Chapter 1 Production Overview...................................................................... 2

1.1 Precautions on commodity inspection and storage.................... 2

Chapter 2 Installation and wiring.....................................................................3

2.1 KD4000-2S(220V) Series Installation Dimension........................3

2.2 KD4000-4T(380V) Series Installation Dimension........................4

2.3 KD4000-2S(220V) basic wiring diagram....................................... 5

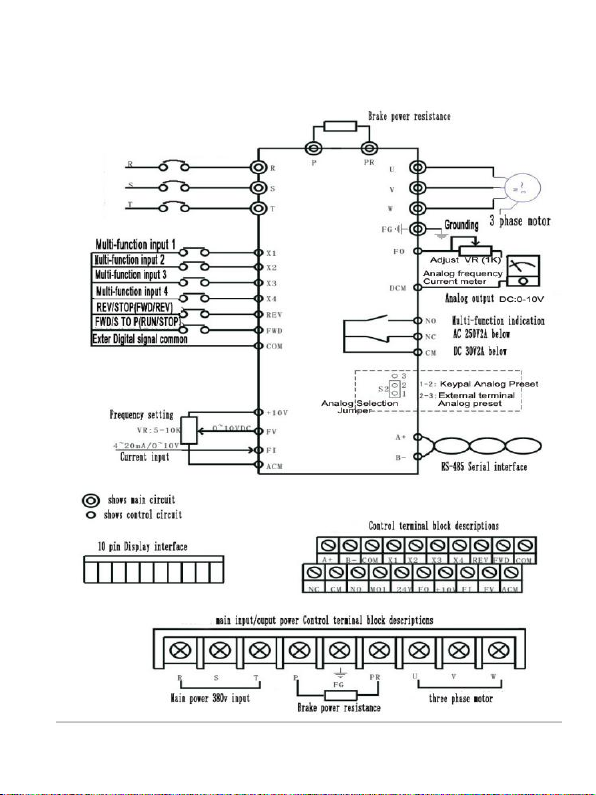

2.4 SD4000-4T (380V) basic wiring diagram...................................... 6

2.5 Control circuit wiring........................................................................7

2.6 Safety Considerations.....................................................................8

Chapter 3 Operation Panel............................................................................ 10

3.1 Operation panel description( digital keypad is optional).......10

I. Digital Keypad Operation........................................................10

II. Digital Keypad Parts and Functions....................................11

III. Explanation of the display.................................................... 12

3.2 Digital Keypad Operating Modes & Programming steps......13

3.3 Please observe below steps to set parameters......................14

3.4 Basic Wiring Diagram................................................................... 15

3.5 Troubleshooting and Fault Information.....................................32

Chapter 4 Quality and Guarantee................................................................ 34