscommonlyset

to2400,thePARITYsettoNONE,andtheHANSHAKING

settoNONEtocompletethebasicsetup.TheremotePC’s

communicationsettingsarechosentomatchthese.

The level of complexity of the Supetrol-2 to Modem

connectioncanrangefromsimpletomorecomplex.

InasimplesystemaremotePCwillcallintothetelephone

numberofthe modem.The modemwillanswer the call,

andestablishaconnectionbetweentheFCandtheremote

PC.Anexchangeofinformationcannowoccur.TheFCwill

actasaslaveandrespondtocommandsandrequestsfor

informationfromtheremoteMASTERPC.TheMASTER

PCwillendtheexchangebyhandingup.

However,it ismorecommon thattheFCwillbeusedto

control the modem. In these applications the following

communicationmenusettingswouldbeused:

RS232USAGE=MODEM

DEVICE ID, BAUD RATE, PARITY, and

HANDSHAKINGareset

MODEMCONTROL=YES

DEVICE MASTER = YES (When multidropping

several FC's, only one unit will be the DEVICE

MASTER)

MODEMAUTOANSWER=YES(Thisinstructsthe

unittoanswerincomingcalls)

HANGUPIFINACTIVE=YES(Thisinstructstheunit

tohangupthelineifnoactivitiesoccurwithinseveral

minutes).

A more complex form of a remote metering system can

beimplementedwheretheFCwillinitiateacalltocontact

theremotePCatascheduledtimeand/orintheeventofa

problemthathasbeendetected.Intheseapplicationsthe

FChasadditionalsetupcapabilitiesincluding:

TheFCmusthaveauniqueidentierassignedtoit

(usingtheTAGNUMBER)

CallOutTelephonenumbermustbeenteredinthe

CALLOUTNUMBER

Thescheduledcallouttimeforthedailyreadingmust

beenteredinCALLOUTTIME

Adecisionmustbemadewhethertheunitwillbeused

tocallonerror(s)inCALLONERROR

Theparticularerrorconditionstocalloutonmustbe

denedintheERRORMASK

TheNUMBEROFREDIALStobeattemptediflineis

busymustbeenteredinthatcell

HANGUPIFINACTIVE=YESwilldisconnectthecall

ifremotecomputerdoesnotrespond.

ConsulttheUniversalSerialCommandsUserManualfor

detailsontheindividualcommandssupportedbytheFC.

ContacttheFlowApplicationsGroupforadiscussiononthe

remotemeteringsystemcapabilitiesyouareconsidering.

NOTE: Some modems can be congured in advance to

answer incoming calls, terminate phone connections if

communicationsislost.Insuchapplicationstheremaybe

noneedfortheFCtobefunctioningto“control”themodem.

SettingtheRS233USAGE=COMPUTERwilllikelywork.

RS-485 Serial Port (optional)

The RS-485 serial port can be used for accessing ow

rate,total,pressure,temperature,densityandalarmstatus

information.Theportcanalsobeusedforchangingpresets

andacknowledgingalarms.

FC Flow Computer

8

2. Installation

2.1 General Mounting Hints:

TheFCFlowComputershouldbelocatedinanareawithaclean,dryatmosphere

whichisrelativelyfreeofshockandvibration.Theunitisinstalledina5.43"(138mm)

wideby2.68"(68mm)highpanelcutout.(seeMountingDimensions)Tomountthe

FlowComputer,proceedasfollows:

a.Preparethepanelopening.

b.Slidetheunitthroughthepanelcutoutuntiltheittouchesthepanel.

c.Installthescrews(provided)inthemountingbracketandslipthebracketoverthe

rearofthecaseuntilitsnapsinplace.

d.Tightenthescrewsrmlytoattachthebezeltothepanel.3in.lb.oftorquemust

beappliedandthebezelmustbeparalleltothepanel.

NOTE: TosealtoNEMA4X/IP65specications,suppliedbezelkitmustbeused

andpanelcannotexmorethan.010".

Whentheoptionalbezelkitisused,thebezeladaptormustbesealedto

thecaseusinganRTVtypesealertomaintainNEMA4X/IP65rating.

General Mounting Hints

Mounting Procedure

NEMA4X / IP65 Specications

FC FC

BezelAdaptor

Gasket

MountingBracket

MountingBracket

Standard Mounting Bezel Kit Mounting

Dimensions

Dotted Line Shows Optional Bezel Kit

Panel

Cutout

5.43

(138)

2.68

(68)

Dimensions are in inches (mm)

5.67 (144)

2.83

(72)

3.43

(87)

6.18

6.15

(156) 0.5

(13)

0.28 (7.2)

0.4 (10)

2.2 Mounting Diagrams:

FC Flow Computer

9

1.10

(28)

1.10

(28)

7.8 (198)

4.72 (120)

0.59

(15)

0.75” Conduit Knockouts

(5 places)

1.06

(27)

9.4 (238)

7.3 (184)

2.34 (59.5)

8.4 (213.4)

4.13 (105)

2.33 (59)

0.385

(9.8)

Security Tag

Provisions

0.625”ø 0.75”ø 5 places

1.10

(28)

1.10

(28)

1.10

(28)

1.10

(28)

1.10

(28)

1.10

(28)

Wall Mount (mountingoptionW)

2.2 Mounting Diagrams:

(continued)

NEMA4 Wall Mount (mountingoptionN)

FC Flow Computer

10

Explosion Proof Mount (mountingoptionX)

2.2 Mounting Diagrams:

(continued)

Explosion Proof Mount (mountingoptionE)

9.31

(236.5)

12.06

(306.3)

3.81

(96.8)

6.56

(166.6)

.28 ±.02

(7.1 ±.5)

1.31

(33.3)

8.88

(225.5)

3.5

(88.9)

10.19

(258.8)

2.5

(63.5)

2.5

(63.5)

5.09

(129)

3.0

(76.2)

1/4" - 20UNC-2B

TAP x 5/16" DEEP

(6) HOLES CENTERED

ON THREE SIDES FOR

MOUNTING

1/2"- 14 NPT PLUGS

(2 PLACES)

10.6

(269.2)

1/4" - 20UNC-2B

TAP x 5/16" DEEP

(6) HOLES CENTERED

ON THREE SIDES FOR

MOUNTING

3.5

(88.9)

3

(76.2)

2.13

(54)

1.75

(44.5)

5.1

(129.5)

.25

(6.35)

.5

(12.7)

4.63

(117.5)

10.19

(258.8)

3.13

(79.4)

3.13

(79.4)

3

(76.2)

.5

(12.7)

FC Flow Computer

11

3.1 Steam Mass

Measurements:

Aowmetermeasurestheactualvolumeowinasteamline.Atemperatureand/or

pressuresensorisinstalledtomeasuretemperatureand/orpressure.

Calculations:

• Density and mass ow are calculated using the steam tables stored in the ow

computer.

• With square law device measurement the actual volume is calculated from the

differentialpressure,takingintoaccounttemperatureandpressurecompensation.

• Saturatedsteamrequireseitherapressureortemperaturemeasurementwiththeother

variablecalculatedusingthesaturatedsteamcurve.

• OptionalsteamtrapmonitoringusingCompensationInput1.

Input Variables:

Superheated Steam: Flow,temperatureandpressure

Saturated Steam: Flow,temperatureorpressure

Output Results:

• DisplayResults

MassorVolumeFlowRate,ResettableTotal,Non-ResettableTotal,Temperature,

Pressure,Density(optional:peakdemand,demandlasthour,time/datestamp)

• AnalogOutput

Mass or Volume Flow Rate, Temperature, Pressure Density, Peak Demand,

DemandLastHour

• PulseOutput

MassorVolumeTotal

• RelayOutputs

Mass or Volume Flow Rate , Total, Pressure, Temperature, Alarms, Peak

Demand,DemandLastHour

Applications:

Monitoring mass ow and total of steam. Flow alarms are provided via relays and

dataloggingisavailableviaanalog(4-20mA)andserialoutputs.

STEAM MASS

Steam Mass

Illustration

3. Applications

FlowmeterTemperature

Transmitter

PRINT

5

0–

TIME

CLEAR

•

MENU

ENTER

HELP

TEMP

4

PRE 1

3

RATE

2

TOTAL

1

GRAND

6

SCROLL

7

PRE 2

8

DENS

9

Pressure

Transmitter

Mass Flow

MassFlow=volumeow•density(T,p)

Calculations

*

* or Steam Trap Monitor

*

* or Steam Trap Monitor

FC Flow Computer

12

3.2 Steam Heat

Measurements:

Aowmetermeasurestheactualvolumeowinasteamline.Atemperatureand/or

pressuresensorisinstalledtomeasuretemperatureand/orpressure.

Calculations:

• Density,massowandheatowarecalculatedusingthesteamtablesstoredinthe

owcomputer.Theheatisdenedastheenthalpyofsteamunderactualconditions

withreferencetotheenthalpyofwateratT=0°C.

• With square law device measurement the actual volume is calculated from the

differentialpressure,takingintoaccounttemperatureandpressurecompensation.

• Saturatedsteamrequireseitherapressureortemperaturemeasurementwiththeother

variablecalculatedusingthesaturatedsteamcurve.

• Optionalsteamtrapmonitoringusingcompensationinput.

Input Variables:

Superheated Steam: Flow,temperatureandpressure

Saturated Steam: Flow,temperatureorpressure

Output Results:

• DisplayResults

Heat, Mass or Volume Flow Rate, Resettable Total, Non-Resettable Total,

Temperature, Pressure, Density (optional: peak demand, demand last hour,

time/datestamp)

• AnalogOutput

Heat, Mass or Volume Flow Rate, Temperature, Pressure, Density, Peak

Demand,DemandLastHour

• PulseOutput

Heat,MassorVolumeTotal

• RelayOutputs

Heat,MassorVolumeFlowRate,Total,Pressure,TemperatureAlarms,Peak

Demand,DemandLastHour

Applications:

Monitoringheatowandtotalheatofsteam.Flowalarmsareprovidedviarelaysand

dataloggingisavailableviaanalog(4-20mA)andserialoutputs.

STEAM HEAT

Heat Flow

HeatFlow=Volumeow•density(T,p)•Sp.Enthalpyofsteam(T,p)

Calculations

Steam Heat

Illustration

Temperature

Transmitter

PRINT

5

0–

TIME

CLEAR

•

MENU

ENTER

HELP

TEMP

4

PRE 1

3

RATE

2

TOTAL

1

GRAND

6

SCROLL

7

PRE 2

8

DENS

9

Pressure

Transmitter

Orifice Plate

with DP Transmitter

FlowmeterTemperature

Transmitter

PRINT

5

0–

TIME

CLEAR

•

MENU

ENTER

HELP

TEMP

4

PRE 1

3

RATE

2

TOTAL

1

GRAND

6

SCROLL

7

PRE 2

8

DENS

9

Pressure

Transmitter

*

* or Steam Trap Monitor

*

* or Steam Trap Monitor

FC Flow Computer

13

3.3 Steam Net Heat

Measurements:

A owmetermeasurestheactual volumeowinasteamline.Atemperatureand a

pressuresensorareinstalledtomeasuretemperatureand/orpressure.Allmeasurement

aremadeonthesteamsideofaheatexchanger.

Calculations:

• Density,massowandnetheatowarecalculatedusingthesteamtablesstoredinthe

owcomputer.Thenetheatisdenedasthedifferencebetweentheheatofthesteam

andtheheatofthecondensate.Forsimplicationitisassumedthatthecondensate

(water)hasatemperaturewhichcorrespondstothetemperatureofsaturatedsteam

atthepressuremeasuredupstreamoftheheatexchanger.

• With square law device measurement the actual volume is calculated from the

differentialpressure,takingintoaccounttemperatureandpressurecompensation.

• Saturatedsteamrequireseitherapressureortemperaturemeasurementwiththeother

variablecalculatedusingthesaturatedsteamcurve.

• Optionalsteamtrapmonitoringusingcompensationinput.

Input Variables:

Superheated Steam: Flow,temperatureandpressure

Saturated Steam: Flow,temperatureorpressure

Output Results:

• DisplayResults

Heat, Mass or Volume Flow Rate, Resettable Total, Non-Resettable Total,

Temperature, Pressure, Density, (optional: peak demand, demand last hour,

time/datestamp)

• AnalogOutput

Heat, Mass or Volume Flow Rate, Temperature, Pressure, Density, Peak

Demand,DemandLastHour

• PulseOutput

Heat,MassorVolumeTotal

• RelayOutputs

Heat,MassorVolumeFlowRate,Total,Pressure,TemperatureAlarms,Peak

Demand,DemandLastHour

Applications:

Monitoringthethermalenergywhichcanbeextractedbyaheatexchangertakinginto

account the thermal energy remaining in the returned condensate. For simplication

it is assumed that the condensate (water) has a temperature which corresponds to

the temperature of saturated steam at the pressure measured upstream of the heat

exchanger.

STEAM NET HEAT

Net Heat Flow

NetHeatFlow=Volumeow•density(T,p)•[ED(T,p)–EW(TS(p))]

ED = Specicenthalpyofsteam

Ew = Specicenthalpyofwater

TS(p) = Calculatedcondensationtemperature

(=saturatedsteamtemperatureforsupplypressure)

Calculations

Steam Net Heat

Illustration

FlowmeterTemperature

Transmitter

PRINT

5

0–

TIME

CLEAR

•

MENU

ENTER

HELP

TEMP

4

PRE 1

3

RATE

2

TOTAL

1

GRAND

6

SCROLL

7

PRE 2

8

DENS

9

Pressure

Transmitter

Water

Steam

*

* or Steam Trap Monitor

FC Flow Computer

14

3.4 Steam Delta Heat

Measurements:

Measuresactualvolumeowandpressureofthesaturatedsteaminthesupplypiping

as well as the temperature of the condensate in the downstream piping of a heat

exchanger.

Calculations:

• Calculatesdensity,massowaswellasthedeltaheatbetweenthesaturatedsteam

(supply)andcondensation(return)usingphysicalcharacteristictablesofsteamand

waterstoredintheowcomputer.

• With square law device measurement the actual volume is calculated from the

differentialpressure,takingintoaccounttemperatureandpressurecompensation.

• Thesaturatedsteamtemperatureinthesupplylineiscalculatedfromthepressure

measuredthere.

Input Variables:

Supply: Flowandpressure(saturatedsteam)

Return: Temperature(condensate)

Output Results:

• DisplayResults

Heat, Mass or Volume Flow Rate, Resettable Total, Non-Resettable Total,

Temperature, Pressure, Density (optional: peak demand, demand last hour,

time/datestamp)

• AnalogOutput

Heat, Mass or Volume Flow Rate, Temperature, Pressure, Density, Peak

Demand,DemandLastHour

• PulseOutput

Heat,MassorVolumeTotal

• RelayOutputs

Heat,MassorVolumeFlowRate,Total,Pressure,TemperatureAlarms,Peak

Demand,DemandLastHour

Applications:

Calculatethesaturatedsteammassowandtheheatextractedbyaheatexchanger

takingintoaccountthethermalenergyremaininginthecondensate.

STEAM DELTA HEAT

Delta Heat Flow

NetHeatFlow=Volumeow•density(p)•[ED(p)–EW(T)]

ED = Specicenthalpyofsteam

Ew = Specicenthalpyofwater

Note:Assumesaclosedsystem.

Calculations

Steam Delta Heat

Illustration

Pressure

Transmitter Flowmeter

Temperature

Transmitter

PRINT

5

0–

TIME

CLEAR

•

MENU

ENTER

HELP

TEMP

4

PRE 1

3

RATE

2

TOTAL

1

GRAND

6

SCROLL

7

PRE 2

8

DENS

9

Water

Saturated

Steam

FC Flow Computer

15

3.5 Corrected Gas Volume

Measurements:

Aowmetermeasurestheactualvolumeowinagasline.Temperatureandpressure

sensorsareinstalledtocorrectforgasexpansioneffects.

Calculations:

• CorrectedVolumeiscalculatedusingtheow,temperatureandpressureinputsaswell

asthegascharacteristicsstoredintheowcomputer(see"FLUIDDATA"submenu).

Usethe"OTHERINPUT"submenutodenereferencetemperatureandreference

pressurevaluesforstandardconditions.

Output Results:

• DisplayResults

CorrectedVolumeorActualVolumeFlowRate,ResettableTotal,Non-Resettable

Total,Temperature,Pressure,Density(optional:peakdemand,demandlasthour,

time/datestamp)

• AnalogOutput

CorrectedVolumeorActualVolumeFlowRate,Temperature,Pressure,Density,

PeakDemand,DemandLastHour

• PulseOutput

CorrectedVolumeorActualVolumeTotal

• RelayOutputs

CorrectedVolumeorActualVolumeFlowRate,Total,pressure,Temperature

Alarms,PeakDemand,DemandLastHour

Applications:

Monitoringcorrectedvolumeowandtotalofanygas.Flowalarmsareprovidedviarelays

anddataloggingisavailableviaanalog(4-20mA)andserialoutputs.

CORRECTED

GAS VOLUME

Volume Flow

Pulse Input; Average K-Factor

inputfrequency•timescalefactor

VolumeFlow=

K-Factor

Analog Input; Linear

VolumeFlow=%input•FullScaleFlow

Corrected Volume Flow

P TrefZ

ref

CorrectedVolumeFlow=VolumeFlow• • •

P

ref T Z

Calculations

Corrected

Gas Volume

Illustration

FlowmeterTemperature

Transmitter

PRINT

5

0–

TIME

CLEAR

•

MENU

ENTER

HELP

TEMP

4

PRE 1

3

RATE

2

TOTAL

1

GRAND

6

SCROLL

7

PRE 2

8

DENS

9

Pressure

Transmitter

FC Flow Computer

16

Temperature

Transmitter

PRINT

5

0–

TIME

CLEAR

•

MENU

ENTER

HELP

TEMP

4

PRE 1

3

RATE

2

TOTAL

1

GRAND

6

SCROLL

7

PRE 2

8

DENS

9

Pressure

Transmitter

Orifice Plate

with DP Transmitter

FlowmeterTemperature

Transmitter

PRINT

5

0–

TIME

CLEAR

•

MENU

ENTER

HELP

TEMP

4

PRE 1

3

RATE

2

TOTAL

1

GRAND

6

SCROLL

7

PRE 2

8

DENS

9

Pressure

Transmitter

3.6 Gas Mass

Measurements:

Aowmetermeasurestheactualvolumeowinagasline.Temperatureandpressure

sensorsareinstalledtomeasuretemperatureandpressure.

Calculations:

• Density and mass ow are calculated using gas characteristics stored in the ow

computer.

• With square law device measurement the actual volume is calculated from the

differentialpressure,takingintoaccounttemperatureandpressurecompensation.

Output Results:

• DisplayResults

MassorVolumeFlowRate,ResettableTotal,Non-ResettableTotal,Temperature,

Pressure,Density(optional:peakdemand,demandlasthour,time/datestamp)

• AnalogOutput

Mass or Volume Flow Rate, Temperature, Pressure, Density, Peak Demand,

DemandLastHour

• PulseOutput

MassorVolumeTotal

• RelayOutputs

MassorVolumeFlowRate,Total,Pressure,Temperature,DensityAlarms,Peak

Demand,DemandLastHour

Applications:

Monitoringmassowandtotalofgas.Flowalarmsareprovidedviarelaysanddatalogging

isavailableviaanalog(4-20mA)andserialoutputs.

GAS MASS

Mass Flow

P TrefZ

ref

MassFlow=ActualVolumeFlow•ρref• • •

P

ref T Z

ρref = Referencedensity

Tref = Referencetemperature

Pref = Referencepressure

Zref = ReferenceZ-factor

Calculations

Gas Mass

Illustration

Table of contents

Other Niagara Measuring Instrument manuals